Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

425results about How to "Gentle process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polydopamine-based biofunction modification method

InactiveCN102000658AImprove deformation resistanceImprove stabilityPretreated surfacesCoatingsAir atmosphereMetallic materials

The invention discloses a polydopamine-based biofunction modification method. The method comprises the following steps of: soaking clean inorganic / metal materials in dopamine alkaline aqueous solution with a pH value of 7.2 to 10, introducing oxygen to fully oxidize the clean inorganic / metal materials to obtain a monolayer polydopamine modification layer, drying, placing the material in the air atmosphere at 50 to 200 DEG C, performing thermal oxidation to obtain a multi-layer firmly-combined high-reactivity polydopamine layer, and soaking the treated material into the amino-containing and sulfydryl-containing biofunctional molecular solution to obtain a firmly combined biofunction simulate modification layer on the surface of the materials. The polydopamine modification layer obtained bythe method has excellent anti-deformation performance, stability and reactivity, can directly react with amino or the sulfydryl in the biomolecule to immobilize the bioactive molecule on the surface by covalent bonds; moreover, the process is simple, the condition is mild, and the method is easy to implement.

Owner:CO WITH LTD LIABILITY OF MEDICAL SCI +1

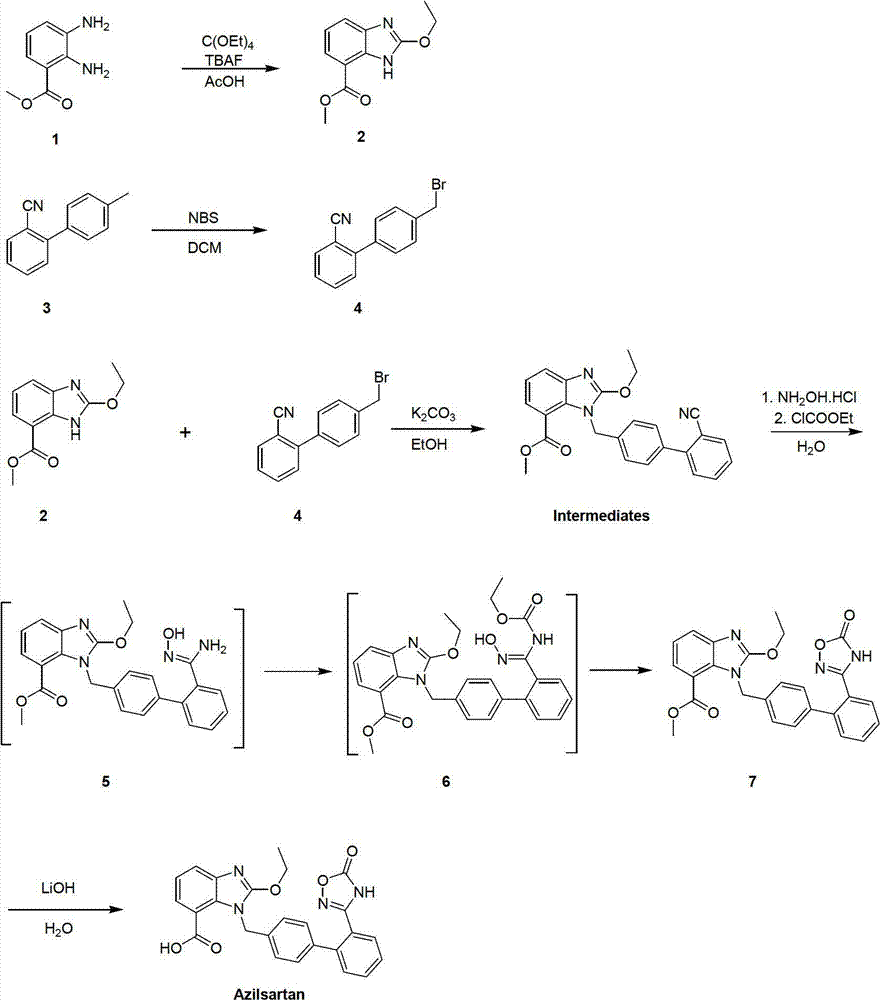

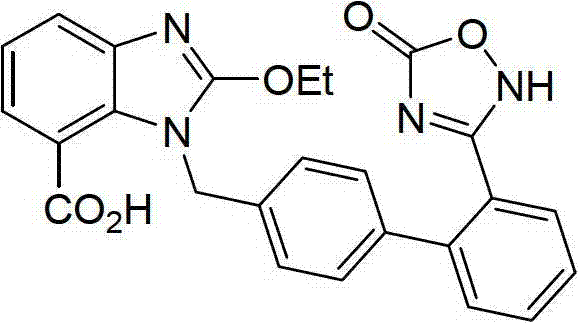

Preparation method of azilsartan

InactiveCN102766138AReduce usageEmission reductionOrganic chemistryEthyl chloroformateCarboxylic salt

The invention relates to a preparation method of azilsartan, comprising the following steps of: (1) preparing ethoxybenzimidazole-7-methyl carboxylate; (2) preparing 2-cyan-4'-bromomethyl biphenyl; (3) dissolving the ethoxybenzimidazole-7-methyl carboxylate and the 2-cyan-4'-bromomethyl biphenyl into ethanol; adding potassium carbonate to react to obtain 1-[(2'-cyan diphenyl-4-yl)methyl]-2-ethoxybenzimidazole-7-methyl carboxylate; (4) suspending the 1-[(2'-cyan diphenyl-4-yl)methyl]-2-ethoxybenzimidazole-7-methyl carboxylate in water; adding hydroxylamine hydrochloride, sodium hydroxide and tetrabutylammonium fluoride; heating and reflowing, and then cooling; adding the sodium hydroxide and ethyl chloroformate, heating and reflowing to obtain azilsartan methyl ester; and (5) hydrolyzing the azilsartan methyl ester to obtain a product. The preparation method of the azilsartan, disclosed by the invention, has the advantages of being short in process route, high in yield, and safe and reliable; and the purity of the azilsartan obtained by using the method is high.

Owner:WENZHOU PEOPLES HOSPITAL

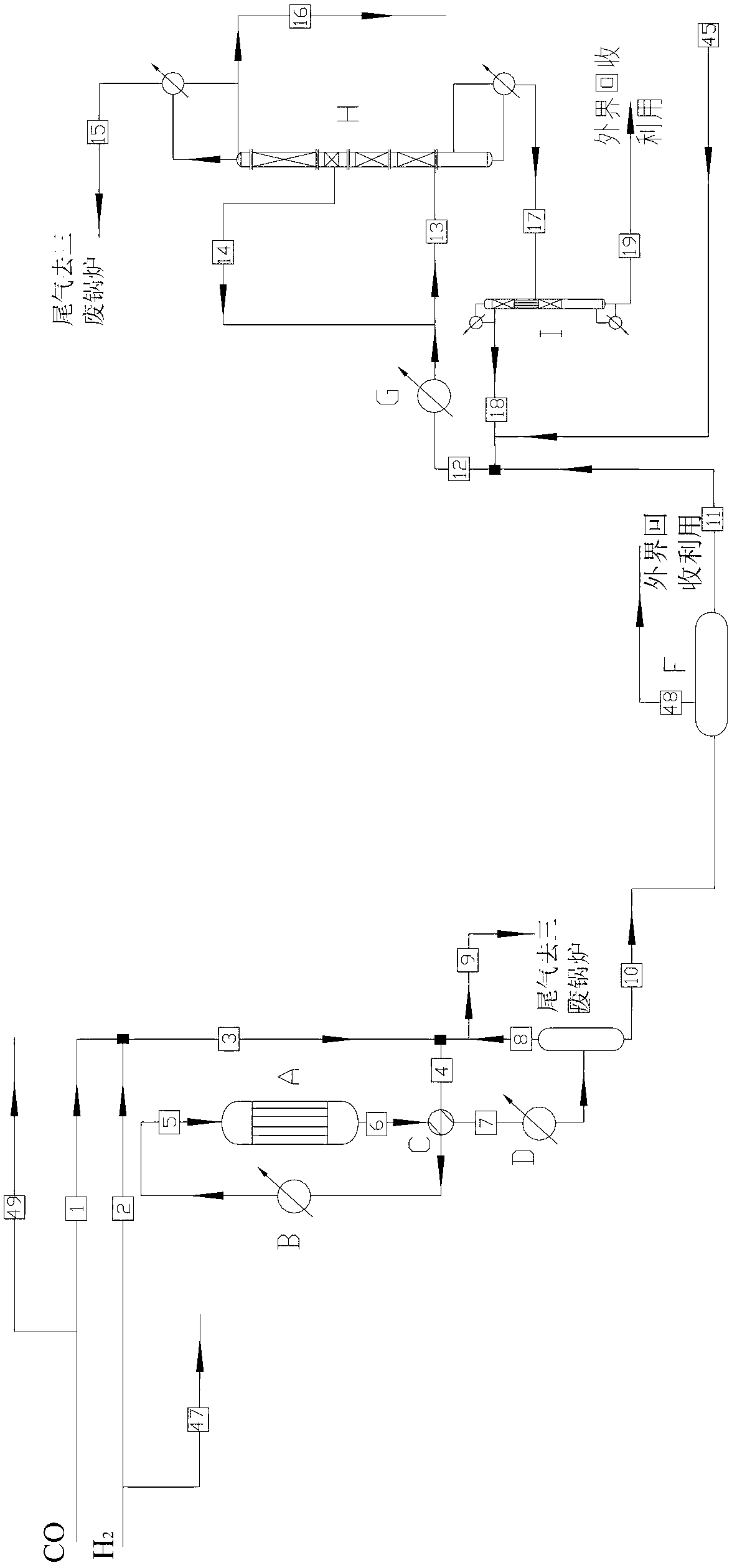

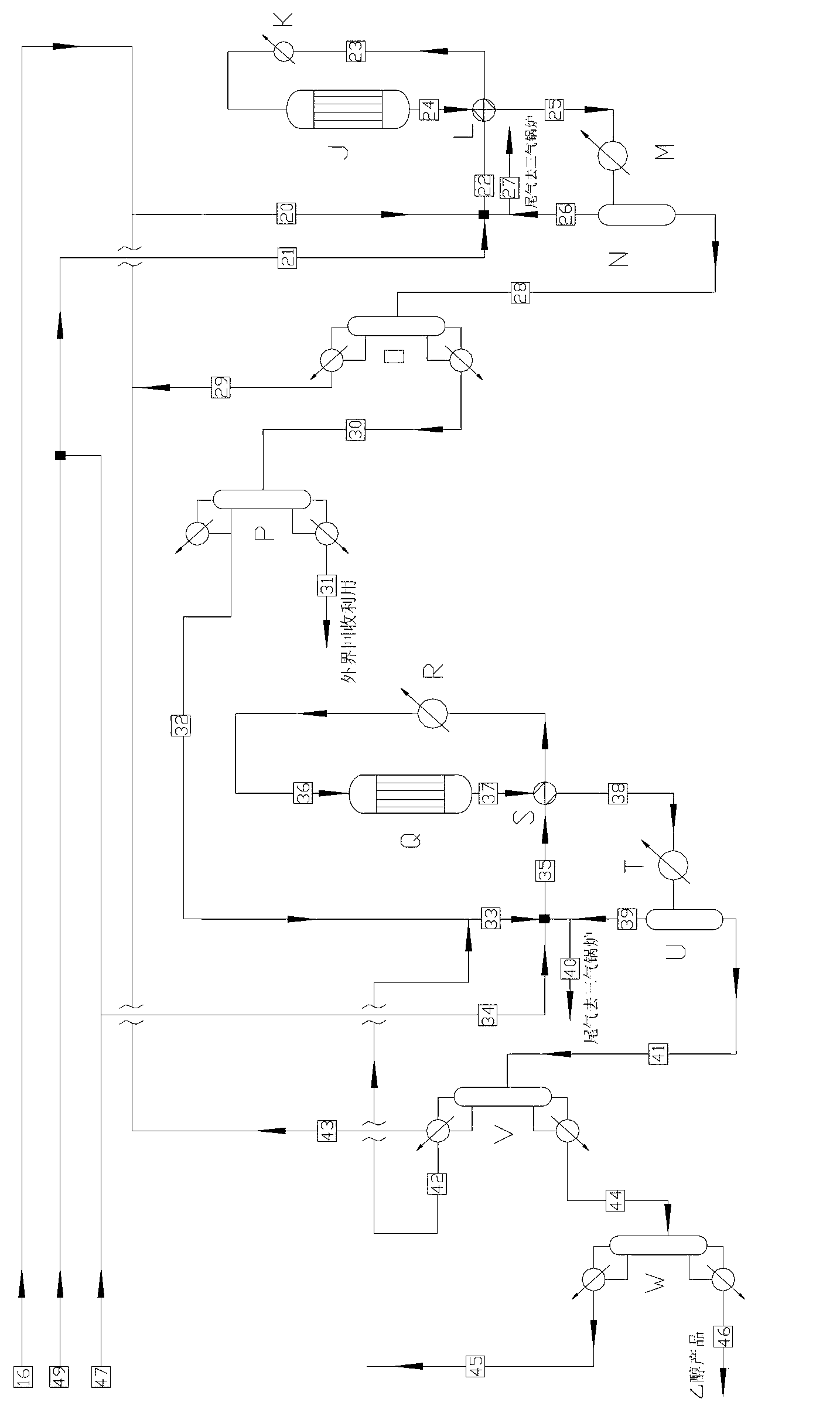

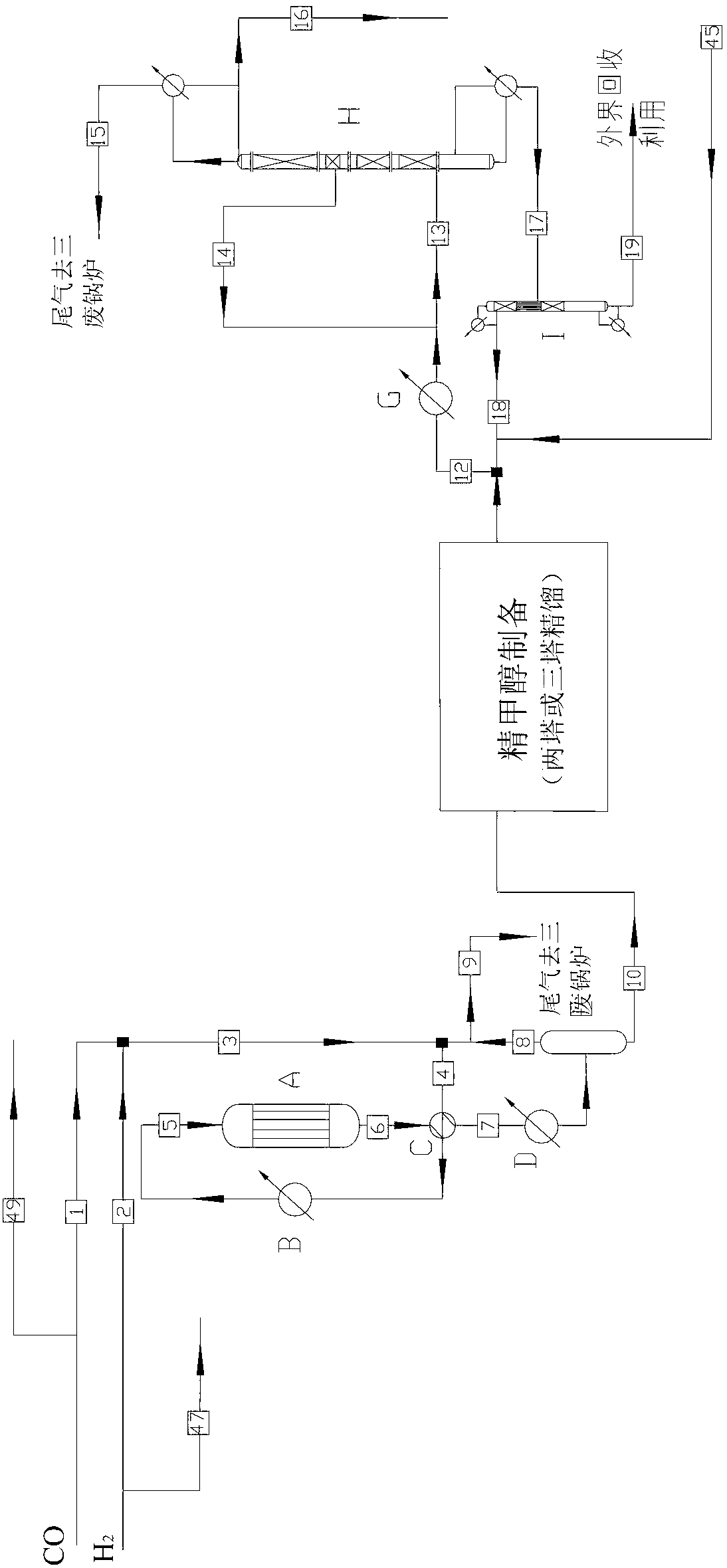

Process for indirectly producing alcohol with synthetic gas and application of process

ActiveCN103012062AReduce energy consumptionMild reaction conditionsOrganic compound preparationHydroxy compound preparationHydrogenMethyl acetate

The invention relates to a process for indirectly producing alcohol with synthetic gas. The process comprises the steps that the synthetic gas formed by mixing industrial carbon monoxide with hydrogen is taken as a raw material to synthesize methanol; methanol is dehydrated to prepare dimethyl ether; dimethyl ether, carbon monoxide and hydrogen are mixed for carbonylation reaction to prepare methyl acetate; methyl acetate is purified and hydrogenated; a hydrogenated product is purified; and an alcohol product is obtained. An adopted catalyst, the process and a device have the characteristics of high conversion per pass and high effective utilization rate of reaction heat; the load of separating a crude product is reduced greatly; the production flow is shortened; and the production energy consumption is reduced greatly.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

