Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

158results about How to "Fine particle size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Engineering standardized construction process control method and system on basis of BIM (building information modeling)

InactiveCN105335559ASolve a variety of problems that are difficult to find and low in efficiencyEasy to monitor remotelySpecial data processing applicationsRemote controlComputer science

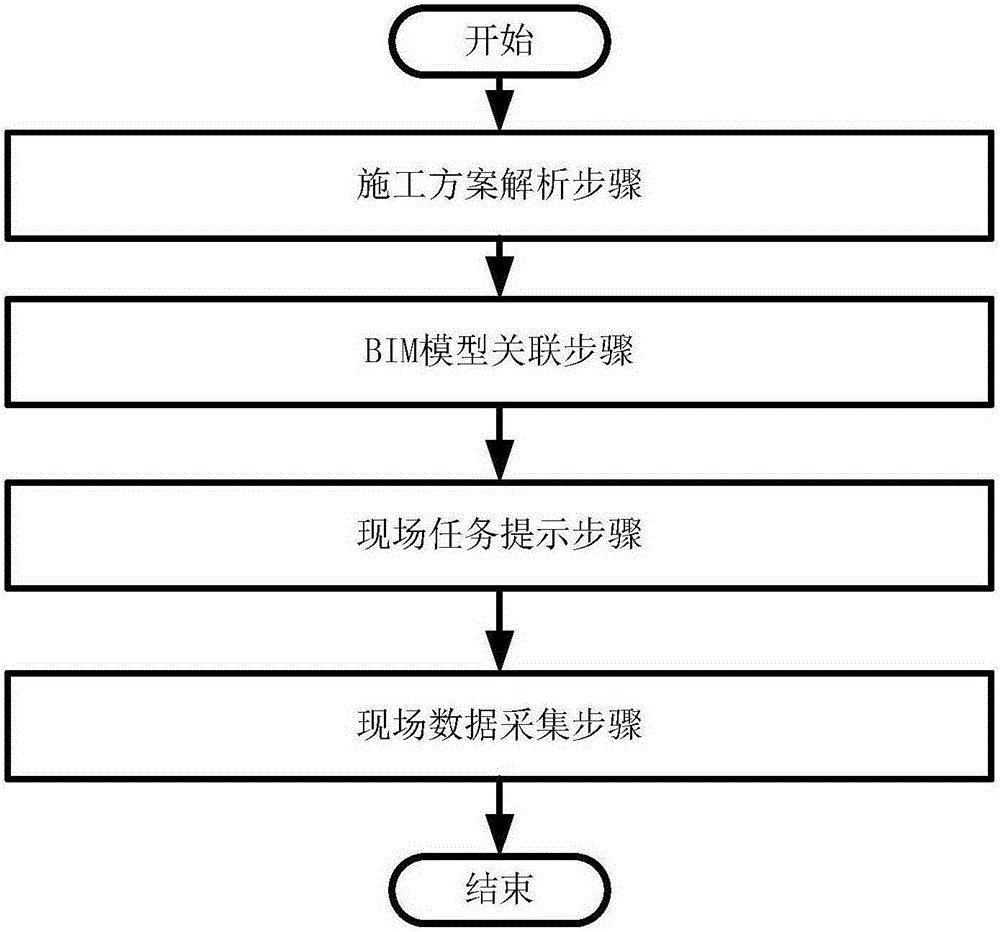

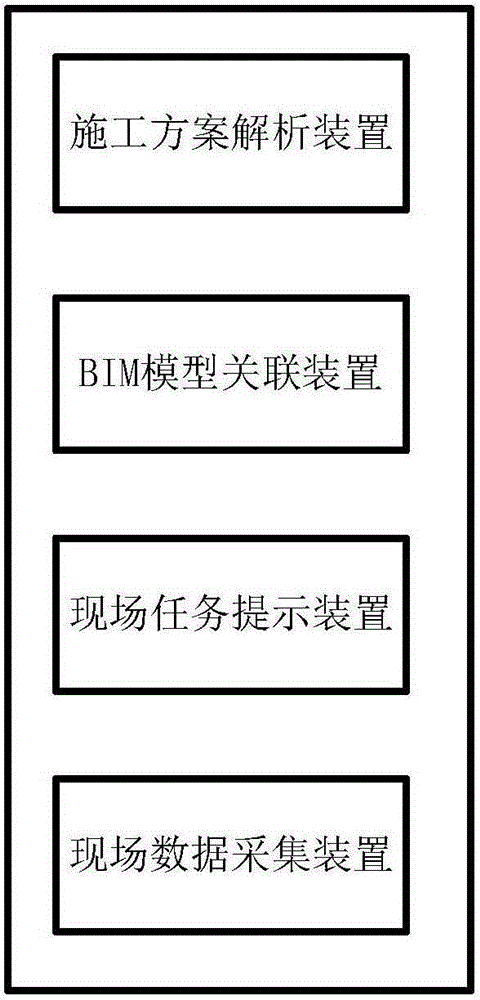

The invention provides an engineering standardized construction process control method on the basis of BIM (building information modeling). The method comprises a construction scheme analysis step, a BIM model association step, an on-site task prompt step, and an on-site data collection step. The invention also provides a corresponding system. According to the engineering standardized construction process control method and system on the basis of the BIM, each construction procedure is created or searching is performed to obtain a corresponding subtask, the subtask is associated with building components in a BIM model, according to instructing information such as subtask prompt, operation instruction and the like, the engineering which is completed and executed step by step is namely standard engineering; retention of on-site data collection can be performed in a engineering process, is convenient for tracing in the future, and remote control on live on-site construction is also convenient to be performed.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD +1

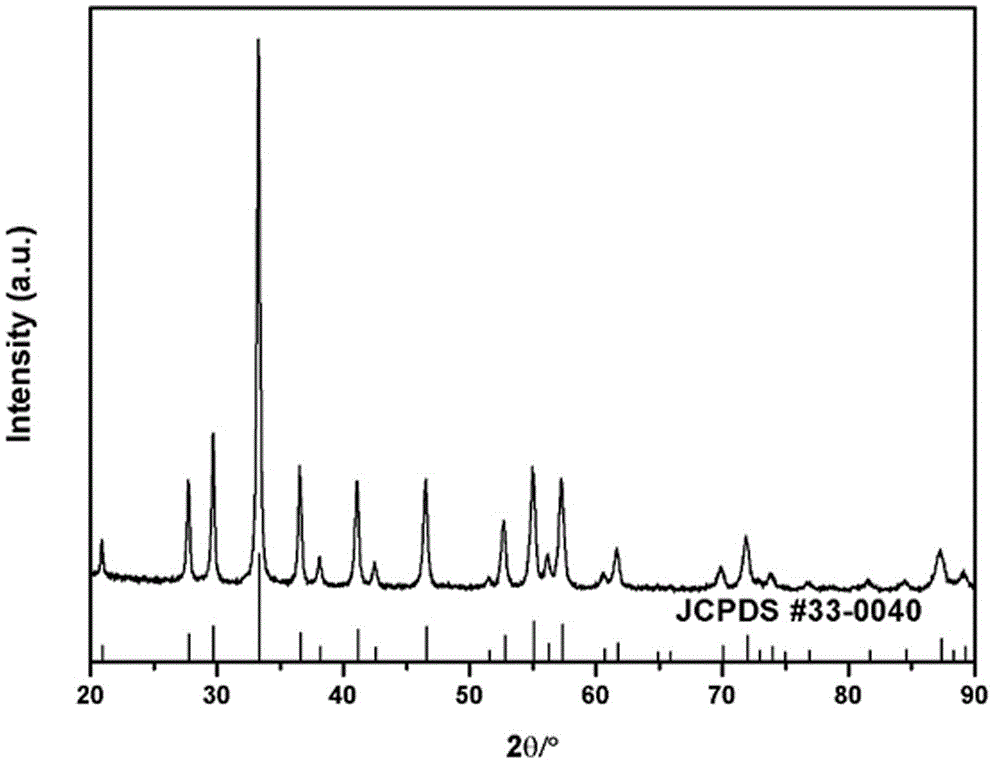

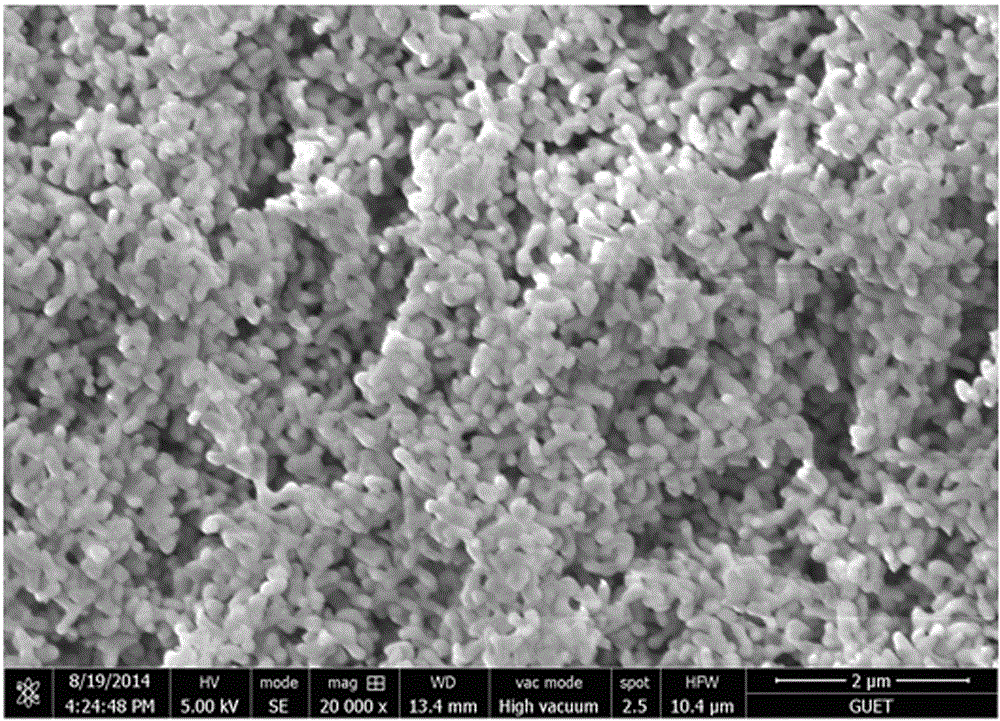

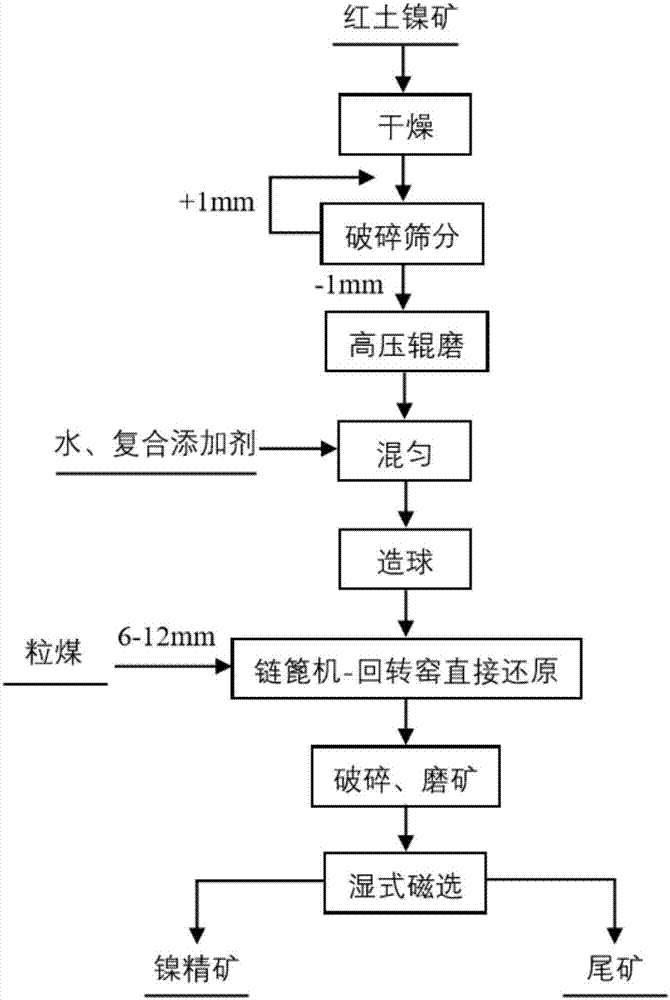

Method for preparing high-nickel concentrate from low-grade red soil nickel ore

InactiveCN102242252ALarge specific surface areaGood ball formingMagnetic separationMass ratioHigh pressure

