Method for recovering associated sulphide copper-zinc ore from cyaniding slag of gold-silver concentrate

A technology for sulfide ore, copper and zinc, applied in solid separation, flotation and other directions, can solve problems such as deteriorating factory operating environment, hydrogen cyanide gas overflow, safety problems, etc., to reduce environmental pollution, improve economic benefits, and improve resource utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

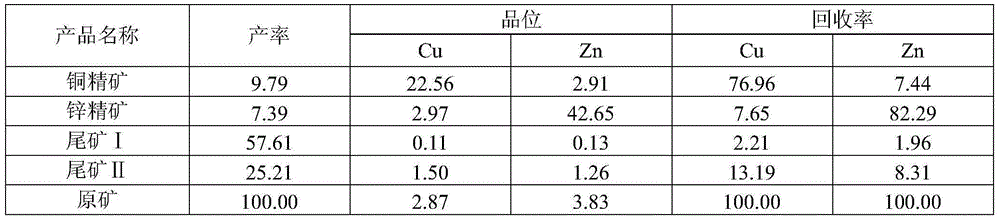

Embodiment 1

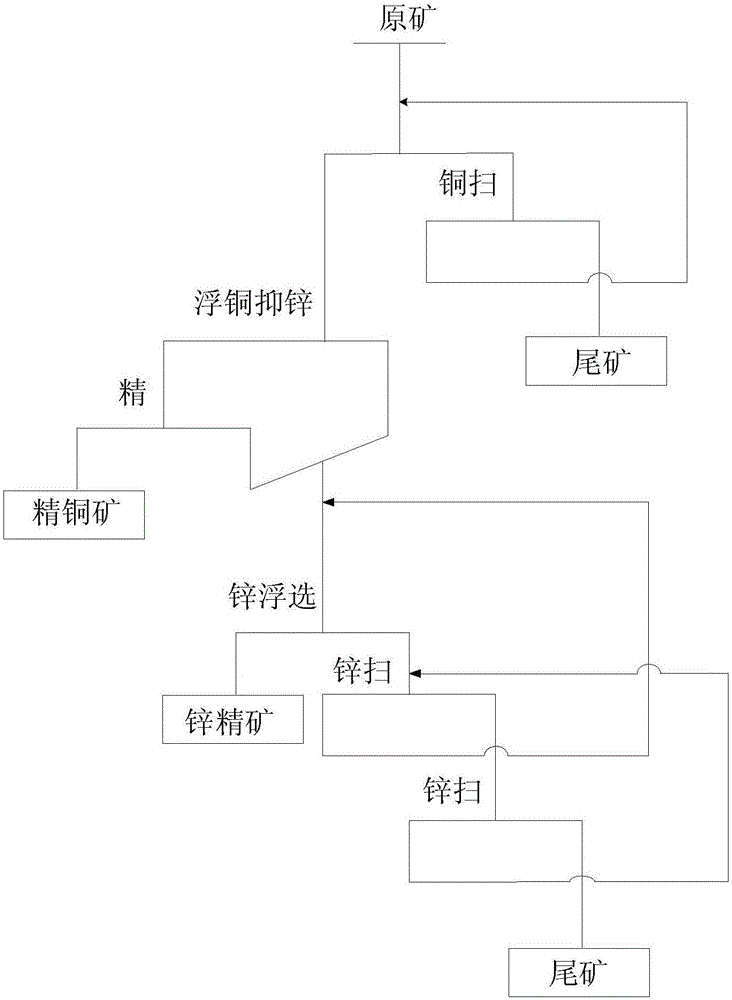

[0025] like figure 1 Shown process flow diagram of the present invention, reclaims the method for associated copper-zinc sulfide ore from gold-silver concentrate cyanide slag, comprises the steps:

[0026] 1) Pulping: add 2.86% copper, 3.85% zinc, and 29.51% sulfur gold and silver cyanide slag into water for pulping. The pulp concentration is 30%. Add LGY-01 activator 12000g / t and stir for 5 minutes.

[0027] 2) Copper-zinc mixed flotation: add 70g / t of combined collector of butyl xanthate and butylamine black medicine, 10g / t of foaming agent, conduct a rough separation, and perform a second sweep to obtain a copper-zinc mixed coarse concentrate , the weight ratio of butyl xanthate and butylamine black medicine is 3:2, and the foaming agent is 2 # Oil.

[0028] 3) Copper-zinc rough concentrate suppresses zinc and floats copper: Add 3000g / t of inhibitor combined with sodium sulfide and zinc sulfate at a ratio of 2:1, stir for 2 minutes, conduct a rough separation, and obtain ...

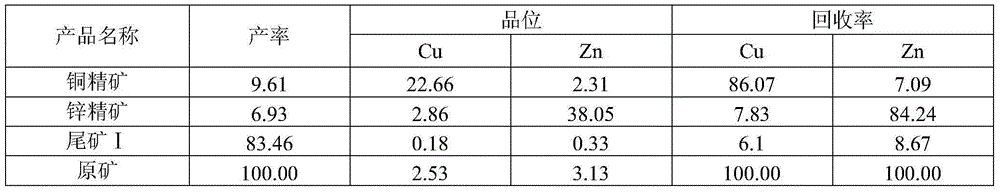

Embodiment 2

[0032] Adopt the step of the inventive method to reclaim certain cyanide slag as

[0033] 1) Pulping: Add water to a cyanide slag containing 2.53% copper, 3.13% zinc, and 25.86% sulfur for pulping. The pulp concentration is 30-35%, preferably 33%. Add LGY-01 activator 10000g / t, stirring for 5 minutes.

[0034] 2) Copper-zinc mixed flotation: add 80g / t of combined collector of butyl xanthate and butylamine black medicine, 12g / t of foaming agent, conduct first roughing, and second sweeping to obtain copper-zinc mixed coarse concentrate , the weight ratio of butyl xanthate and butylamine black medicine is 3:2, and the foaming agent is 2 # Oil.

[0035] 3) Copper-zinc flotation: Add 3000g / t inhibitor of sodium sulfide and zinc sulfate combined in a ratio of 2:1, stir for 2 minutes, conduct a rough separation, and obtain a copper concentrate; select copper tails The ore uses lime to adjust the pH value of the pulp at about 11, adding 600g / t of copper sulfate as an activator of z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com