Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Guaranteed nitrogen content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flux-cored wire used for super duplex stainless steel gas shielded welding and preparation method thereof

ActiveCN110142529ASimple welding processReduce acidityWelding/cutting media/materialsSoldering mediaAusteniteZircon

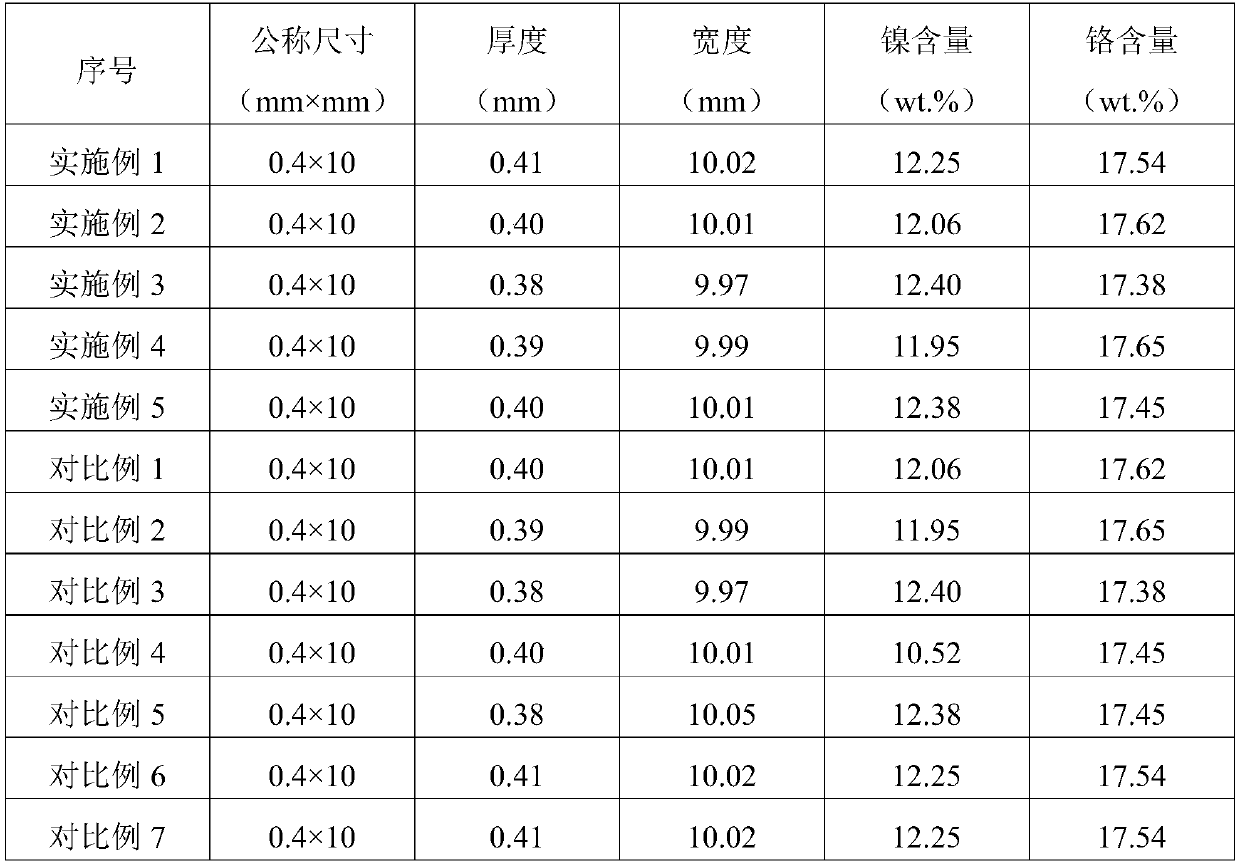

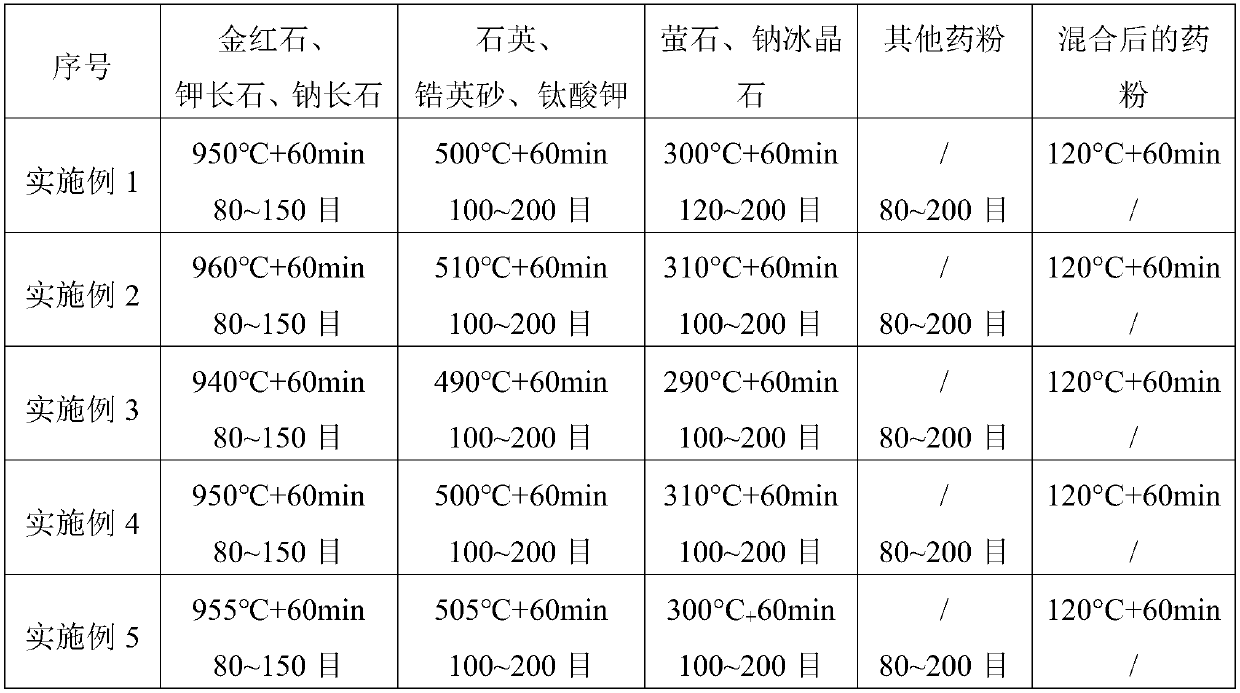

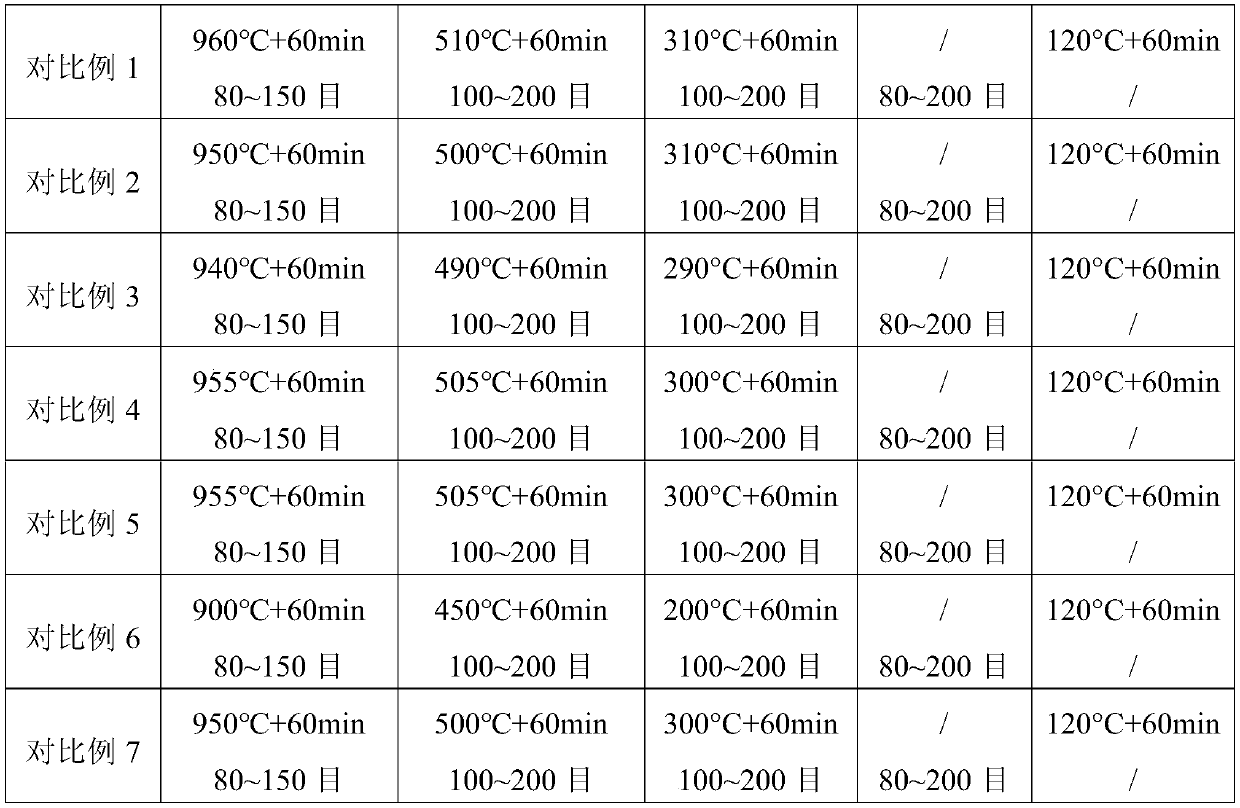

The invention discloses a flux-cored wire used for super duplex stainless steel gas shielded welding and a preparation method thereof. The flux-cored wire is composed of an external use steel belt andflux powder, wherein the external use steel belt is made of an austenitic stainless steel belt with 17.0%-18.0% of chromium and 11.0%-12.5% of nickel; and the flux powder comprises the following components of, in percentage by weight, 36.0%-38.0% of chromium powder, 9.0%-13.0% of high-nitrogen chromium iron, 2.5%-3.0% of electrolytic manganese metal, 4.0%-5.0% of molybdenum powder, 0.5%-1.0% of ferrosilicon, 1.0%-1.5% of ferrotitanium, 0.5%-1.0% of aluminum-magnesium alloy, 18.0%-20.0% of rutile, 1.0%-2.0% of quartz, 5.0%-6.0% of zircon sand, 1.0%-1.5% of potassium feldspar, 3.0%-3.5% of albite, 1.0%-1.5% of fluorite, 0.5%-1.0% of sodium cryolite, 1.0%-1.5% of potassium titanate, 0.1%-0.3% of bismuth oxide and the balance iron powder. According to the flux-cored wire used for super duplexstainless steel gas shielded welding and the preparation method thereof, the components and the two-phase proportion of deposited metal can be balanced, thus obtaining a duplex stainless steel welding joint which is good in forming quality and excellent in corrosion resistance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

System and method for removing sulfur and mercury out of flue gas by adding organic catalyst to wet spraying absorption tower

InactiveCN103301748AHigh removal rateGuaranteed nitrogen contentAmmonium nitratesDispersed particle separationOrganocatalysisAmmonium sulfate

The invention discloses a system for removing sulfur and mercury out of flue gas by adding an organic catalyst to a wet spraying absorption tower. The system comprises flue gas absorption equipment, ammonia water storage and supply equipment, dust separation and catalyst recycling equipment, evaporative crystallization equipment and process water equipment, wherein the ammonia water storage and supply equipment and the dust separation and catalyst recycling equipment are respectively communicated with the flue gas absorption equipment; the dust separation and catalyst recycling equipment is connected with the evaporative crystallization equipment; and the evaporative crystallization equipment is connected with the process water equipment. The invention simultaneously discloses a method for removing sulfur and mercury by utilizing the system. The mixture of the organic catalyst and emulsion comes into countercurrent contact with flue gas in the wet spraying absorption tower and purify and absorb the flue gas and then desulfurization saline solution is sent to a three-phase separator and the evaporative crystallization equipment to produce ammonium sulfate, thus reaching the aims of multi-effect control of the flue gas, energy conservation, consumption reduction and cost reduction.