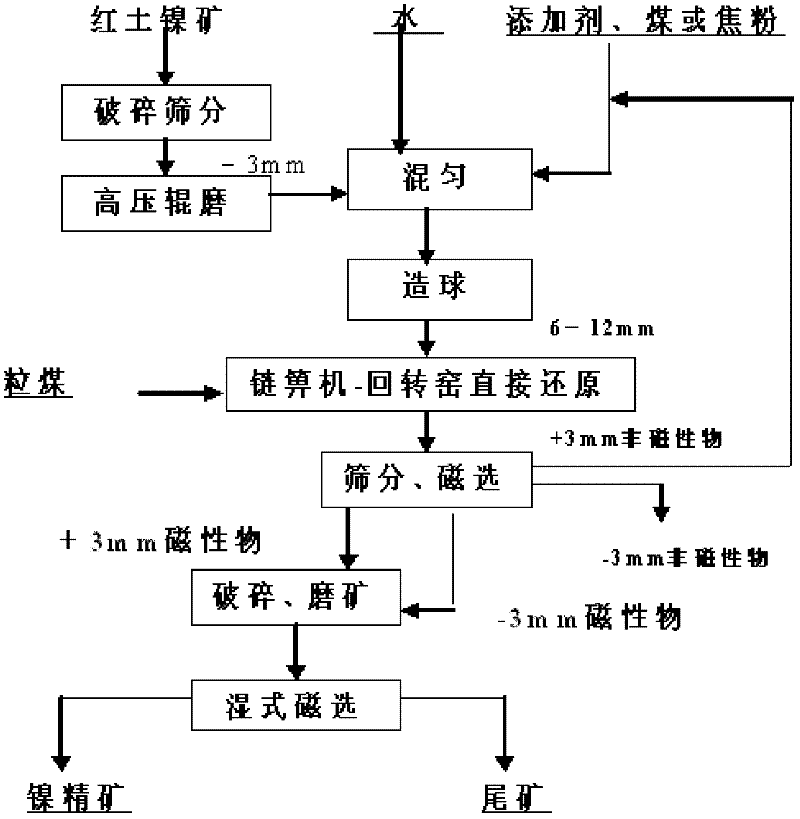

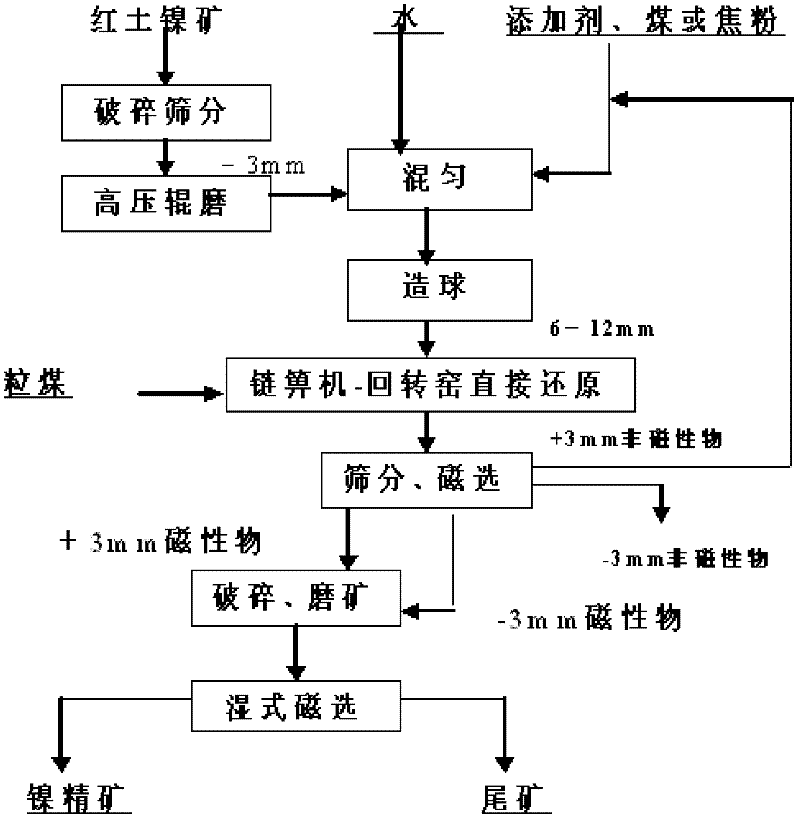

The invention discloses a method for preparing a high-nickel concentrate from a low-grade red soil nickel ore, which comprises the following steps of: drying the low-grade red soil nickel ore until water content is 13 to 16 percent, crushing to ensure that the size of all particles is less than 3mm, grinding by using a high-pressure roller mill to ensure that particles with the size of less than 0.074mm account for 80 percent and specific surface area is not less than 2,000cm<2> / g, adding 15 to 20 percent of composite binder and 1 to 5 percent of coal powder, and pelletizing by using a disc pelletizer to obtain green pellets with the size of 6 to 16mm; drying and preheating the green pellets on a chain grate for water removal and solidification to ensure that each piece of pellet entering a kiln has the compression strength of over 500N; directly adding the preheated and solidified pellets into a rotary kiln, and reducing at the temperature of between 1,100 and 1,250 DEG C for 60 to 120 minutes by using pea coal as a reducing agent in a mass ratio of the reducing coal to the pellets of 0.8-1.0; and cooling a reduction product, sieving, performing magnetic separation to obtain a magnetic product, crushing, grinding, and performing magnetic separation to obtain the high-nickel concentrate, wherein the composite additive comprises the following components: Na2CO3 and CaO, iron oxide powder, the coal powder and sodium humate in a ratio of (30-60):(20-30):(20-30):(5-10). The method is high in adaptability and nickel recovery rate and suitable for mass production.

Owner:CENT SOUTH UNIV

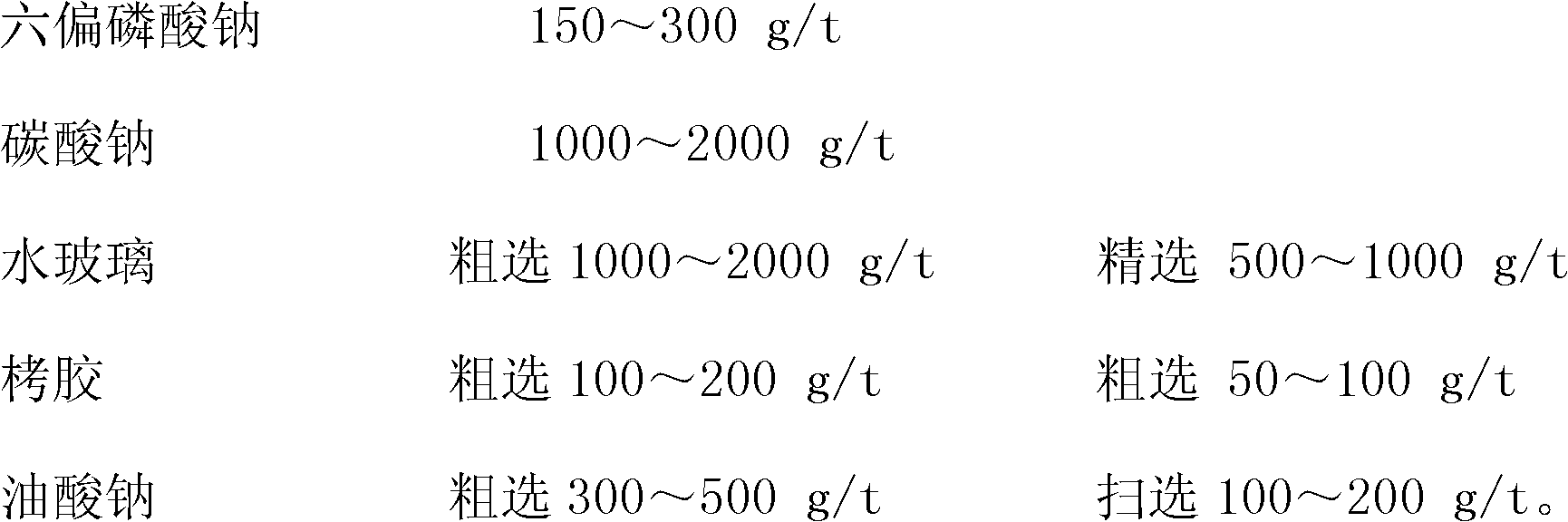

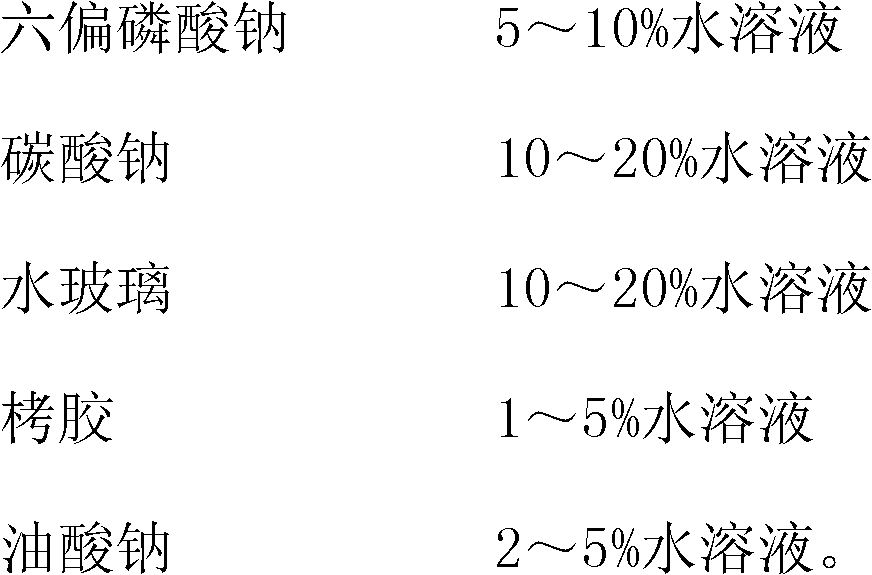

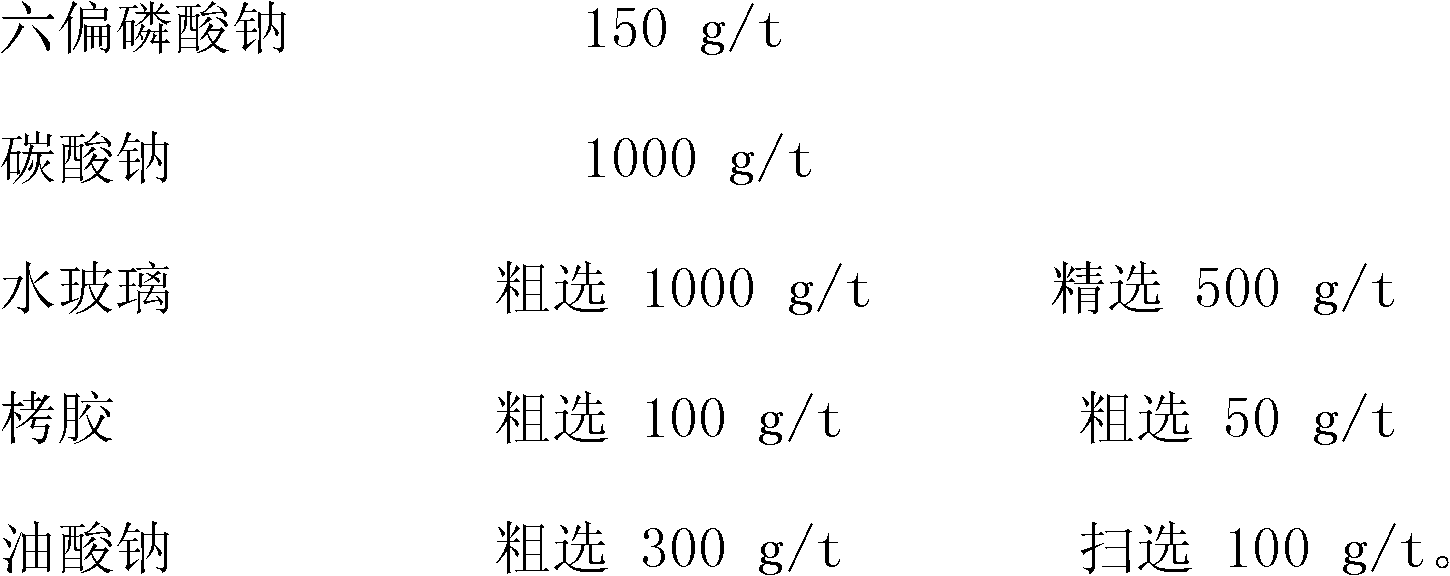

Method for recovering fine mud cassiterite

The invention discloses a method for recovering fine mud cassiterite. The method comprises the following steps of dispersing a fine mud cassiterite mineral in an agitator by using sodium hexametaphosphate as a dispersing agent, grading the fine mud cassiterite mineral by using a high frequency fine screen, recovering the graded fine mud cassiterite mineral through gravity separation by using a fine mud cassiterite table concentrator to obtain fine mud rough concentrates in different particle sizes, and combining the fine mud rough concentrates in different particle sizes and performing floatation recovery on the fine mud cassiterite to obtain a cassiterite concentrate. By the method, the fine mud cassiterite can be effectively recovered, and the fine mud cassiterite concentrate of which the cassiterite grade is 45.87-46.21 percent and the recovery rate is 52.51-56.75 percent can be obtained under the condition that the fed mineral has the cassiterite grade of 0.37-0.45 percent.

