Method for raising leaching rate of silver cyanide

A technology of cyanidation leaching and leaching rate, which is applied in the field of production and processing technology for silver extraction by roasting cyanide, can solve the problems of no longer recycling of silver, waste of resources, etc., and achieve the effects of improving utilization rate and leaching rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

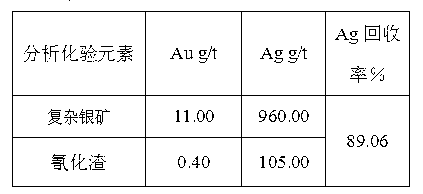

[0016] A kind of method for improving silver chloride leaching rate of the present embodiment comprises the following steps:

[0017] 1. Add complex silver ore with a gold content of 11 g / t and a silver content of 960 g / t, sodium sulfate with a concentration of 2%, and sodium carbonate with a concentration of 2% in a mass ratio of 1:0.02:0.02 In the tank, the complex silver ore is powdery, add water to adjust the pulp concentration to 65%, keep stirring continuously for 3 hours at normal temperature and pressure;

[0018] 2. Carry out boiling roasting, specifically: pump the slurry obtained in step 1 to the slurry storage tank, enter the fluidized furnace through a spray gun for boiling roasting, add compressed air through a Roots blower during the process, and control the temperature at 550-600°C for roasting, roasting The time is controlled within 10-30 seconds;

[0019] 3. The calcined sand after roasting is transported to the acid leaching tank by scraper for acid leachin...

Embodiment 2

[0025] The difference between this embodiment and embodiment 1 lies in step 1, specifically:

[0026] Add complex silver ore with gold content of 12 g / t and silver content of 1100 g / t, sodium sulfate with a concentration of 2.5%, and sodium carbonate with a concentration of 2.5% into the slurry mixing tank at a mass ratio of 1:0.02:0.03 , the complex silver ore is powdery, add water to adjust the slurry concentration to 68%, and stir continuously for 4 hours at normal temperature and pressure;

[0027] The assay result and related data of the present embodiment are as shown in table 2

[0028] Table 2: The assay result and relevant data of embodiment 2

[0029]

Embodiment 3

[0031] The difference between this embodiment and embodiment 1 lies in step 1, specifically:

[0032] Add complex silver ore with gold content of 13.5g / t and silver content of 1326 g / t, sodium sulfate with a concentration of 2%, and sodium carbonate with a concentration of 2% into the slurry mixing tank at a mass ratio of 1:0.03:0.02 , the complex silver ore is powdery, add water to adjust the slurry concentration to 70%, and stir continuously for 5 hours at normal temperature and pressure;

[0033] The assay result and related data of the present embodiment are as shown in table 2

[0034] Table 3: The assay result and related data of embodiment 3

[0035]

[0036] The invention is a method for increasing the leaching rate of silver chloride. Because sodium sulfate and sodium carbonate are added in the roasting process, the recovery rate of silver can reach 89.06-90.49%, which improves the utilization rate of resources and the economic benefits of enterprises .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com