Owner:光阳工程技术有限公司

Preparation method of activated carbon with capability of efficiently adsorbing CO2

The invention provides a preparation method of activated carbon with capability of efficiently adsorbing CO2. The preparation method comprises the following steps: adding p-aminophenol after reaction of melamine and formaldehyde, carrying out reflux reaction for 4-8h, cooling until room temperature, then adding a methanol solution of F127 or P123, respectively segmenting at temperatures of 100-120 DEG C, 130-160 DEG C, 170-190 DEG C, 210-230 DEG C and 240-260 DEG C, respectively curing to obtain nitrogen-containing prepolymer, then carbonizing, mixing a carbonized material and KOH, activating for 0.5-2.0h, repeatedly washing by deionized water until neutrality finally, and drying to obtain the product. The activated carbon has the advantages of high specific surface area, high nitrogen content and high CO2 adsorption performance.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

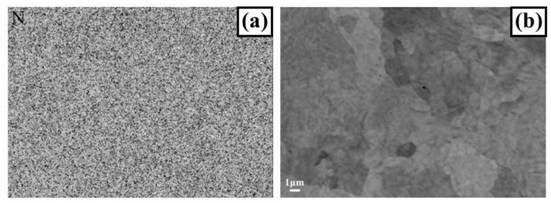

Nitrogen-containing high-entropy alloy composite material and preparation method thereof

ActiveCN110548869AIncrease back stressReduced germinationAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingHigh entropy alloys

The invention belongs to the field of alloys, in particular to a nitrogen-containing high-entropy alloy composite material and a preparation method thereof. The nitrogen-containing high-entropy alloycomposite material has mixed crystal tissues with coarse crystals and fine crystals alternately distributed. The preparation method comprises the following steps: I, preparing nitrogen-containing high-entropy pre-alloy powder, wherein metal elements in the nitrogen-containing high-entropy pre-alloy powder are selected from at least three of Fe, Co, Cr, Ni and Mn; and S2, shaping the nitrogen-containing high-entropy pre-alloy powder obtained in the S1 by means of the selective laser melting technique to obtain the high-entropy alloy. The preparation process is simple and controllable. The obtained product is fine and uniform in tissue, uniform in nitrogen distribution in a blank, also uniform in integral nitrogen distribution, good in mechanical property and good in corrosion resistance, thereby, providing necessary conditions for engineering applications of the nitrogen-containing high-entropy alloy.

Owner:CENT SOUTH UNIV

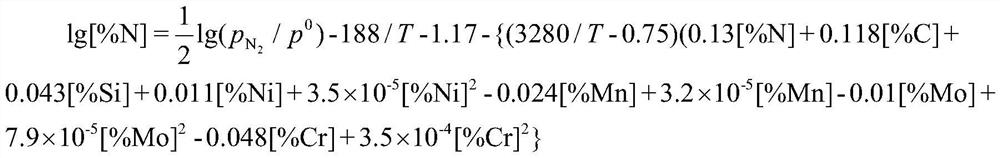

High-nitrogen austenitic stainless steel smelting method

The invention relates to a high-nitrogen austenitic stainless steel smelting method. The high-nitrogen austenitic stainless steel smelting method comprises the following steps of (1) blast-furnace molten iron pretreatment, (2) refining in a top-bottom combined blowing TSR stainless steel refining furnace, (3) refining outside a ladle refining furnace and (4) continuous casting. Compared with the prior art, the high-nitrogen austenitic stainless steel smelting method has the characteristics that the smelting cost is low, and the plate blank surface and interior quality meets the steel type requirements of the high-nitrogen austenitic stainless steel.

Owner:SHANDONG TAISHAN STEEL GROUP

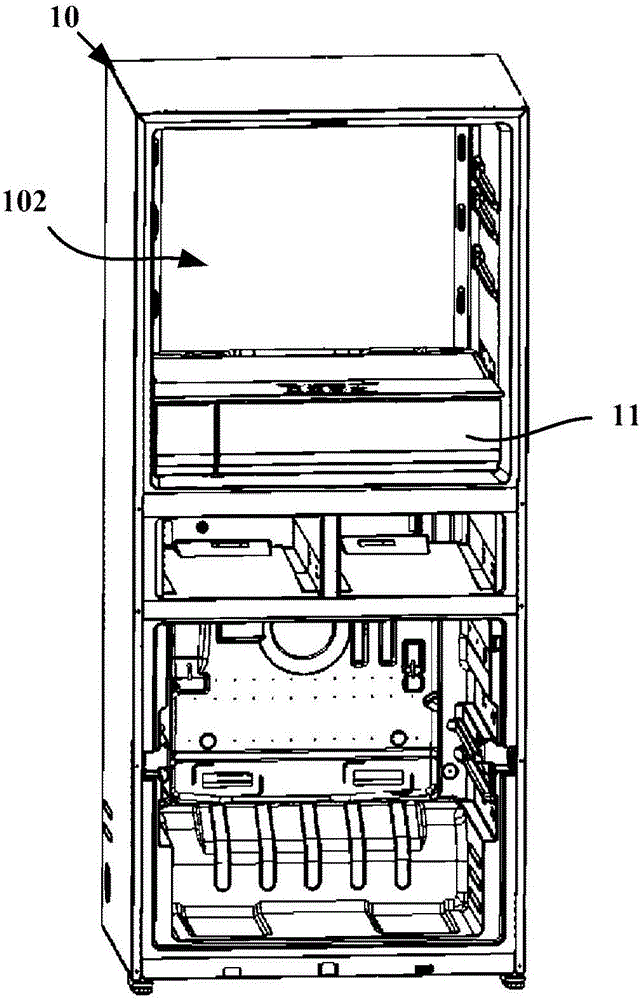

Refrigerator

ActiveCN106705536AReduce intensityGuaranteed respirationLighting and heating apparatusDomestic refrigeratorsControl modeAirflow

