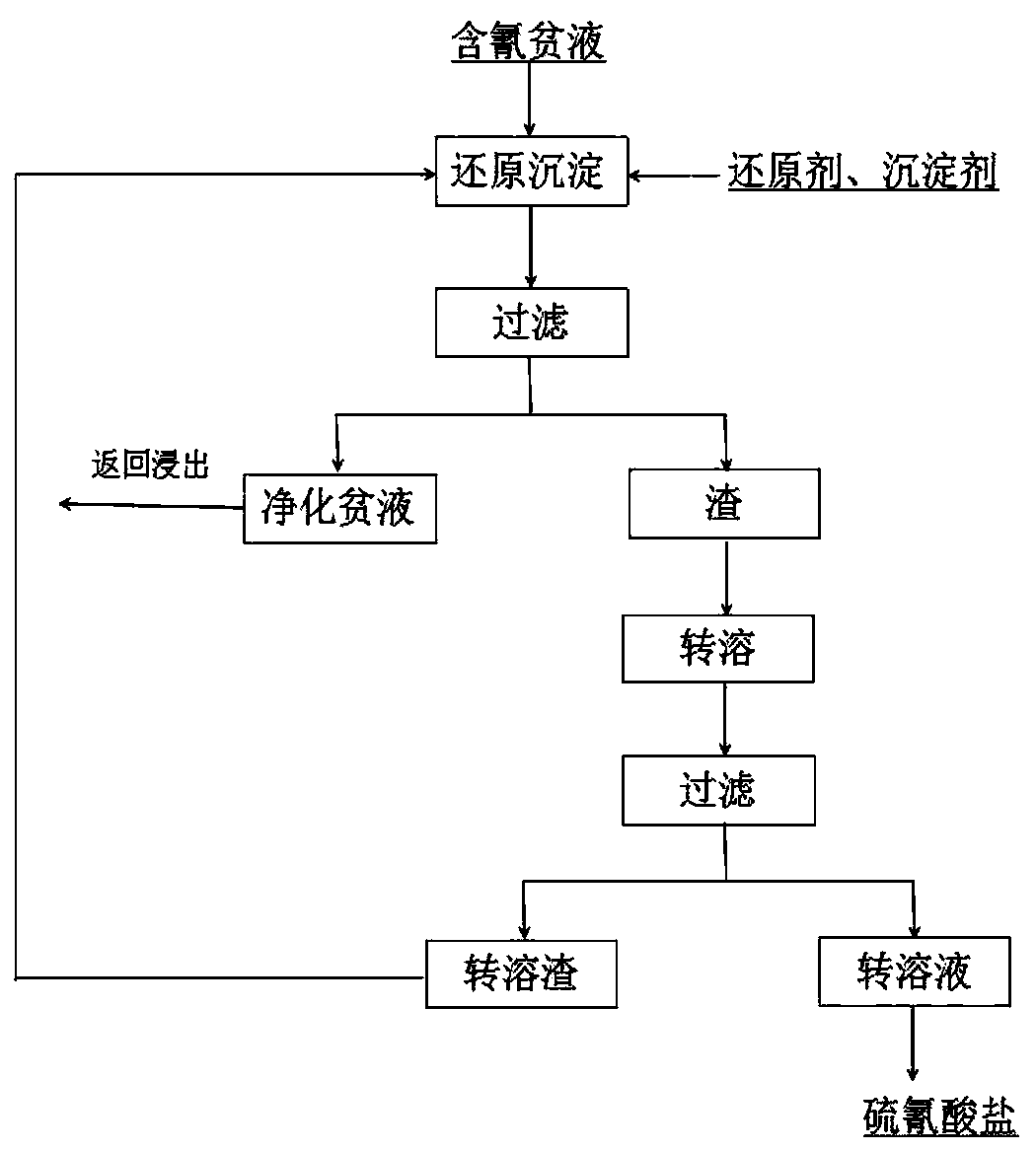

Method for realizing short-process and green cyclic utilization of cyanogen-containing barren solution

A short process, lean liquid technology, applied in the direction of thiocyanic acid, process efficiency improvement, etc., can solve the problems of low current efficiency, low precipitation purity, high processing cost, achieve recycling, significant economic benefits, and improve dissolution rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

