Method for recovering copper from copper flotation system liquids of tailings after cyaniding gold extraction

A technology for cyaniding tailings and recovering copper, which is applied in the field of copper recovery, can solve problems such as the lack of effective treatment methods, the inability to effectively recover metal copper, and environmental pollution, so as to achieve great environmental benefits and social benefits, and improve resource integration Use and increase the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

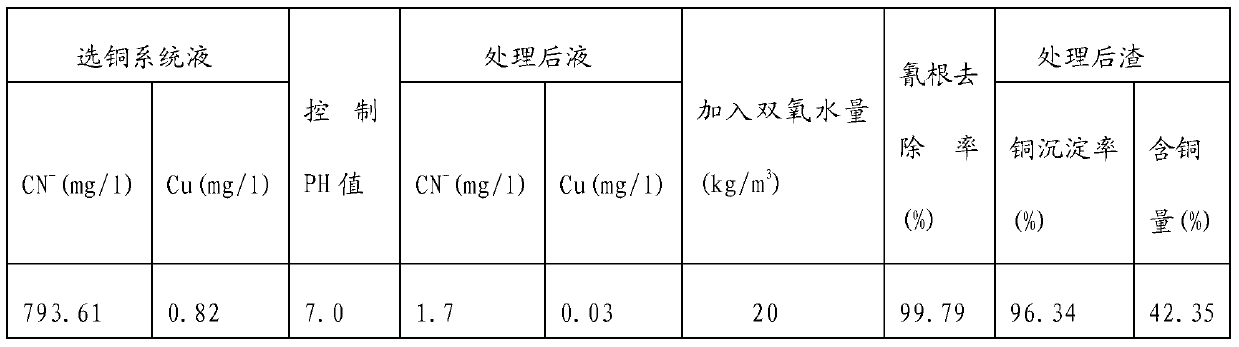

Embodiment 1

[0021] One-step direct cyanidation of gold concentrate suitable for direct cyanidation treatment

[0022] Grind the gold concentrate suitable for direct cyanidation treatment, adjust the slurry concentration to 30%, control the mass percentage concentration of sodium cyanide at 0.55%, carry out stirring and leaching for 72 hours, and then filter and wash to obtain precious liquid containing gold and silver and cyanide Chemical tailings, precious liquid for replacement and extraction of gold;

[0023] Two-step cyanidation tailings for lead separation to produce lead concentrate and lead separation tailings

[0024] Concentrate the cyanide tailings, press filter, adjust the slurry of the produced filter cake, add lime, control the pH=9.5, add 0.008% collector butyl xanthate and 0.008% foaming agent 2# flotation oil, Carry out the operation of first roughing, second refining and second sweeping of lead, the resulting lead concentrate is sold after pressure filtration, and the le...

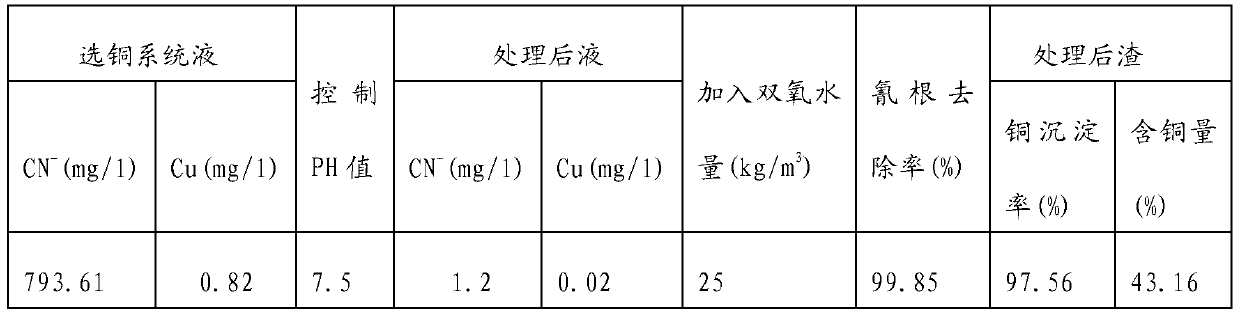

Embodiment 2

[0032] One-step direct cyanidation of gold concentrate suitable for direct cyanidation treatment

[0033] Grind the gold concentrate suitable for direct cyanidation treatment, adjust the slurry concentration to 33%, control the mass percentage concentration of sodium cyanide at 0.58%, carry out stirring and leaching for 72 hours, and then filter and wash to obtain precious liquid containing gold and silver and cyanide Chemical tailings, precious liquid for replacement and extraction of gold;

[0034] Two-step cyanidation tailings for lead separation to produce lead concentrate and lead separation tailings

[0035] Concentrate the cyanide tailings, press filter, adjust the slurry of the produced filter cake, add lime, control the pH=10.0, add 0.010% collector butyl xanthate and 0.010% foaming agent 2# flotation oil, Carry out the operation of first roughing, second refining and second sweeping of lead, the resulting lead concentrate is sold after pressure filtration, and the l...

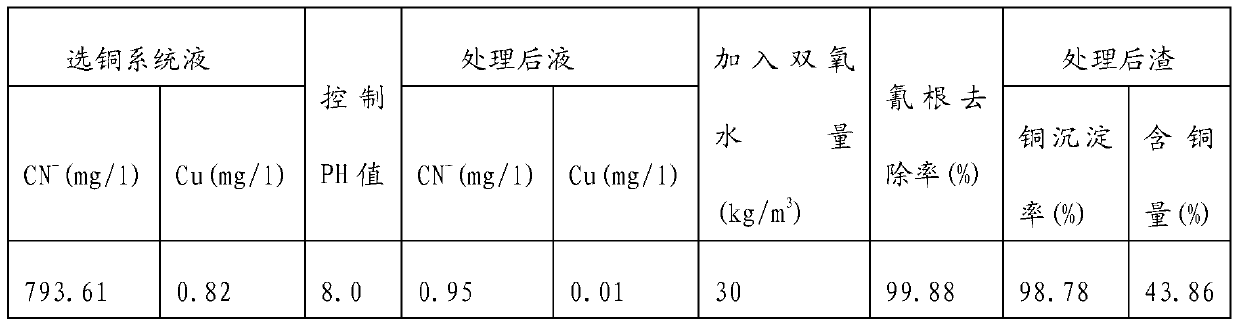

Embodiment 3

[0043] One-step direct cyanidation of gold concentrate suitable for direct cyanidation treatment

[0044]Grind the gold concentrate suitable for direct cyanidation treatment, adjust the slurry concentration to 35%, control the mass percentage concentration of sodium cyanide at 0.60%, carry out stirring and leaching for 72 hours, and then filter and wash to obtain precious liquid containing gold and silver and cyanide Chemical tailings, precious liquid for replacement and extraction of gold;

[0045] Two-step cyanidation tailings for lead separation to produce lead concentrate and lead separation tailings

[0046] Concentrate the cyanide tailings, press filter, adjust the slurry of the produced filter cake, add lime, control the pH=11.5, add 0.012% collector butyl xanthate and 0.012% foaming agent 2# flotation oil, Carry out the operation of first roughing, second refining and second sweeping of lead, the resulting lead concentrate is sold after pressure filtration, and the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com