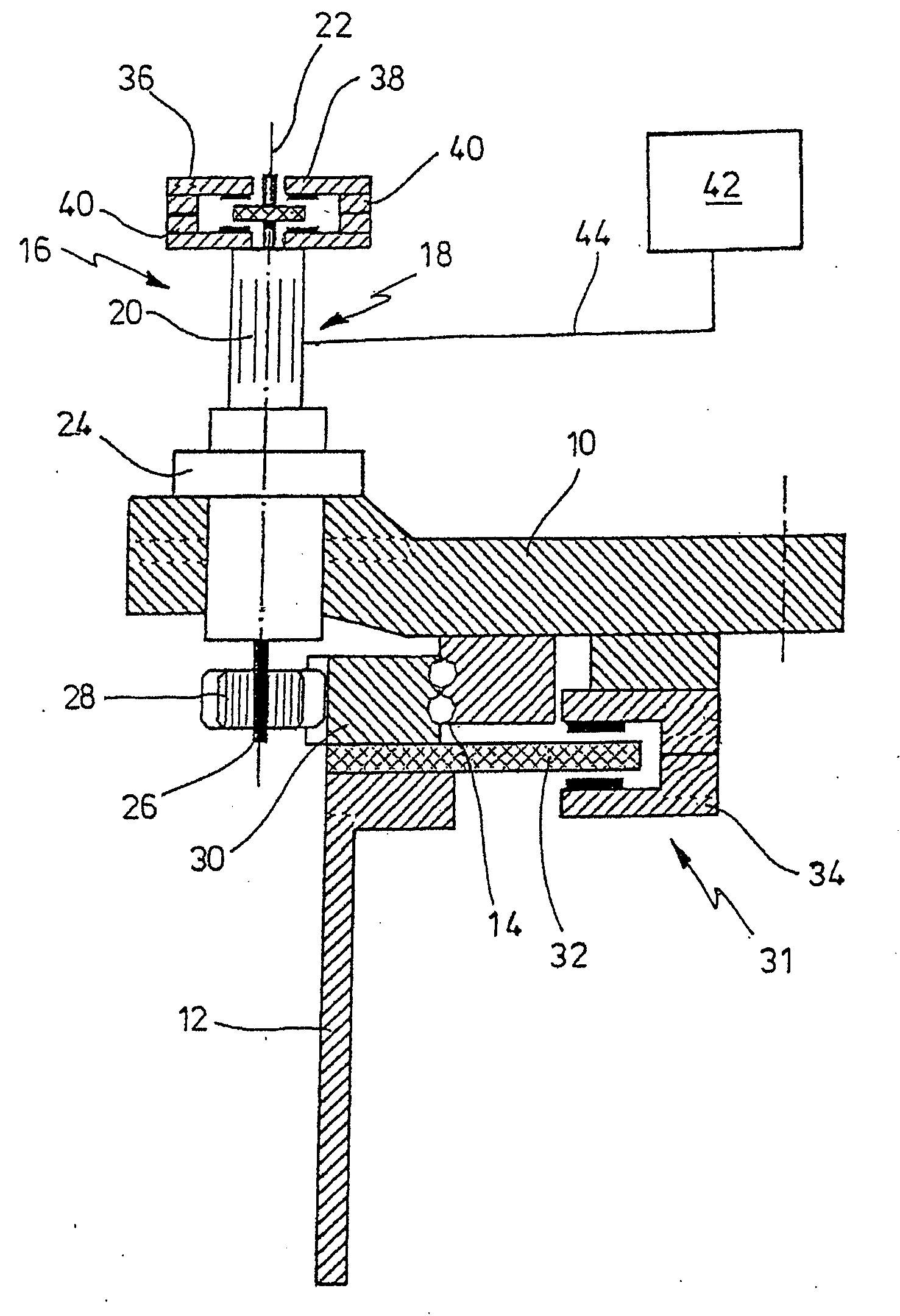

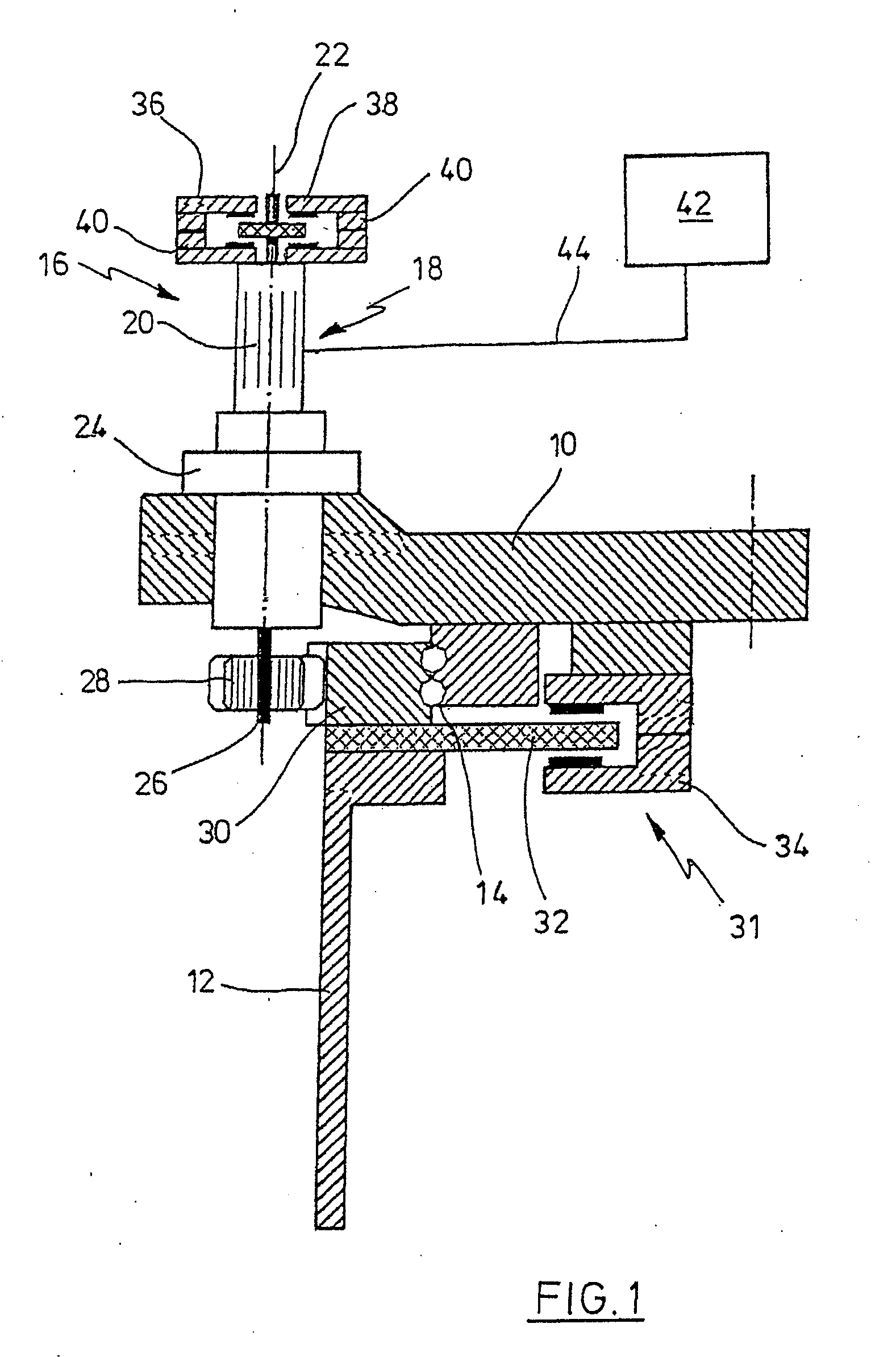

Method and apparatus for rotating a component of a wind energy plant

ActiveUS20090232652A1Increase stiffnessMinimizing total elasticityPropellersPump componentsWind powerElectric motor

The invention is related to a method for rotating a component of a wind energy plant by traversing an adjustment device, wherein the adjustment device comprises at least two adjustment drives, each one thereof having at least one electric motor, for traversing the adjustment device, and wherein during the traversing of the adjustment device, the electric motor of at least one of the at least two adjustment drives is operated at another rotational speed than the electric motor of at least one other of the at least two adjustment drives. Furthermore, the invention is related to a corresponding device.

Owner:NORDEX ENERGY SE & CO KG

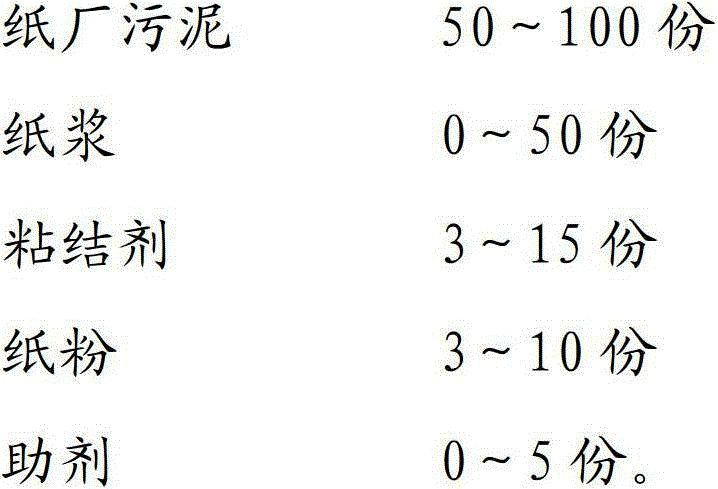

Cat litter for pets and preparation method of cat litter

The invention relates to the technical field of articles for pet garbage cleaning, in particular to cat litter for pets and a preparation method of the cat litter. The cat litter for pets comprises the following ingredients in parts by weight: 50 to 100 parts of paper plant sludge, 0 to 50 parts of paper pulp, 3 to 10 parts of bonding agents, 3 to 5 parts of paper dust and 0 to 5 parts of auxiliary agents, wherein the paper fiber length in the paper pulp is 1.5 to 3mm, and the paper fiber length in the paper dust is 0.5 to 1.5mm. The cat litter for pets has the advantages that the specific gravity is light, the adsorption capacity is high, the caking effect is good, the processing is easy, the environment protection is excellent, and in addition, the cost is low. The flow process of the preparation process of the cat litter is continuous, the time is saved, during the raw material stirring homogenization and granulation, the process is mild, and the operation is easy.

Owner:朱群

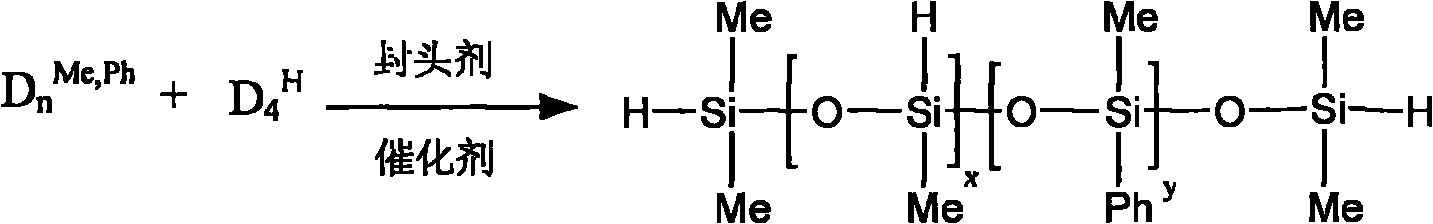

Preparation of methyl phenyl hydrogen-containing silicone oil for LED encapsulation

InactiveCN101328268ALow costMild conditionsOther chemical processesSemiconductor/solid-state device detailsLed packagingChemistry

The invention discloses a method for preparing an organic substance, in particular to a method for preparing methyl phenyl cyclosiloxane for LED packaging. The method takes methyl phenyl cyclic siloxane (Dn<Me, Ph>, n is equal to 3 and 4) and tetramethyl tetrahydric cyclotetrasiloxane (D4<H>) as monomers; under the protection of N2, an end-capping agent is added into the cyclosiloxane monomer which is subjected to pressure reduction and water removal to copolymerize under the action of a catalyst, then the filtration is performed to recover the catalyst, and the a low molecular compound in clear solution is removed under the condition of pressure reduction and high temperature and then is cooled to room temperature to produce a target product. The method has the advantages of easily-obtained raw materials, low cost, mild conditions, simple process, simple and convenient operation, no pollution, and easiness for industrialization. A product prepared by the method has good effect in the packaging process of LEDs.

Owner:HANGZHOU NORMAL UNIVERSITY

Preparation method of two-dimension nitrogen- and phosphorus-doped graphene

The invention discloses a preparation method of two-dimension nitrogen- and phosphorus-doped graphene. The preparation method particularly includes following steps: adding hydrotalcite to a proper amount of a sodium butyrate solution, stirring the mixture, aging the mixture, adding 4-dimethyl aminopyridine and n-butyl phosphate, stirring the mixture in a constant-temperature water bath at 60-70 DEG C for 6-8 h, separating a precipitation from liquid, washing the precipitation with deionized water for 2-3 times, drying and grinding the precipitation, sieving the precipitation through a sieve being 20-40 in meshes to obtain modified hydrotalcite powder, heating the modified hydrotalcite powder in a vacuum tubular furnace to 400-600 DEG C under a vacuum condition for calcining the powder for 2-4 h, adding the calcined powder to a hydrochloric acid solution, separating the precipitation and finally heating the precipitation to 2000-2500 DEG C under the vacuum condition to perform heat treatment for 3-6 h, and cooling a product to obtain the two-dimension nitrogen- and phosphorus-doped graphene. The preparation method is simple in raw materials and is mild in conditions.