Owner:广西华锡集团股份有限公司

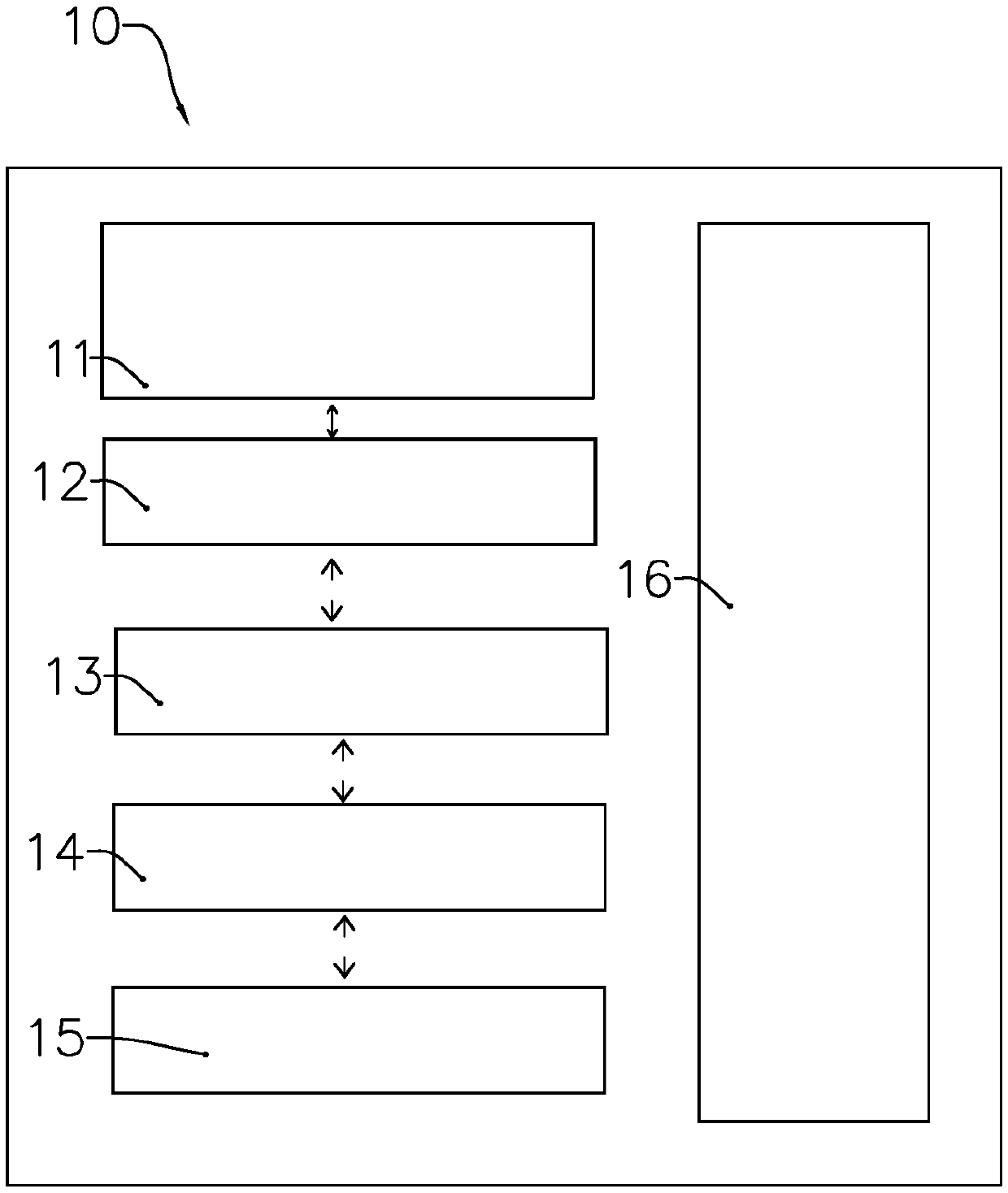

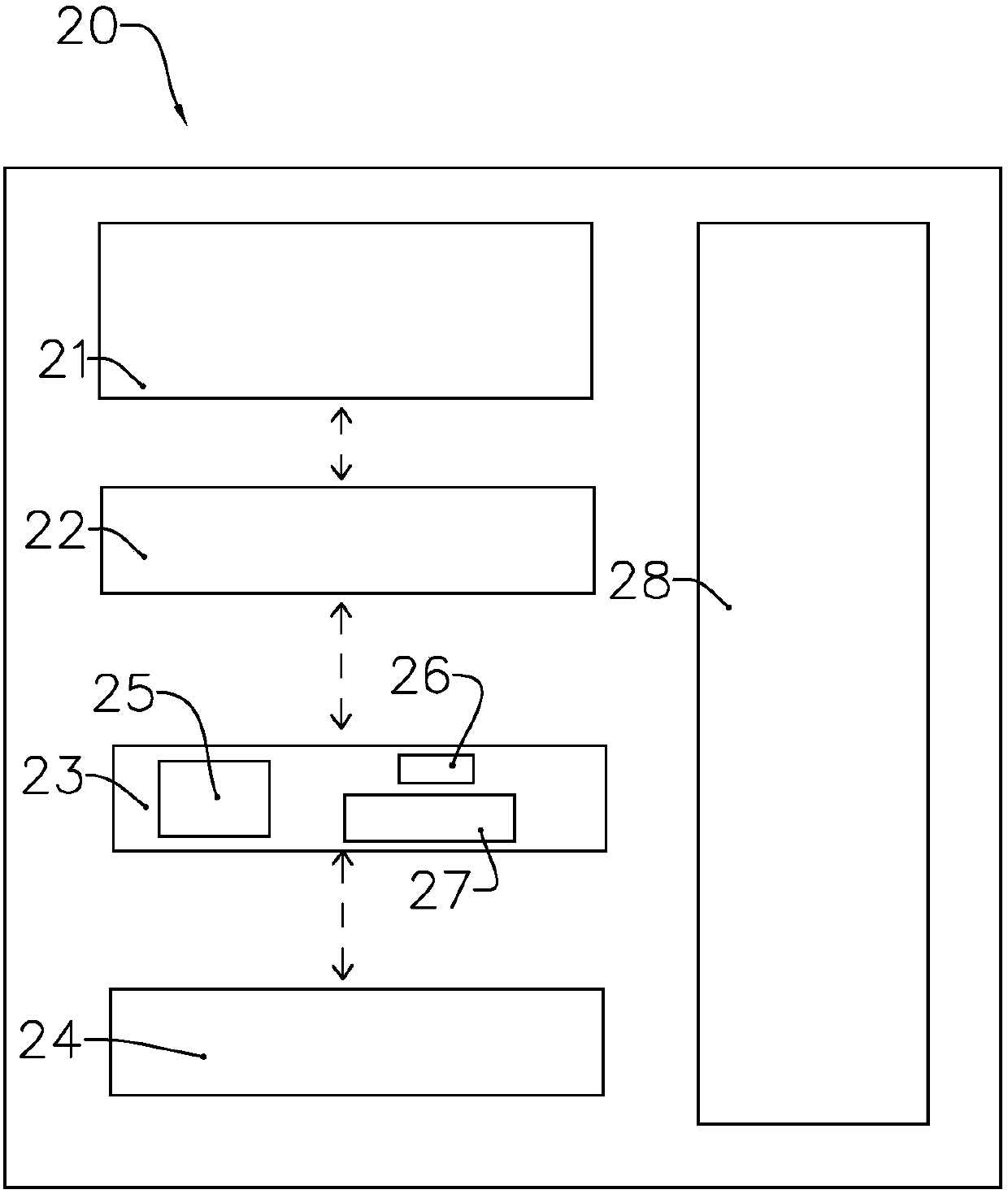

Course selection and scheduling system and method thereof

ActiveCN107610012AFlexible class schedulingFine particle sizeData processing applicationsGranularitySemi automatic

The invention relates to a course selection and scheduling system and method. The system includes a course selection system and a course scheduling system, and the course selection system and the course scheduling system can realize data exchange. The course selection system includes a first application service layer module, a first algorithm module, a data access layer module, a buffer layer module, a database module, and a database cluster level module. In addition, the course scheduling system includes a second application service layer module, a second algorithm module, a computing platform and a data storage layer module which are sequentially connected. The course scheduling mode is advantaged by flexibility, fine granularity, free constraint combination, combination of mobile learning and non-mobile learning classes, and high compatibility. The automatic schedule generation algorithm allows semi-automatic or manual distribution, the strength of course scheduling can be refined to each student, and the weight of each constraint can be flexibly adjusted to support course scheduling of mobile learning and non-mobile learning classes at the same time.

Owner:皇晓琳

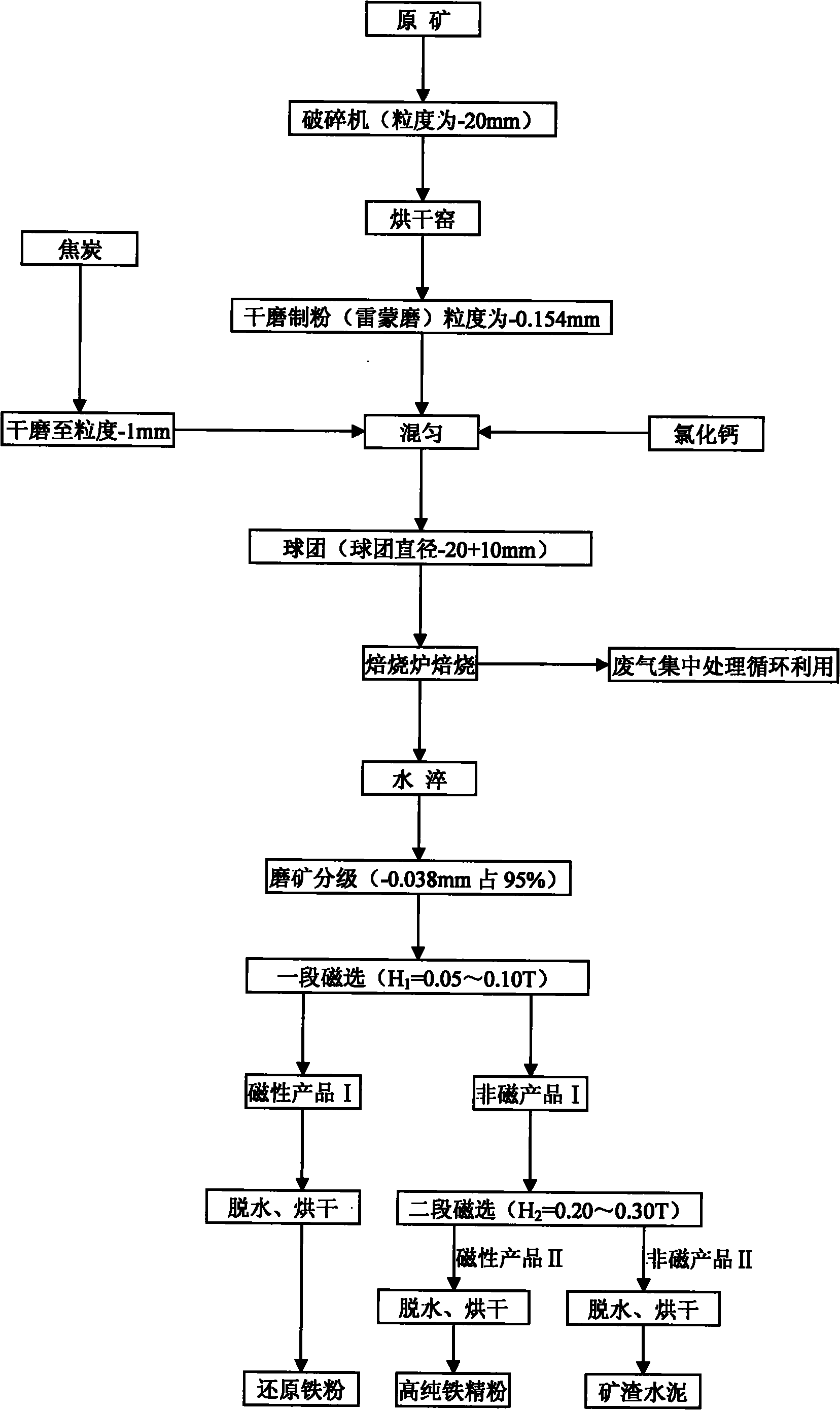

Method for preparing reductive iron powder and high-purity refined iron powder by using iron ores

The invention discloses a method for preparing reductive iron powder and high-purity refined iron powder by using iron ores. The method comprises the following steps of: ore crushing, dry grinding for preparing powder, reducing agent preparation, uniform mixing of pellet materials, pellet preparation, pellet roasting, water quenching, grinding and classification, magnetic separation, product dehydration and drying and the like so as to obtain the high-purity refined iron powder. The method has the advantages of simple process, wide application range and strong operability; the products are diversified, and the reductive iron powder and the high-purity refined iron powder can be obtained; the waste gas is reclaimed for recycling, the tailings are used as raw materials for slag cement and the tail water is used in a closed cycle mode, so the method belongs to an environment-friendly process; and the products have stable quality. The method is particularly adaptive to chlorination and reduction of the iron ores with characteristics of thin disseminated grain size, complex ore composition, high impurity (sulfur, phosphorus, arsenic and silicon) content and the like.

Owner:昆明晶石矿冶有限公司

Method for preparing ceramic material by virtue of copper tailings

ActiveCN105541296ARealize resource utilizationGood environmental benefitsCeramic materials productionClaywaresSocial benefitsSlag

The invention discloses a method for preparing a ceramic material by virtue of copper tailings, and belongs to the fields of industrial solid waste resource comprehensive utilization and environmental protection. The method comprises the following steps of ball-milling and mixing 35 to 55 parts by weight of copper tailings, 25 to 40 parts by weight of steel slag, 10 to 25 parts by weight of clay, 0 to 15 parts by weight of feldspar, 0 to 10 parts by weight of talc and the like, and executing the procedures of sieving, drying, pressing or extrusion molding, sintering and the like to obtain the ceramic material, wherein the firing temperature is 1,080 to 1,160 DEG C. According to the method, the ceramic material is synergistically prepared from the copper tailings and the steel slag, and the ratio of the using amount of industrial solid waste to the total weight of the raw materials in the ceramic material reaches 65 to 85 percent, so that the industrial solid waste can be resourcefully utilized in large scale, and obvious social benefits and environmental benefits can be achieved; the copper tailings and the steel slag are small in granularity, so that ball-milling energy consumption in a ceramic material production process can be reduced; the sintering temperature is lower, so that the sintering energy consumption of the ceramic material can be reduced, and economic benefits are achieved; the method is relatively simple in process and easy to popularize and use.