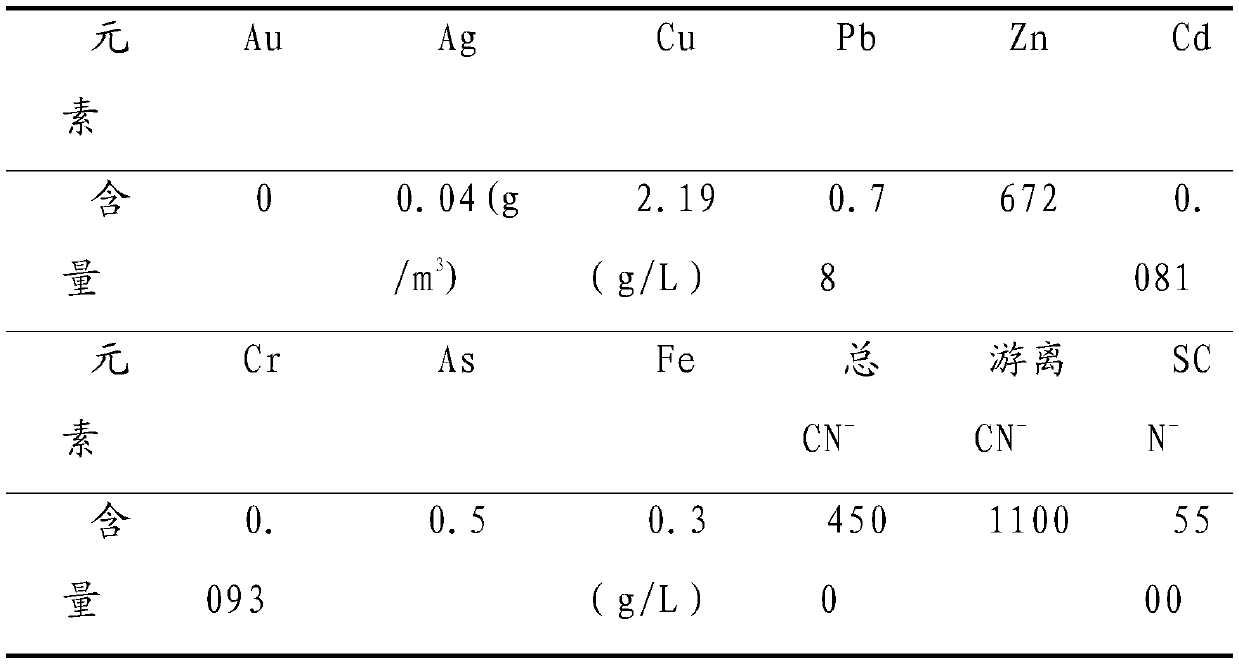

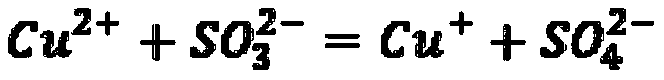

[0044] (1) Take 2L of cyanogen-containing poor solution, that is, 2L of high-concentration thiocyanate-containing coking wastewater, and add NaHSO 3 18g, CuSO 4 ·5H 2 O40g was made into a solution, added dropwise evenly, keeping pH=9, stirring and reacting for 2h after the dosing was completed; adding NaHSO 3 4g, CuSO 4 ·5H 2 O6.4g was made into a solution, added dropwise evenly, kept pH=9, and stirred for 2h with air blowing; filtered to obtain the filtrate (SCN - : 77ppm, CN - : 40ppm) and reduced sediment residue, the filtrate is returned to leaching or oxidation treatment (1L / m 3 Hydrogen peroxide) total cyanide concentration is 0.15ppm, thiocyanate 8.9ppm, copper concentration 0.19g / L, and the reduction precipitation slag is processed in the next step;

[0045] (2) Use sodium hydroxide solution to adjust the pH to 14, mix it with the reduced precipitation slag according to the liquid-solid ratio of 3:1, then add 2g / L sodium sulfide, control the stirring speed at 6...

Embodiment 2

[0049] (1) Get 2L of cyanogen-containing poor liquid, which can be high-concentration thiocyanate-containing coking wastewater, or other high-concentration cyanogen-containing waste liquid, and add Na 2 SO 3 14g, CuSO 4 ·5H 2 O 35g was made into a solution, and the pH=9 was maintained. After the dosing was completed, the reaction was stirred for 1 hour; Na was added 2 SO 3 6g, CuSO 4 ·5H 2 O 10g was made into a solution, kept at pH=9, and stirred for 1 hour with blowing air; filtered to obtain the filtrate and reduced precipitate, the filtrate was returned to leaching, and the reduced precipitate was processed in the next step;

[0050] (2) Use sodium hydroxide solution to adjust the pH to 14, mix it with the reduced precipitation residue according to the liquid-solid ratio of 10:1, then add 5g / L sodium sulfide, control the stirring speed at 600r / min for leaching for 4 hours, and filter to obtain the leachate and alkali leaching residue , thiocyanate conversion rate of...

Embodiment 3

[0054] (1) Take 2L of cyanogen-containing poor solution, add Na 2 SO 3 24g, CuSO 4 ·5H 2 O 60g was made into a solution, kept at pH=9, stirred and reacted for 4h after the dosing was completed; added Na 2 SO 3 12g, CuSO 4 ·5H 2 O 15g was made into a solution, kept at pH=9, stirred with air for 4 hours; filtered to obtain the filtrate and reduced precipitate, the filtrate was returned for leaching, and the reduced precipitate was processed in the next step;

[0055] (2) Use sodium hydroxide solution to adjust the pH to 12, mix it with the reduced precipitation slag at a liquid-solid ratio of 10:1, then add 4g / L sodium sulfide, control the stirring speed at 600r / min for leaching for 2 hours, and filter to obtain the leaching solution and alkali leaching residue , thiocyanate conversion rate of 90%;

[0056] (3) Alkali leaching solution and gold-bearing ore are at a liquid-solid ratio of 3:1, adjust pH = 11, rotate at 600r / min, and leaching for 24 hours under the conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com