Electrolytic silver plating solution

An electroplating solution and electrolytic silver technology, applied in the field of electrolytic silver electroplating solution, can solve the problems of silver electroplating film gloss, reflectance surface roughness, gloss effect, etc., achieve high reflectivity, reduce cost, and improve manufacturing yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

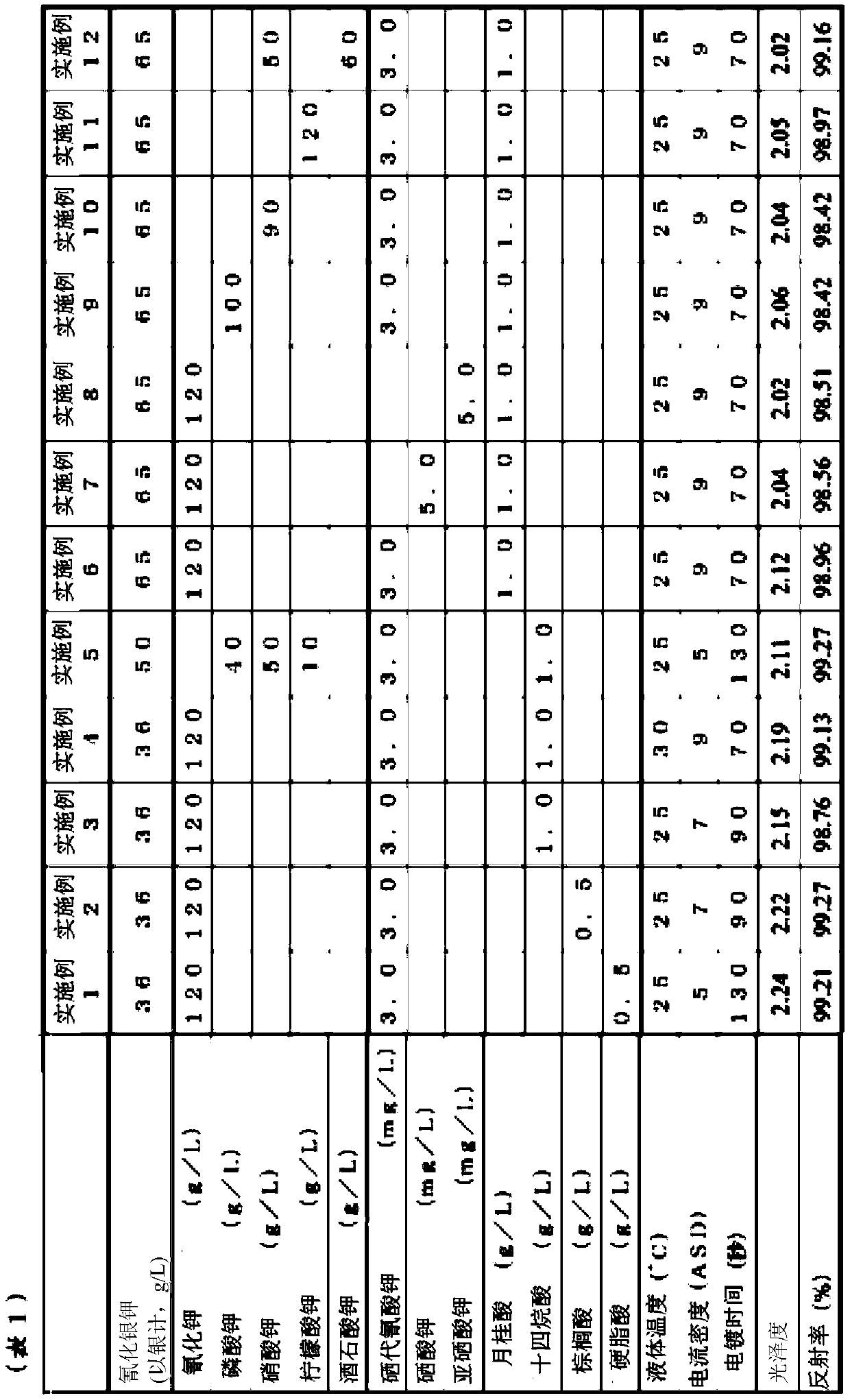

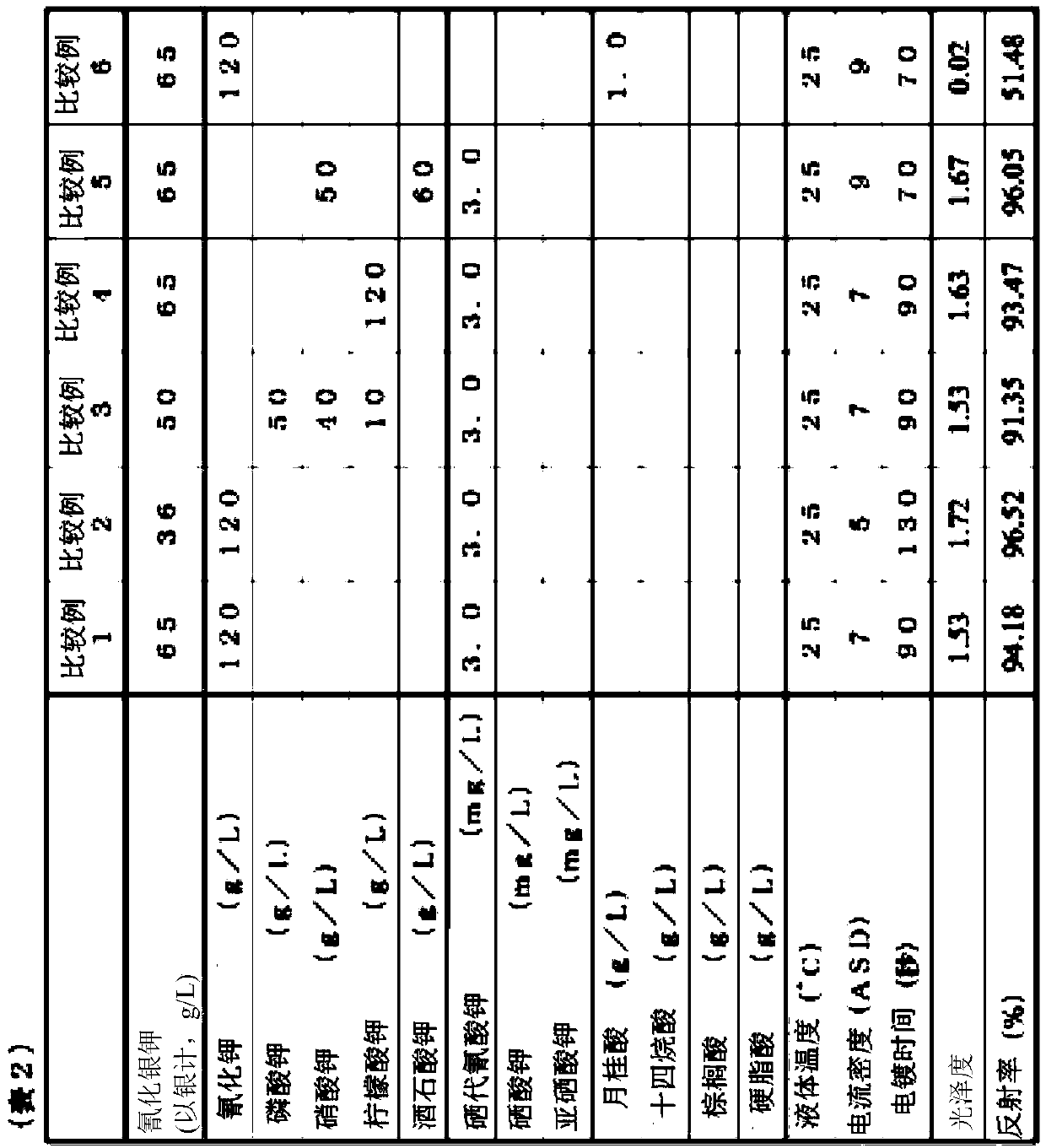

Embodiment 1~12、 comparative example 1~5

[0056] As the object to be plated, use 0.1dm 2 copper plate. First, it is neutralized with dilute sulfuric acid after degreasing treatment with an alkaline degreasing liquid. Thereafter, about 1 μm matte copper plating was performed by means of a cyanide bath. Thereafter, about 0.1 μm silver plating was performed by a cyanide-based high-current rapid bath (striker bath).

[0057] The plating solutions of Examples 1-12 and Comparative Examples 1-5 were prepared with the compositions described in Tables 1 and 2. The object to be plated was immersed in 1 L of the prepared plating solution, and electrolytic silver plating was performed under the conditions described in Tables 1 and 2 until the thickness of the silver film became 4 μm, washed with clean pure water, and then dried. In addition, the density|concentration of the selenium compound in Table 1 is an amount converted into selenium.

[0058] Gloss and reflectance were measured for the silver coatings of Examples 1 to 1...