Owner:ENERGY RES INST OF JIANGXI ACAD OF SCI

Low-grade fluorite silicon reduction mineral processing process

Owner:SHANDONG ZHAOJIN GROUP

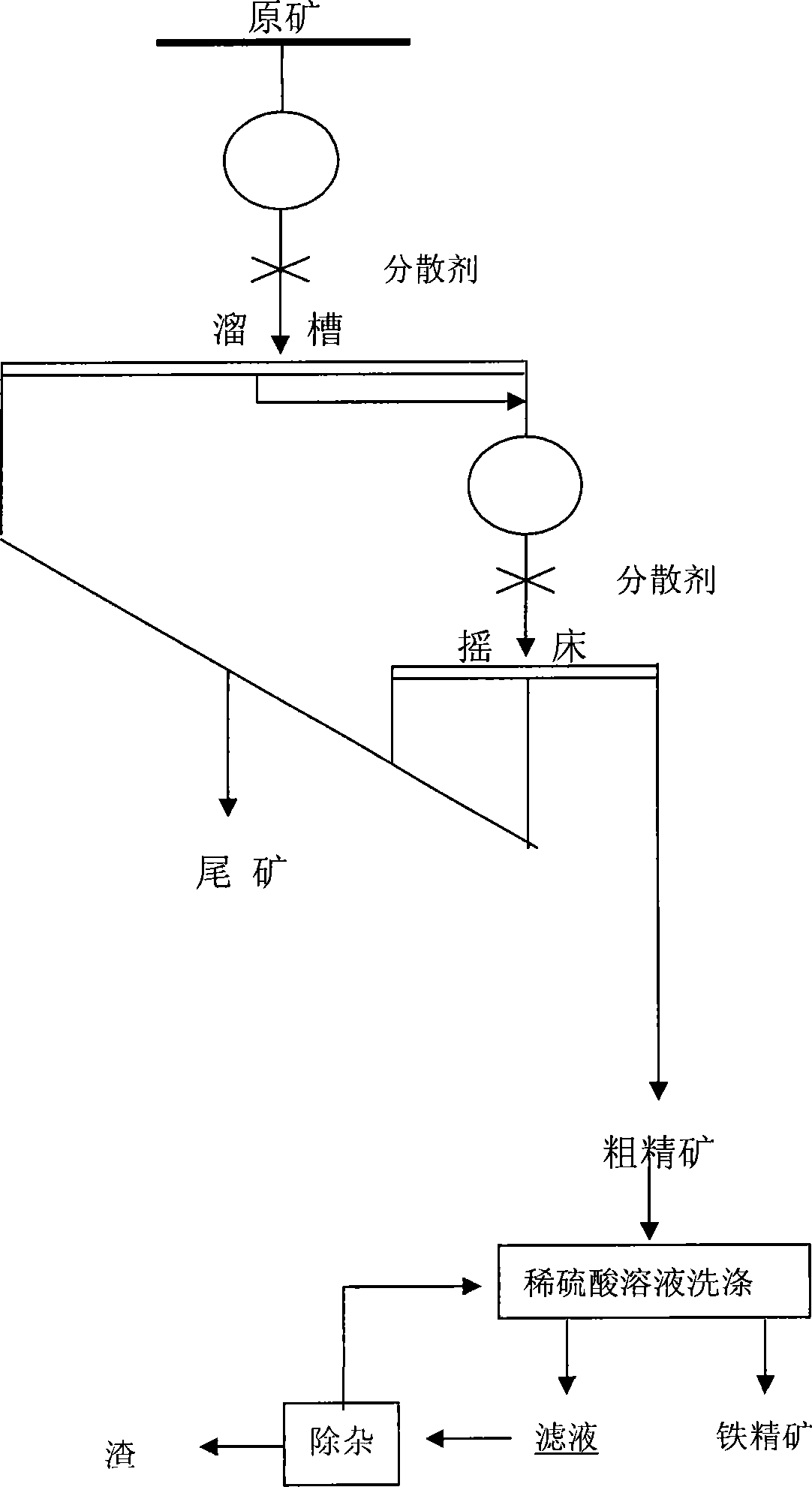

Method forpreparing iron concentrate for making iron from phosphorus-containing oolitic hematite

InactiveCN101054625AAvoid muddyingRaise the gradeProcess efficiency improvementGranularityRoom temperature

The invention discloses a method of producing iron ore concentrate containing roe - like phosphorus hematite for iron manufacture, comprising crashing the roe - like ore, wet grinding until the hematite of granularity < 0.074mm are 40-60 mass% of whole hematite, adjusting the pulp mass percent concentration to 20%-30%, adding the water glass as dispersant of 0.5-1.0kg / t, agitating adequately, selecting by helix shoot, grinding produced ore concentrate until the one with the granularity < 0.074mm are more than 80 mass%, having the water glass as dispersant of 0.2-0.5kg / t, agitating to disperse uniformly, then selecting by shaking table, washing produced iron ore concentrate in room temperature by 0.5%-1.5% dilute sulfuric acid solution for 5-15 minutes, centrifugal separation, in which the solid are iron ore concentrate. The invention treats the roe - like phosphorus hematite to obtain the iron ore concentrate with a tenor of 62%, P content less than 0.06%. The invention can fully and reasonably apply rich roe - like phosphorus hematite resource in our country, has a good effect of dephosphorization and a low cost. And produced iron ore concentrate have a high recovery ratio.

Owner:CENT SOUTH UNIV

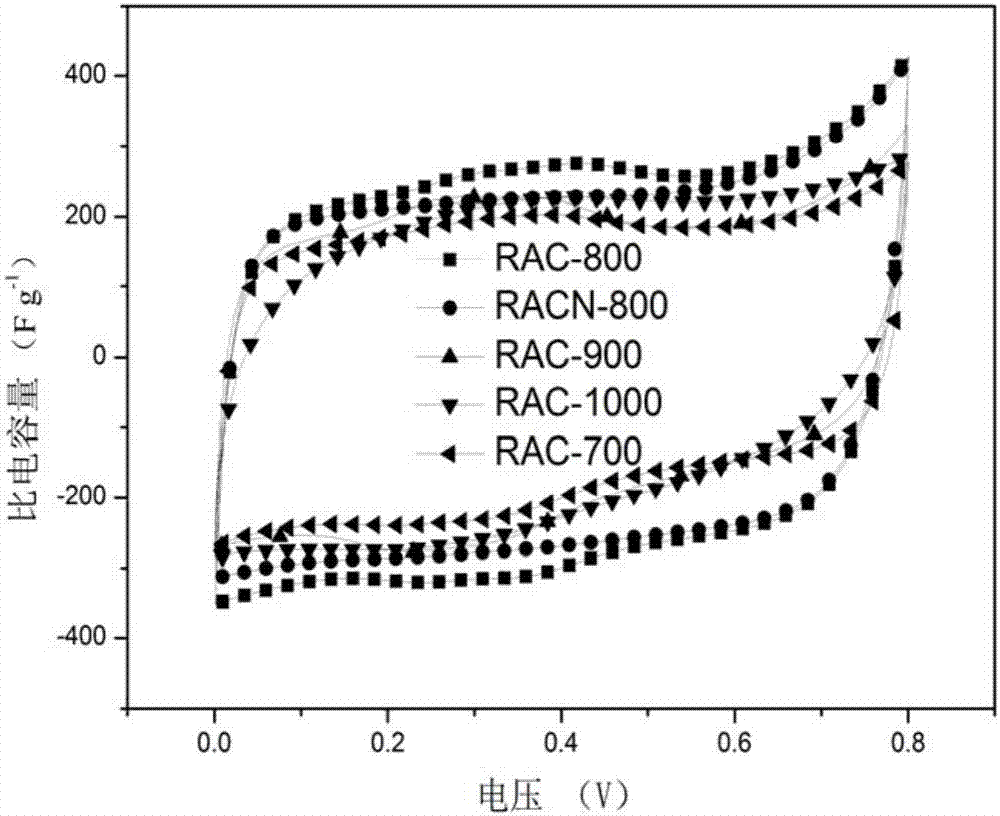

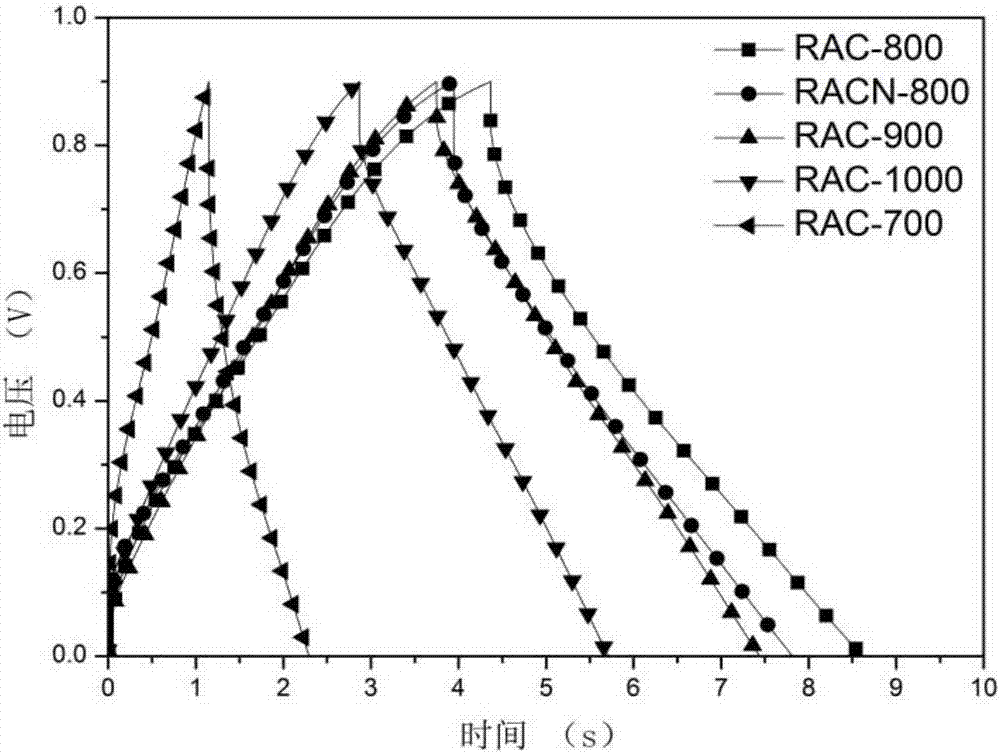

Preparation method of starch-based super-capacitor active carbon material

ActiveCN107043109AWide variety of sourcesFine particle sizeCarbon compoundsAir atmosphereCarbonization

The invention discloses a preparation method of a starch-based super-capacitor active carbon material. The preparation method comprises following steps: 1, a starch-based biomass raw material is subjected to low temperature carbonization treatment, an obtained carbonized product is washed respectively with hydrochloric acid, nitric acid, and deionized water so as to remove inorganic impurities; 2, a hydroxide is prepared into an aqueous solution, the obtained aqueous solution is mixed with a starch-based carbonized material obtained in step 1, and an obtained mixed material is subjected to dipping and drying; 3, starch-based carbonized material particles obtained via dipping of the alkaline solution in step 2 are delivered into a calciner for calcining activation at air atmosphere, and natural cooling is adopted for cooling to room temperature; and 4, an active carbon material obtained via activation is subjected to acid pickling, water washing, and drying so as to obtain the powdery starch-based super-capacitor active carbon material without grinding. The raw materials are widely available and cheap; the preparation method is simple; yield is high; product particle size is uniform; the sphere diameter and the specific surface area are controllable; and the preparation method is suitable for instrulized production.

Owner:南京正森环保科技有限公司

Copper powder for electrically conductive paste, and electrically conductive paste

InactiveCN101896629AFine copper powderExcellent oxidation resistanceFixed capacitor electrodesTransportation and packagingElectrically conductiveCopper

Disclosed is a copper powder which has a good balance between oxidation resistance and electrical conductivity in spite of having a small grain size. Also disclosed is a copper powder for use in an electrically conductive paste, which is reduced in the variations in shape or grain size and has a low oxygen content. Further disclosed is an electrically conductive paste. In the copper powder for an electrically conductive paste, Si (silicon) is contained in the inside of each particle at a content of 0.1 to 10 atm%.

Owner:MITSUI MINING & SMELTING CO LTD

Production method and device of zinc dust

InactiveCN102105608AEasy to controlFine particle sizeCrucible furnacesMethods of productionZinc products

A method of production of Zinc dust, which includes melting Zinc products in a melting furnace on a semi-continuous basis, transferring at least a part of the molten Zinc products to a vaporizing furnace, vaporizing the molten Zinc in the vaporizing furnace into Zinc vapour on a substantially continuous basis, transferring Zinc vapour from the vaporizing furnace to a condenser, and condensing the Zinc vapour to form Zinc dust and cycling the Zinc vapour in the condenser and making the Zinc vapour pass through a cyclone type cooler. A Zinc dust production device includes a vertical crucible melting furnace (12), a vertical crucible vaporizing furnace (14), a condenser (18) in fluid flow communication with the vaporizing furnace for receiving Zinc vapour into the condenser, wherein the condenser is provided with a heat exchanger in the form of a vapour cycle system (58).

