Leaching rate prediction method for wet metallurgy gold cyaniding leaching process

A technology of hydrometallurgy and prediction method, applied in the direction of instrument, adaptive control, control/regulation system, etc., can solve the problems of reducing detection cost, increasing consumption of raw materials and energy, and high cost, and achieving the effect of ensuring leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0132] Example 1: Prediction of leaching rate in single-stage leaching process

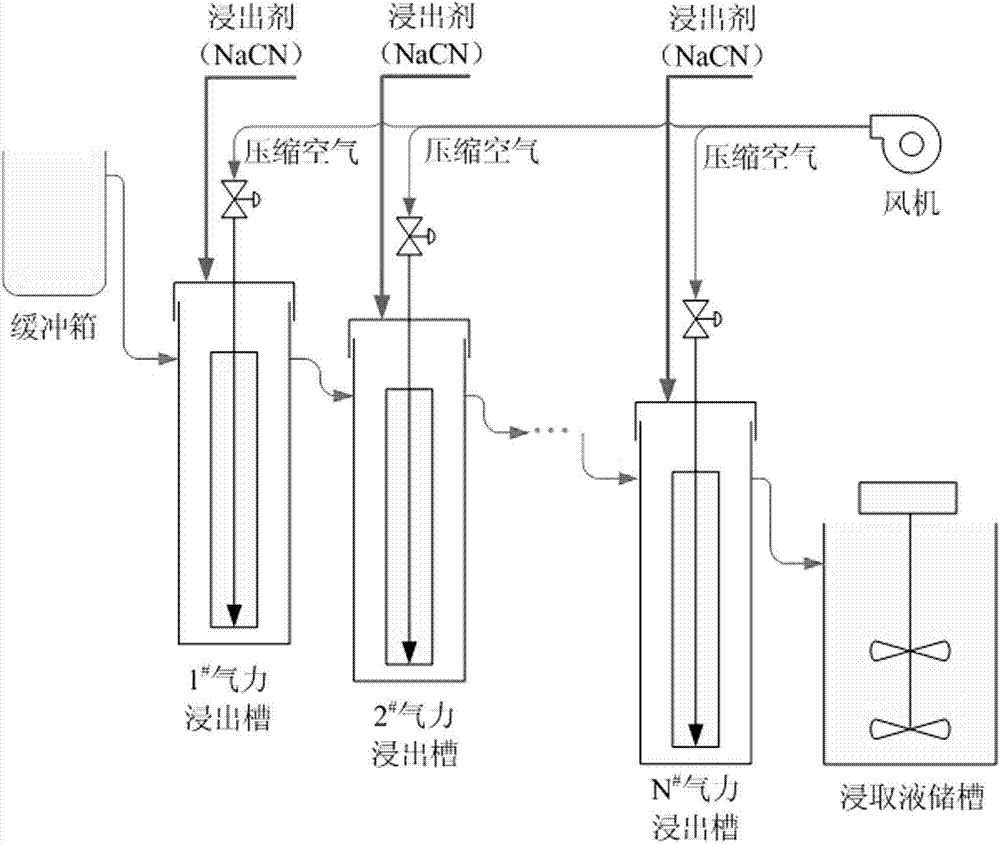

[0133] The gold leaching tanks on the production line of the gold cyanide leaching process are pneumatic leaching tanks connected in series, and the dissolved oxygen required for the leaching process is supplied by feeding compressed air into each tank and produces pneumatic stirring to make the reaction more thorough. .

[0134] 1. Prediction model independent variable and dependent variable: solid phase flow Qs in ore pulp, liquid phase flow Ql in ore pulp, sodium cyanide addition flow Qcn in each leaching tank i , the initial grade c of gold in the solid phase s0 , the initial concentration of cyanide ions in the liquid phase c cn0 , the initial concentration of gold in the liquid phase c l0 , leaching rate a.

[0135] 2. Data set: Collect the actual production data (independent variable and dependent variable) of the three-month leaching process of the gold cyanide leaching workshop corres...

Embodiment 2

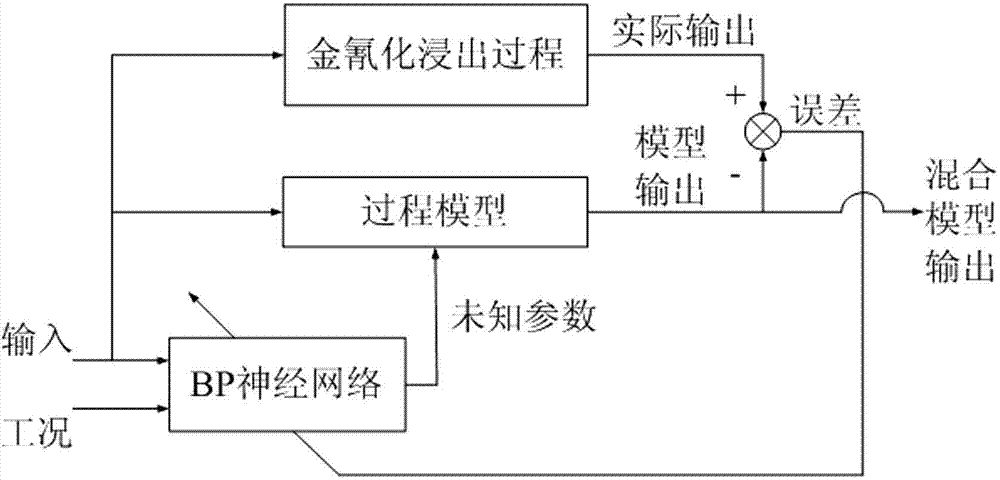

[0156] Example 2: Prediction of the total leaching rate in the leaching process

[0157] This embodiment considers the prediction of the total leaching rate of the entire cyanide leaching workshop.

[0158] In order to verify the prediction accuracy of the serial mixing model of the present invention to the total leaching rate, we establish a serial mixing model according to a method similar to Example 1 to predict the gold leaching rate in the historical production data, and compare the predicted results of the model with The actual value of the off-line test in the laboratory was compared, and 30 test data samples were selected, and the mean square error was 0.0624. Table 2 shows the actual value of the off-line test and the serial mixed model of the total leaching rate of the gold cyanide leaching process after standardization. Predicted values, forecast error values, and curve trends. In summary, the prediction accuracy of the serial mixing model established by the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com