The invention provides a refrigerator. The refrigerator comprises a box body, a gas adjusting membrane assembly and a gas sucking pump assembly. A storing space and a compressor cabin are defined inside the box body. A storing container is arranged in the storing space, and a refreshment space is defined inside the storing container. The gas adjusting membrane assembly is arranged in the way that oxygen in airflow of a surrounding space of the gas adjusting membrane assembly can more penetrate through a gas adjusting membrane to enter an oxygen-enriched gas collecting cavity relative to nitrogen in the airflow. The inlet end of the gas sucking pump assembly communicates with the oxygen-enriched gas collecting cavity in a controlled mode through a pipeline and a pipeline switching mechanism, so that gas in the oxygen-enriched gas collecting cavity is pumped to the outside of the refreshment space, and the actual nitrogen content in the refreshment space is within the range of 81% to 98%. According to the refrigerator disclosed by the invention, the actual nitrogen content in the refreshment space is within a proper range, and aerobic respiration strength of a food material can be effectively lowered; and meanwhile, a basic respiration effect is guaranteed, anaerobic respiration of the food material is avoided, and therefore the storage effect of the food material is improved and the refreshing time of the food material is prolonged.

Owner:大连海尔电冰箱有限公司 +2

Smelting and casting process for smelting high-nitrogen non-magnetic stainless steel by using argon oxygen furnace

The invention relates to a smelting and casting process for smelting high-nitrogen non-magnetic stainless steel by using an argon oxygen furnace. The process comprises the following steps: firstly, melting 510-530kg / t of returned stub bars, 300-320kg / t of high-carbon ferrochrome, 8-40kg / t of ferromolybdenum, 14-30kg / t of electrolytic nickel and 5-10kg / t of carburant by using an intermediate frequency furnace, sampling the steel when the temperature is greater than or equal to 1560 DEG C, and then, putting the steel into the argon oxygen furnace; then, supplementing alloy into the argon oxygenfurnace according to the sampling result, performing decarburization to be less than 0.01%, adding 10-25kg / t of special ferrosilicon for reduction, adding 200-240 kg / t of electrolytic manganese, adding 5-10kg / t of aluminum, raising the temperature, and adding 20-30kg / t of ferromanganese nitride alloy in two batches; discharging the steel into a steel ladle; and transferring the steel to a pouringstation to be molded by pouring by adopting a top pouring method, and adding 0.5-1kg / t of protecting slag into the mold. The process provided by the invention is environment-friendly and low in cost and increases the utilization ratio of molten steel by 8%; and by adding the protecting slag into the mold, the surface quality of an electrode blank is ensured, and mold release is facilitated.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

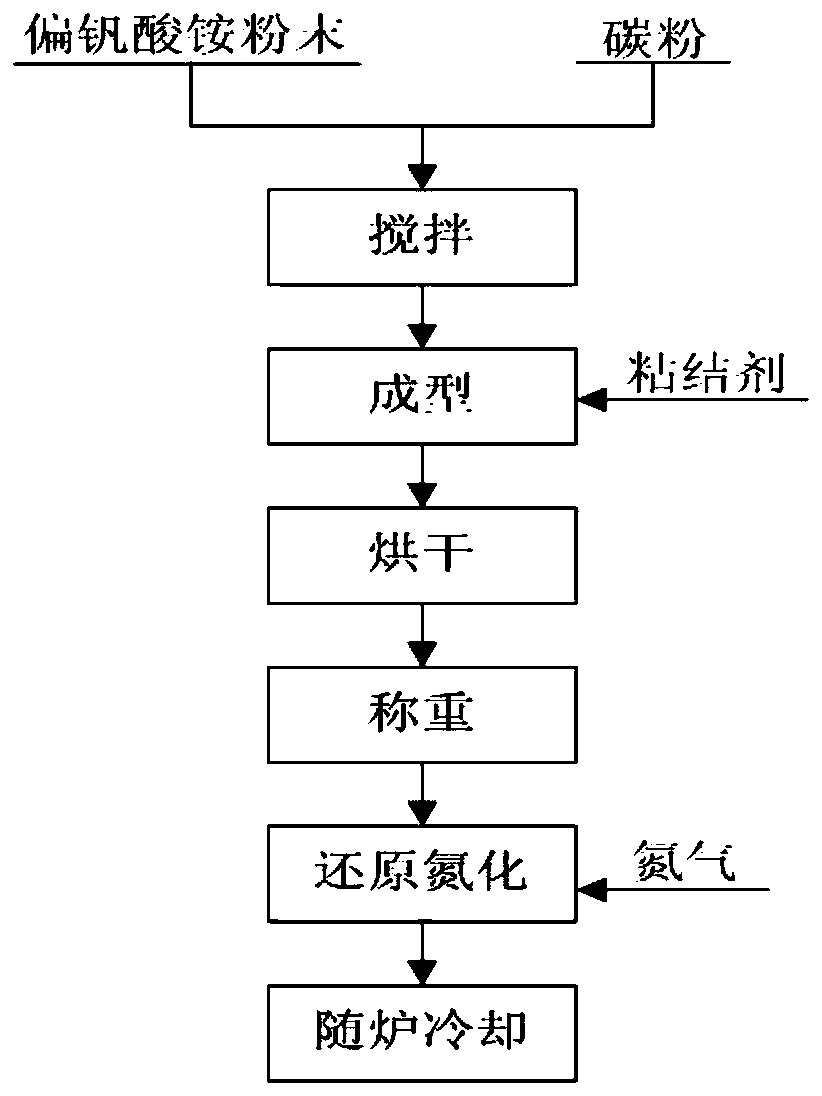

Method for preparing vanadium nitride

ActiveCN107673317AAvoid meltingAvoid wastingNitrogen-metal/silicon/boron binary compoundsVanadium nitrideNitrogen atmosphere

The invention discloses a method for preparing vanadium nitride, which comprises the following steps: step 1, carrying out pre-reduction on a test specimen prepared from ammonium metavanadate powder and carbon powder in a heating furnace by nitrogen, wherein in the pre-reduction process, a temperature in the heating furnace is 650 to 670 DEG C, nitrogen flow is 210 to 270mL / min, and heat preservation time of the heating furnace is 2 to 4 hours; step 2, after ending heat preservation in the step S1, warming the heating furnace to a temperature of 1,300 to 1,500 DEG C and carrying out final reduction on the test specimen, wherein the final reduction process, nitrogen flow in the heating furnace is 210 to 270mL / min, and heat preservation time of the heating furnace is 4 to 5 hours; step 3, after ending heat preservation in the step S2, carrying out furnace cooling on the test specimen in nitrogen atmosphere, so that the obtained test specimen is the vanadium nitride. According to the method disclosed by the invention, the vanadium nitride is prepared by the ammonium metavanadate, so that a calcination section can be omitted, and the aims of simplifying a production process, reducing production cost of an enterprise and reducing pollution are fulfilled.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

