Preparation of methyl phenyl hydrogen-containing silicone oil for LED encapsulation

A technology of LED encapsulation and methylphenylcyclosiloxane, applied in chemical instruments and methods, other chemical processes, electrical components, etc., can solve problems such as troublesome operation, many types, and great differences in product composition, and achieve operational The effect of simplicity, mild conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

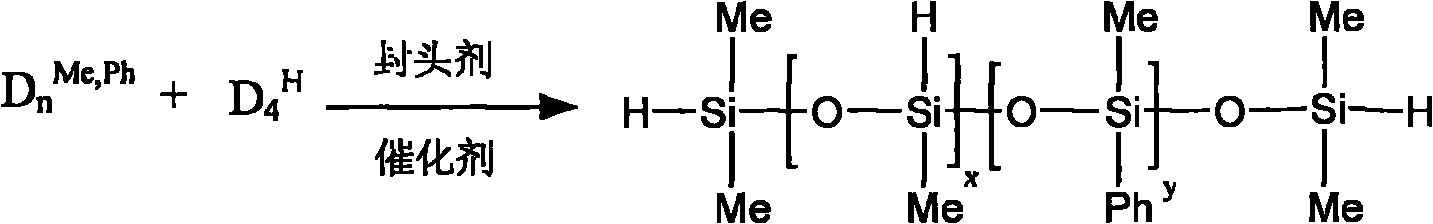

Method used

Image

Examples

Embodiment 1

[0028] in N 2 Add polysiloxane monomer D to a 100mL dry three-necked bottle under protection n Me,Ph (35.36 g, (MePhSiO) unit 0.26 mol) and D 4 H (8.4g, (MePhSiO) unit 0.14mol), remove the moisture in the polysiloxane monomer at 35℃~45℃ / -0.096MPa, then add 0.67g end capping agent 1,1,3,3 -Tetramethyl-1,3-dihydrodisiloxane, 2.24g strong acid type large pore cation exchange resin, in N 2 Under the protection, the polymer was polymerized at 40 °C for 5 hours, and the strong acid type large pore cation exchange resin was recovered by suction filtration. Reduce the pressure to -0.096MPa, gradually heat up to 205°C to remove low molecular compounds, stop heating when there is no fraction within 5min, and cool to room temperature to obtain a colorless and transparent product with a yield of 73%. Refractive index n of the obtained methylphenyl hydrogen-containing silicone oil D 25 =1.5195, after 1 The mass percentage of Si-H measured by H-NMR is 0.276%, the Ph / Si (molar ratio)...

Embodiment 2

[0030] in N 2 Add polysiloxane monomer D to a 100mL dry three-necked bottle under protection n Me,Ph (35.36 g, (MePhSiO) unit 0.26 mol) and D 4 H(8.4g, (MePhSiO) unit 0.14mol), remove the moisture in the polysiloxane monomer at 35℃~45℃ / -0.096MPa, then add 0.67g end capping agent 1,1,3,3 -Tetramethyl-1,3-dihydrodisiloxane, 2.24g strong acid type large pore cation exchange resin, in N 2 Under the protection, polymerize at 50 °C for 5 hours, and recover the strong acid type large-pore cation exchange resin by suction filtration. Reduce the pressure to -0.096MPa, gradually heat up to 205°C to remove low molecular compounds, stop heating when there is no fraction within 5min, and cool to room temperature to obtain a colorless and transparent product with a yield of 78%. Refractive index n of the obtained methylphenyl hydrogen-containing silicone oil D 25 =1.5225, after 1 The mass percentage of Si-H measured by H-NMR is 0.277%, the Ph / Si (molar ratio) is 0.623, and the numbe...

Embodiment 3

[0032] in N 2 Add polysiloxane monomer D to a 100mL dry three-necked bottle under protection n Me,Ph (35.36 g, (MePhSiO) unit 0.26 mol) and D 4 H (8.4g, (MePhSiO) unit 0.14mol), remove the moisture in the polysiloxane monomer at 35℃~45℃ / -0.096MPa, then add 0.67g end capping agent 1,1,3,3 -Tetramethyl-1,3-dihydrodisiloxane, 2.24g strong acid type large pore cation exchange resin, in N 2 Under the protection, polymerize at 65 °C for 5 h, and recover the strong acid type large-pore cation exchange resin by suction filtration. Reduce the pressure to -0.096MPa, gradually heat up to 205°C to remove low molecular compounds, stop heating when there is no fraction within 5min, and cool to room temperature to obtain a colorless and transparent product with a yield of 79%. Refractive index n of the obtained methylphenyl hydrogen-containing silicone oil D 25 =1.5230, after 1 The mass percentage of Si-H measured by H-NMR is 0.287%, the Ph / Si (molar ratio) is 0.658, and the number a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com