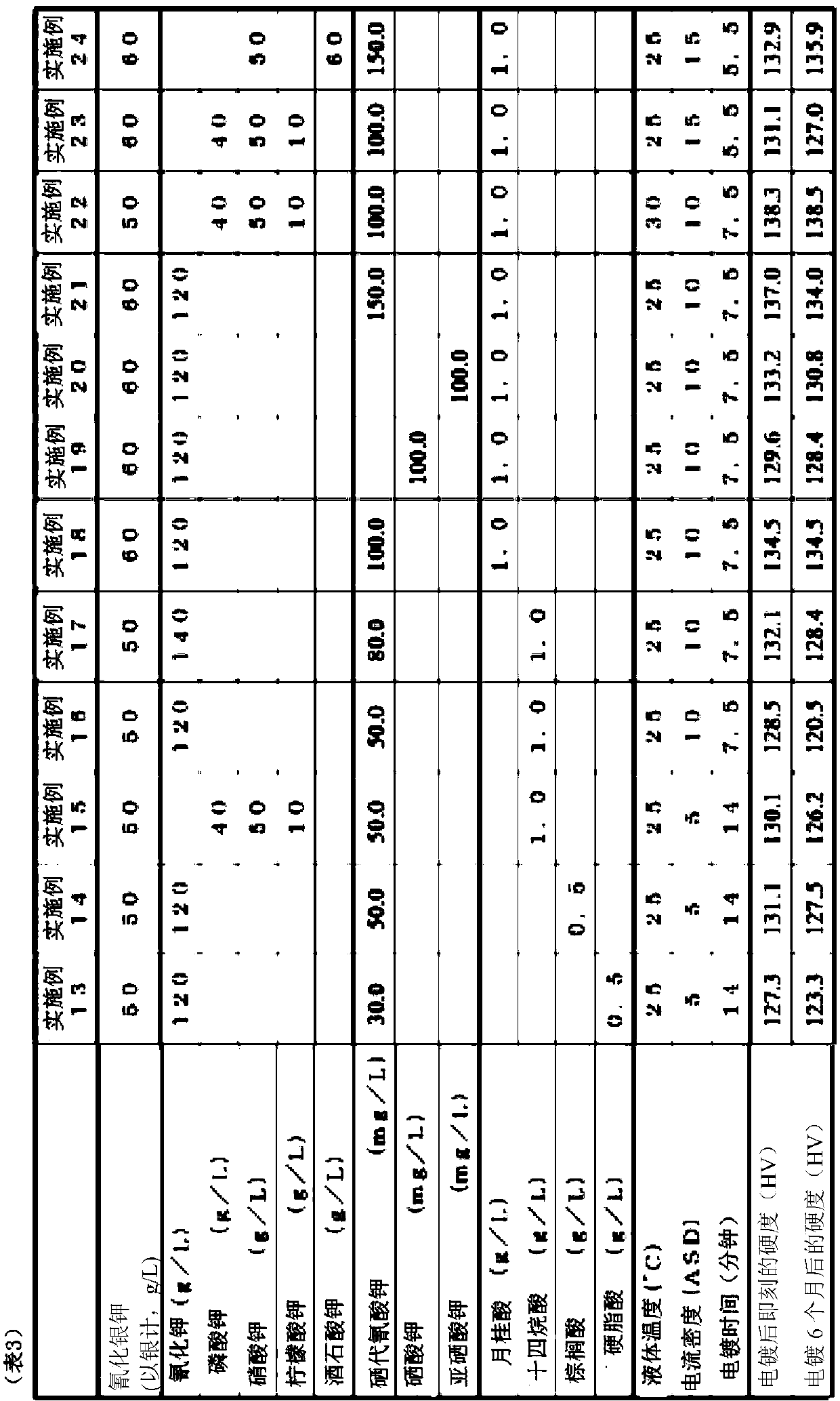

Embodiment 13~24、 comparative example 7~11

[0065] (Examples 13-24, Comparative Examples 7-11, Reference Examples 1-2)

[0066] As the object to be plated, use 0.1dm 2 copper plate. First, after degreasing treatment with an alkaline degreasing liquid, it is neutralized with dilute sulfuric acid. Thereafter, about 1 μm matte copper plating was performed by means of a cyanide bath. Thereafter, approximately 0.1 μm silver plating was performed by a cyanide-based high-current rapid bath.

[0067] The electroplating solutions of Examples 13-24, Comparative Examples 7-11, and Reference Examples 1-2 were prepared with the compositions described in Tables 3 and 4. The object to be plated was immersed in 1 L of the prepared plating solution, electrolytic silver plating was performed under the conditions described in Tables 3 and 4 until the thickness of the silver film became 20 μm, washed with clean pure water, and dried.

[0068] The hardness was measured about the silver coating films of Examples 13-24, Comparative Exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com