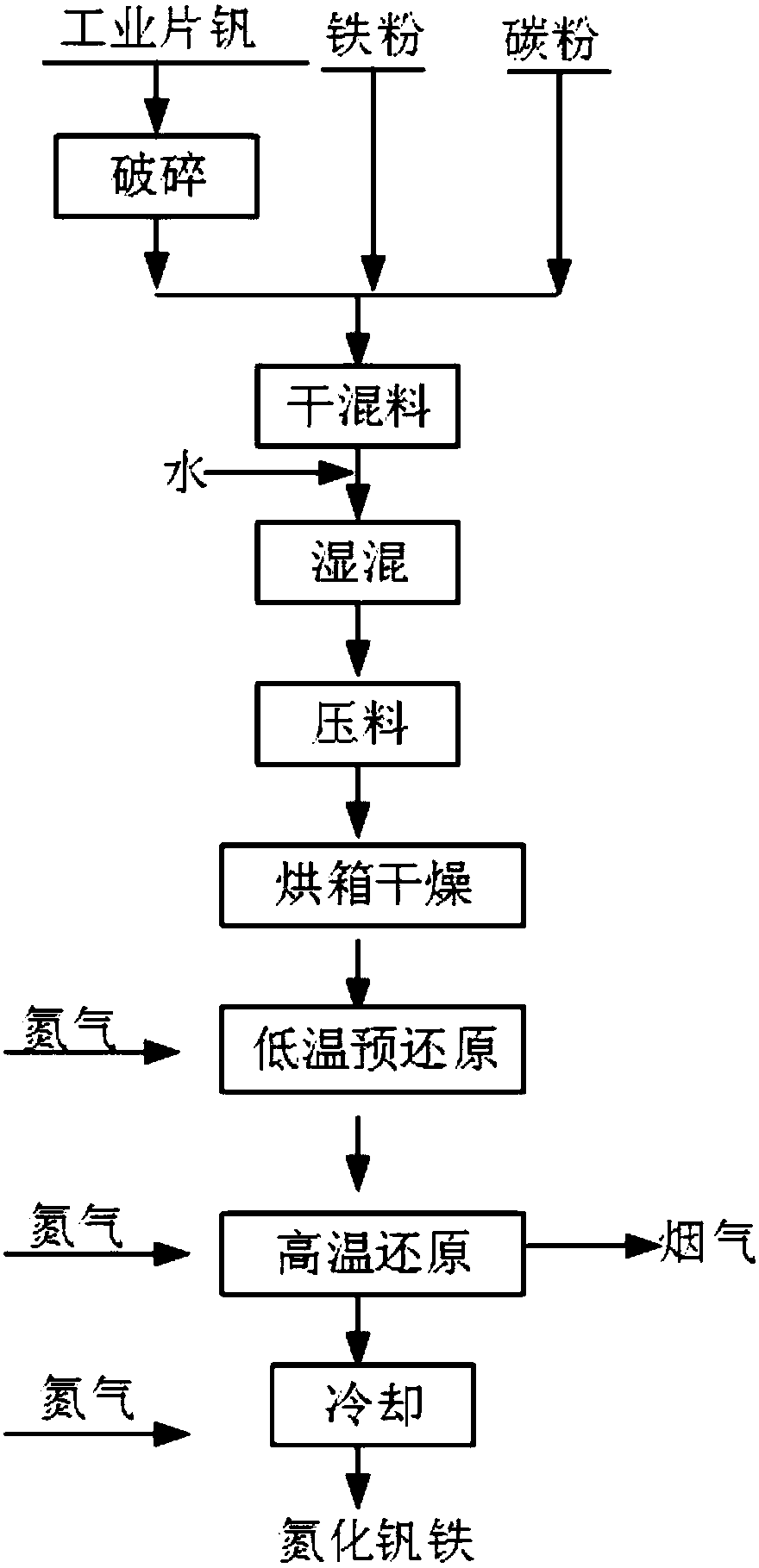

Method for preparing nitrided ferrovanadium

The invention discloses a method for preparing nitrided ferrovanadium. The method comprises the following steps that (1), a sample fabricated by uniformly mixing and pressing vanadium oxide powder, iron powder and carbon powder is subjected to prereduction through the nitrogen gas in a heating furnace, in the prereduction process, the temperature in the heating furnace is 650 + / -20 DEG C, the nitrogen gas flow is 150-180 L / h, and the heat preservation time of the heating furnace is 3-5 hours; (2), after heat preservation in step (1) is finished, the temperature of the heating furnace is then increased to 1200-1500 DEG C to perform final reduction on the sample, in the final reduction process, the nitrogen gas flow in the heating furnace is 150-180 L / h, and the heat preservation time of theheating furnace is 2-3 hours; (3), after heat preservation in step (2) is finished, the sample is cooled along with the furnace in the atmosphere of the nitrogen gas, and an obtained product is the nitrided ferrovanadium. According to the method, the vanadium oxide powder serves as the raw material, the iron powder serves as the iron source, the carbon powder serves as a reducing agent, the nitrogen gas is introduced into the heating furnace for reaction, and the method has the advantages that the procedure is simple, no vanadium slag is generated, the vanadium utilization rate is high, resources are saved, the environment is protected, and the production cost can be lowered.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

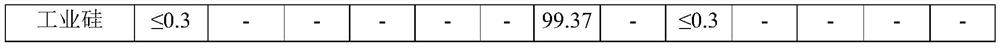

Water-soluble solid silicon fertilizer and production method and preparation device thereof

InactiveCN105254428AImprove stress resistanceIncrease productionFertilizer mixturesCarboxymethyl celluloseWater soluble

The invention belongs to the technical field of inorganic silicon and particularly relates to water-soluble solid silicon fertilizer and a production method and a preparation device thereof. The water-soluble silicon fertilizer is prepared from, by weight, 40-60% of quick-resolving sodium silicate, 10-20% of sodium humate, 10-20% of urea, 5-10% of magnesium sulfate, 5-10% of liquid sodium silicate and 0.1-0.2% of sodium carboxymethyl cellulose, wherein the modulus of the quick-resolving sodium silicate is 2.85-3.0, the content of water-soluble silicon elements in the quick-resolving sodium silicate is calculated as 50-75% according to the content of silicon dioxide, the modulus of the liquid sodium silicate is 3.2-3.3, and the content of water-soluble silicon elements in the liquid sodium silicate is calculated as 26-27% according to the content of silicon dioxide. The content of water-soluble silicon dioxide of the water-soluble silicon fertilizer is high, the fertilizer application amount is small, the cost performance is high, the water-soluble solid silicon fertilizer can be applied as base fertilizer for plants and can also be applied to topdressing of water flush fertilizer, and the water-soluble solid silicon fertilizer can be widely applied to all soil lacking silicon.

Owner:山东龙港硅业科技有限公司

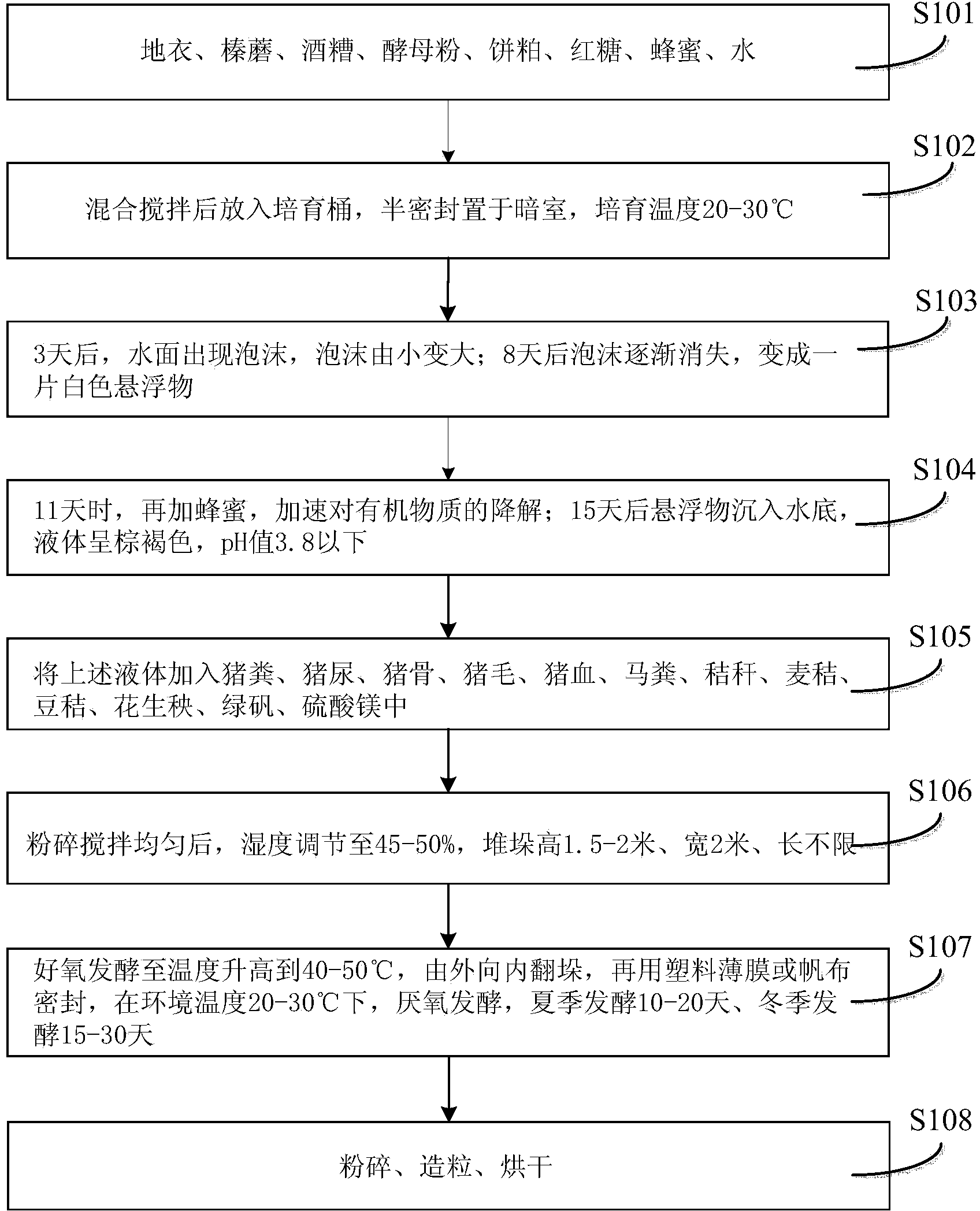

Organic fertilizer prepared from recovered wastes of pig farm and preparation method thereof

InactiveCN103951481AAchieve recyclingSolve pollutionBio-organic fraction processingOrganic fertiliser preparationScrapChemistry

The invention discloses an organic fertilizer prepared from recovered wastes of a pig farm and a preparation method thereof. The method comprises the following steps: preparing lichens, mellea armillaria sporophore, stillage, yeast powder, cake pulp, brown sugar, honey and a proper amount of water; after mixing and stirring the raw materials, putting the raw materials in a culture barrel and placing the barrel in a darkroom in a semi-hermetical manner, wherein the culture temperature is 20-30 DEG C, and after 15 days when suspended solids immerse to water, the liquid is brown and the pH value is bellow 3.8; adding pig manure, pig urine, pig bone, pig hair, pig blood, horseshit, straws, wheat straws, beanstalks, peanut stalks, copperas and magnesium sulfate into the liquid; after uniformly smashing and stirring, carrying out anaerobic fermentation at an environmental temperature of 20-30 DEG C for 10-20 days in summer and 15-30 days in winter; and smashing, prilling and drying. The organic fertilizer prepared from recovered wastes of the pig farm disclosed by the invention solves the problem of environmental pollution caused by the wastes, soil hardening caused by chemical fertilizers used on soil and unabiding fertilizer efficiency.

