A kind of lubricating oil ashless dispersant and preparation method thereof

An ashless dispersant and lubricating oil technology, which is applied in lubricating compositions, additives, petroleum industry, etc., can solve the problems of low nitrogen content and alkali value, can not be effectively prevented, and the dispersion effect is not good, so as to prolong the service life and increase the adsorption and suspending ability, avoiding the effect of excessive viscosity growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

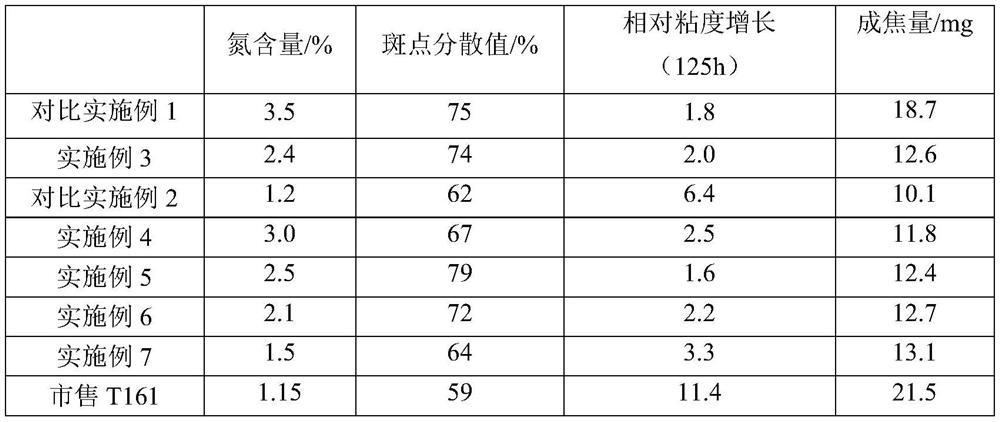

Examples

preparation example Construction

[0044] The preparation method of the lubricating oil ashless dispersant provided by the present invention is the preparation method of the above-mentioned lubricating oil ashless dispersant, and comprises the following steps:

[0045] (1) First, add hydrocarbyl-substituted succinic anhydride and base oil into the reactor, heat up to 70-90°C, stir evenly, add a compound containing carboxyl and hydroxyl groups, and continuously react at 130-150°C for 5-8 hours, then at 130-150°C for 5-8 hours Dewatering at 140-160°C for 2-4 hours to obtain intermediate product A;

[0046] (2) adding the intermediate product A into the reactor, heating up to 95~110℃, adding polyvinylpolyamine compound and polyetheramine compound at the same time, reacting at 115~125℃ for 2~3 hours, then warming up to The water is removed at 150-160° C. for 5-8 hours, and the ashless dispersant B is obtained by cooling.

[0047] In some embodiments, the hydrocarbyl-substituted succinic anhydride is oil-soluble, a...

Embodiment 1

[0058] Preparation of intermediate products

[0059] 1000g of polyisobutylene succinic anhydride (PIBSA-2300, 0.43mol) and 800g of base oil Youbase4 were added to a 4L four-necked flask with a stirring and a thermometer, the temperature was raised to 85°C, and after stirring for 30min to mix well, 52.4g (0.69mol) ) glycolic acid was added to the four-necked flask, and the temperature was raised to 150°C at a rate of 10°C / h. After continuous reaction for 8 hours, continued at 150°C, a large amount of nitrogen gas was introduced to remove water for 2.5 hours to obtain an intermediate product A1 with an acid value It is 44.8KOH mg / g.

Embodiment 2

[0061] Preparation of intermediate products

[0062] 1000g of polyisobutylene succinic anhydride (PIBSA-2300, 0.43mol) and 800g of base oil Youbase4 were added to a 4L four-necked flask with a stirring and a thermometer, the temperature was raised to 85°C, and after stirring for 30min to mix well, 65g (0.86mol) Glycolic acid was added to the four-necked flask, and the temperature was raised to 145°C at a rate of 10°C / h. After 8 hours of continuous reaction, the temperature was raised to 150°C, and a large amount of nitrogen was introduced for stripping and removing water for 2.5 hours to obtain an intermediate product A2 with an acid value. 56KOH mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com