Owner:JINING XINRUIDA INFORMATION TECH CO LTD

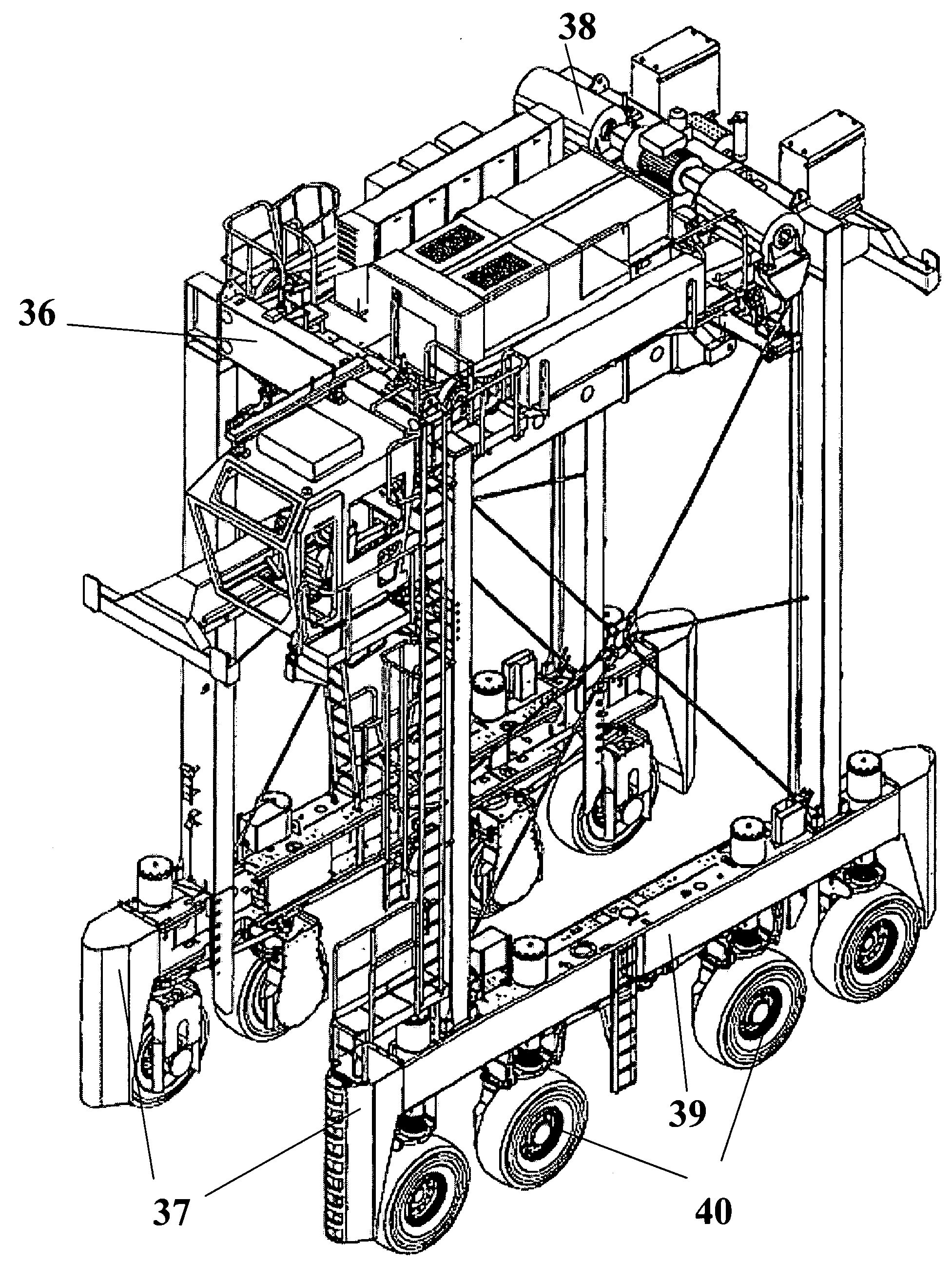

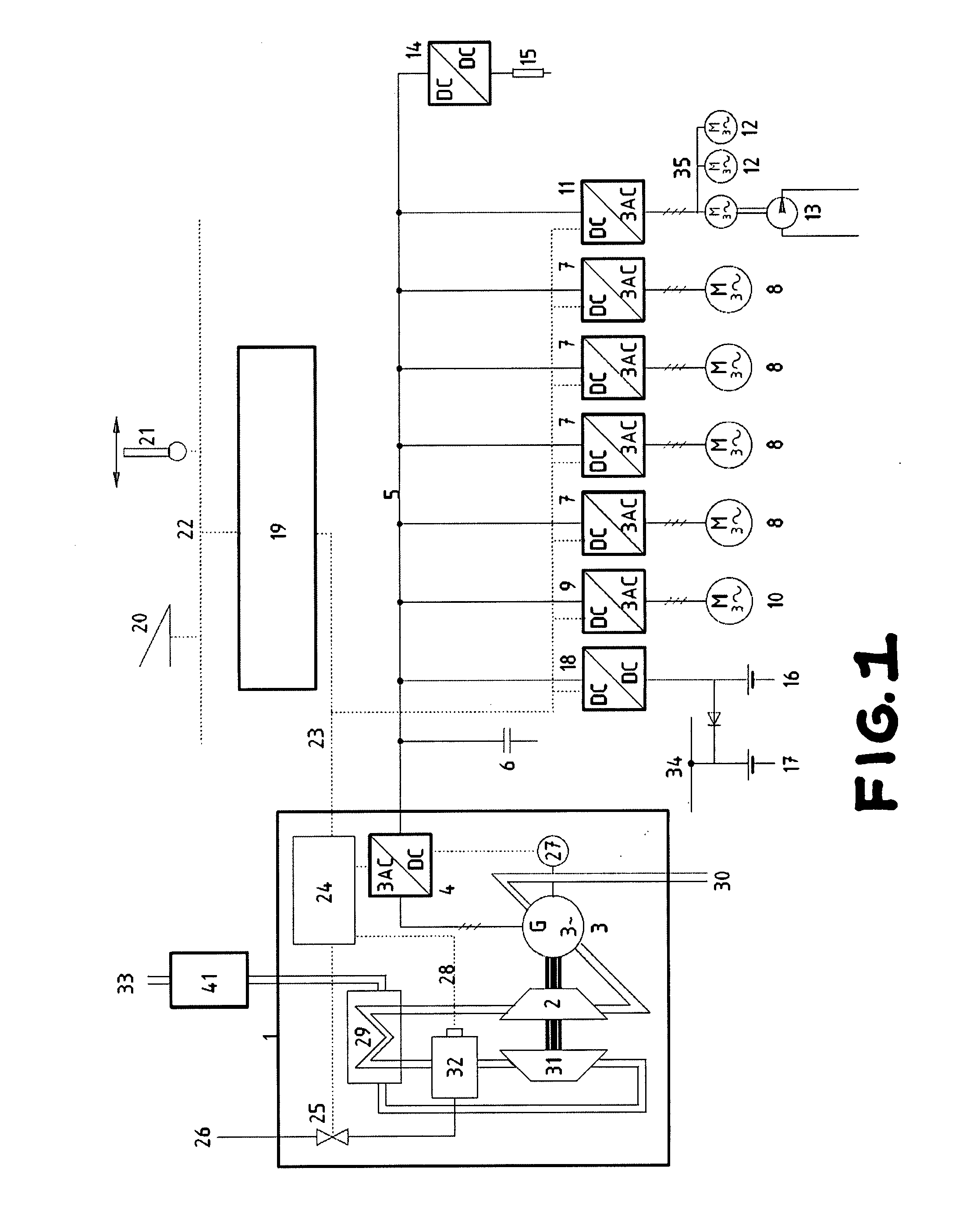

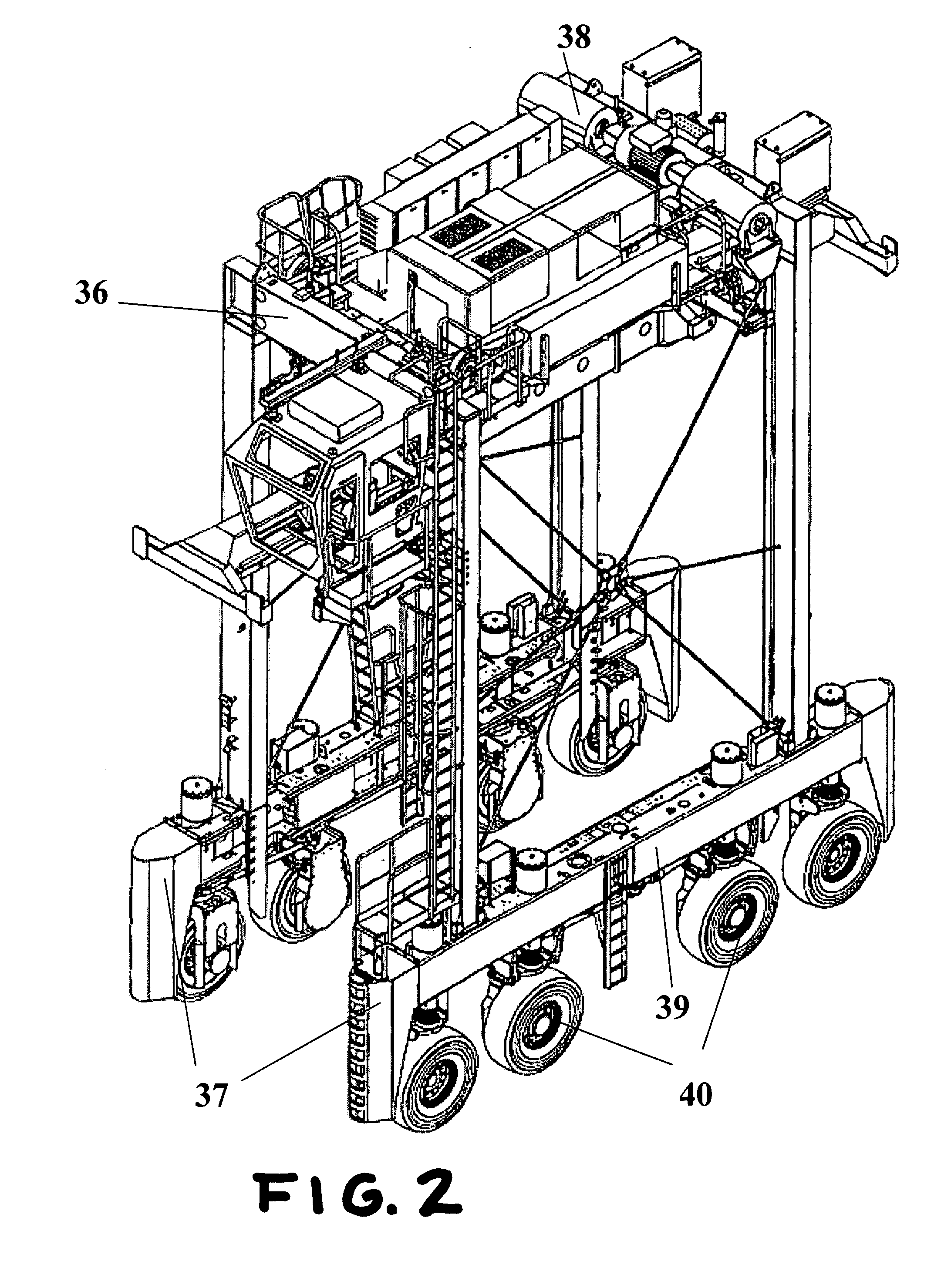

Straddle carrier having a low-emission and low-maintenance turbine drive

InactiveUS20080121444A1Less maintenance and replacementGentle processHybrid vehiclesVehicle sub-unit featuresElectricityDrive wheel

A straddle carrier having an electric drive system, consisting of a lower and an upper frame, which are connected with one another by means of supports. A lifting mechanism with hoists is disposed on the upper frame, and the lower frame consists of chassis carriers having electrically driven wheels, and a power generation unit that feeds its generated electric power into a direct voltage intermediate circuit, to which current inverters for supplying the travel, lifting, and auxiliary motors are connected. The power generation unit represents a micro gas turbine having an attached power generator, the power of which is passed to the travel, lifting, and auxiliary motors. The straddle carrier can be produced at low weight and maintained under advantageous conditions. Furthermore, the straddle carrier can be operated under environmentally friendly conditions.

Owner:NOELL MOBILE SYST

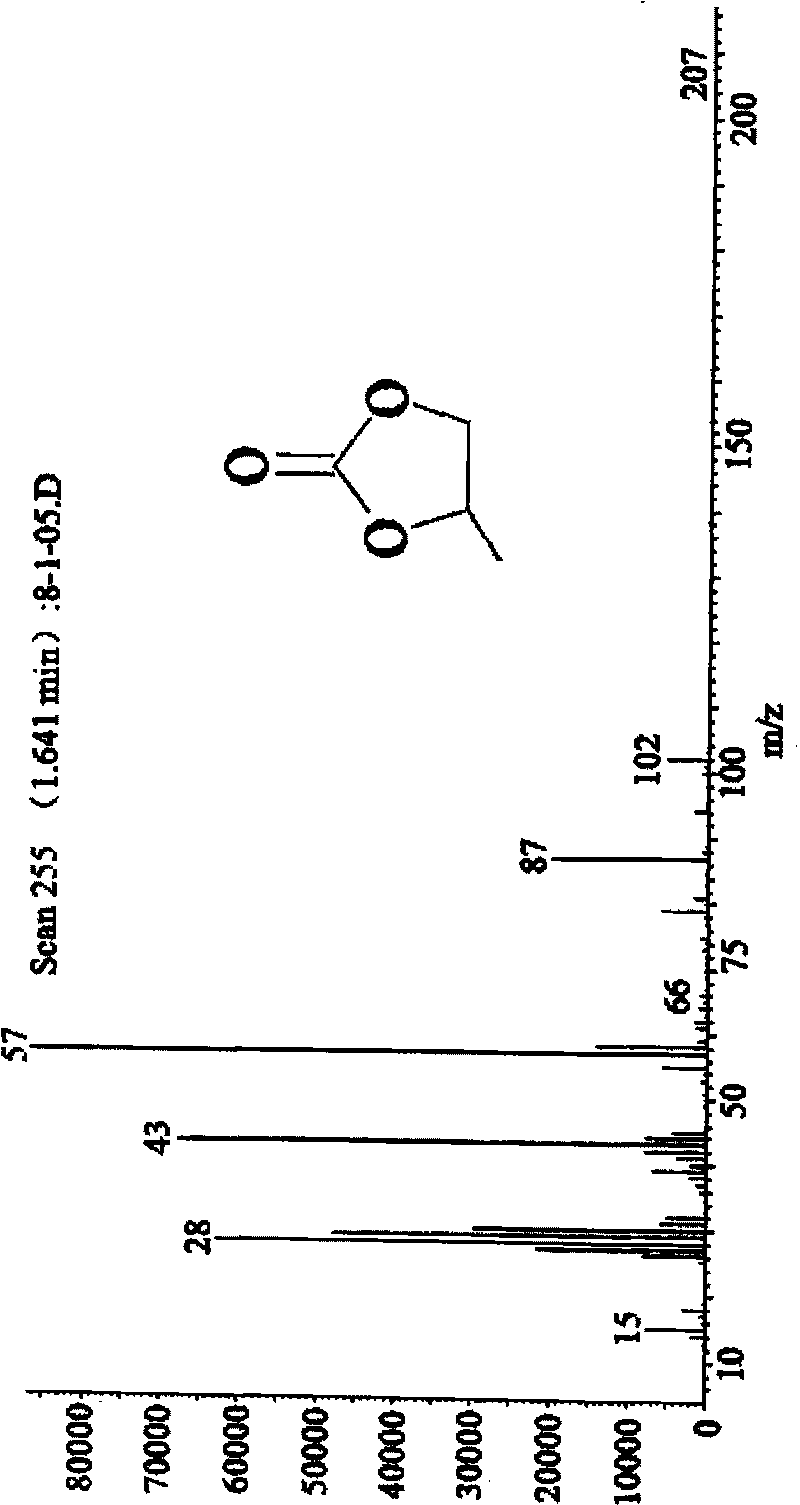

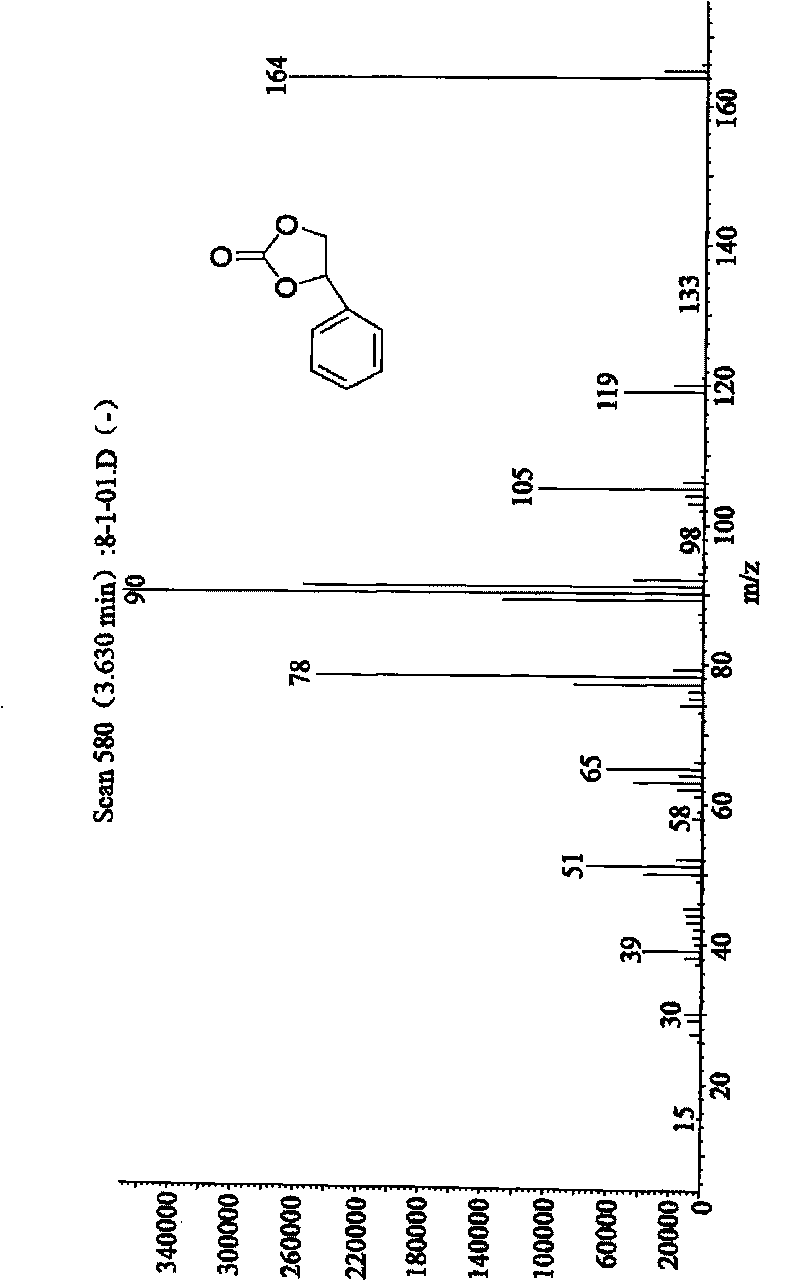

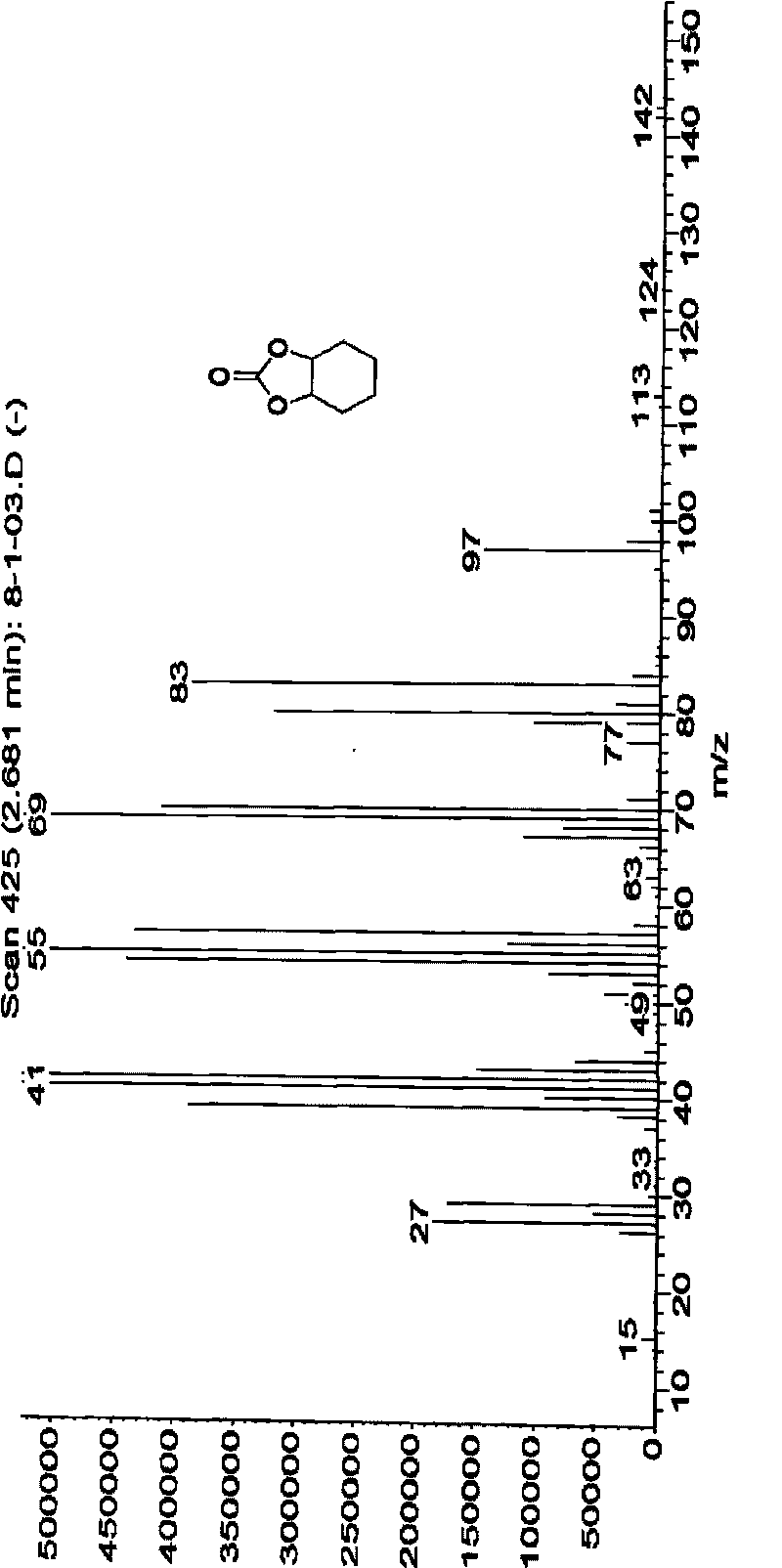

Method for synthesizing cyclic carbonate ester in presence of acidic ionic liquid catalyst

The invention discloses a method for synthesizing cyclic carbonate ester in presence of an acidic ionic liquid catalyst, which relates to a method for synthesizing the cyclic carbonate ester. The invention solves the problems of strict reaction conditions, low catalyst activity, environmental pollution and high cost of the traditional method for synthesizing the cyclic carbonate ester. In the method of the invention, the acidic ionic liquid catalyst is adopted, and carbon diode and an epoxy compound undergo cycloaddition to form the corresponding cyclic carbonate ester. The method has the advantages of mild reaction conditions, high catalyst activity, environmental protection and low cost.

Owner:HEILONGJIANG UNIV

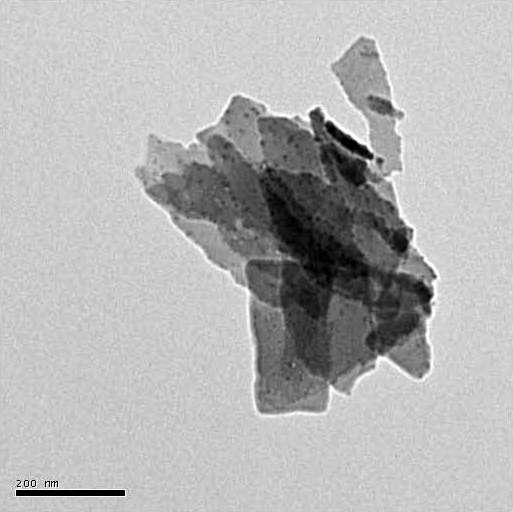

Method for preparing flaky nano copper powder

The invention discloses a method for preparing flaky nano copper powder, comprising the following steps: compounding a copper salt aqueous solution with a surfactant to obtain a mixed solution A, wherein the water in the copper salt aqueous solution and the surfactant form a surfactant compound system; (2) compounding a reducing agent aqueous solution with the surfactant which is the same as that used in step (1) to obtain a mixed solution B, wherein the water in the reducing agent aqueous solution and the surfactant form the surfactant compound system; (3) mixing the mixed solution B obtained in step (2) and the mixed solution A obtained in step (1) by stirring at the temperature of 20 DEG C to 80 DEG C, and reacting completely with stirring; and (4) carrying out solid and liquid separation on the product, washing the solid, and carrying out vacuum drying to obtain the flaky nano copper powder. The method of the invention has mild condition, simple process, short production period, low equipment investment and low preparation cost, and is easy to realize industrial production. The prepared flaky nano copper powder has consistent appearance, uniform size and good dispersibility.

