Method for preparing probiotics microcapsule and its application

A technology of probiotics and microcapsules, which is applied in the field of preparation of probiotic microcapsules, can solve the problems of lactic acid bacteria cell damage, instability between batches, and slow formation of microcapsules, so as to improve survival ability, biological activity, and professional The effect of low quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Lactobacillus casei and its application

[0038] Lactobacillus casei (Lactobacillus casei) CCTCC NO: M 2010163, this strain has a high removal efficiency of algae toxins, and can effectively remove cholesterol. The strain is used in the field of health food, and has the effects of inhibiting the growth of harmful microorganisms, improving human immunity, and assisting nutrient digestion. See patent application 201010238658.8 for details.

[0039] Taking CCTCC NO: M 2010163 as the starting strain, it was cultured in the seed medium to the logarithmic growth phase, centrifuged and washed to obtain the pure strain, and the prepared sterile sodium alginate (2%, w / v) solution was combined with Modified starch (2%, w / v) is mixed thoroughly in equal volume, and the probiotic concentration after mixing is 10 9 cfu / mL. The mixed liquid is sprayed into CaCl through the spray nozzle 2 (3%, w / v) in solution, Ca 2+ Cross-linking with sodium alginate to form microcapsules. Af...

Embodiment 2

[0047] Take CCTCC NO: M 2010163 as the starting strain, cultivate it in the seed medium to the logarithmic growth phase, centrifuge and wash to obtain the pure strain, and prepare the sterile sodium alginate (1%, w / v) solution with Modified starch (1%, w / v) is fully mixed in equal volume, and the probiotic concentration after mixing is 10 8 cfu / mL. The mixed liquid is sprayed into CaCl through the spray nozzle 2 (1%, w / v) in solution, Ca 2+ Cross-linking with sodium alginate to form microcapsules. After static solidification for 120 min, physiological saline was washed three times, filtered, and dried to obtain microcapsules.

[0048] Detection Indicator

[0049] a) Appearance characterization: Observed by scanning electron microscope, it is found that the microcapsules are intact, and the bacteria are alive and inside the microcapsules;

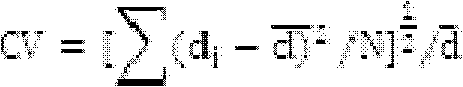

[0050] b) Measurement of the embedding rate: The embedding rate is determined according to the method for measuring the embedding rate describe...

Embodiment 3

[0055] Taking CCTCC NO: M 2010163 as the starting strain, it was cultured in the seed medium to the logarithmic growth phase, centrifuged and washed to obtain the pure strain, and the prepared sterile sodium alginate (5%, w / v) solution was combined with Modified starch (5%, w / v) is fully mixed in equal volume, and the probiotic concentration after mixing is 10 10 cfu / mL. The mixed liquid is sprayed into CaCl through the spray nozzle 2 (5%, w / v) in solution, Ca 2+ Cross-linking with sodium alginate to form microcapsules. After static solidification for 120 min, physiological saline was washed three times, filtered, and dried to obtain microcapsules.

[0056] Detection Indicator

[0057] a) Appearance characterization: Observed by scanning electron microscope, it is found that the microcapsules are intact, and the bacteria are alive and inside the microcapsules;

[0058] b) Determination of the embedding rate: The embedding rate is determined according to the method for determining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com