Owner:ZINCHEM A DIV OF ZIMCO GROUP

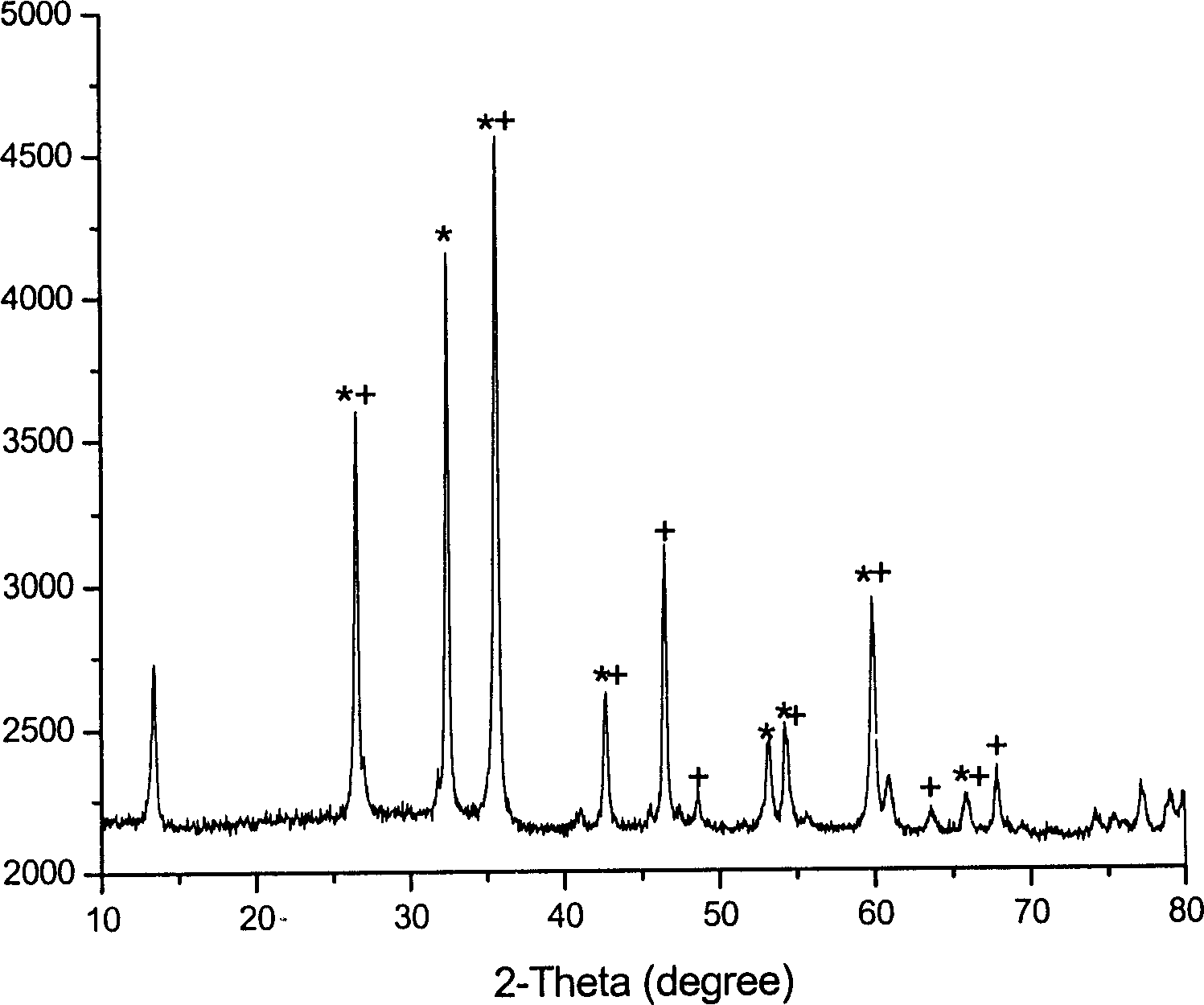

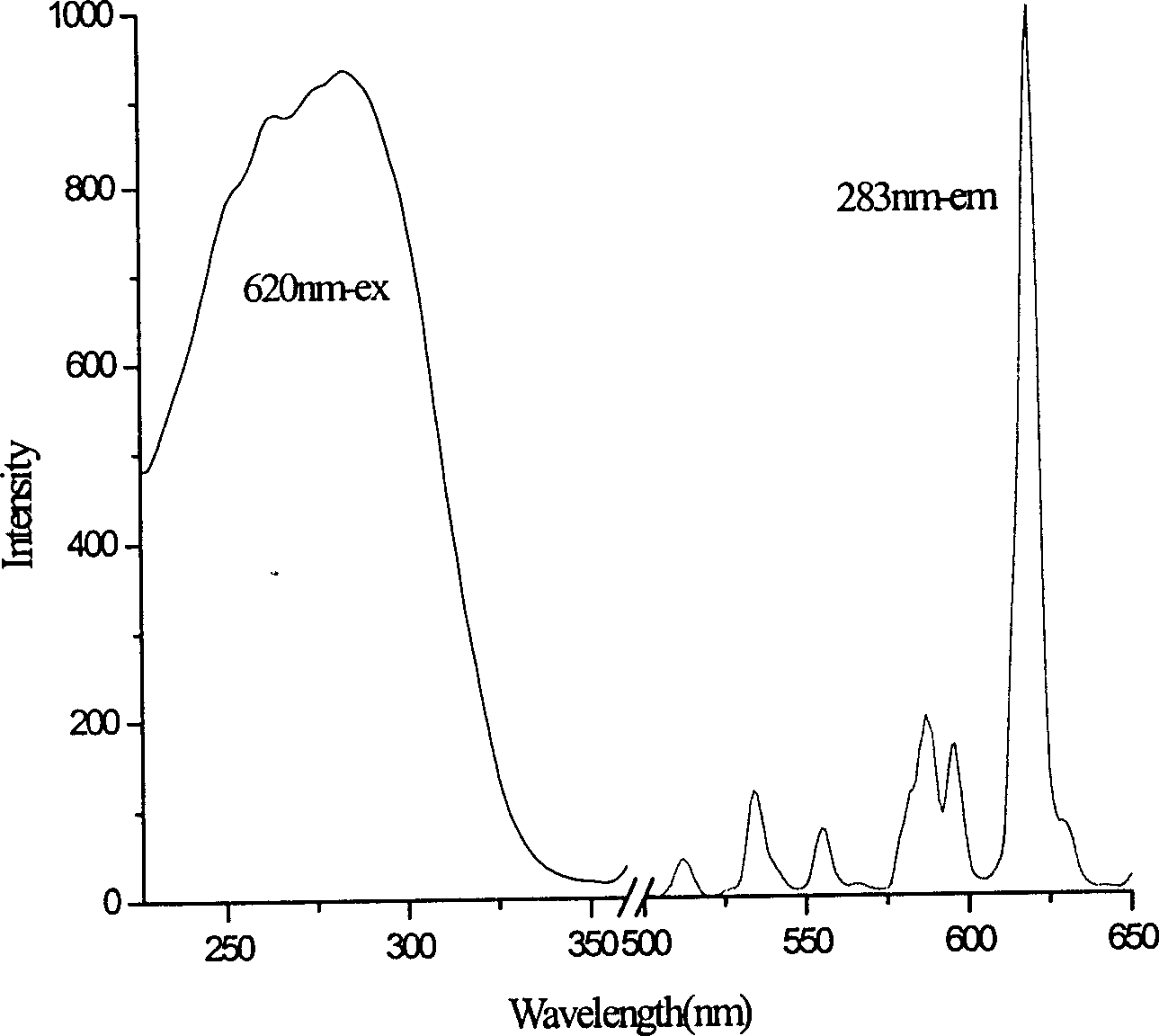

Rare earth nano silicate red phosphor and its preparation method

InactiveCN1702145AImprove light color purityFine particle sizeLuminescent compositionsLuminous intensityEngineering

The invention discloses a rare-earth nanometer metasilicate red fluorophor and the method for preparation. It contains the following setups: dissolving sensitizer activator substrate yttrium oxide in norbiline (or azotic acid), pressure-reduced distilling to eliminate water and excess acid, adding alcohol to prepare clear and transparent solution, and adding substrate silicon material to prepare transparent sol, pressure-reduced distilling to eliminate alcohol and acquiring powder solid, and adglutinating in 550-750 Deg. C by 2-4 hours to prepare the product. It prepares rare-earth nanometer red fluorescent powder in a low temperature (600 Deg. C) and a short time (3 hours), the average grain diameter being about 60-80 nm, the luminous intensity strong, chemical and optical property stable, the material easily obtained and cheap. Chemical expression formula of the rare-earth nanometer red fluorescent powder is as following: (YxSiy0z: Euj, Mn.

Owner:SHANGHAI NORMAL UNIVERSITY

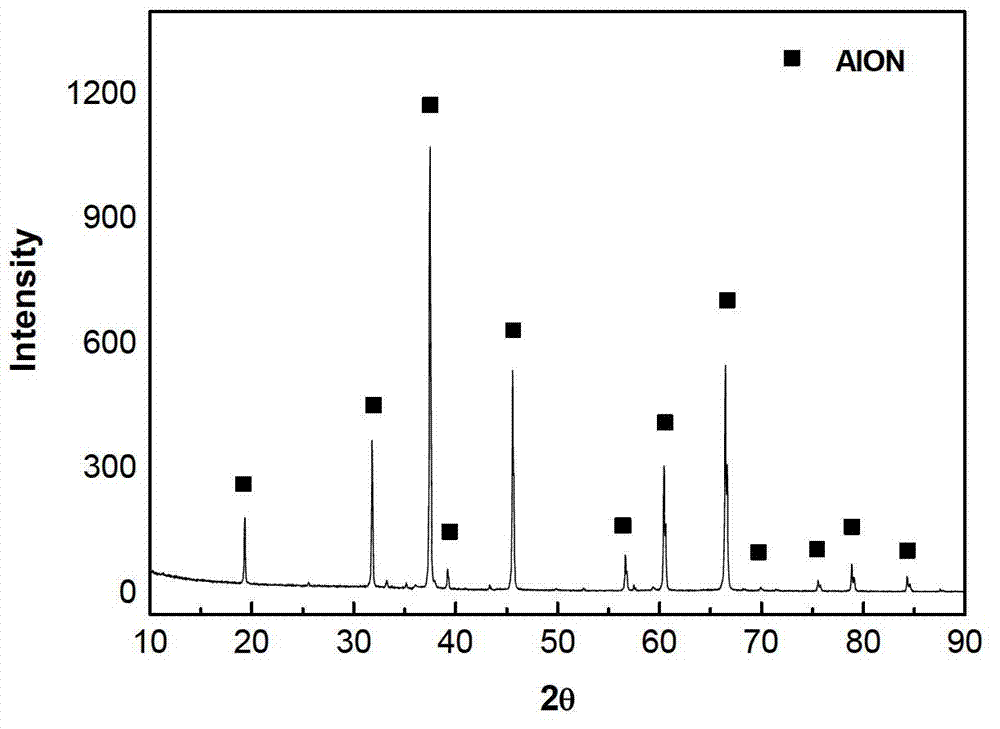

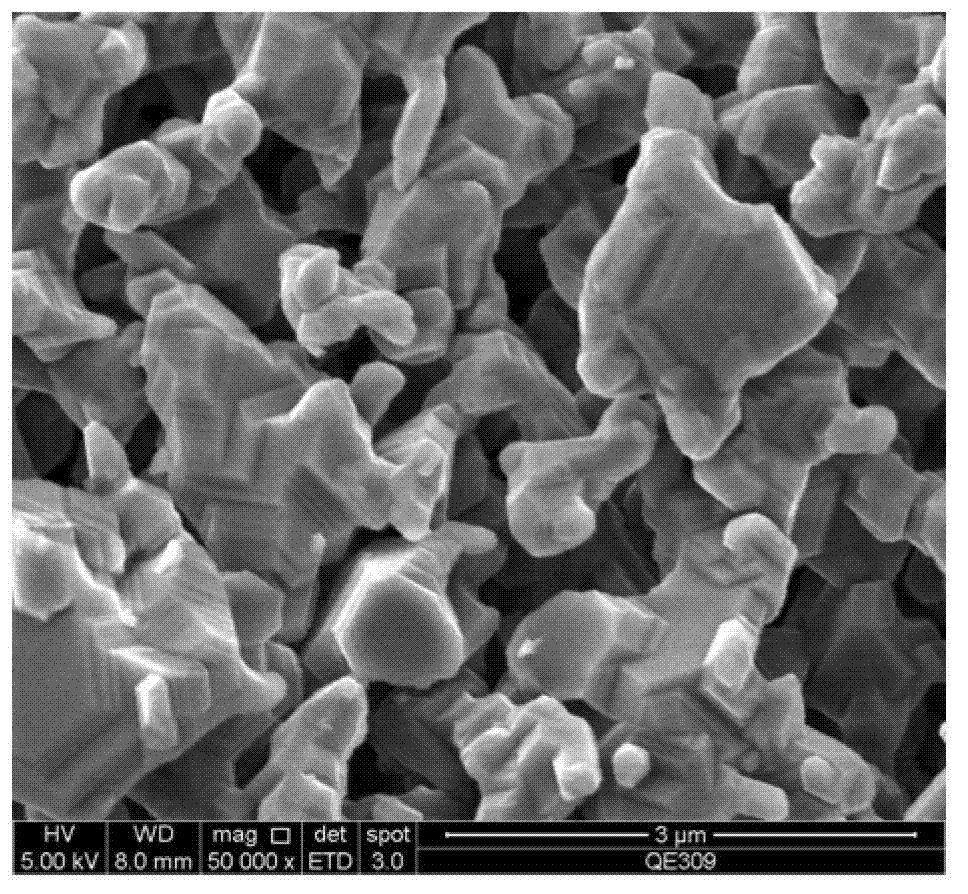

Method for rapidly preparing AlON ceramic powder by means of carbon thermal reduction