Owner:尊领科技集团有限公司 +1

Method for preparing probiotics microcapsule and its application

InactiveCN102228235AImprove survivabilityImprove biological activityFood preparationFood biotechnologyChemistry

Owner:JIANGNAN UNIV

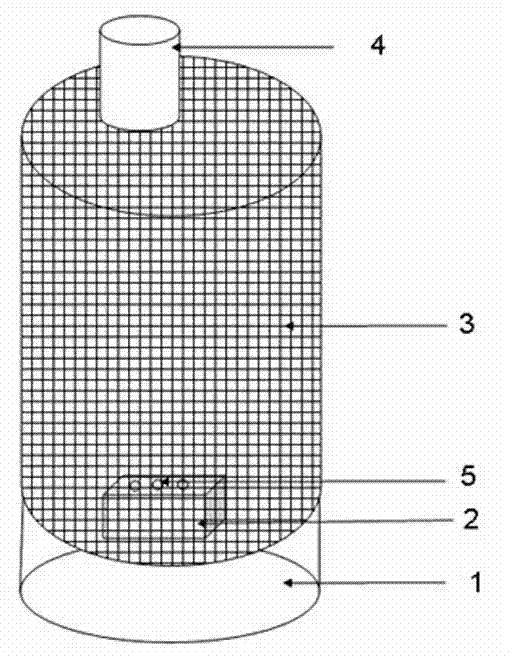

Physiological lubricant for helping parturient to safely give birth and preparation method thereof

The invention provides a physiological lubricant for helping a parturient to safely give birth and a preparation method thereof, relating to the field of medical technologies. The method comprises the following steps: placing purified water in a container; adding sodium chloride, propanediol, glycerin, HEC (hydroxyethyl cellulose) and xanthan gum to the purified water; evenly stirring under the temperature of 60+ / -2 DEG C; and cooling to normal temperature and then sealing and packaging. The preparation method is simple and reasonable, wild in process, convenient to operate and good in finished product stability. The physiological lubricant is a safe obstetrical agent for helping normal childbirth and reducing pains in the childbirth process of the parturient.

Owner:JIANGSU KANGBAO MEDICAL EQUPMENT

Method for feeding lepidopteron

InactiveCN103960204APrevent escapeImprove hatchabilityChemicalsAnimal husbandryAnimal scienceDisinfectant

The invention discloses a method for feeding lepidopteron. In the feeding process, a tray type net cage is used as a main feeding tool. The method comprises steps of collecting eggs, sterilizing, hatching larvae from the eggs, feeding the larvae, feeding pupas, feeding imagoes and the like, wherein gauze or plastic ropes are used as an oviposition substrate for collecting the eggs; the eggs are sterilized by using a formaldehyde solution with the volume concentration of 3-4%; the eggs are hatched and fed in an illumination incubator; the larvae are sterilized by using a sodium hypochlorite solution with the volume concentration of 8-12%; pupas feather in the tray type net cage; the feathering imagoes are continuously fed in the net cage and the eggs are collected and sterilized. The tray type net cage is simple and convenient to operate, the insects are effectively prevented from escaping and the cleaning can be carried out at any time; in the feeding process, eggs and larvae are disinfected by using different disinfectants, the disinfection effect is thorough and gentle, the bacteria are effectively prevented from mass propagation, and the hatchability of the eggs, the feathering rate of pupa are also improved, the hatchability of the eggs can be 95-96%, and the feathering rate of pupa can be 98%.

Owner:QINGDAO AGRI UNIV

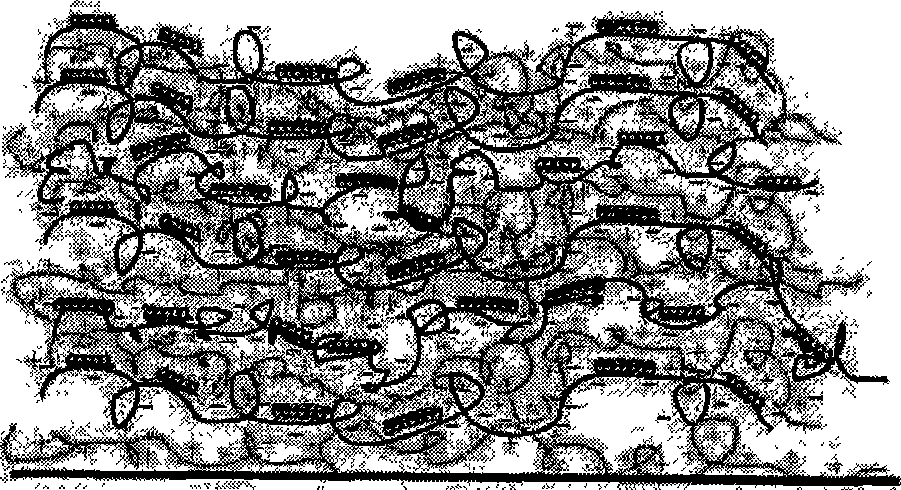

Compound film enhanced by inclusion complex of ring molecule and polymer and preparation method thereof

InactiveCN101462388AStrong specificityGood controllabilitySynthetic resin layered productsSolventSelf assemble

The invention discloses a composite membrane reinforced by an inclusion complex of ring molecules and a polymer. The composite membrane is mainly formed by a polymer layer consisting of a linear polymer or a branch polymer and an inclusion complex layer formed by serially sleeving the ring molecules on partial chain links of the polymer which are compounded and accumulated layer by layer. The preparation of the composite membrane mainly comprises the following steps: a polymer component and a ring molecule component are dissolved into a solvent respectively to be prepared into a solution; and a substrate material is alternately immersed into the solution prepared by the polymer component and the ring molecule component, is kept stand for a period of time, and is taken out to remove excessive adhesive substances, and a multi-layer membrane system can be obtained by circulating the process. Compared with the prior art, a supermolecular multi-layer membrane greatly strengthens the mechanical property and the friction-resistant performance of the multi-layer membrane by introducing a self-assembling inclusion component of the polymer and the ring molecules, and has broad varieties of selectable polymers and broad application prospect.

Owner:SICHUAN UNIV

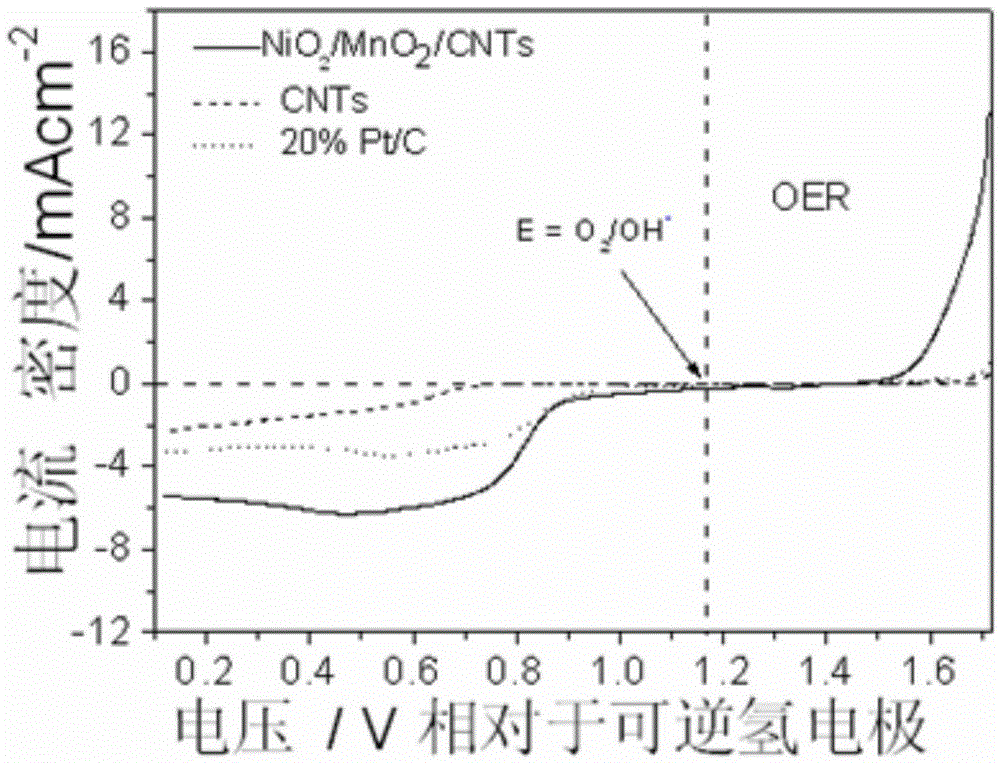

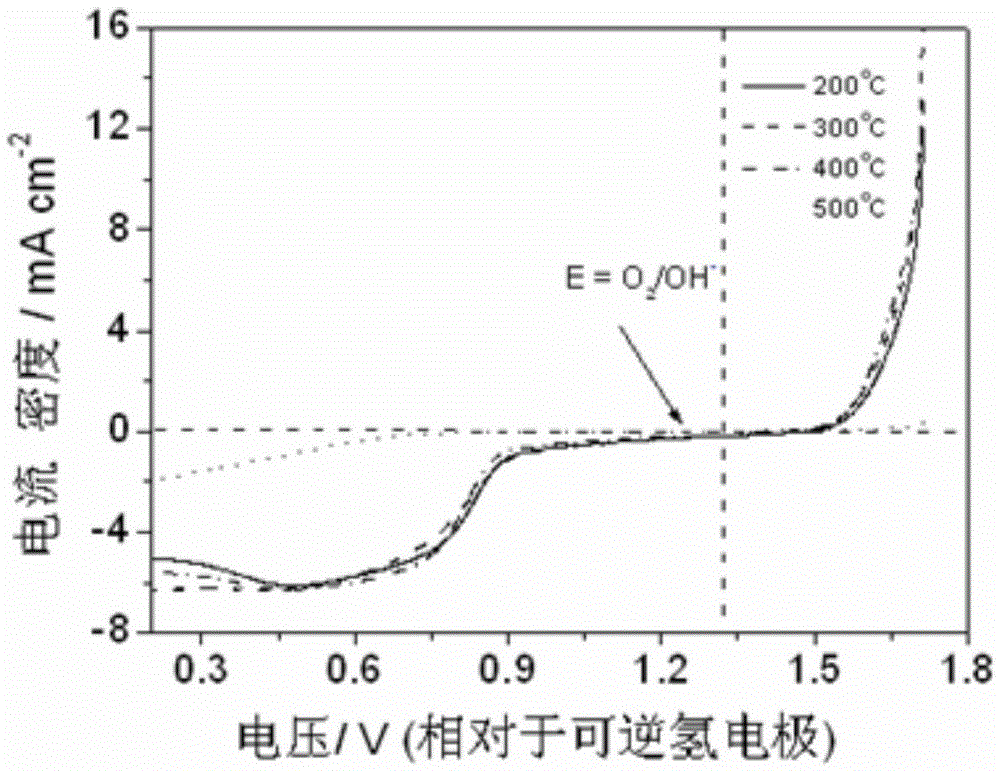

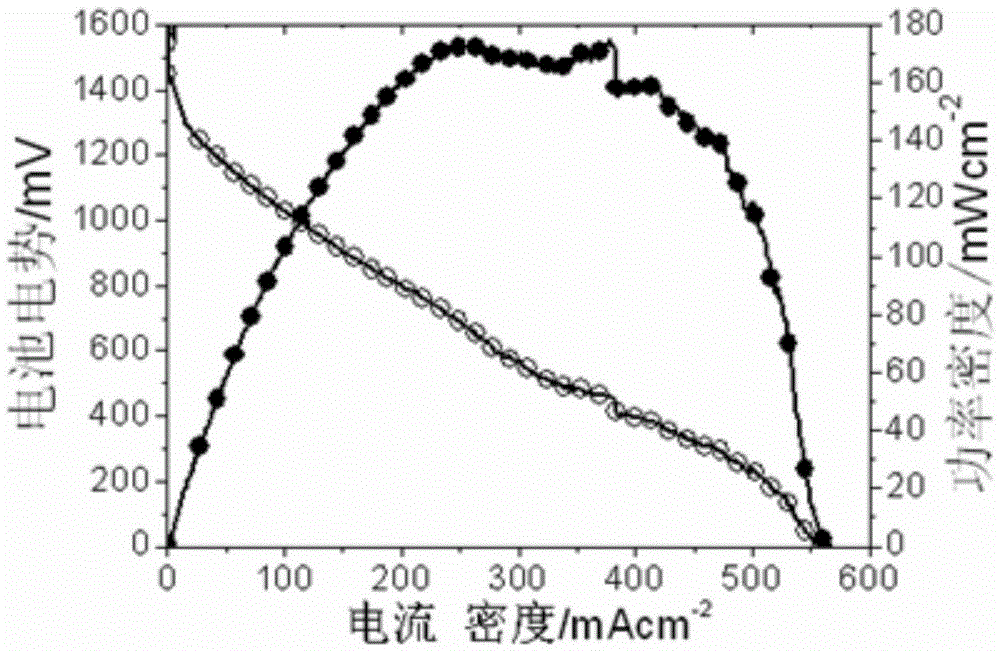

Nickel manganese/carbon nanotube composite catalyst and preparation and application thereof

InactiveCN105289643AImprove electrochemical performanceImprove charge and discharge performanceCell electrodesMetal/metal-oxides/metal-hydroxide catalystsManganeseCarbon nanotube

The invention relates to a nickel manganese / carbon nanotube composite catalyst and preparation and application thereof. The bifunctional catalyst comprises a carbon nanotube and nickel manganese (NiMnO4) spinel. A manganese dioxide precursor, nickelous acetate and the carbon nanotube are dissolved in ammonia water and undergo ultrasonic dispersion, undergo a hydrothermal reaction for 3-6 h at 130-150 DEG C, are cooled to room temperature, cleaned, dried and calcinated, and the nickel manganese / carbon nanotube composite catalyst is obtained. The nickel manganese / carbon nanotube composite catalyst is applied to an air electrode of a metal-air battery. The nickel manganese / carbon nanotube composite catalyst has efficient oxygen reduction performance and efficient oxygen evolution performance and can be applied to metal-air batteries.

Owner:DONGHUA UNIV

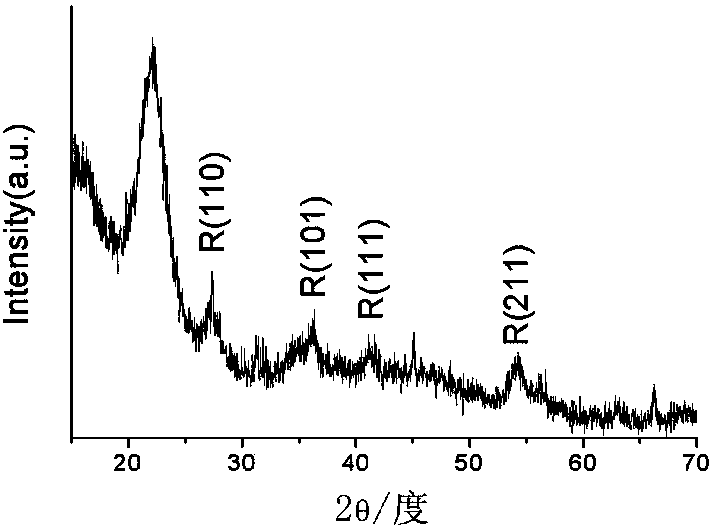

Hydrophobic and ultraviolet radiation aging-resistant wood-based composite material and preparation method thereof

InactiveCN104260169AGood for maintaining good performanceMaintain good performanceWood treatment detailsReed/straw treatmentTitaniumAqueous solubility

The invention discloses a hydrophobic ultraviolet radiation aging-resistant wood-based composite material and a preparation method thereof. The surface layer of the composite material is of a titanium dioxide layer with a micro-nano secondary structure and the crystal structure of the composite material is of a rutile type. The preparation method comprises the processes of precursor solution preparation, multistage dipping and drying: firstly dispersing a water-soluble titanium source in a 5-7mol / L sodium chloride aqueous solution to obtain a solution a, wherein the concentration of the water-soluble titanium source is guaranteed to be 0.001-0.500 mol / L; uniformly adding an alkaline matter into the solution a to obtain a precursor solution, wherein the concentration of the alkaline matter is guaranteed to be 0.001-0.500 mol / L; dipping a wooden base material into the precursor solution, reacting at a room temperature for 1-10 days, cleaning and drying for 1-2 days to obtain a wood-based composite material; dipping the wood-based composite material in 0.8-1.2% of a low-surface energy matter solution, reacting at a room temperature for 0.2-1 day and drying for 1-2 days to obtain the hydrophobic ultraviolet radiation aging-resistant wood-based composite material. According to the preparation method, a titanium dioxide surface layer with a rutile type micro-nano secondary structure can be constructed on the surface of the wooden base material so that the wood-based composite material is excellent in hydrophobicity and ultraviolet radiation aging resistance.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Continuous two-stage preparation of solvent-free polyacrylate hotmelt PSAs

ActiveUS6881442B2High molecular weightHigh throughputFilm/foil adhesivesOrganic dyesSolvent freeAntioxidant

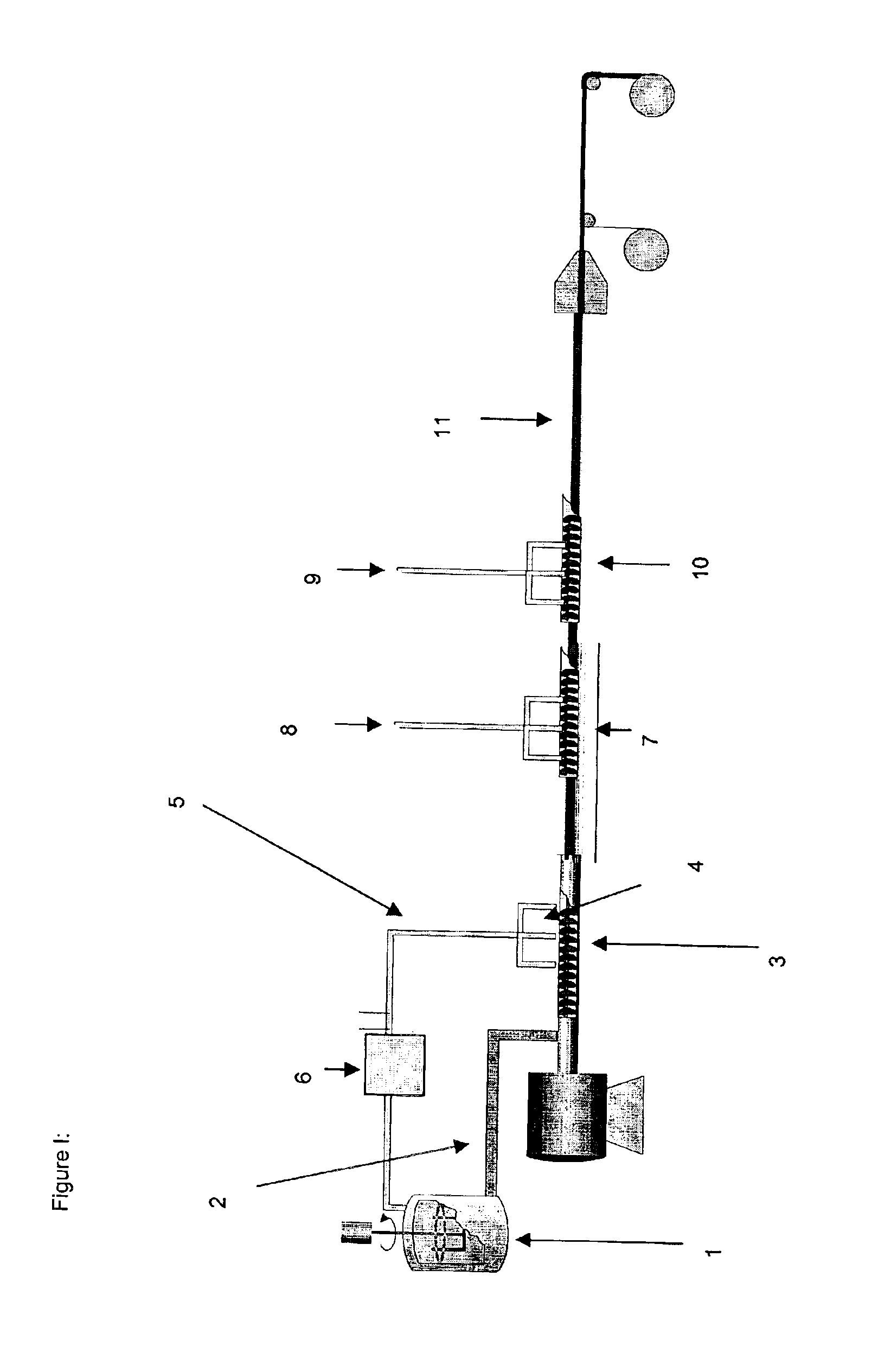

In a continuous two-stage process for preparing solvent-free polyacrylate hotmelt pressure sensitive adhesives which is gentle on the polymer and redeploys the solvent used in the process the following steps are carried out:polymerizing a self-adhesive pressure sensitive adhesive in solution, the solvent having a low vapor pressure;continuously mixing the polymer solution with antioxidants and preheating the mixture under superatmospheric pressure without boiling it;concentrating the polymer solution to a residual solvent content of less than 0.1% by weight in a concentrating extruder under the effect of reduced pressure and elevated temperatures;condensing, collecting, and re-using the solvent stripped off in the extruder;compounding the abovementioned solvent-freed hotmelt pressure sensitive adhesive with tackifying resins, fillers, stabilizers, crosslinkers or other additives in a second extruder at a moderate melt temperature;transferring the blended solvent-free self-adhesive pressure sensitive adhesive to a downstream coating unit.

