Method for preparing tobacco stem cellulose through microbial solid fermentation process

A technology of microbial fermentation and solid state fermentation, applied in the field of tobacco processing, can solve problems such as bad odor, and achieve the effects of reducing equipment investment, saving energy and improving overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

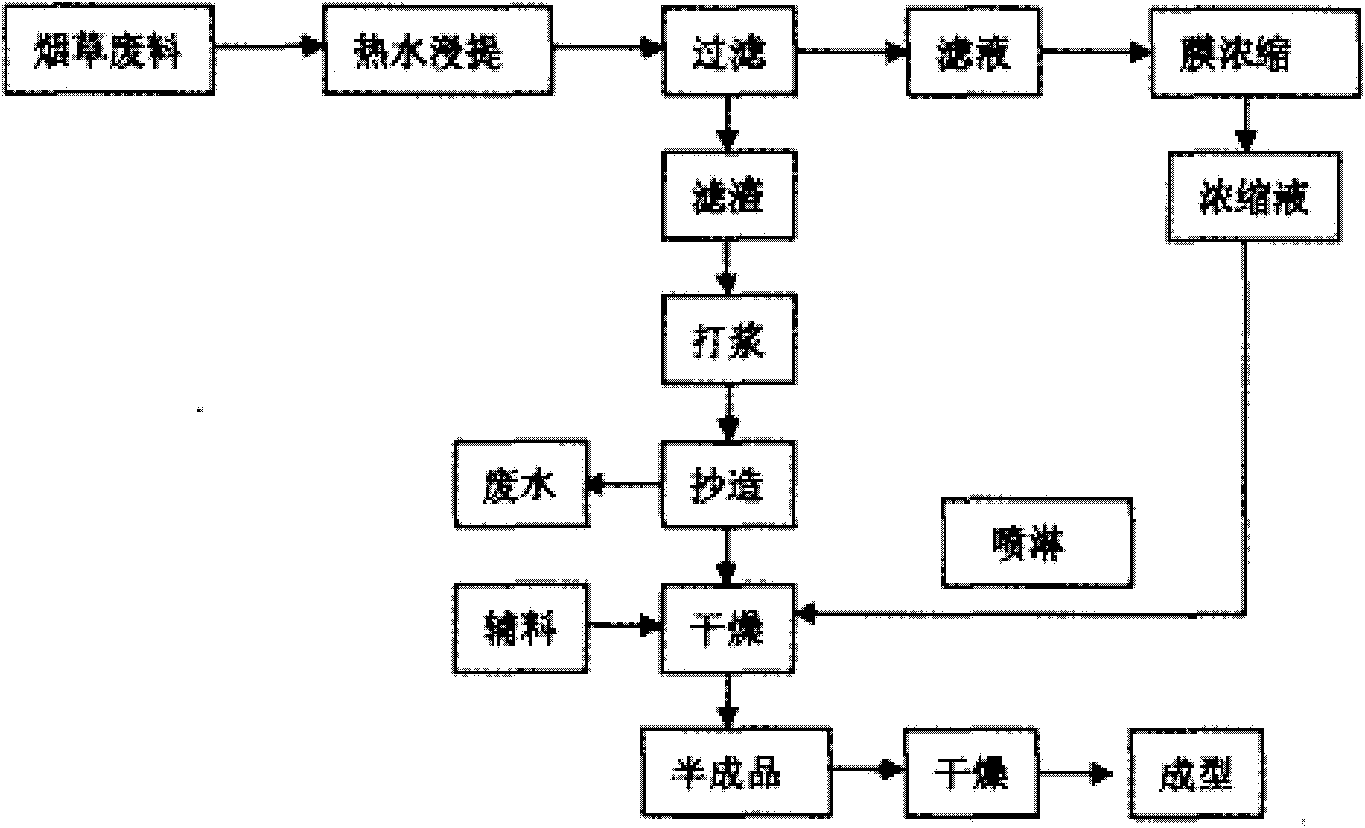

Method used

Image

Examples

Embodiment 1

[0060] Effect of Fermentation Time on Tobacco Stem Yield and Residual Pectin Content