The invention provides a method for rapidly preparing AlON ceramic powder by means of carbon thermal reduction. The method takes low-cost gamma-Al2O3 powder and a carbon source, uniformly mixing the raw materials by means of wet-process ball milling, then drying and putting the raw materials in a zirconium oxide crucible, conducting a high-temperature carbon thermal reduction nitridation reaction at the high-pressure nitrogen atmosphere of 0.1-1MPa, quickly synthesizing the AlON powder, and then removing carbon at the low temperature of 500-900 DEG C to obtain the superfine, high-purity and uniformly dispersed single-phase AlON powder. Compared with the prior art, rapid sintering and carbon thermal reduction are combined under the condition of high nitrogen pressure, so that the activity of the AlON powder is improved, the preparation process is simplified, the preparation cost is lowered, and the method has an excellent industrialized application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

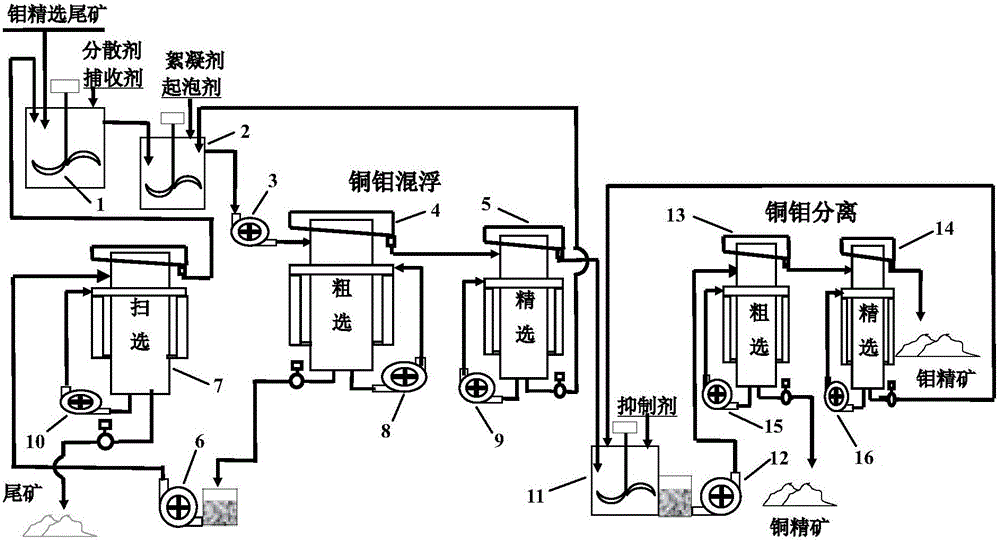

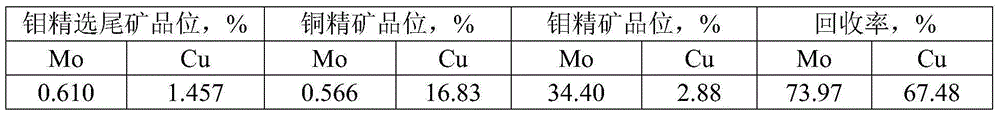

Selective flocculation-column flotation recovery method and system of micro-fine particle molybdenum cleaner tailings

InactiveCN104984835AEnsure efficient sortingGood sorting effectDifferential sedimentationFlotationParticle separationCopper

The invention discloses a selective flocculation-column flotation recovery method and system of micro-fine particle molybdenum cleaner tailings. The method includes the following steps that: a dispersing agent and a collecting agent are added, so that first stirring and pulp conditioning is performed, and therefore, mineral particles can be fully dispersed, and the surface hydrophobicity of target mineral particles can be improved; a flocculating agent and a foaming agent are added, so that second stirring and pulp conditioning is performed, and therefore, the target mineral particles can be flocculated selectively; the cyclonic-static fine bubble floatatation column is utilized to perform copper-molybdenum mixed floating, and a roughing-concentration-scavenging floatation process is adopted, and as a result, copper-molybdenum mixed floated concentrates and tailings can be obtained; an inhibitor is added in the copper-molybdenum mixed floated concentrates, so that third stirring and pulp conditioning is performed; and the cyclonic-static fine bubble floatatation column is utilized to perform copper-molybdenum separation, and a roughing-concentration floatation process is adopted, so that molybdenum concentrates and copper concentrates can be obtained. According to the selective flocculation-column flotation recovery method and system of micro-fine particle molybdenum cleaner tailings of the invention adopted, two kinds of micro-fine particle separation ways, namely, selective flocculation and column flotation, are adopted to recover molybdenum and copper in molybdenum concentrates and tailings, and therefore, the comprehensive utilization rate of mineral resources can be improved, and the selective flocculation-column flotation recovery method and system have excellent economic benefits and social benefits.