Owner:TESA SE

Synthesis method of 1-ethoxy-1,3,3,5,5-pentafluorocyclotriphosphonitrile

InactiveCN104558045AMild reaction conditionsGentle processGroup 5/15 element organic compoundsSecondary cellsEthoxidineBiochemical engineering

The invention relates to a synthesis method of 1-ethoxy-1,3,3,5,5-pentafluorocyclotriphosphonitrile, which comprises the following steps: a. in a catalyst-added organic solvent, substituting six chlorine atoms of hexachlorocyclotriphosphonitrile with fluorate to prepare a hexafluorocyclotriphosphonitrile-containing product, and distilling to remove the byproduct and solvent, thereby obtaining the hexafluorocyclotriphosphonitrile; and b. reacting the hexafluorocyclotriphosphonitrile obtained in the step a with ethylate in a catalyst-added organic solvent to substitute one fluorine atom with one ethoxy group so as to obtain a product containing 1-ethoxy-1,3,3,5,5-pentafluorocyclotriphosphonitrile, and distilling to remove the byproduct and solvent, thereby obtaining the 1-ethoxy-1,3,3,5,5-pentafluorocyclotriphosphonitrile. The synthesis method has the advantages of mild reaction conditions and high reaction controllability, and is convenient for industrial production. The method also has the advantages of simple technical process, low energy consumption, recoverable solvent, higher yield and higher product purity.

Owner:湖北诺邦科技股份有限公司

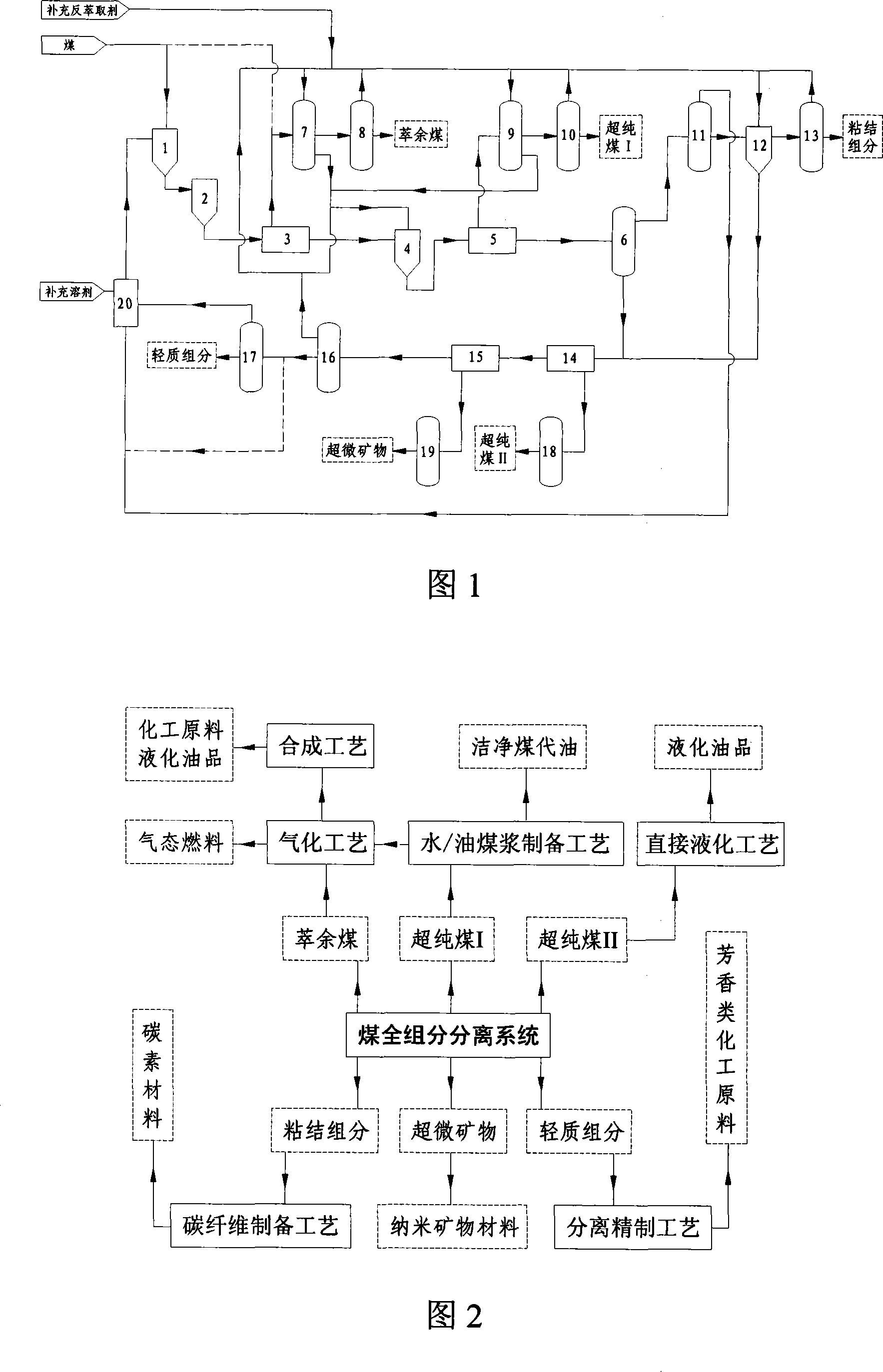

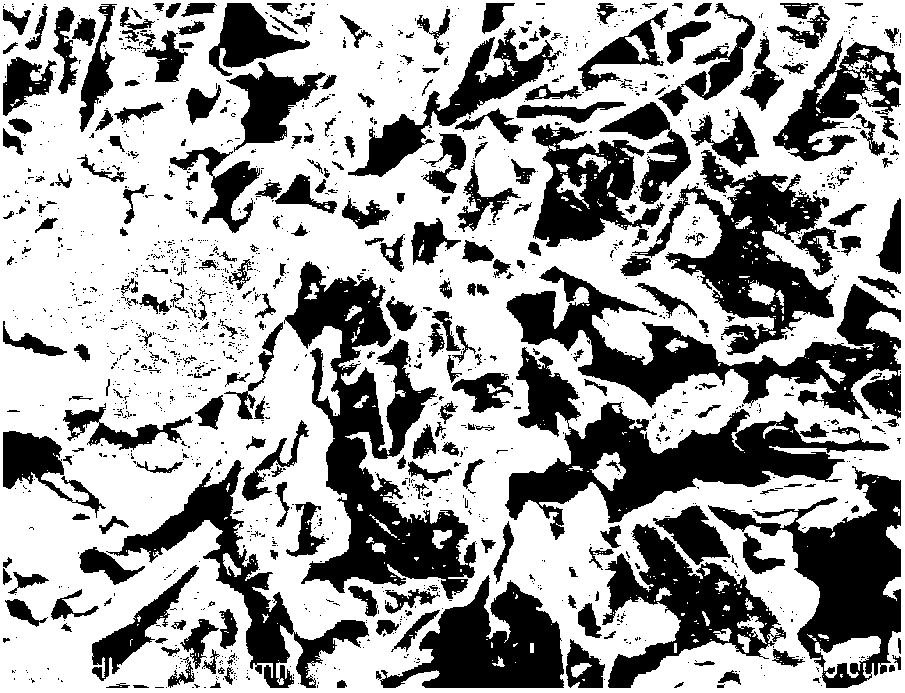

Mild technique for separating coal whole components

The invention relates to a mild technique of coal complete group separation, which belongs to the separating technique of coals. And the method comprises the following steps: mixing and extracting raw coal with the mixed dissolvent of dissolvent A and dissolvent B, separating out solid-phase component, getting coal residue after drying, adding dissolvent in the liquid phase which is separated out to reversely extract, precipitating solid body, obtaining superpurity coal I after washing solid-phase component which is separated from solid and liquid, stewing the liquid matter which is separated out, and layering, separating liquid in one of the stratification, recycling use, reversely extracting residual liquid to get solid-state matter, and getting binding component after drying, liquid of another layering liquid gets into a crude membrane separator, obtaining super-purity coal II after drying solid matter which is separated out, getting ultra-micro mineral after drying the solid matter which passes through a fine membrane separator and being separated through membrane, liquid of fine membrane separator normally presses a rectifying tower, separating out dissolvent C, dissolvent B and dissolvent A to repeatedly use, and residues are lightweight component. The technique has simple technique equipment, mild process, simple control and low production cost, and dissolvent can be recycled to use. The mild technique separates coals into six matters, which opens up different processing and conversion to each group of coal, and improves the value, value in use and environmental benefit of coal.

Owner:CHINA UNIV OF MINING & TECH

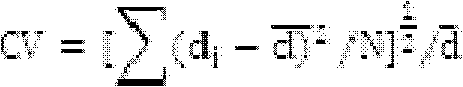

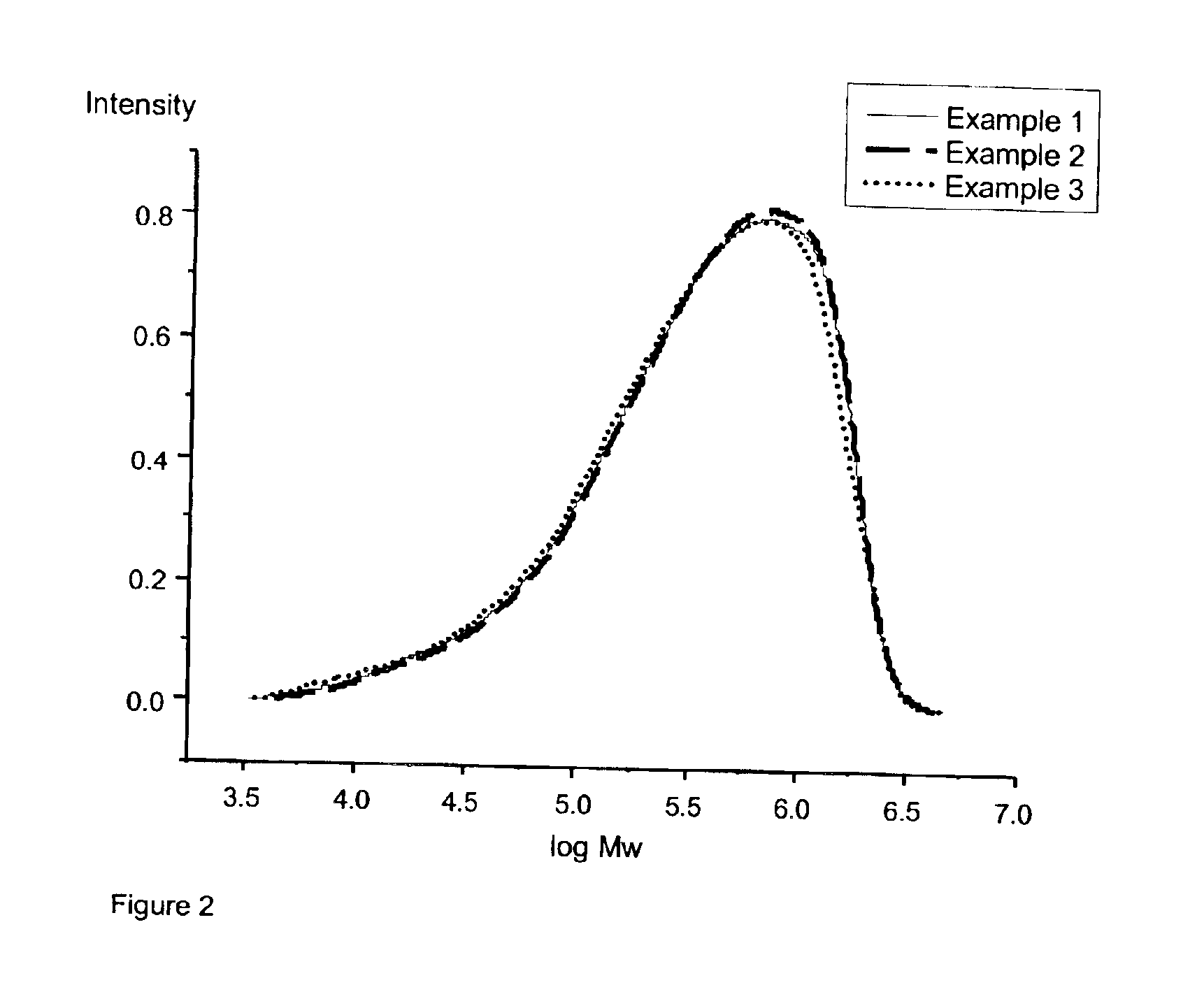

Preparation method of ceftriaxone sodium crystal and evaluation method of ceftriaxone sodium aqueous solution turbidity

ActiveCN102993215AReduce the incidence of allergic reactionsHigh clarityOrganic chemistryMaterial analysis using radiation diffractionCLARITYHypersensitive response

The invention relates to a preparation method of ceftriaxone sodium crystal, wherein the obtained ceftriaxone sodium is the crystal of the same subtype, and the subtype crystal has the best clarity, the lowest anaphylaxis occurrence rate and the highest safety in comparison with all crystals. The preparation method is simple in technology and excellent in reproducibility. The invention further relates to an evaluation method of ceftriaxone sodium aqueous solution turbidity, wherein a powder X-ray diffraction technology and a scanning electron microscope technology are used, in combination with statistical methods, a method for evaluating the ceftriaxone sodium crystal form is established, three subtypes of the ceftriaxone sodium crystal form is defined for the first time, and the relation between the subtypes and the aqueous solution turbidity is established, thus, rapid evaluation on crystal form and aqueous solution turbidity of ceftriaxone sodium samples becomes possible, and the method has great practical value.

Owner:YOUCARE PHARMA GROUP +1

Cold pad-batch dyeing process for pure cotton fabric

InactiveCN102535201ALower average tensionLow frictionTextile storage in superimposed formTextile storage in wounded formRoom temperaturePlastic film

The invention discloses a cold pad-batch dyeing process for pure cotton fabric. The process flow comprises the steps of: padding and rolling a mixed liquor of a dye and an alkaline agent, coiling and plastic film coating, rotating stacking, primary water washing, soaping, secondary water washing and drying. In the padding and rolling process, an active dye at a concentration of 10g / l is adopted, 10-15 g / l of water glass is adopted as the alkaline agent, a concentration of urea is 3 to 5g / l and a concentration of sodium sulfate is 10g / l. The rotating stacking process is performed for 16h at a room temperature of 10-15 DEG C. By the adoption of the process of the invention, energy can be saved, consumption can be reduced, the fixation ratio of the dye is increased, the grade of the product is improved, and the process cost is low. Besides, the conditions of the cold pad-batch dyeing process are moderate, the fabric is subjected to low tension and small friction, and the apparent effects and hand-feel of the fabric are improved to a great extent.

Owner:CHANGSHU KAIDA PRINTING & DYEING

Synthesis method of lithium difluorophosphate

ActiveCN106882782AImprove conversion rateHigh puritySecondary cellsPhosphorus compoundsDifluorophosphateSynthesis methods

The invention relates to a synthesis method of lithium difluorophosphate, belonging to the technical field of lithium battery electrolyte. The synthesis method is characterized by comprising the following steps: respectively adding P2O5, lithium-containing inorganic salt and dried organic solvent into a closed reaction kettle at normal temperature, airtightly stirring and cooling to -50DEG C to 30DEG C, displacing the atmosphere in the kettle three times with dried inert gas, increasing the temperature to 95DEG C-105DEG C after the content of moisture in the kettle is less than 1ppm, boosting pressure to 0.7MPa-0.85MPa; then introducing POF3, reacting for 5-15 hours under stirring, wherein the reaction temperature and pressure are respectively at 60DEG C to 180DEG C, and 0.5MPa to 2.5MPa, and the molar ratio of POF3 to P2O5 to lithium-containing inorganic salt is 1 to (0-1.5) to (1-5); and then filtering to obtain a filtrate, removing solvent, and recrystallizing solid to obtain crystal. The synthesis method has mild conditions, no side reactions appear, the technology process is simple, the product is easily separated and extracted, the moisture and free chlorine values are low, and the purity of the prepared product is high.

