Twisting machine spindle brake

A technology of brakes and twisting machines, which is applied in textiles and papermaking, and can solve the problems of machine equipment damage, twisting missing strands, waste silk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

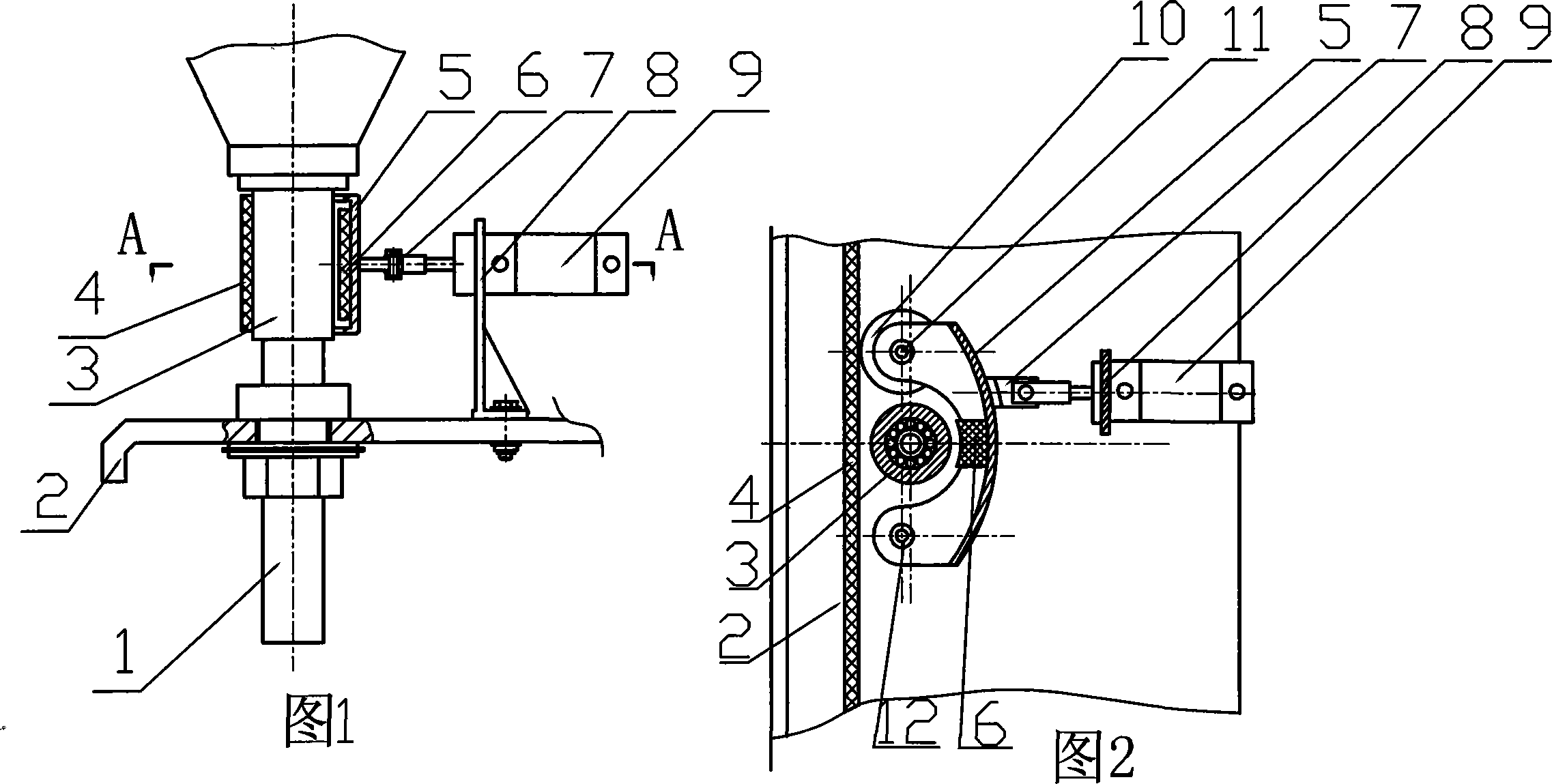

[0012] In the spindle brake of the twisting machine shown in Figure 1 and Figure 2, the spindle includes a spindle base 1 and a spindle disc 3, the spindle base 1 is fixed on the dragon bar 2, and the spindle disc 3 can be rotated at a high speed through the spindle rod. On the spindle base 1; the transmission dragon belt 4 is tangentially attached to the spindle disc 3 to drive the spindle for high-speed twisting, winding and rotation. On the opposite side of the ingot 3 and the drive belt 4, there is a brake swing arm 5, the brake swing arm 5 adopts a steel plate stamping part; On the dragon rib 2, the other end of the brake swing arm 5 is equipped with a dragon belt push wheel 10 through the dragon belt push wheel pin 11 and a rolling bearing (not shown in the figure), and the dragon belt push wheel 10 is close to the transmission dragon belt 4 the drive side.

[0013] A brake block 6 is fixedly mounted on the inner side of the brake swing arm 5, and the brake block 6 is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com