Owner:CHINA UNIV OF MINING & TECH

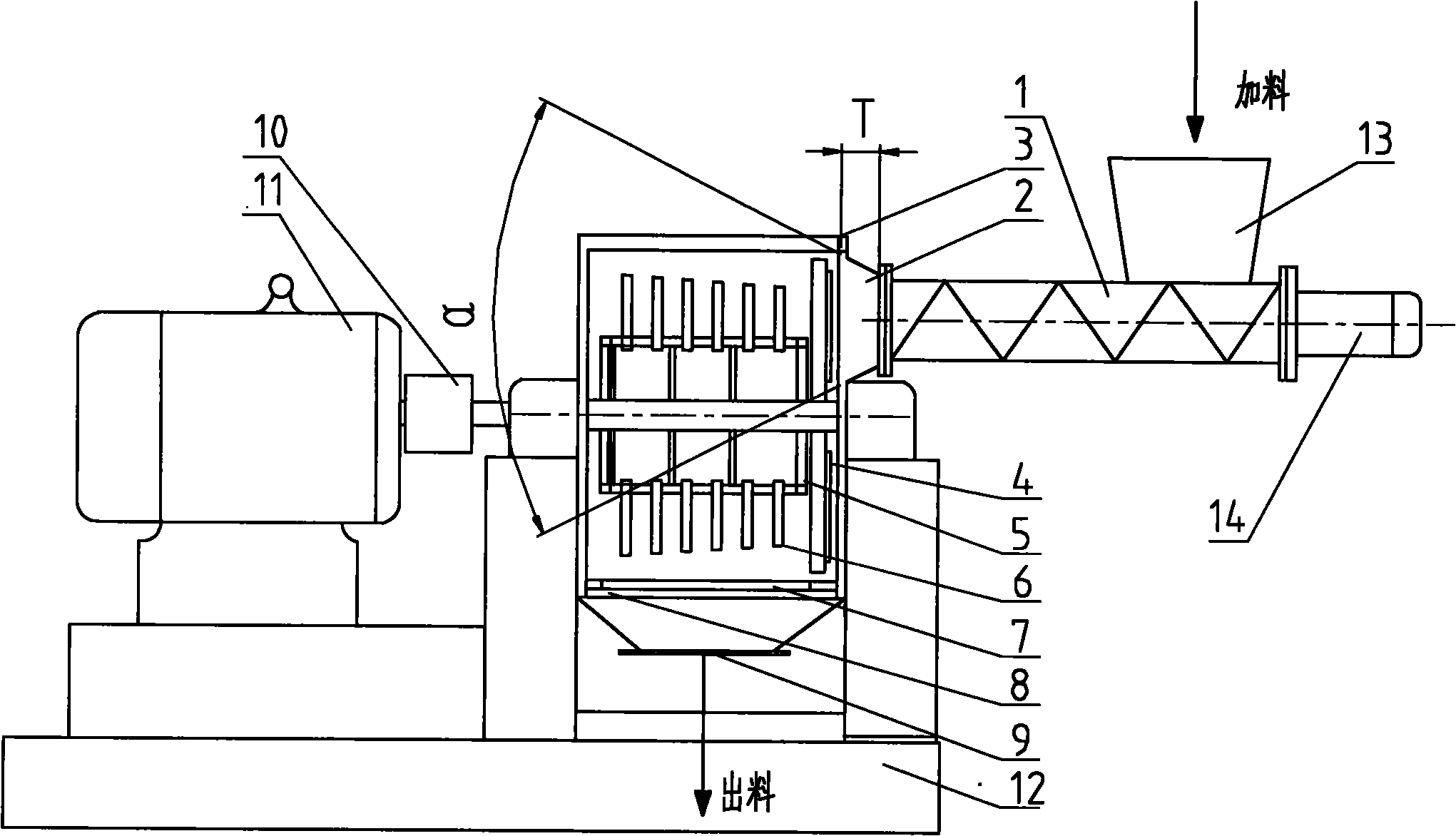

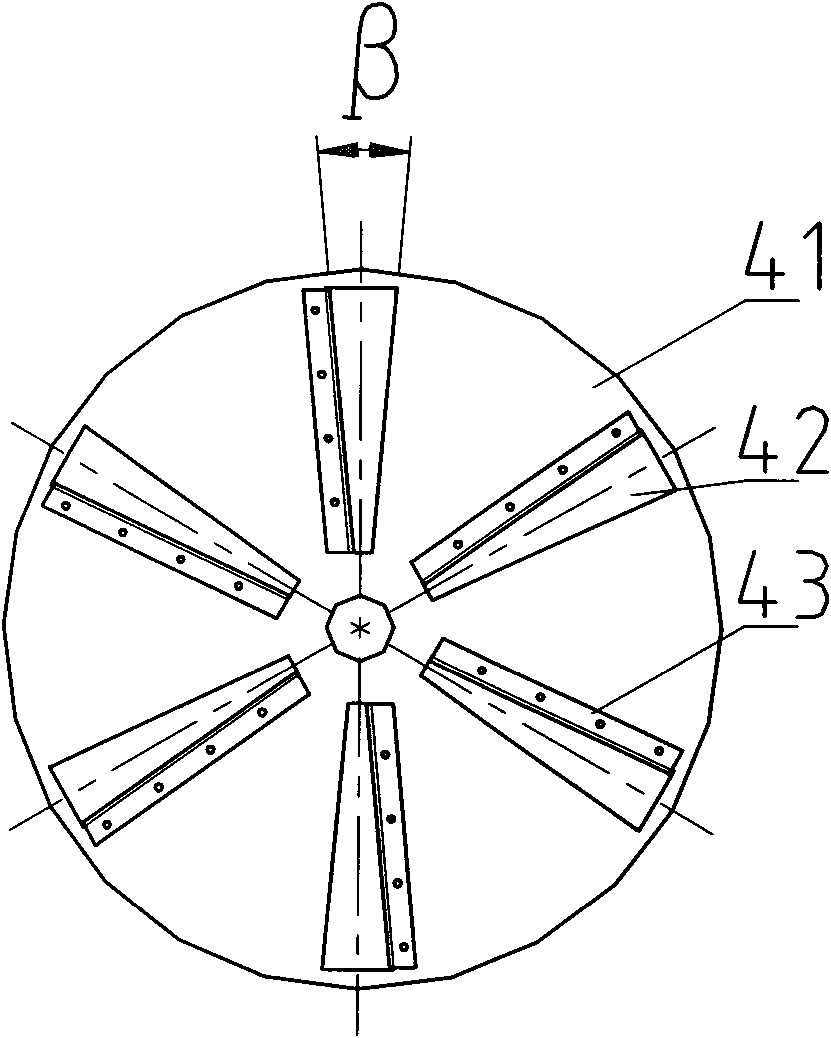

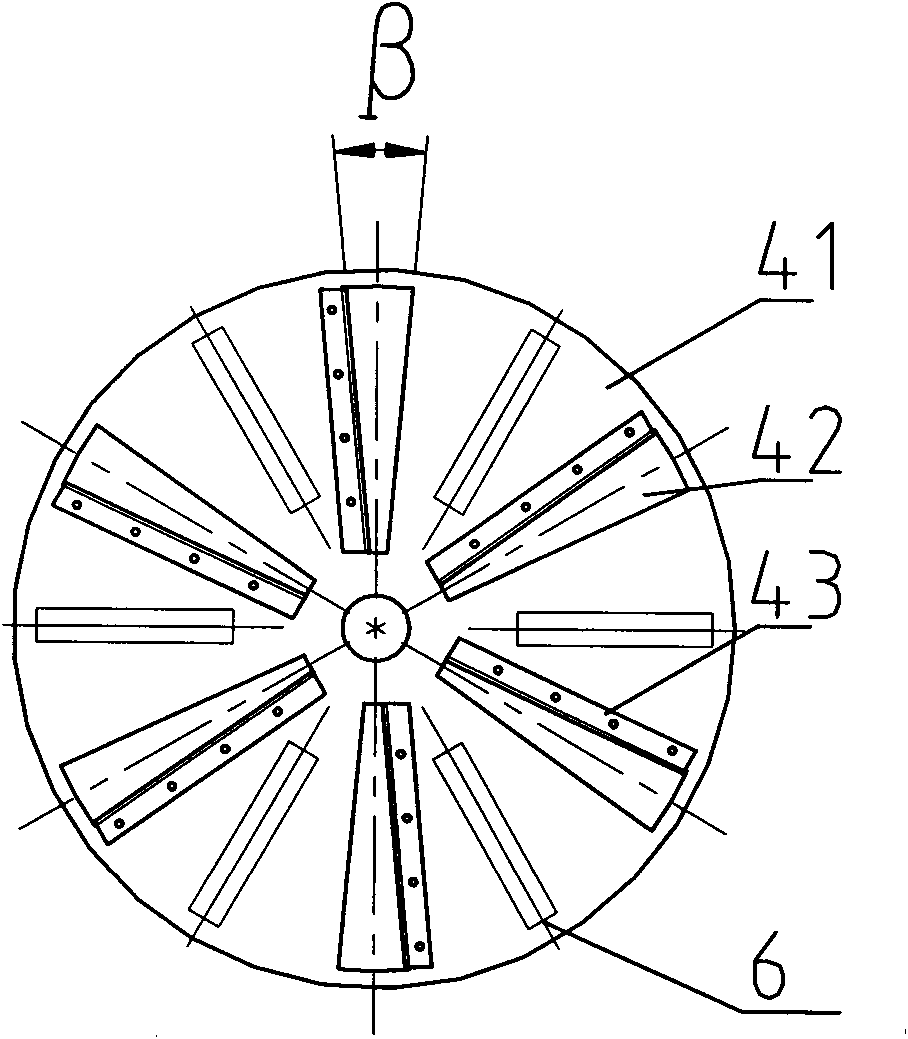

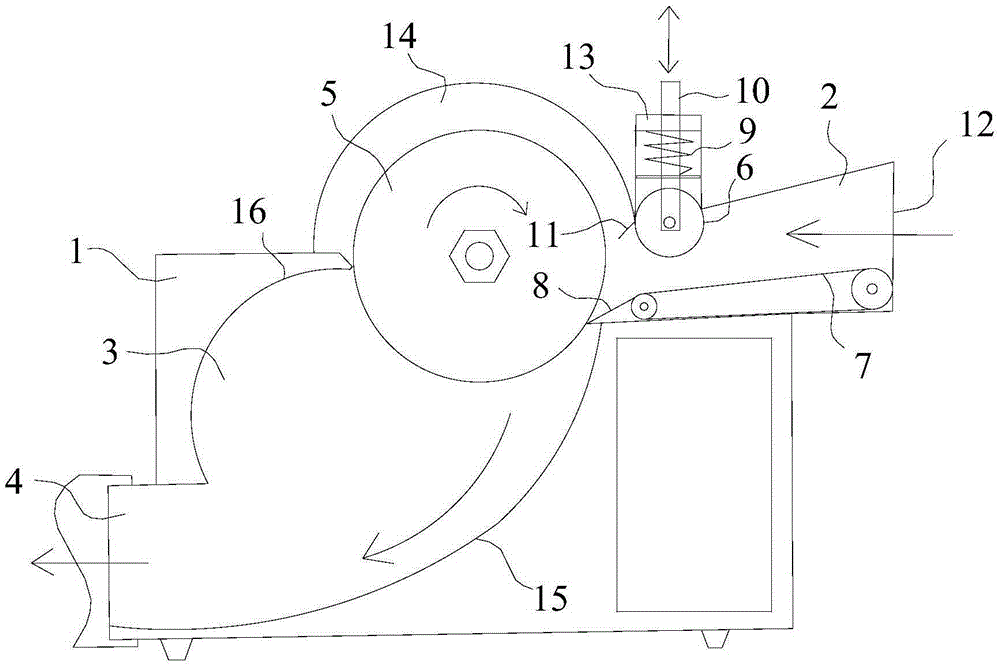

Special cut-off pulverizer for enteromorpha

The invention relates to a special pulverizer structure for enteromorpha for pulverizing long-fiber connected materials, in particular to a special cut-off pulverizer for enteromorpha. In the invention, a power shaft of a stand (12), provided with a motor (11), extends into a shell (3), a cylindrical rotor (5) is fixedly arranged on the power shaft, and a plurality of rows of hammer pieces (6) are fixed on the outer surface along the shaft; the upper part at the other side of the shell (3) is provided with a feed hole, a cylindrical feed drum is outwards extended through a diffusion type feedsection (2) which is big inside and small outside, and a forced material supply auger (1) is also arranged; the starting end of the feed drum is provided with a charging hole (13); the power shaft isprovided with a cut up mechanism (4) close to the feed hole; the lower part of the shell (3) is pressed by a screen pressing frame (8) to be provided with a screen net (7), and a discharge hole (9) is arranged below the shell; a plurality of slit cutting holes (42) are uniformly arranged on a cut up disk (41); and a protuberant cutter (43) is arranged at a side edge along the radial direction of the cutting holes (42). The invention changes the form of the traditional pulverizer, is additionally provided with the cutting mechanism, improves the pulverizing efficiency and has quite strong adaptability and high efficiency on long-fiber materials.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Process for preparing negative ion far infrared acrylic yarn

InactiveCN1865544AImprove performanceFine particle sizeMonocomponent synthetic polymer artificial filamentArtifical filament manufactureIonTitanium dioxide

The invention discloses a manufacturing method of anion far infrared acrylic fibre yarn, which is characterized by the following: adding 20: 1-1: 80 super-fine nanometer titanium oxide and tourmaline composite particle additive at 0.1-6 percent (o.w.f) in the polyacrylonitile flux weight. The invention can produce H3O2- ion and far-infrared electromagnetic wave, which purifies air and modifies environment to keep healthy for people.

Owner:SHANGHAI HAIXIN GROUP CO LTD

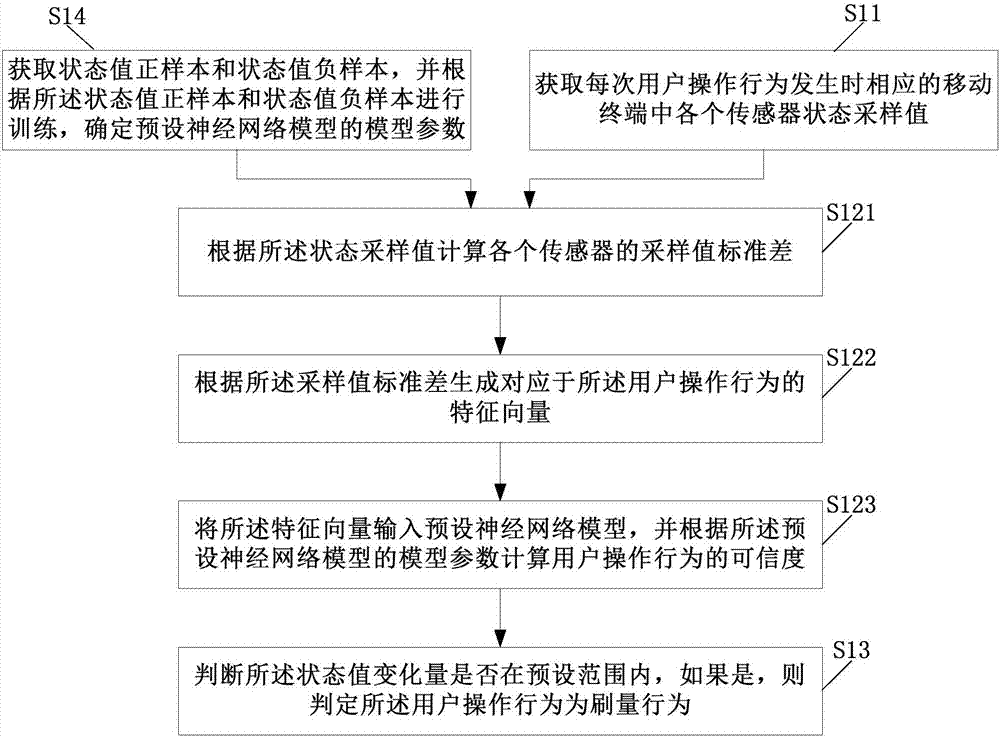

Quantity faking identification method and apparatus for application

InactiveCN107169769AFine particle sizeEffectively respond to fraudulent swiping behaviorCommerceState of artGranularity

The invention discloses a quantity faking identification method and apparatus for an application. The method comprises the steps of obtaining a state sampling value of each sensor of a corresponding mobile terminal when a user operation behavior occurs each time; according to the state sampling value of each sensor, calculating the credibility of the user operation behavior; and if the credibility is in a preset range, judging that the corresponding user operation behavior is a quantity faking behavior. Compared with the prior art, the quantity faking identification method provided by the invention has the advantages that the granularity is finer; an operation behavior of a user of a group can be identified; cheat of the operation behavior disguised by the malicious user can be avoided; a cheating quantity faking behavior disguised as single or small-quantity downloading can be effectively coped with; no historical operation information and account information of the user are required; and the method has the advantage of good anti-quantity faking capability.

Owner:ALIBABA (CHINA) CO LTD

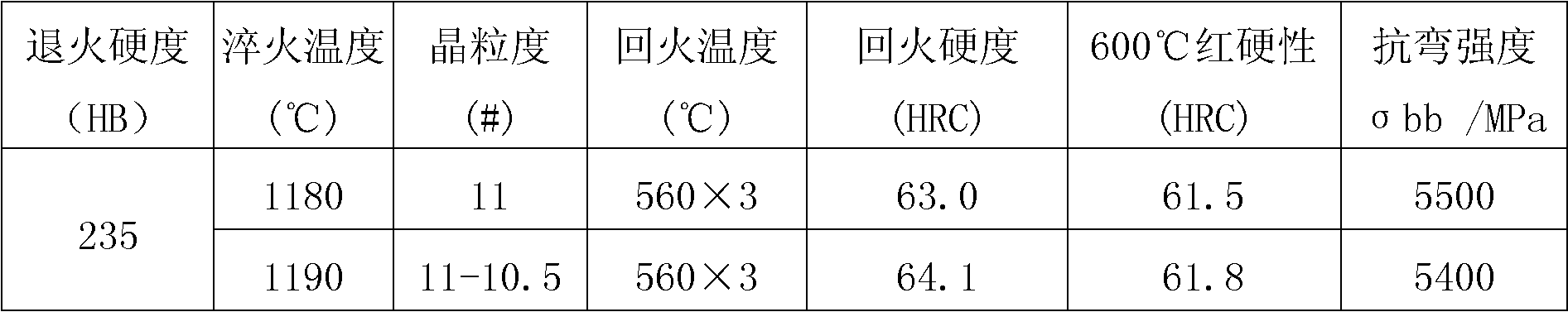

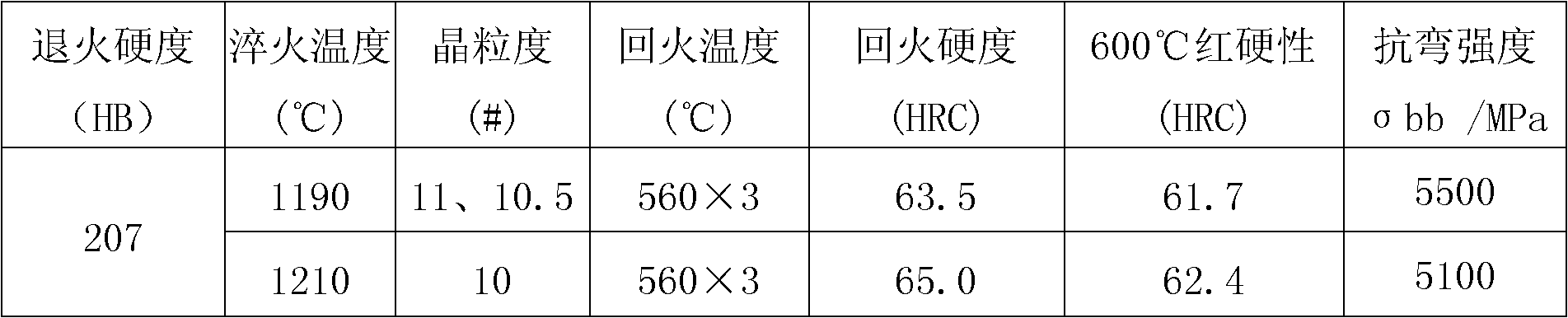

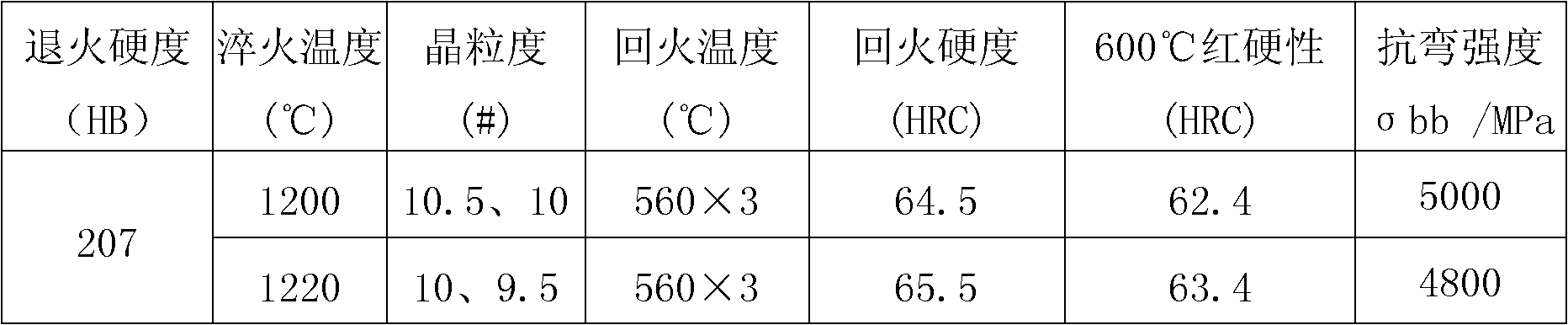

High-speed tool steel for drill bit

The invention discloses high-speed tool steel for drill bits, which comprises the following components: 0.90-0.98% of C; 5.00-5.80% of W; 4.00-4.60% of Mo; 3,80-5.00% of Cr; 1.80-2.20% of V; 0.25-0.45% of Mn; 0.2-0.40% of Si; 0.08-0.30% of Nb; 1.30-1.60% of Co; not more than 0.03% of P; not more than 0.03% of S; and the balance of Fe. According to the invention, the using amounts of precious metal tungsten and molybdenum are reduced; a little niobium is added; the steel is provided with good application performance and processing performance; and prepared cutters have increased service life.