Owner:山东永浩新材料科技有限公司

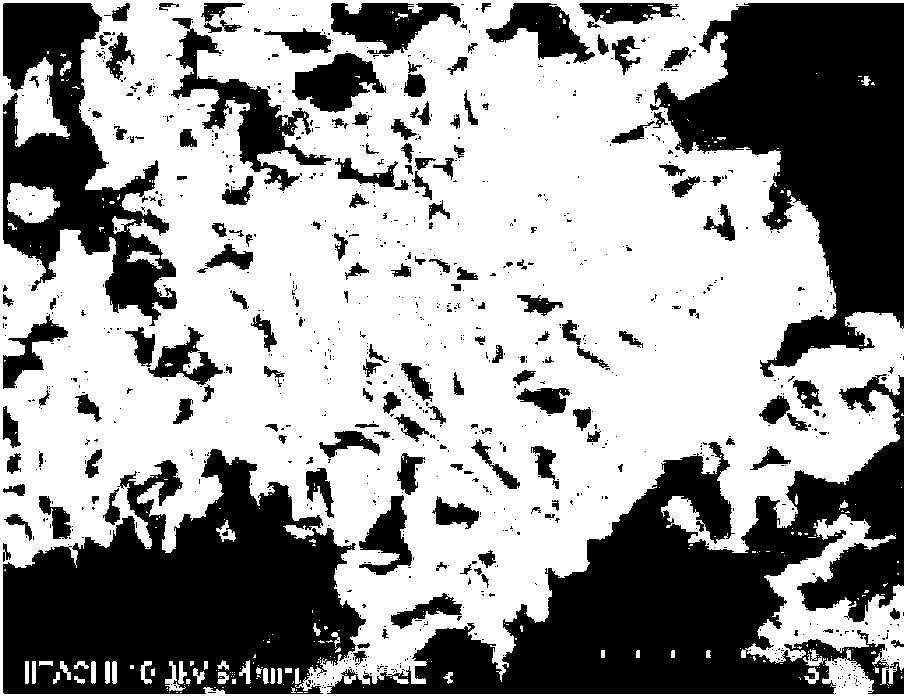

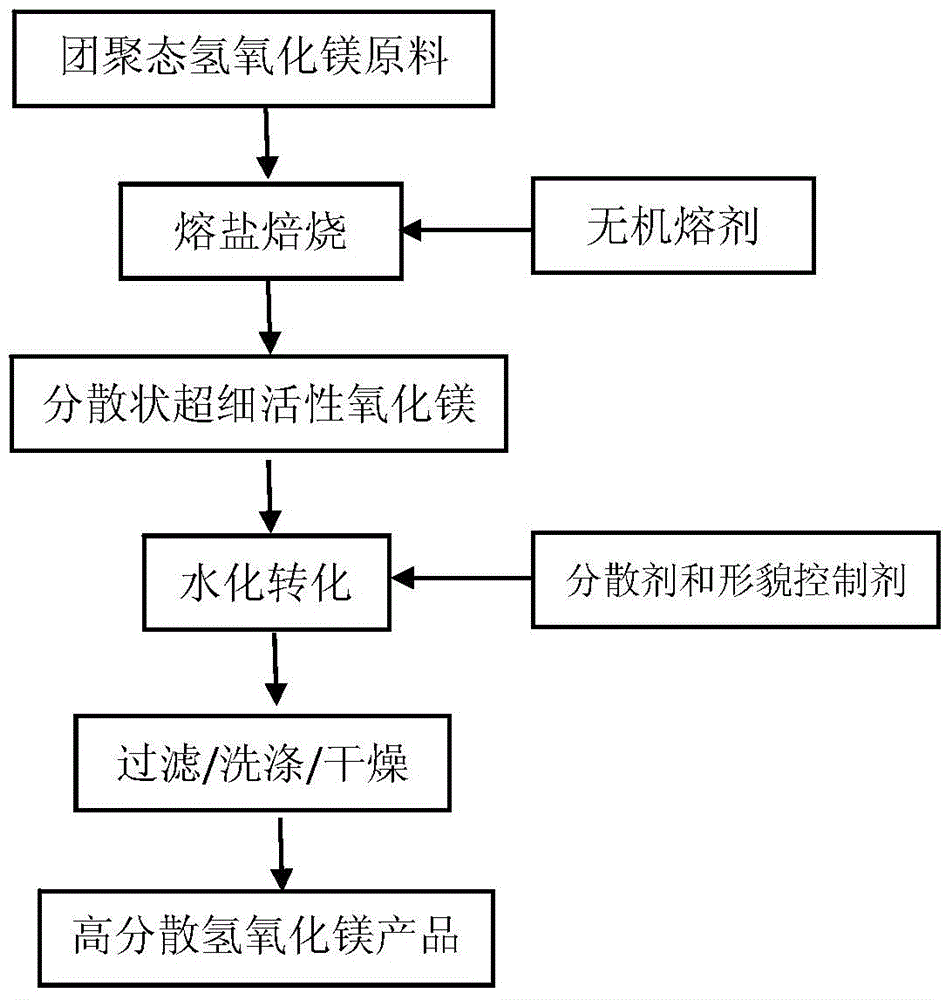

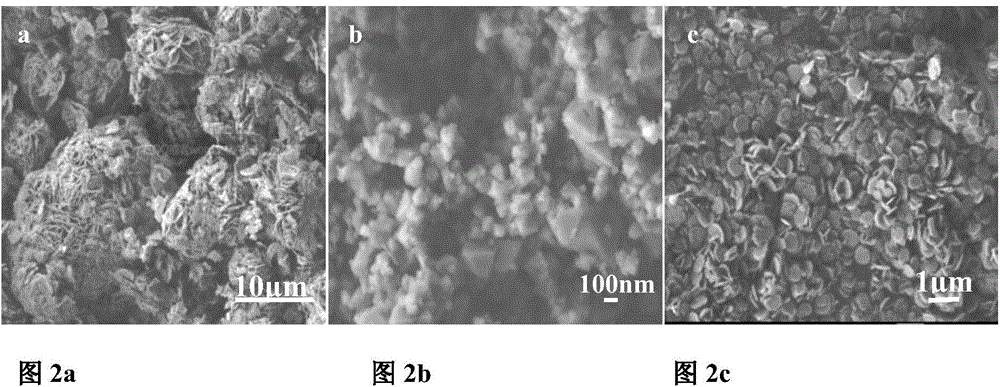

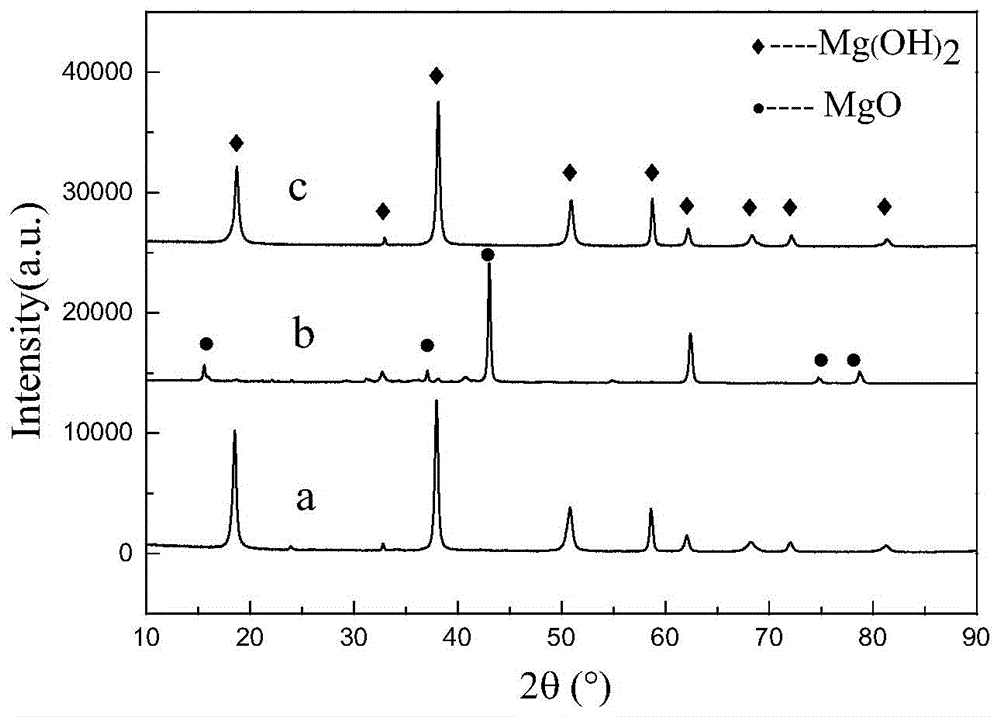

Method for preparing high dispersed magnesium hydroxide from agglomerated state magnesium hydroxide

ActiveCN104609449AImprove product added valueSimple processMagnesium hydroxideInorganic ChemicalWastewater

The invention relates to a method for preparing high dispersed magnesium hydroxide from agglomerated state magnesium hydroxide, and belongs to the technical field of the preparation of inorganic chemical industry materials. According to the method disclosed by the invention, the high dispersed magnesium hydroxide is prepared through the following steps: using agglomerated state magnesium hydroxide as a raw material, wherein the original average particle diameter is 0.1-3 microns, and the average agglomerated particle diameter is 5-50 microns, firstly, mixing the raw material with proper amount of inorganic solvent, and roasting the mixture for 0.5-6 hours at the temperature of 300-700 DEG C, so as to form dispersed superfine active magnesium oxide; then, adding the magnesia to an aqueous solution containing a dispersing agent and a morphological control agent, and performing hydration conversion for 0.5-6 hours at the temperature of 10-100 DEG C so as to obtain the high dispersed magnesium hydroxide of which the original average particle diameter is 0.1-3 microns, the average agglomerated particle diameter is 0.5-4.0 microns, the morphology is regular, and the particle diameters are homogeneous. The method disclosed by the invention is simple in technology, is mild in process, and is high in added value of a product. The magnesium hydroxide prepared by the method disclosed by the invention is regular in morphology and is good in dispersion, can be used as a basic inorganic chemical industry product to be used in the fields of flame resistance, foods, desulphurization, wastewater treatment and the like.

Owner:TSINGHUA UNIV

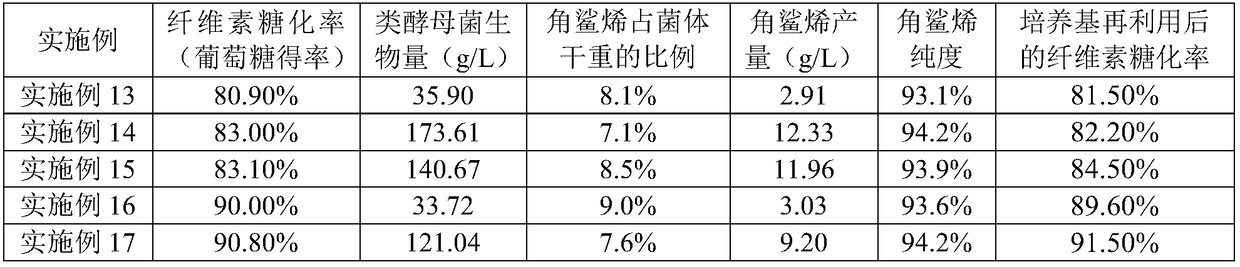

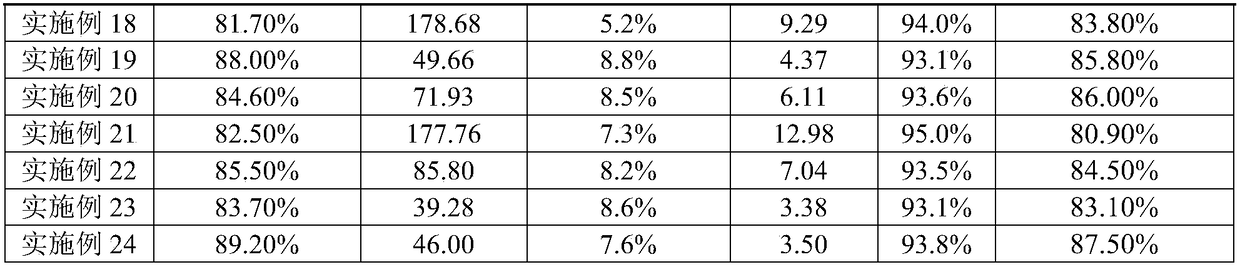

Method for preparing squalene by adopting lignocellulose

ActiveCN108866112ASolve market needsReduce manufacturing costDistillation purification/separationWaste based fuelCelluloseDry weight

The invention provides a process for preparing squalene by taking lignocellulosic agricultural and forestry wastes as raw materials, which aims at problems in the aspect of the production of squaleneby microbial fermentation in the prior art. The process comprises the steps of pre-treatment, saccharification, yeast-like fungi fermentation and squalene extraction and the like. According to the process provided by the invention, lignocellulose biological saccharification is combined with yeast-like fungi high-density fermentation; by adopting lignocellulose biomass as raw material, on the one hand, the cost of enzyme usage and the production cost of squalene microbial fermentation in a saccharification stage are significantly reduced; on the other hand, the problem of comprehensive utilization of the agricultural and forestry wastes is solved. In addition, medium and fermentation medium in the lignocellulose saccharification stage can be recycled, water can be saved and usage of chemicals can be reduced, and has significant effect on reducing the discharge of wastewater and reducing the cost. In the process provided by the invention, the squalene yield can reach 13 g / L, accounting for 5% of the dry weight of thallus, and the purity of refined squalene is higher than 93%.

Owner:青岛中科潮生生物技术有限公司

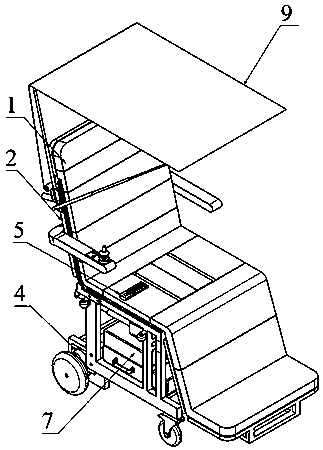

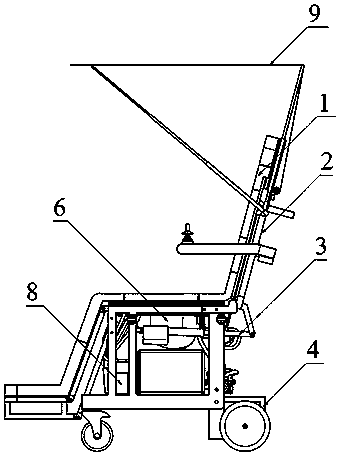

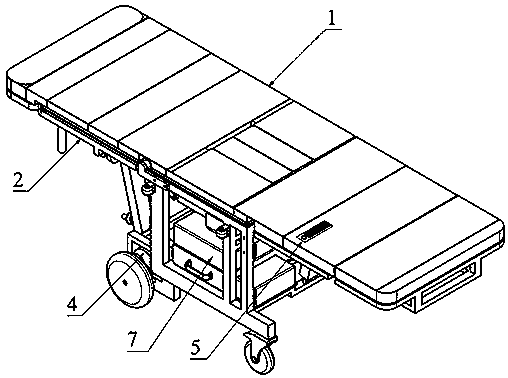

Intelligent wheelchair vehicle with nursing function

PendingCN109602550AWith nursing functionEasy to go to the toilet by yourselfWheelchairs/patient conveyanceNursing bedsVehicle frameWheelchair

The invention relates to the field of intelligent nursing, in particular to an intelligent wheelchair vehicle with a nursing function. The intelligent wheelchair vehicle includes a movable vehicle body, a movable vehicle frame, an electric device, a traveling device, a control device, a toilet device, a power supply, an air supply device and a sun shading device. The movable vehicle body is installed on the movable vehicle frame, the movable vehicle frame is equipped with the electric device, the traveling device, the control device, the toilet device, the power supply and the air supply device, the movable vehicle frame can be transformed into sitting, lying down and turning over states, the toilet device is provided with a toilet, the toilet is connected with a cleaning device and a drying device, the air supply device separately communicates with air bags in the movable vehicle body, and the sun shading device is installed at the upper part of the movable vehicle frame. Compared with the prior art, the intelligent wheelchair vehicle with the nursing function of the invention is used as a vehicle and a bed, has the functions of transferring and turning over, and at the same time,the intelligent toilet is arranged to facilitate users to go to the toilet by themselves, the functions of cleaning, drying and odor prevention also be provided, and the work of nurses is greatly alleviated.