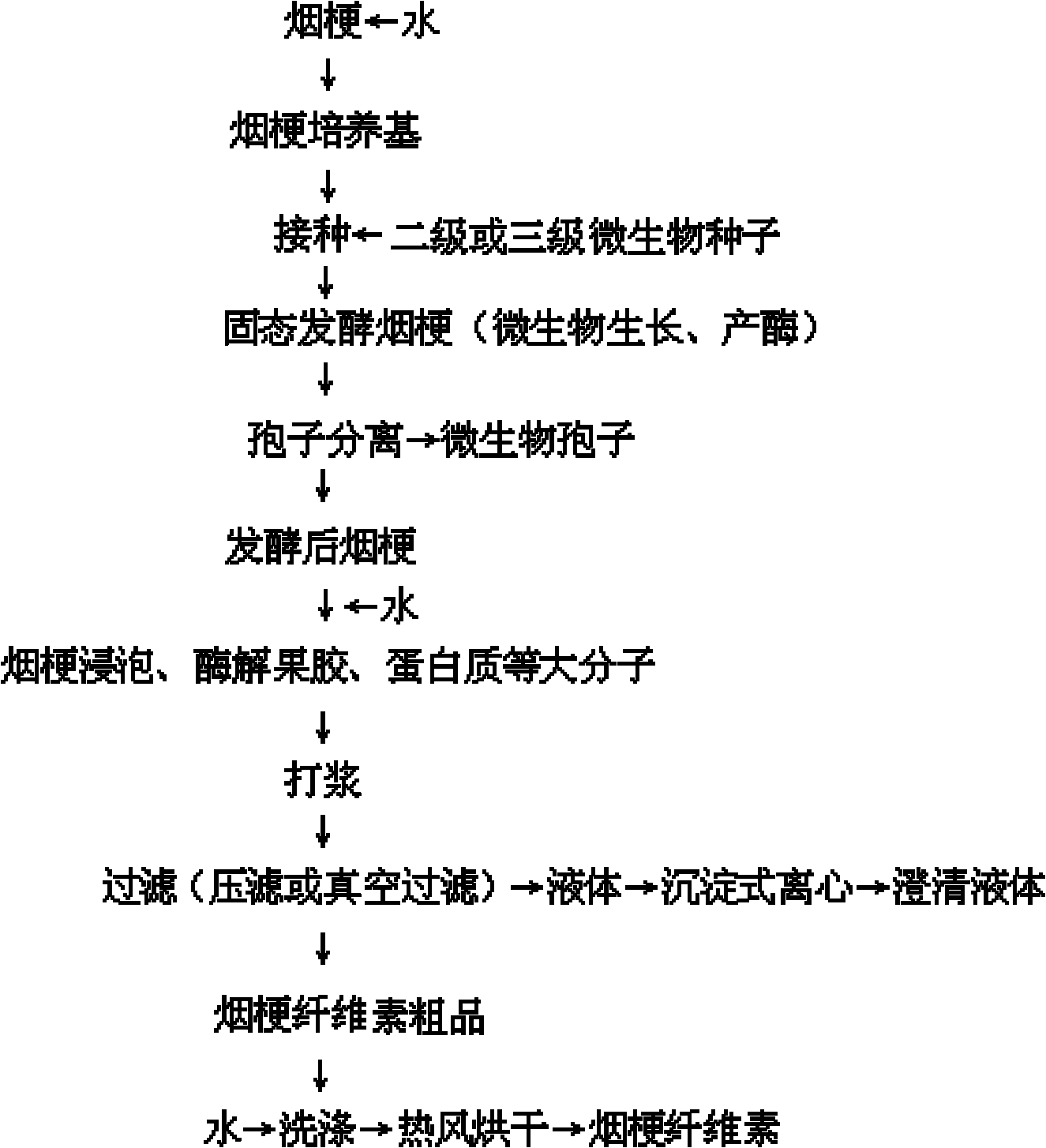

[0061] Solid-state fermentation method: add 50g of tobacco stems to a sterilized 1000ml Erlenmeyer flask, add 30mL of water, inoculate 20mL of Aspergillus niger secondary seed solution, and place them in a solid-state incubator at 30°C for 32h, 38h, 44h, 50h, 56h respectively , 62h, after the end of fermentation, soak in 0.1mol / L, pH 4.4 citric acid buffer solution for 24h, rub the fermented tobacco stems into pieces, wash them with clean water, filter through a sieve to remove bacteria and sundries, and place the remaining tobacco stem residues in Dry at 40°C, measure its weight, and calculate the yield.

[0062] The impact of different fermentation times on the yield of tobacco stem residue is shown in Table 1, and the tobacco stems in fermentation are as follows: Figure 4 shown. Tobacco stem residues fermented at different times by Figure 5 shown. As can be seen from Table 1, with t...

Embodiment 2

[0068] Comprehensive experiment of Aspergillus niger solid-state fermentation of tobacco stems: A small-scale solid-state fermentation tank was used to ventilate and ferment tobacco stems, and Aspergillus niger was used as the strain.

[0069] (1) Preparation of spore suspension:

[0070] Aspergillus niger was selected as the fermentation microorganism, PDA slant medium was used, and after streak inoculation, it was cultured at 30°C for 5 days to obtain mature spores of Aspergillus niger. Add 60 mL of sterile water to the cultured eggplant bottle (8×24cm) on the slant, scrape off the spores with an inoculation shovel; transfer the spore suspension to a sterile Erlenmeyer flask containing glass beads; break up to obtain Spore suspensions in which the concentration of spores in the spore suspension is not less than 10 7 individual / mL.