Owner:ZHEJIANG MAOYANGGANG AGRI DEV CO LTD

Urea sulfate coated urea slow-release granular fertilizer and preparation method therefor

ActiveCN105001023ARealize double-membrane double-controlling effectLow costUrea compound fertilisersFertilizer mixturesCoated ureaMetasilicate

The invention discloses a urea sulfate coated urea slow-release granular fertilizer. The urea sulfate coated urea slow-release granular fertilizer is prepared through the following steps of: adding 100kg of urea granules of which the diameters are 2-4.5mm to a rotary drum type coating machine, preheating the urea granules to 40-45 DEG C, spraying 1-10kg of a binder namely urea sulfate, uniformly mixing the preheated urea granules and the urea sulfate so as to obtain a mixture, spraying 1-20kg of metasilicate powder, cooling the mixture and the metasilicate powder, spraying 1-10kg of mounting addition agents (a mixture of solid paraffin and liquid paraffin) of which the temperature is 50-60 DEG C, cooling the mixture, the metasilicate powder and the mounting addition agents to a room temperature, and repeating the coating operation 2-3 times. The binder namely the urea sulfate is prepared through the steps of slowly adding1-2kg of concentrated sulfuric acid of 90-98wt% to every 1-10kg of urea and performing a reaction in a reaction tank. The urea sulfate coated urea slow-release granular fertilizer disclosed by the invention adopts a urea sulfate metasilicate slow-release film, tests prove that the urea sulfate metasilicate slow release film has a favorable slow-release effect, and in the slow-release process, the slow-release film is not liable to collapse and is easy to degrade. The urea sulfate has subacidity, so that the application range of the urea sulfate is wider than that of sulfur coating urea. The urea sulfate coating film realizes double-film double-control effects, and has the advantages of high efficiency, environmental protection, low cost and the like.

Owner:JILIN YUNTIANHUA AGRI DEV CO LTD

Preparation method of cerebrolysin vial with high and stable nitrogen content

InactiveCN103919807AHigh and stable nitrogen contentGuaranteed nitrogen contentPowder deliveryUnknown materialsFreeze-dryingHydrolysate

The invention discloses a preparation method of cerebrolysin vial with high and stable nitrogen content. The preparation method comprises the following steps: preparing degreased brains; carrying out enzymolysis with pepsase; carrying out enzymolysis with pancreatin; and concentrating the prepared solutions to obtain a cerebrolysin vial composition. The composition has the advantages that any exogenous amino acid is not added, the nitrogen content is up to 6 to 20mg / mL, proper auxiliary materials are also contained, and thus the natural cerebrolysin vial solution can be prevented from producing any undissolved substance on the premise that the high nitrogen content is ensured, and the similarity is more than 0.9. The method and composition provided by the invention are in accordance with the national standard and meet the requirements on producing a freeze-dried powder injection preparation.

Owner:云南盟生药业有限公司

A kind of preparation method of the active carbon of efficient adsorption CO2

The invention provides a preparation method of activated carbon with capability of efficiently adsorbing CO2. The preparation method comprises the following steps: adding p-aminophenol after reaction of melamine and formaldehyde, carrying out reflux reaction for 4-8h, cooling until room temperature, then adding a methanol solution of F127 or P123, respectively segmenting at temperatures of 100-120 DEG C, 130-160 DEG C, 170-190 DEG C, 210-230 DEG C and 240-260 DEG C, respectively curing to obtain nitrogen-containing prepolymer, then carbonizing, mixing a carbonized material and KOH, activating for 0.5-2.0h, repeatedly washing by deionized water until neutrality finally, and drying to obtain the product. The activated carbon has the advantages of high specific surface area, high nitrogen content and high CO2 adsorption performance.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

RH refining method for removing inclusions in molten steel

The invention provides an RH refining method for removing inclusions in molten steel. According to the method, nitrogen bottom blowing is carried out during the early and medium stages of RH vacuum treatment, and nitrogen serves as RH lift gas; a denitriding path in molten steel is controlled to prevent nitrogen elements in the molten steel from being removed from bubbles, application method the nitrogen separation and nitrogen increase process during vacuum treatment are carried out simultaneously to ensure that sufficient nitrogen elements are separated out from the molten steel with the inclusions as the core; and meanwhile, the effect of stably removing the inclusions in the molten steel is achieved under the condition that molten steel is continuously replaced and renewed in the RH refining process. The removal rate of small-size inclusions reaches up to 90% or more, the cleanliness of the molten steel is remarkably improved, and meanwhile, stable and continuous production can berealized at low cost.

Owner:MAANSHAN IRON & STEEL CO LTD

Culture medium for Coprinus comatus

InactiveCN107253870ASolve pollutionIncrease calciumCalcareous fertilisersExcrement fertilisersBiotechnologyBiology

The invention discloses a culture medium for Coprinus comatus, made from, by weight, 55-64 parts of straws, 15-19 parts of sundry sawdust, 9-12 parts of livestock excrement, 8-12 parts of wheat bran, 1-2 parts of gypsum powder, 1-2 parts of quick lime, 1-2 parts of urea, 1-2 parts of phosphorus fertilizer, 0.5-0.8 part of a biological fermenting agent, and 80-90 parts of water. The culture medium has the advantages that the culture medium has good breathability, high water-holding capacity and sufficient nitrogen content, can provide sufficient support for the cultivation of Coprinus comatus, has rich and complete nutrition and can provide sufficient vitamins and trace elements for Coprinus comatus; crop straws are used as a main material, the environmental pollution due to straw incineration can be solved, and considerable benefits are achieved at low cost; a preparation method of the culture medium is simple and feasible, fermenting time is greatly shortened, operating efficiency is improved, and the culture medium has more promising application prospect.

Owner:浦江县美泽生物科技有限公司

Rural domestic wastewater treatment device and method based on MBBR coupling anaerobic-aerobic process integration

PendingCN113184994ASolve pollutionGuaranteed Phosphate ContentWater treatment parameter controlTreatment with anaerobic digestion processesEnvironmental chemistryAnaerobic bacterium

The invention discloses a rural domestic wastewater treatment device based on MBBR coupling anaerobic-aerobic process integration. The device comprises an MBBR anaerobic chamber, an MBBR anoxic chamber and an MBBR aerobic chamber, a large amount of anaerobic bacteria are enriched in the MBBR anaerobic chamber for anaerobic hydrolysis, wastewater enters the device, a large amount of sulfur autotrophic denitrifying bacteria are enriched in the MBBR anoxic chamber for denitrification, and a large amount of nitrifying bacteria and phosphorus phagocytosis bacteria are enriched in the MBBR aerobic chamber. Gravity curved screens and sedimentation tanks are additionally arranged at the water outlet tail ends of the anaerobic tank and the aerobic tank, so that the flow of MBBR filler and activated sludge is ensured, the defect that the biological population ecology is influenced by drifting of suspended filler in different stages in the MBBR is overcome, and the nitrogen and phosphorus removal efficiency is improved. The system not only retains the advantages of large specific surface area and high efficiency of the MBBR, but also can greatly reduce the generation of excess sludge, and can realize regulation and control of nitrogen and phosphorus indexes of rural domestic wastewater.