Owner:深圳首明科技有限公司

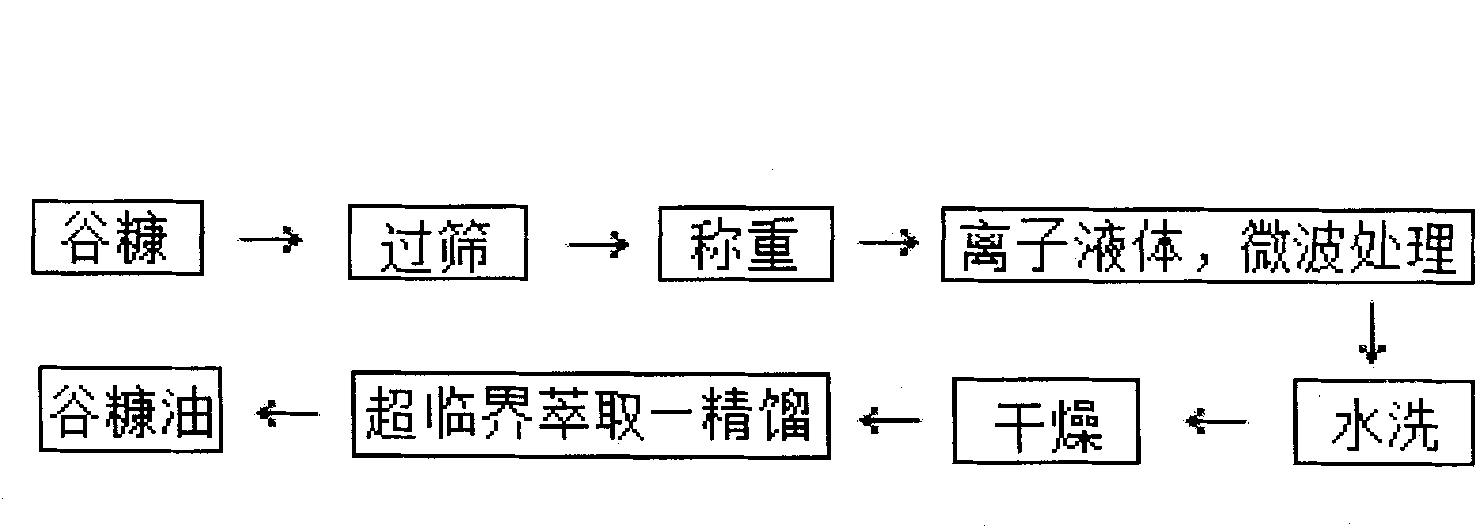

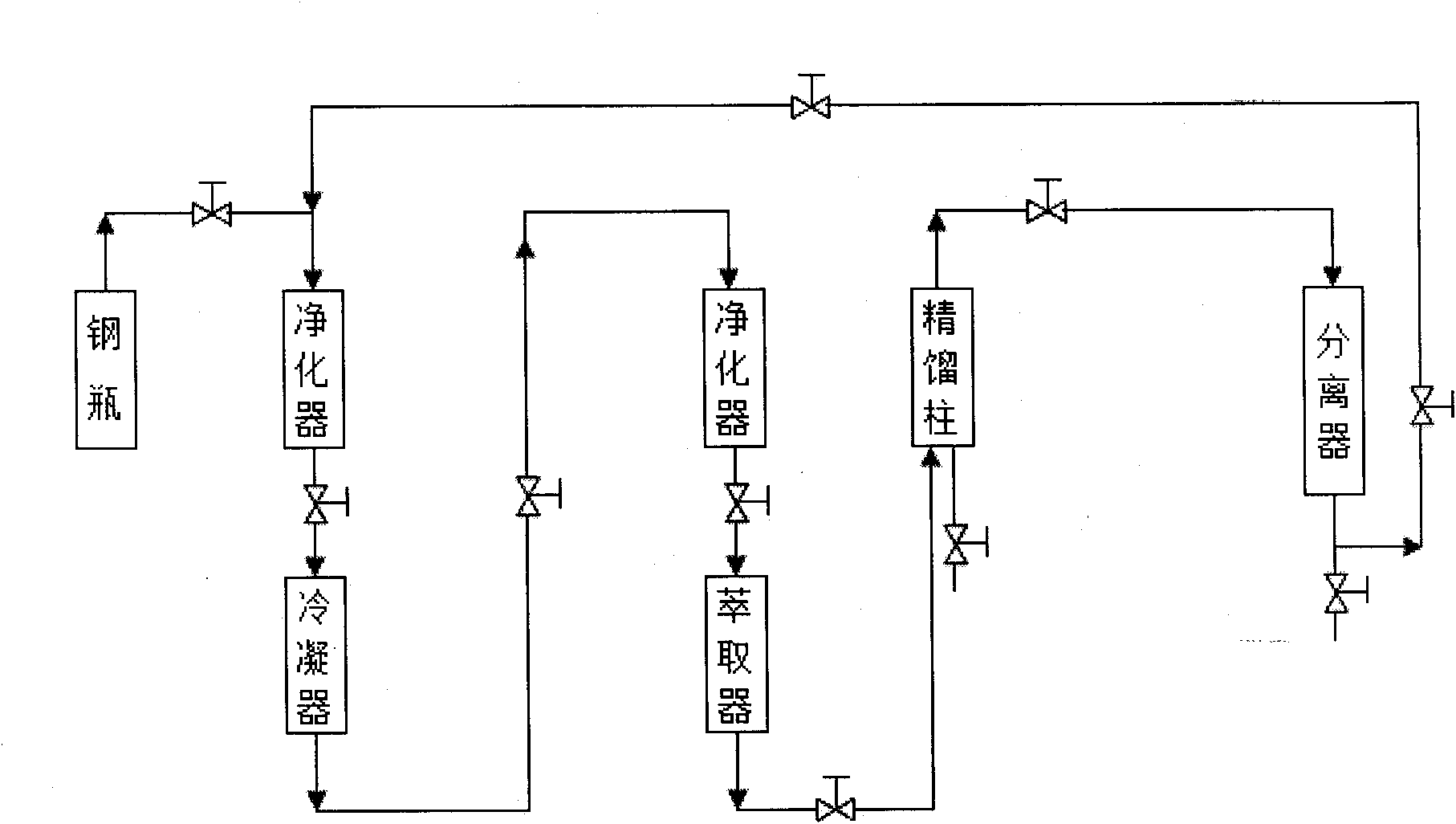

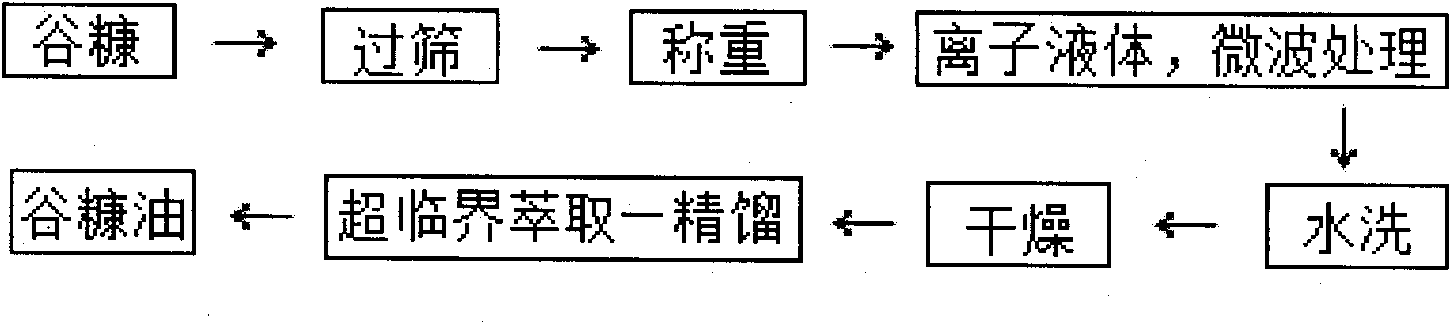

Method for extracting rice bran oil by using ionic liquid and supercritical carbon dioxide (CO2)

The invention discloses a method for extracting rice bran oil by using ionic liquid and supercritical carbon dioxide (CO2). The method comprises the following steps of: A, under a microwave heating condition, soaking rice bran in the ionic liquid BmimC1, reclaiming the BmimC1 and drying the rice bran, wherein the using amount ratio of the rice bran to the BmimC1 is 10:2-3(g / ml); and B, performing supercritical extraction, rectification and purification on the rice bran obtained in the step A by using CO2 fluid in supercritical CO2 fluid extraction and rectification integrated equipment to obtain the rice bran oil. The rice bran oil is obtained by preprocessing the rice bran by using the ionic liquid to dissolve cellulose husks of the rice bran, damage the residual cell walls of the rice bran and inhibit the biologic enzyme activity of the rice bran and performing extraction and rectification on the rice bran by using the supercritical CO2 fluid extraction and rectification integrated equipment.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

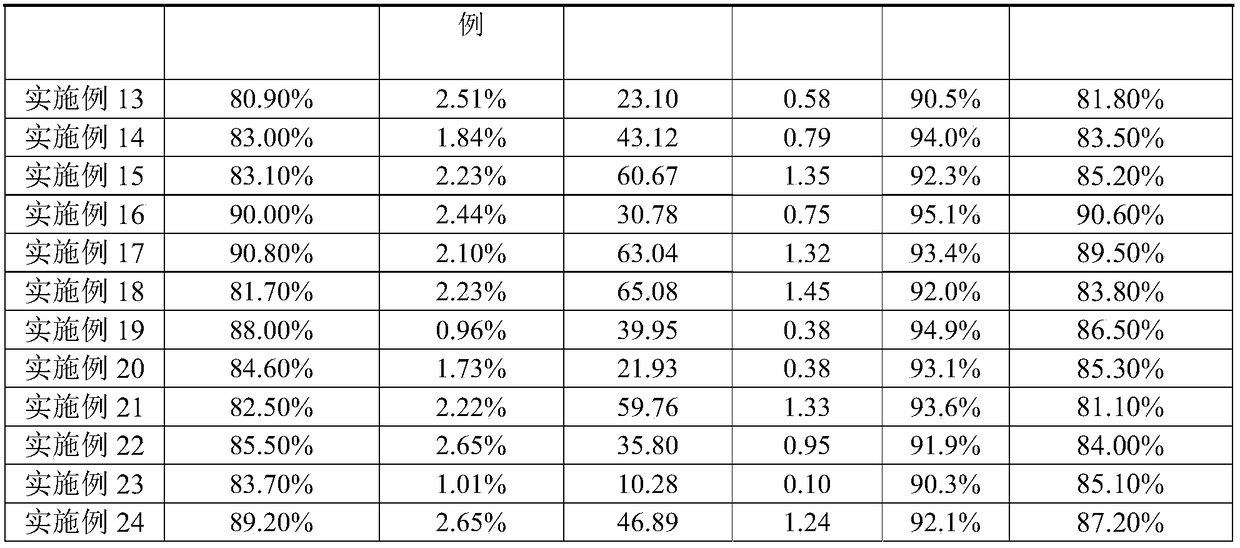

Method for preparing astaxanthin by adopting lignocellulose

ActiveCN108977493AReduce manufacturing costSolve the use problemMicroorganism based processesFermentationMicroorganismDry weight

The invention provides a technology for producing astaxanthin through efficient saccharifying of lignocellulose type agricultural and forest wastes, aiming at the problems in the aspects of producingthe astaxanthin by fermenting through phaffia rhodozyma and carrying out enzymolysis on lignocellulose. The technology comprises the steps of pre-treating, saccharifying, carrying out phaffia rhodozyma fermentation, extracting the astaxanthin and the like. According to the technology provided by the invention, a lignocellulose biomass is used as a raw material, so that on one hand, the enzyme utilization cost of a saccharifying phase and a production cost of microorganism fermentation are remarkably improved; on the other hand, the comprehensive utilization problems of the agricultural and forest wastes are also solved. By combining biological saccharifying of the lignocellulose and a high-density fermentation phase of the phaffia rhodozyma, ash obtained by saccharifying can be further used as a solid matrix of yeast fermentation and the fermentation density is improved. In the technology provided by the invention, the ratio of the astaxanthin to the dry weight of thalli can reach 2.6percent and the biomass of yeast thalli can reach 65g / L. The purity of the obtained refined astaxanthin is greater than 90 percent through technologies including molecular distillation and the like.

Owner:青岛中科潮生生物技术有限公司

Decontamination of surfaces contaminated with prion-infected material with gaseous oxidizing agents

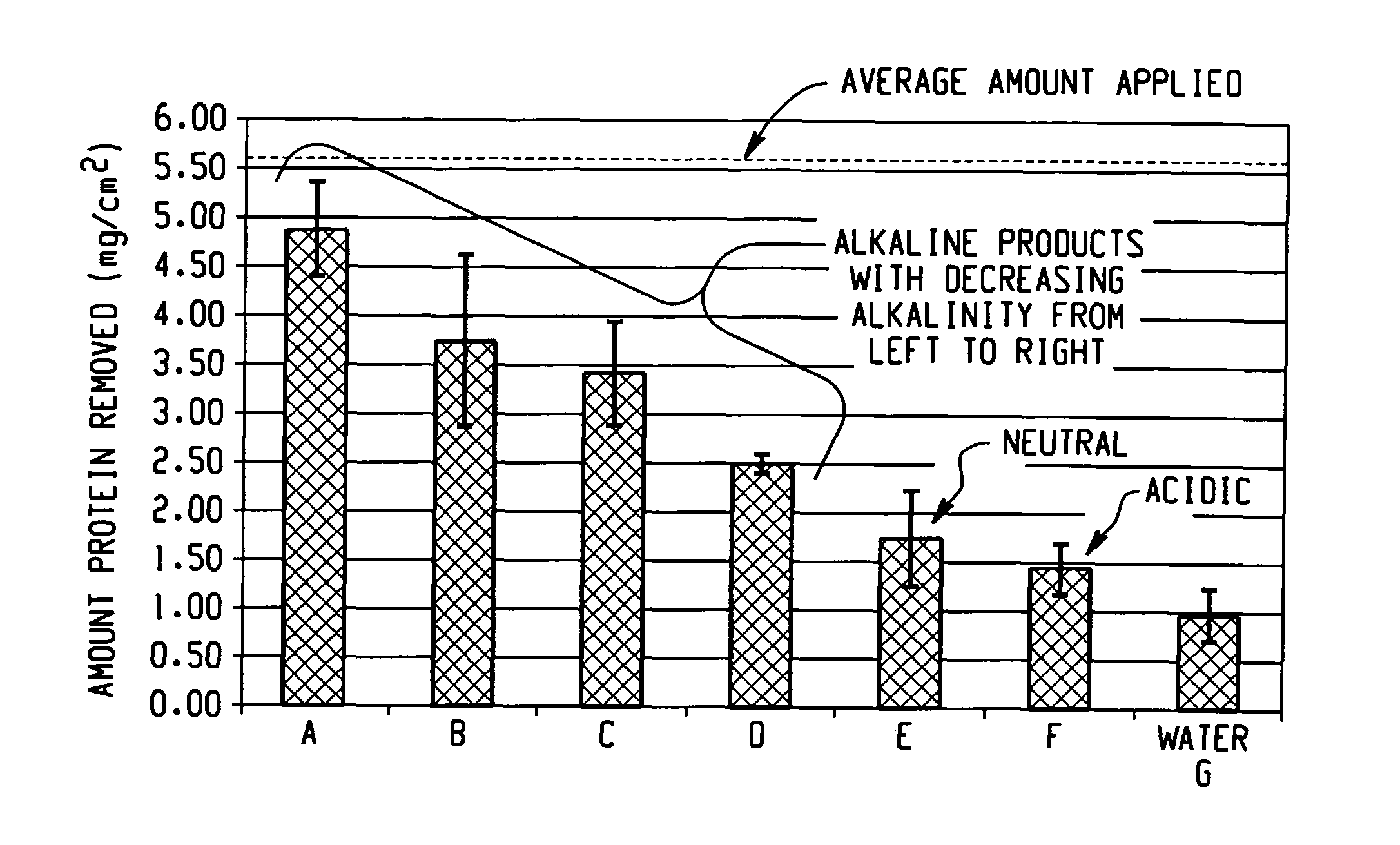

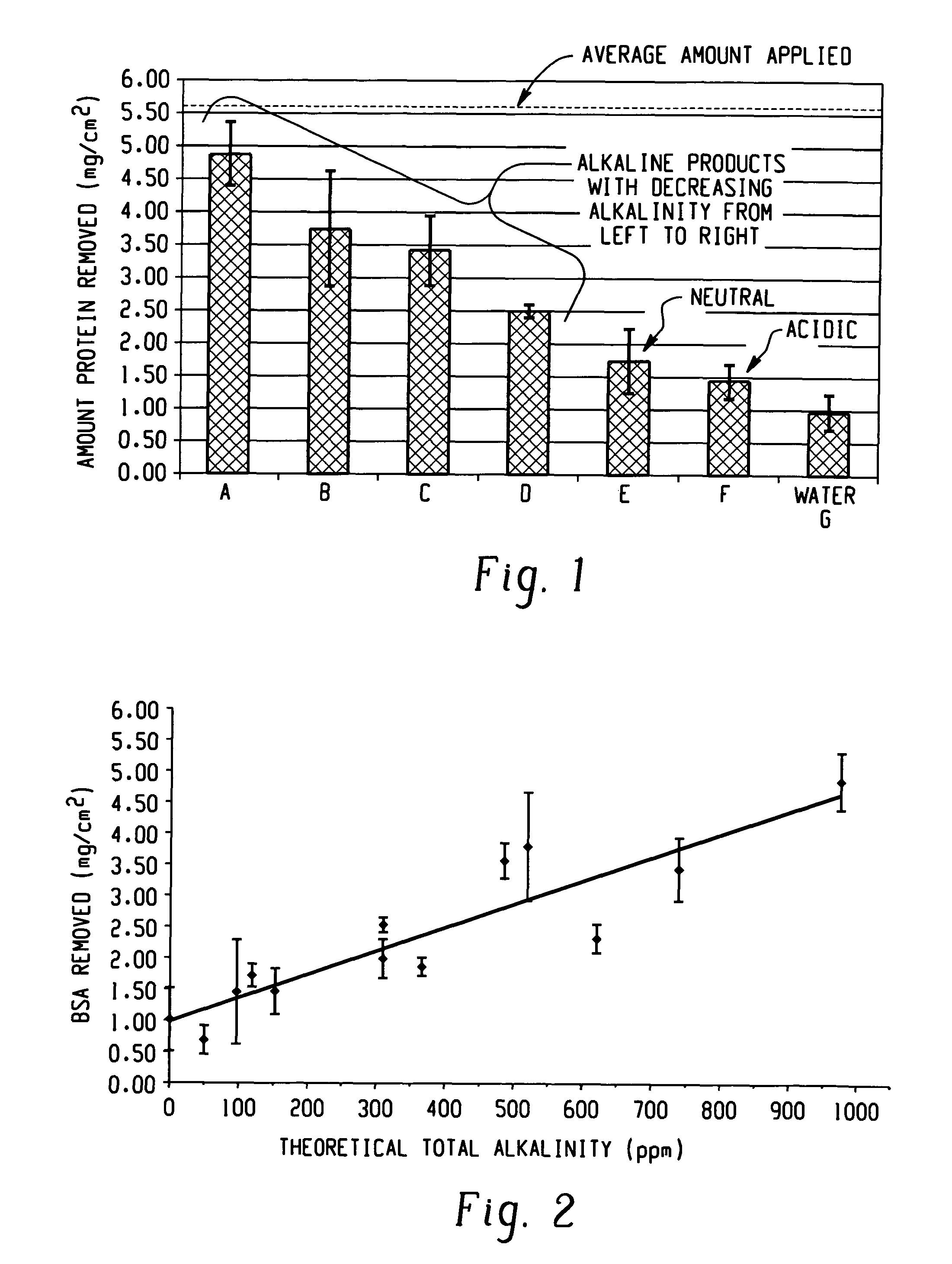

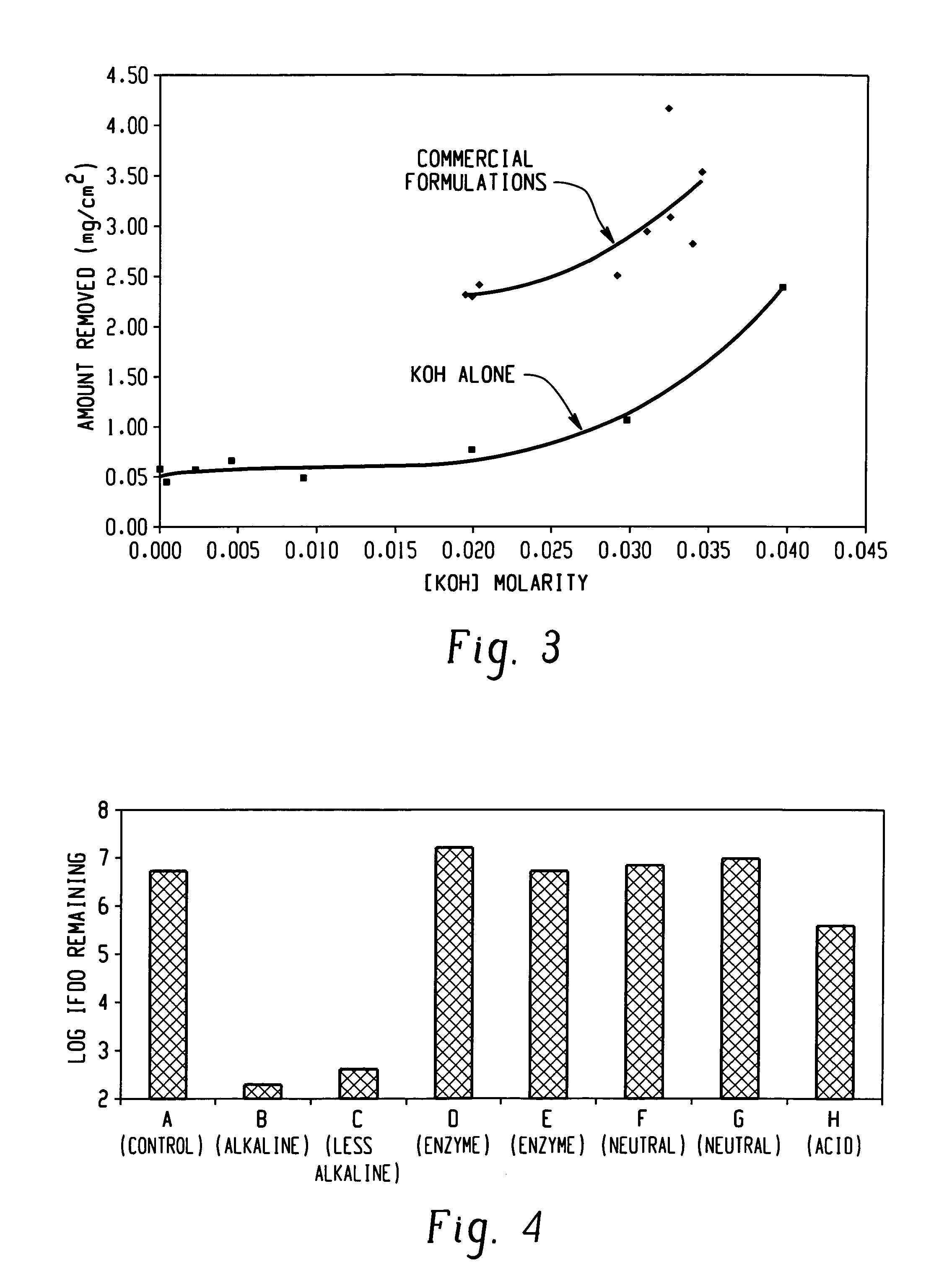

ActiveUS7803315B2Gentle processThe process is fast and efficientInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsProtein materialsCleansing Agents

A surface which carries a material which is infected with prions is cleaned with an alkaline cleaning solution to remove as much proteinaceous material as possible from the surface. The solution contains an alkaline cleaning agent which attacks prions remaining on the surface and which attacks prions removed from the surface during the cleaning step. After the cleaning step, the surface is exposed to a strong gaseous oxidant, preferably hydrogen peroxide vapor. The hydrogen peroxide or other strong oxidant attacks the prions, particularly the unclumped prion strands, deactivating the prions.

