Method and system for high-solid content continuous enzymolysis of biomass raw materials

A biomass raw material, high solid content technology, applied in the direction of biochemical equipment and methods, biofuels, biomass post-treatment, etc., can solve the problems affecting the industrialization process of cellulosic ethanol technology, and achieve the convenience of automatic control, cellulase The effect of speeding up the solution process and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

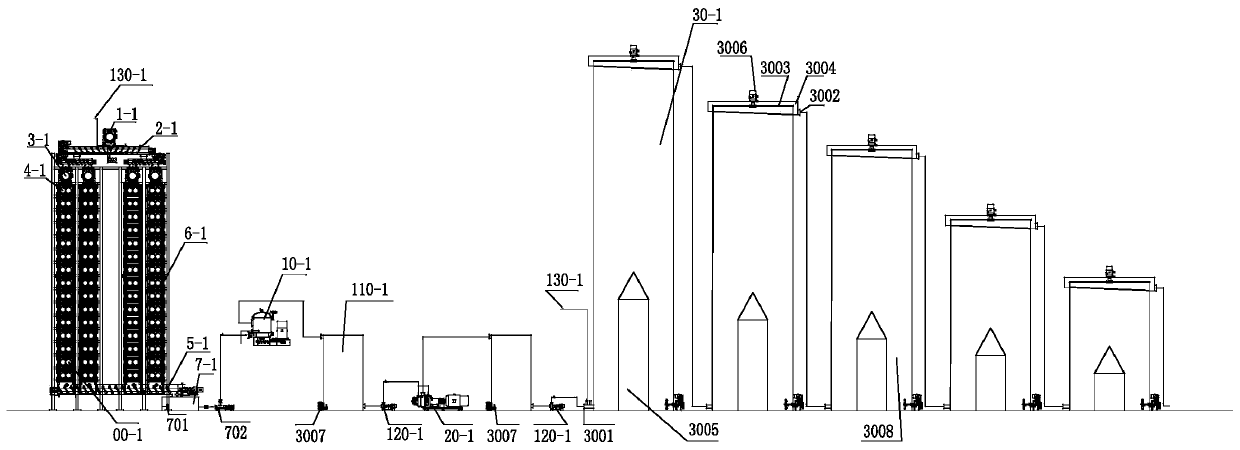

Image

Examples

Embodiment 1

[0069] 1. The pretreated straw material, adjust the solid content of the material to 25%, and continuously enter the spiral heating conveyor 1-1 of the high-concentration pre-enzymolysis system 00-1. The steam heats the material through the inlet 102 on both sides, and the thermometer is installed Port 104 has a probe to control the heating to a temperature of 55°C; pH instrument installation port 101 has a probe for detection, and the pH value is controlled to be 5.0-5.5, and samples are regularly taken from the sampling port 103 for testing;

[0070] 2. The material with adjusted solid content, temperature, and ph value enters the two-way feeding screw machine system 2-1, and distributes the material evenly to each Arrange the mixing conveyor 3-1 of the pre-enzymolysis screw machine combination system 6-1, and meter the enzyme preparation at the enzyme preparation inlet 203 at the inlet end;

[0071] 3. The mixing conveyor 3-1, through the spiral belt blade 304 and the mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com