Owner:ZHEJIANG UNIV

ArHeN2CO2 protective gas for consumable electrode gas shielded nickel-based welding wire

PendingCN109530889AGuaranteed nitrogen contentIncrease densityShielding gas supply/evacuation devicesCarbon Dioxide / HeliumShielding gas

The invention provides an ArHeN2CO2 protective gas for a consumable electrode gas shielded nickel-based welding wire. The consumable electrode gas shielded welding adopts the nickel-based welding wireand an ArHeN2CO2 quaternary protective gas, the mixing using amount of the nickel-based welding wire and the ArHeN2CO2 quaternary protective gas comprises the following components of, by mass, 45-50%of Ar, 45-50% of He, 2.5-3.5% of N2, and 2.5-3.5% of CO2; the use amount of the ArHeN2CO2 quaternary protective gas is mixed through different proportions, so that the content of nitrogen elements ina weld joint of a large-thickness plate is ensured, and excellent arc stiffness and strong directivity are achieved; and excellent welding of the nitrogen element without burning loss improves the compactness degree of the weld joint, and the technical problems that the nitrogen element losses and the mechanical property of weld joint is not stable in the welding process are solved. Due to the fact that the method adopting the ArHeN2CO2 quaternary gas to be mixed according to the proportions to serve as the protective gas in NiCrMo-3 nickel-based melting electrode gas shielded welding, the excellent arc stiffness is achieved, the welding efficiency is improved, the construction period is shortened, and the production cost is reduced; and the compactness degree of the weld joint is improved, and the welding difficulty is reduced, and the gas is suitable for being used as the protective gas in application for a consumable electrode gas shielded nickel-based welding wire.

Owner:中国船舶集团渤海造船有限公司

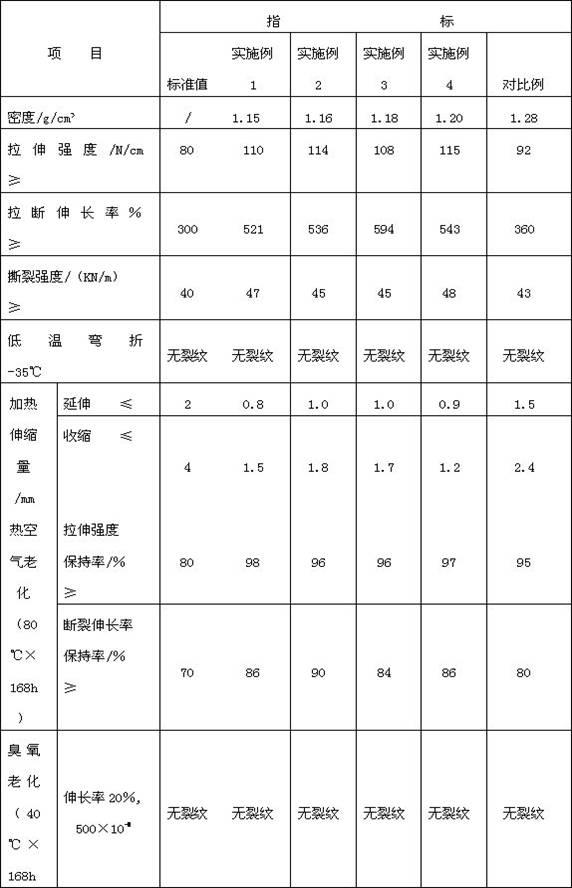

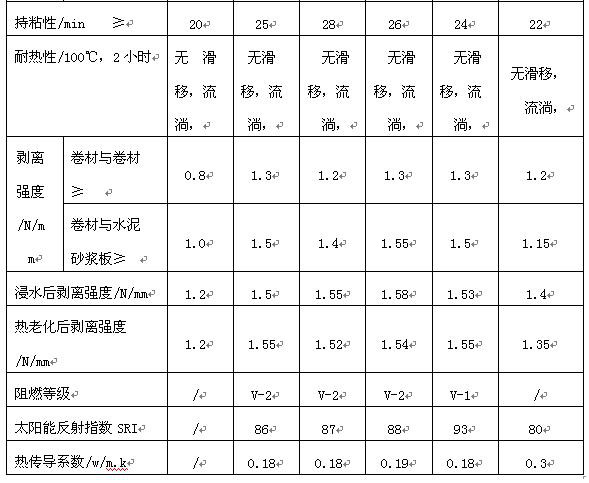

White butyl self-adhesive ethylene propylene diene monomer waterproof roll and production method thereof

ActiveCN112745775AMeet hot and cold deformation needsReduce roof temperatureNon-macromolecular adhesive additivesRoof covering using flexible materialsCyanate esterMethyl cyclohexane

The invention relates to a white butyl self-adhesive ethylene propylene diene monomer waterproof roll and a production method thereof. The white butyl self-adhesive ethylene propylene diene monomer waterproof roll is formed by compounding a base layer, a surface layer and an anti-adhesion isolation layer, the base layer is a white ethylene propylene diene monomer waterproof layer, and the surface layer is a butyl rubber self-adhesive layer; the base layer is based on 100 parts of ethylene propylene diene monomer; other components include 50-80 parts of precipitated silicon dioxide; 30-50 parts of low-melting-point glass powder; 40-70 parts of expanded perlite powder; 10-30 parts of rutile type titanium dioxide; 20-80 parts of a plasticizer; 0.8-1.5 parts of polyethylene glycol; 0.5-2 parts of a coupling agent; 0.2-0.8 part of an antioxidant 1010; 0.3-0.6 part of sulfur; 0.5-1.0 part of triallyl isocyanurate; and 3-9 parts of 1, 1-bis (tert-butylperoxy)-3, 3, 5-trimethylcyclohexane. The temperature of the roof can be greatly reduced by using the roof.

Owner:深润防水科技(山东)有限公司 +1

ArHeN2H2 protective gas for consumable electrode gas shielded nickel-based welding wire

InactiveCN109530892AExcellent arc stiffnessImprove welding efficiencyShielding gas supply/evacuation devicesWeld seamDirectivity

The invention provides an ArHeN2H2 protective gas for a consumable electrode gas shielded nickel-based welding wire. The melting electrode gas shielded welding adopts a nickel-based welding wire and an ArHeN2H2 protective gas, and the mass ratio of the mixed use amount of the nickel-based welding wire and the ARHN2h2 protective gas is as follows, 45-50% of Ar, 45-50% of He, 2.5-3.5% of N2, and 1.0-1.5% of H2. The use amount of the ArHeN2H2 quaternary protection gas is mixed through different proportions, the content of nitrogen elements in the weld joint of the large-thickness plate is guaranteed, excellent arc stiffness is achieved, the directivity is high, free of burning loss of nitrogen elements is achieved, the compactness degree of the welding seam is improved, and the technical problem that the mechanical property of a nitrogen element lost weld joint is not stable in the welding process is solved. In the NiCrMo-3 nickel-based melting electrode gas shielded welding, ArHeN2H2 quaternary gases are mixed according to a ratio to serve as protective gas, excellent arc stiffness is achieved, the welding efficiency is improved, the construction period is shortened, and the production cost is reduced; the compactness degree of the welding seam is improved, and the welding difficulty is reduced; and the ArHeN2H2 protective gas is suitable for being used as a protective gas for aconsumable electrode gas shielded nickel-based welding wire.

Owner:渤海造船厂集团有限公司

Repeated filling type packaging bag nitrogen filling device

InactiveCN108557149AGuaranteed nitrogen contentGuaranteed concentrationPackaging by pressurising/gasifyingNitrogenNitrogen gas

The invention discloses a repeated filling type packaging bag nitrogen filling device. The nitrogen filling device comprises a machine frame and an air inflation sub-clamp mechanism, wherein an air inflation pipe (13) is arranged at the position, between a left sub-clamp and a right sub-clamp of the air inflation sub-clamp mechanism, on the machine frame; rollers (12) are arranged at the upper endpart of the air inflation pipe; a rolling plate (4) is arranged at the position, above the air inflation pipe, of the machine frame, the rollers can roll on the rolling plate, and air inflation pipelifting mechanisms (5) and bag opening packaging mechanisms (15) are arranged on the side edges of the end parts of the rolling plates; and a feeding rotating disc (1) is arranged on the side edge ofthe machine frame, and a packaging bag conveying mechanism (3) is arranged at the position between the machine frame and the feeding rotating disc. According to the nitrogen filling device, the packaging bag conveying mechanism is used for conveying loaded packaging bags to a nitrogen filling station, and the air inflation pipe is used for carrying out continuous and repeated nitrogen filling andpumping on the packaging bags so as to guarantee the nitrogen content and concentration in the bags, so that the shelf life of the materials is properly prolonged, waste caused by the expiration of the materials is effectively avoided, and the material packaging quality is obviously improved.