Owner:AMERICAN STERILIZER CO

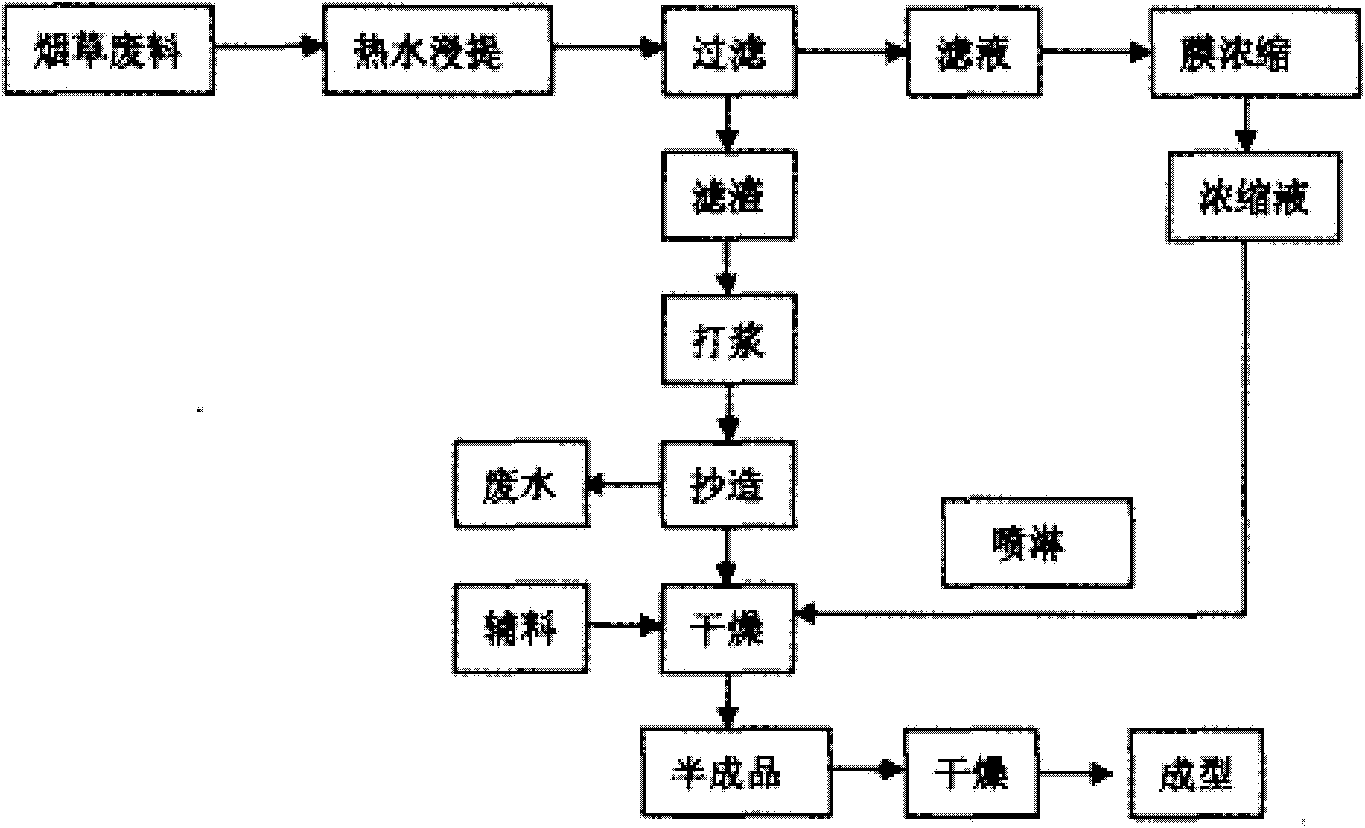

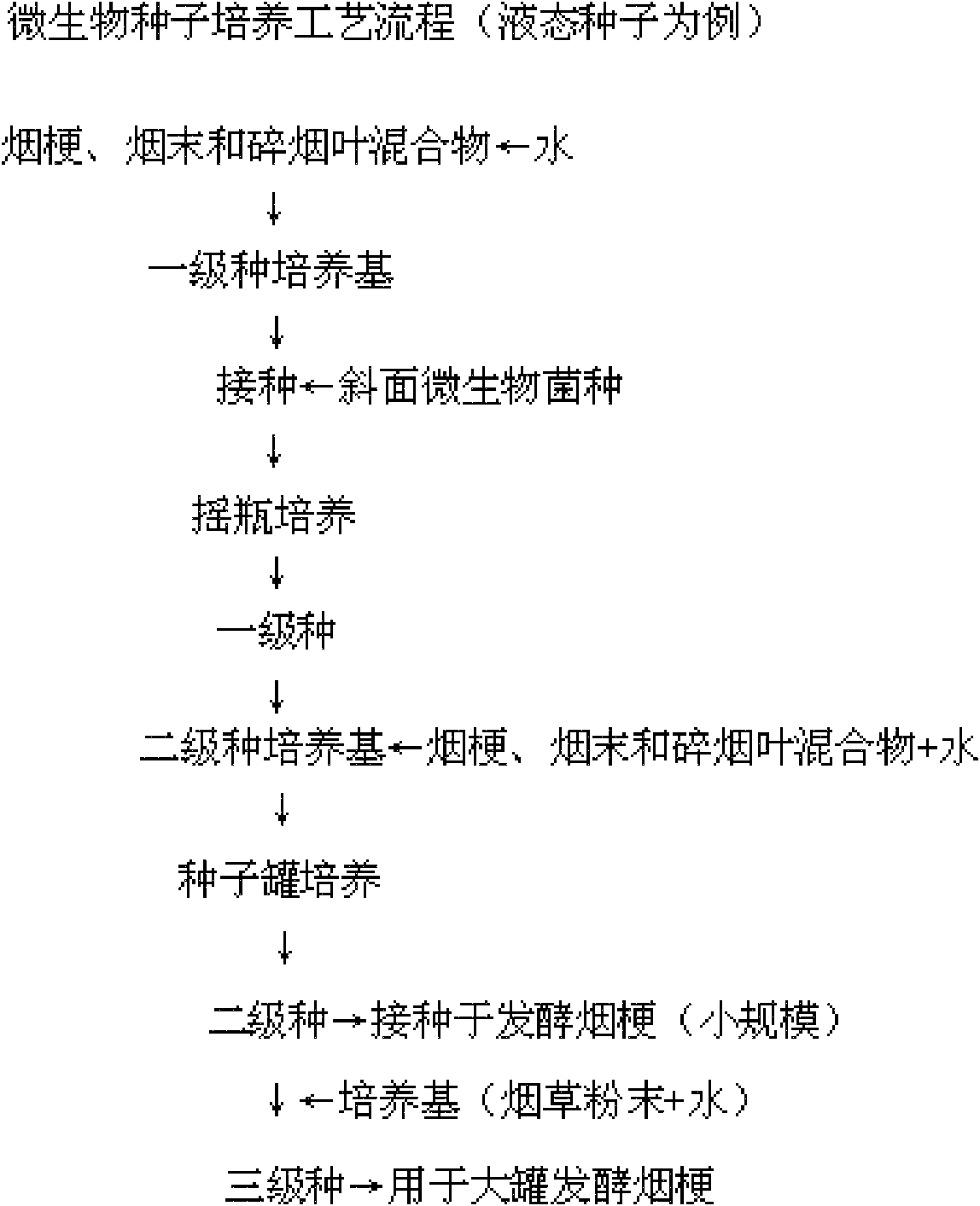

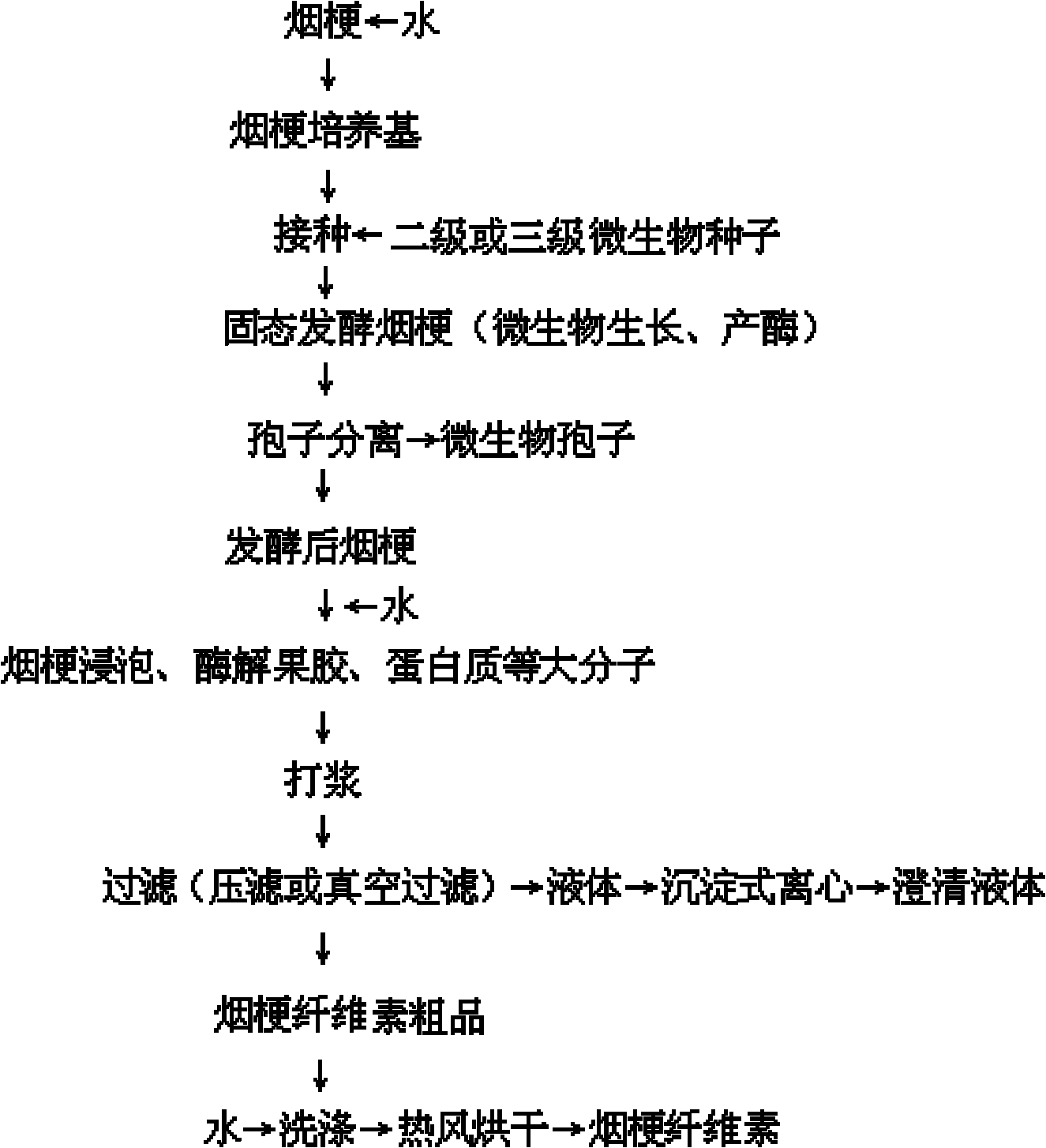

Method for preparing tobacco stem cellulose through microbial solid fermentation process

ActiveCN102217786AHigh substance contentLack of aromaTobacco preparationTobacco treatmentBiotechnologyAmylase

The invention belongs to the technical field of tobacco processing and relates to a method for preparing basic material of a tobacco thin sheet, namely tobacco stem cellulose through the microbial solid fermentation process. Microbes including high-yield prolease, pectolase, ligninase, amylase and other enzymes are selected, and tobacco stems, tobacco smalls and crumbled tobacco are taken as raw materials for preparing microbial seeds, the prepared microbial seeds are inoculated into the tobacco stems for performing solid fermentation, soaking the tobacco stems after fermentation in buffer solution, further performing enzymolysis for degrading the tobacco stems after the enzymolysis, proteins, lignin, pectic substances and other macromolecular substances into micromolecular substances which are easy to be separated from cellulose type substances in the tobacco stems, and further stirring, pulping, filtering and separating for getting water-soluble extract and water-insoluble celluloseof the tobacco stems. The method has the advantages of being simple in process, saving energy, reducing equipment investment and improving the synthetic quality of the tobacco thin sheet, and can greatly reduce the residual quantity of the proteins, pectin, starch and other macromolecules in the tobacco thin sheet.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

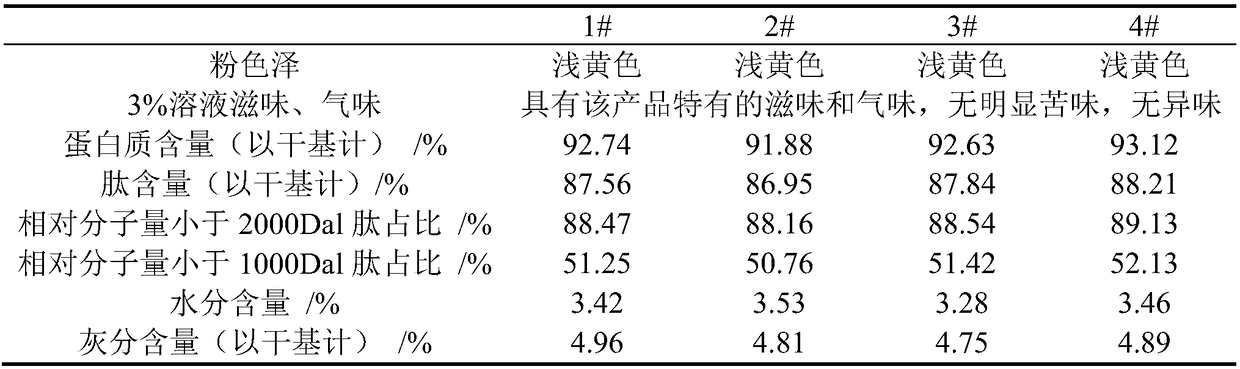

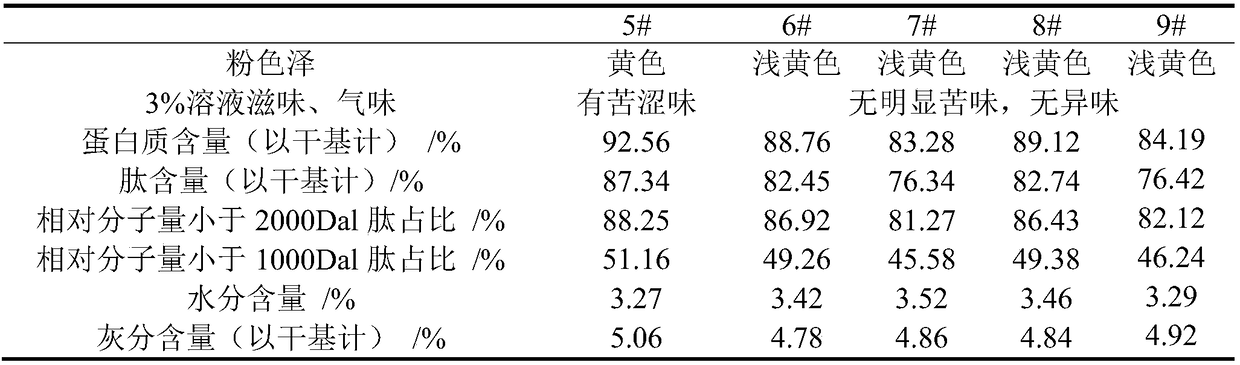

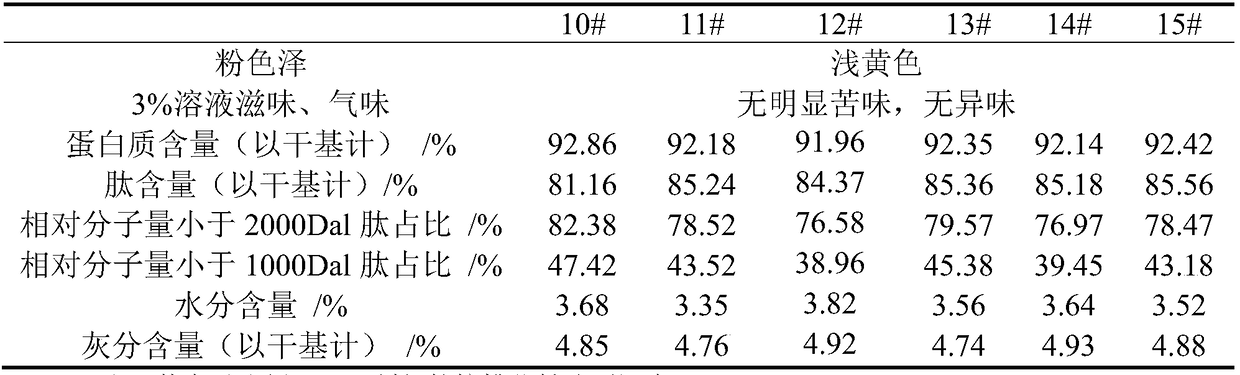

Method for industrially producing high-purity walnut peptide from low-temperature pressed walnut meal as a raw material

ActiveCN108085356ALow denaturationNot easy to removeVegetable proteins working-upFermentationNeutral proteaseAdditive ingredient

The invention discloses a method for industrially producing high-purity walnut peptide from low-temperature pressed walnut meal as a raw material. According to the method, cold pressed walnut meal istaken as a raw material, is dispersed and hydrated, and then is subjected to enzymolysis with tannase, cellulase and medium-temperature amylase; then, a product is denatured, step-by-step enzymolysisis performed with alkaline protease and neutral protease, enzyme deactivation is performed, centrifugation and plate and frame filtration are performed, and high-purity walnut peptide is obtained. industrial preparation of high-purity walnut peptide is realized economically by scientific optimization of pretreatment, enzymolysis and refining processes, the protein content is 90% or higher, the peptide content is 85% or higher, the relative molecular weight is lower than 2000 Dal, peptide accounts for 85% or higher, the relative molecular weight is lower than 1000 Dal and peptide accounts for50% or higher; the product has good quality and light bitterness, is easily mixed with other food ingredients, and has outstanding effects of strengthening the brain, improving intelligence and enhancing immunity. The walnut peptide can be used as a high-quality functional base material to be widely applied to various food and health products.

Owner:广州合诚实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com