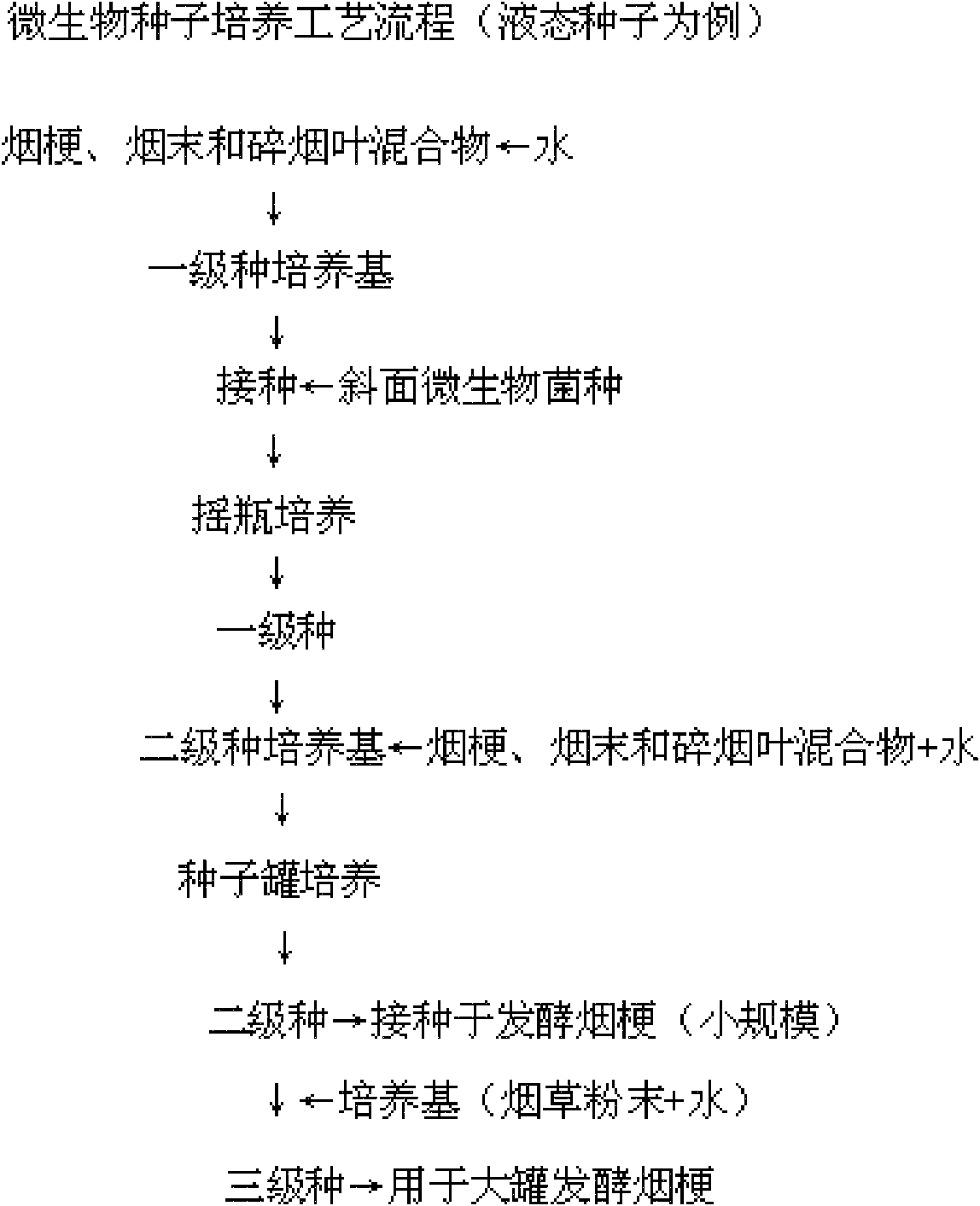

[0071] (2) Preparation of Aspergillus niger primary, secondary, and tertiary seed solutions:

[0072] In a 1L Erlenmeyer flask sterilized at ...

Embodiment 3

[0088] Comprehensive experiment of Aspergillus niger solid-state fermentation of tobacco stems: A small-scale solid-state fermentation tank was carried out to ferment tobacco stems with ventilation, and Aspergillus niger was used as the strain.

[0089] (1) Preparation of spore suspension:

[0090] Aspergillus niger was selected as the fermentation microorganism, PDA slant medium was used, and after streak inoculation, it was cultured at 32°C for 5 days to obtain mature spores of Aspergillus niger. Add 60 mL of sterile water to the cultured eggplant bottle (8×24cm) on the slant, scrape off the spores with an inoculation shovel; transfer the spore suspension to a sterile Erlenmeyer flask containing glass beads; break up to obtain Spore suspension, wherein the concentration of spores in the spore suspension is 10 7 individual / mL.

[0091] (2) Preparation of Aspergillus niger primary, secondary, and tertiary seed solutions:

[0092] In a 1L Erlenmeyer flask sterilized at 121°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com