Owner:浙江简正机械有限公司

ArHeN2 protective gas for consumable electrode gas shielded nickel-based welding wire

PendingCN109530891AGuaranteed nitrogen contentIncrease densityShielding gas supply/evacuation devicesShielding gasWelding process

The invention provides an ArHeN2 protective gas for a consumable electrode gas shielded nickel-based welding wire. The consumable electrode gas shielded welding adopts the nickel-based welding wire and an ArHeN2 protective gas, the mixing using amount of the mass ratio of the nickel-based welding wire and the ArHeN2 protective gas comprises the following components of, 45-50% of Ar, 45-50% of He,and 2.5-3.5% of N2; the use amount of the ArHeN2 protective gas is mixed through different proportions, so that the content of nitrogen elements in a weld joint of a thin plate is ensured, and excellent arc stiffness and strong directivity are achieved; and excellent welding of the nitrogen element without burning loss improves the compactness degree of the weld joint, and the technical problems that the nitrogen element losses and the mechanical property of weld joint is not stable in the welding process are solved. Due to the fact that the method adopting the ArHeN2 ternary gas to be mixed according to the proportions to serve as the protective gas in NiCrMo-3 nickel-based melting electrode gas shielded welding, the excellent arc stiffness is achieved, the welding efficiency is improved,the construction period is shortened, and the production cost is reduced; and the compactness degree of the weld joint is improved, and the welding difficulty is reduced, and the gas is suitable forbeing used as the protective gas in application for a consumable electrode gas shielded nickel-based welding wire.

Owner:中国船舶集团渤海造船有限公司

Urea sulfate-coated urea slow-release granular fertilizer and preparation method thereof

ActiveCN105001023BRealize double-membrane double-controlling effectLow costUrea compound fertilisersFertilizer mixturesWaxMetasilicate

The invention discloses a urea sulfate coated urea slow-release granular fertilizer. The urea sulfate coated urea slow-release granular fertilizer is prepared through the following steps of: adding 100kg of urea granules of which the diameters are 2-4.5mm to a rotary drum type coating machine, preheating the urea granules to 40-45 DEG C, spraying 1-10kg of a binder namely urea sulfate, uniformly mixing the preheated urea granules and the urea sulfate so as to obtain a mixture, spraying 1-20kg of metasilicate powder, cooling the mixture and the metasilicate powder, spraying 1-10kg of mounting addition agents (a mixture of solid paraffin and liquid paraffin) of which the temperature is 50-60 DEG C, cooling the mixture, the metasilicate powder and the mounting addition agents to a room temperature, and repeating the coating operation 2-3 times. The binder namely the urea sulfate is prepared through the steps of slowly adding1-2kg of concentrated sulfuric acid of 90-98wt% to every 1-10kg of urea and performing a reaction in a reaction tank. The urea sulfate coated urea slow-release granular fertilizer disclosed by the invention adopts a urea sulfate metasilicate slow-release film, tests prove that the urea sulfate metasilicate slow release film has a favorable slow-release effect, and in the slow-release process, the slow-release film is not liable to collapse and is easy to degrade. The urea sulfate has subacidity, so that the application range of the urea sulfate is wider than that of sulfur coating urea. The urea sulfate coating film realizes double-film double-control effects, and has the advantages of high efficiency, environmental protection, low cost and the like.

Owner:JILIN YUNTIANHUA AGRI DEV CO LTD

A high-nitrogen steel consumable electrode for pressurized electroslag remelting and its preparation method

ActiveCN113106265BPrevent leakageAvoid oxygenationIncreasing energy efficiencySlag (welding)Molten steel

One aspect of the present invention provides a consumable electrode for pressurized electroslag remelting high-nitrogen steel, which includes a base material of the consumable electrode and at least two cored tubes embedded in the base material of the consumable electrode; the cored tube includes The iron pipe and the nitride alloy filled in the iron pipe, the first end of the cored pipe is located at the end where the consumable electrode base material is inserted into the slag pool, and the second end of the cored tube is located at the end where the consumable electrode base material is away from the slag pool one end. It avoids the leakage of nitrided alloy in the process of electroslag remelting, and improves the composition distribution from the core to the edge of the remelted steel ingot. Another aspect of the present invention provides a method for preparing a consumable electrode for pressurized electroslag remelting high-nitrogen steel, which avoids the oxygenation of molten steel caused by welding, and has a simple preparation process and low cost.

Owner:NORTHEASTERN UNIV LIAONING

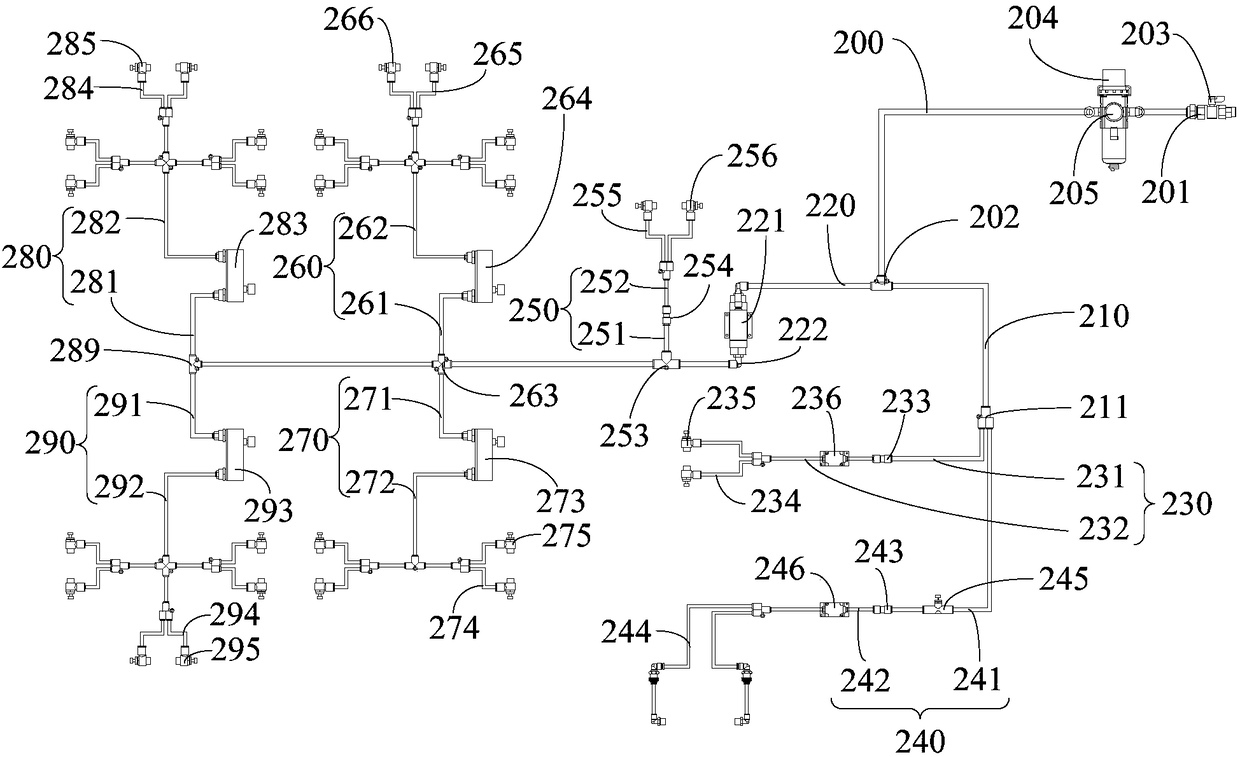

Nitrogen system and glass hot bending machine

PendingCN108218197AQuality improvementReduce consumptionGlass reforming apparatusEngineeringMechanical engineering

The invention discloses a nitrogen system and a glass hot bending machine. The nitrogen system comprises a gas storage tank, a main pipeline, a first separate pipeline, a second separate pipeline, a first branch pipeline, a second branch pipeline, a third branch pipeline, a fourth branch pipeline, a fifth branch pipeline, a sixth branch pipeline and a seventh branch pipeline, wherein the main pipeline is connected with the gas storage tank; the first separate pipeline and the second separate pipeline are connected with the main pipeline; the first branch pipeline and the second branch pipelineare connected with the first separate pipeline; the third branch pipeline, the fourth branch pipeline, the fifth branch pipeline, the sixth branch pipeline and the seventh branch pipeline are connected with the second separate pipeline; the first branch pipeline is communicated with a material charging box; the second branch pipeline is communicated with a material fetching box; the third branchpipeline is communicated with the material charging box; the fourth branch pipeline is communicated with the material fetching box; the fifth branch pipeline, the sixth branch pipeline and the seventhbranch pipeline are communicated with a forming box; a straight-through ball valve and a filtering pressure-relief valve are arranged on the main pipeline; a pressure gauge is arranged on the filtering pressure-relief valve and is used for displaying air pressure.

Owner:SHENZHEN CREATE CENTURY MACHINERY

Flux-cored wire for gas shielded welding of super duplex stainless steel and preparation method thereof

ActiveCN110142529BControl chemical compositionEasy to solveWelding/cutting media/materialsSoldering mediaFerrochromeAustenite

The invention discloses a flux-cored wire used for super duplex stainless steel gas shielded welding and a preparation method thereof. The flux-cored wire is composed of an external use steel belt andflux powder, wherein the external use steel belt is made of an austenitic stainless steel belt with 17.0%-18.0% of chromium and 11.0%-12.5% of nickel; and the flux powder comprises the following components of, in percentage by weight, 36.0%-38.0% of chromium powder, 9.0%-13.0% of high-nitrogen chromium iron, 2.5%-3.0% of electrolytic manganese metal, 4.0%-5.0% of molybdenum powder, 0.5%-1.0% of ferrosilicon, 1.0%-1.5% of ferrotitanium, 0.5%-1.0% of aluminum-magnesium alloy, 18.0%-20.0% of rutile, 1.0%-2.0% of quartz, 5.0%-6.0% of zircon sand, 1.0%-1.5% of potassium feldspar, 3.0%-3.5% of albite, 1.0%-1.5% of fluorite, 0.5%-1.0% of sodium cryolite, 1.0%-1.5% of potassium titanate, 0.1%-0.3% of bismuth oxide and the balance iron powder. According to the flux-cored wire used for super duplexstainless steel gas shielded welding and the preparation method thereof, the components and the two-phase proportion of deposited metal can be balanced, thus obtaining a duplex stainless steel welding joint which is good in forming quality and excellent in corrosion resistance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

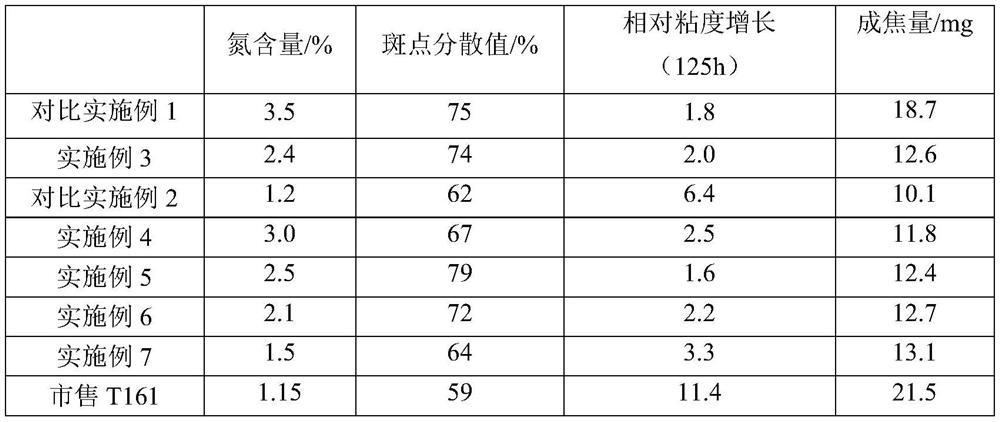

A kind of lubricating oil ashless dispersant and preparation method thereof

ActiveCN114058421BGuaranteed nitrogen contentImprove adsorption capacityAdditivesPolymer scienceBase oil

The invention relates to an ashless dispersant for lubricating oil, which has a structure represented by formula (I) or (II). The invention also relates to a method for preparing an ashless dispersant for lubricating oil, which includes the following steps: (1) First, add hydrocarbyl-substituted succinic anhydride and base oil into a reactor, raise the temperature to 70-90°C, stir evenly, and add carboxyl-containing and hydroxyl compounds, react continuously at 130-150°C for 5-8 hours, and then remove water at 140-160°C for 2-4 hours to obtain intermediate product A; (2) Add the intermediate product A into the reactor and raise the temperature to 95-110°C, add polyethylene polyamine compounds and polyether amine compounds at the same time, react at 115-125°C for 2-3 hours, then raise the temperature to 150-160°C to remove water for 5-8 hours, and cool to obtain ash-free Powder B.

Owner:PETROCHINA CO LTD

A nitrogen-containing high-entropy alloy composite material and its preparation method

ActiveCN110548869BIncrease back stressReduced germinationAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingHigh entropy alloys

The invention belongs to the field of alloys, in particular to a nitrogen-containing high-entropy alloy composite material and a preparation method thereof. The nitrogen-containing high-entropy alloy composite material has a mixed crystal structure in which one layer of coarse grains and one layer of fine grains are alternately distributed. The preparation method includes: step 1, preparing nitrogen-containing high-entropy pre-alloyed powder; in the nitrogen-containing high-entropy pre-alloyed powder, metal elements are selected from at least three of Fe, Co, Cr, Ni, and Mn; In step 2, the nitrogen-containing high-entropy pre-alloyed powder obtained in step 1 is formed by using a selective laser melting technology; and a nitrogen-containing high-entropy alloy is obtained. The preparation process of the present invention is simple and controllable; the structure of the product is fine and uniform, the nitrogen element distribution inside the blank is uniform, the overall nitrogen element distribution is also relatively uniform, the mechanical properties are good, and the corrosion resistance is good; this is to realize the nitrogen-containing high-entropy alloy. Engineering applications provide the necessary conditions.

Owner:CENT SOUTH UNIV

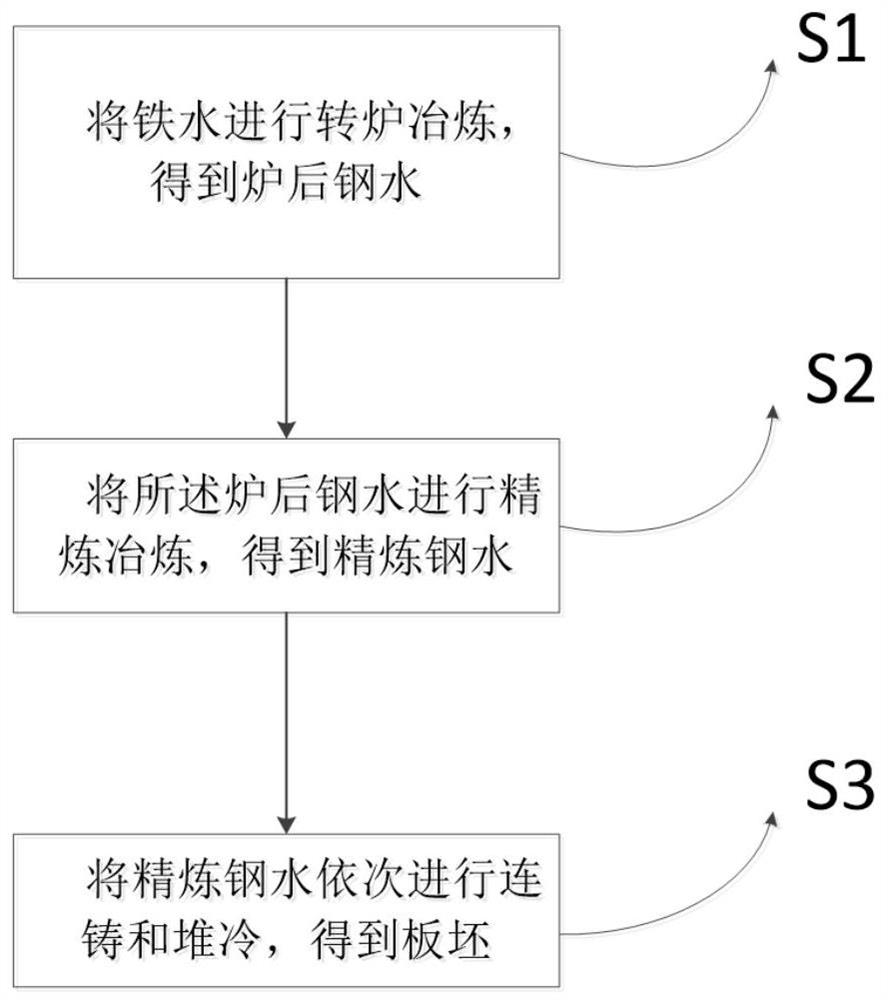

Method for eliminating warped skin on surface of hot alloy steel

ActiveCN114381648AQuality assuranceGuaranteed nitrogen contentManufacturing convertersProcess efficiency improvementSteelmakingMetallurgy

The invention relates to the technical field of steelmaking processes, in particular to a method for eliminating surface warping of hot alloy steel. The method comprises the following steps: smelting molten iron in a converter to obtain molten steel after the converter; refining and smelting the molten steel after the furnace to obtain refined molten steel; the refined molten steel is sequentially subjected to continuous casting and stack cooling, and a plate blank is obtained; the nitrogen content of the molten steel after the furnace is less than or equal to 28ppm by mass concentration; the nitrogen increasing amount of the refined molten steel is smaller than or equal to 6 ppm by mass concentration; in the continuous casting process, the nitrogen increasing amount is smaller than or equal to 3 ppm by mass concentration, and the nitrogen content of the plate blank is smaller than or equal to 40 ppm by mass concentration; in the plate blank, a metallographic structure comprises, by volume fraction, 100% of ferrite; and through a low-temperature hot delivery process of nitrogen production content and stack cooling, precipitation of second-phase particles is reduced, austenite is ensured to be completely converted into ferrite, and the defect of warping of a hot-rolled coil is eliminated.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

A kind of method for preparing vanadium nitride

ActiveCN107673317BAvoid meltingAvoid wastingNitrogen-metal/silicon/boron binary compoundsVanadium nitrideNitrogen atmosphere

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com