Owner:朱昌宏 +1

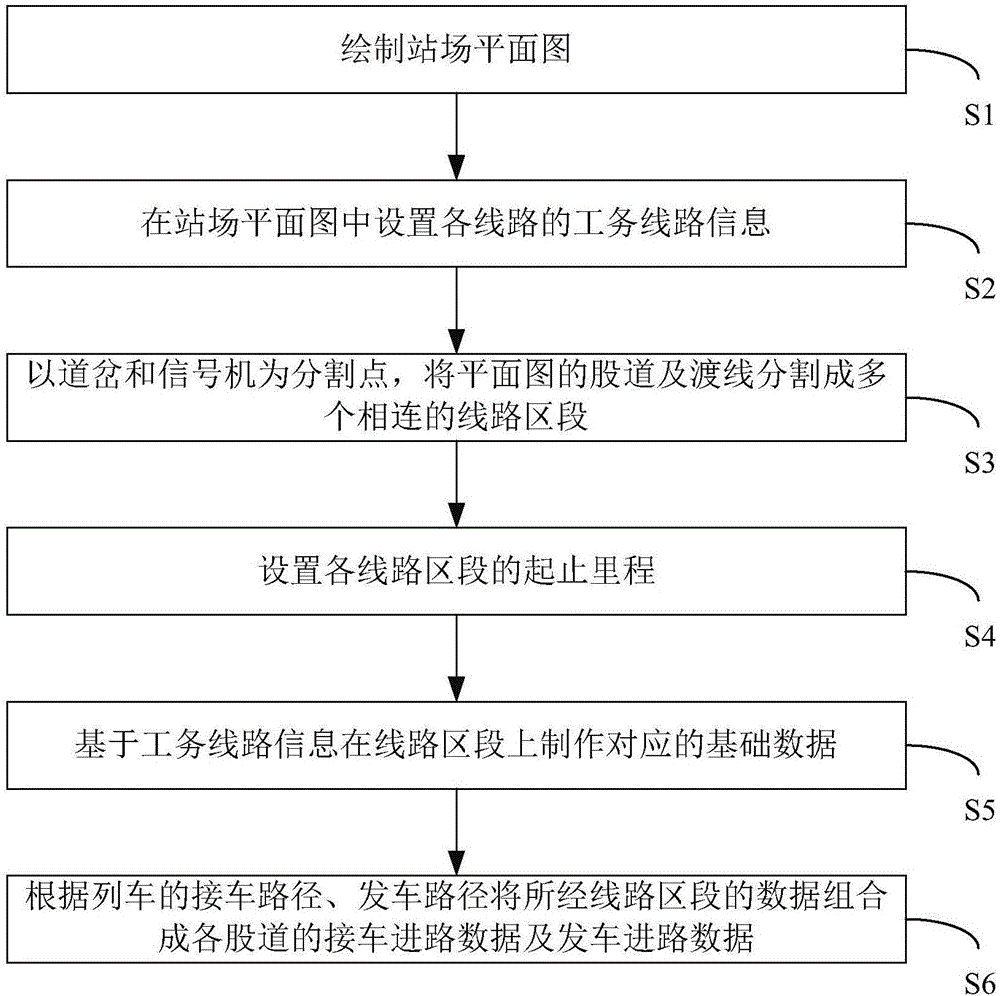

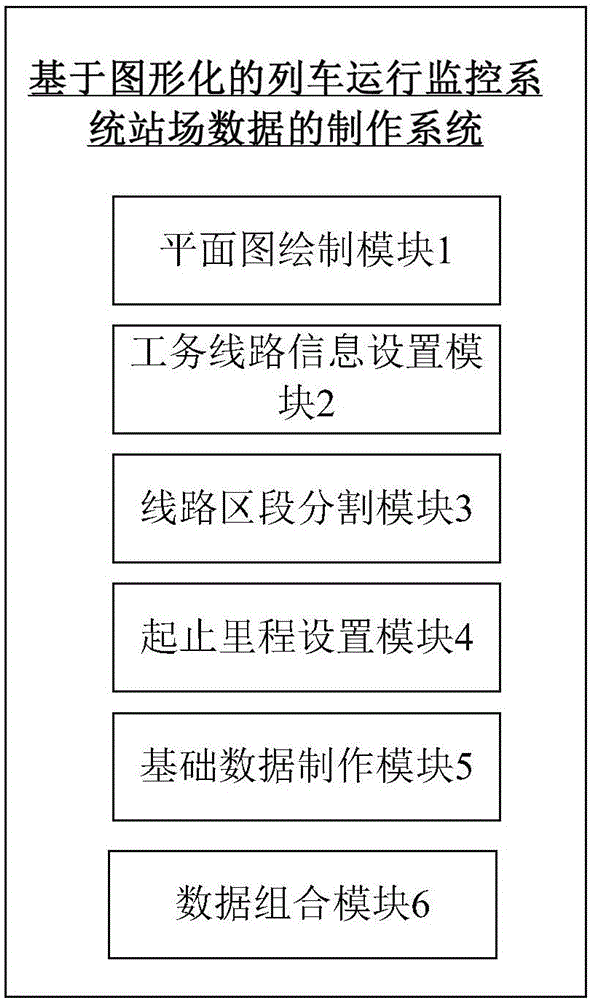

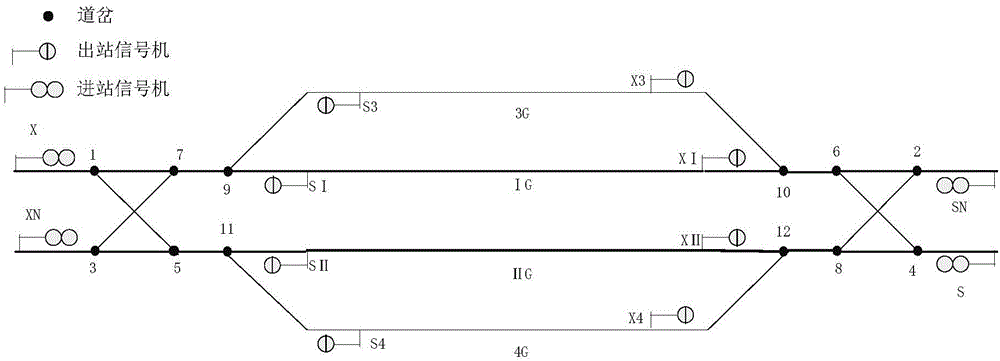

Train running monitoring system station data production method and system based on imaging

ActiveCN106335526AKnow the location of the stationMade preciselyRailway traffic control systemsMonitoring systemEngineering

The invention discloses a train running monitoring system station data production method and system based on imaging, thus realizing the accuracy and intuitiveness of station data, and overcoming the defect that the existing data production way is abstract with lots of repeated and inaccurate data. According to a technical scheme, the method comprises the following steps: drawing a station plan; setting working line information of various lines in the station plan; adopting rail junctions and signal machines as segmentation points, and segmenting station tracks and junction lines in the plan into a plurality of line sections connected with one another; setting a starting mileage of each line section; producing corresponding basic data on the line section on the basis of the working line information; and combining the data of the line section by which a train passes according to a train joint route and a train depart route of the train to form train joint access data and train depart access data of various rail tracks.

Owner:HUNAN CRRC TIMES SIGNAL & COMM CO LTD

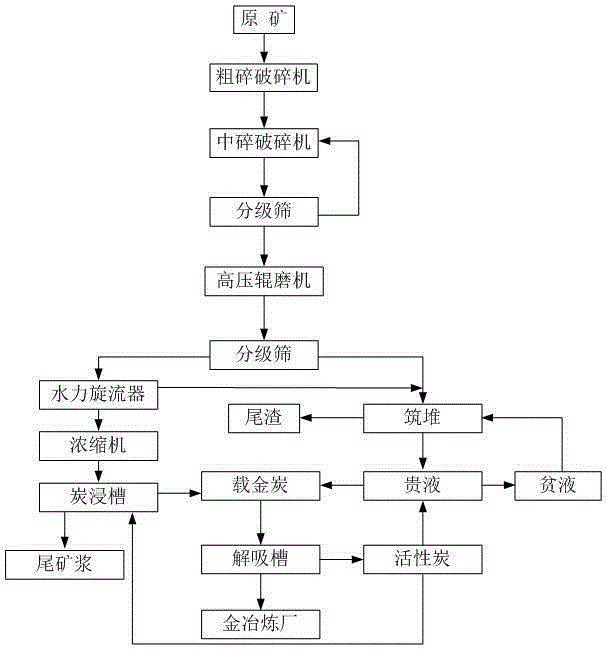

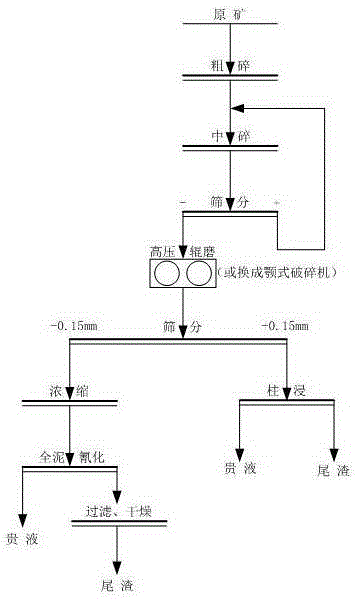

Low-grade gold ore pile soaking technology based on high-pressure roller smashing

InactiveCN105214831AFine particle sizeGood particle size distribution uniformityGrain treatmentsWet separationCrazingCyanide leaching

The invention discloses a low-grade gold ore pile soaking technology based on high-pressure roller smashing and belongs to the technical field of metallurgy. The low-grade gold ore pile soaking technology comprises the following steps that firstly, raw gold ore is coarsely smashed in an open circuit mode, the coarsely-smashed product is all fed into a medium smashing system and classified through a vibrating screen, coarse materials on a screen are returned to medium smashing equipment to continue to be smashed, and proper screened materials enter a high-pressure roller smashing machine; secondly, the proper screened materials are subjected to open circuit fine smashing through the high-pressure roller smashing machine, the product is subjected to combined action of a wet vibrating screen and classifying equipment, fine overflow products are fed into an all-slimed cyanide leaching system, settled sand and coarse grain materials are mixed with lime with properly-blended soda and then fed into a storage yard to be piled together, and the classifying leaching technology of gold ore materials is achieved; thirdly, a precious solution containing gold and tailings are obtained after leaching is completed. According to the low-grade gold ore pile soaking technology, high-pressure roller open-circuit fine smashing is adopted, the product granularity of the product is fine, surface micro cracks are rich, the gold leaching rate can be remarkably increased, consumption of a leaching agent can be reduced, and the piling leaching cycle can be shortened. The product with fine granularity grades is recycled while piling leaching is conducted.

Owner:FUZHOU UNIV

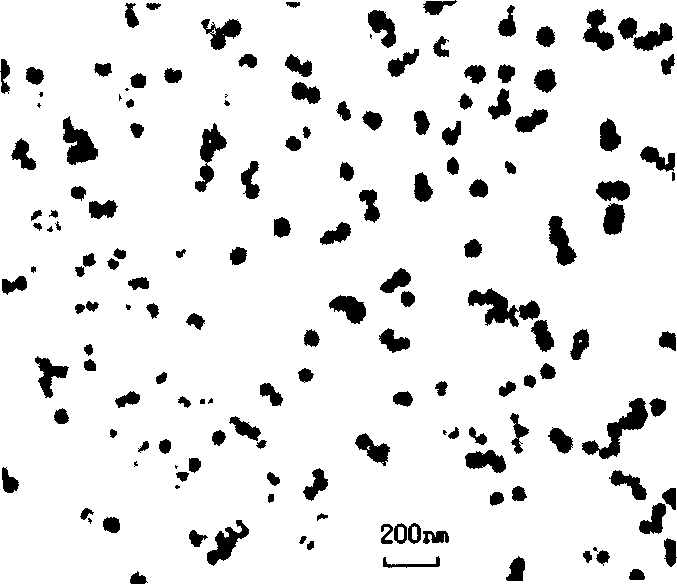

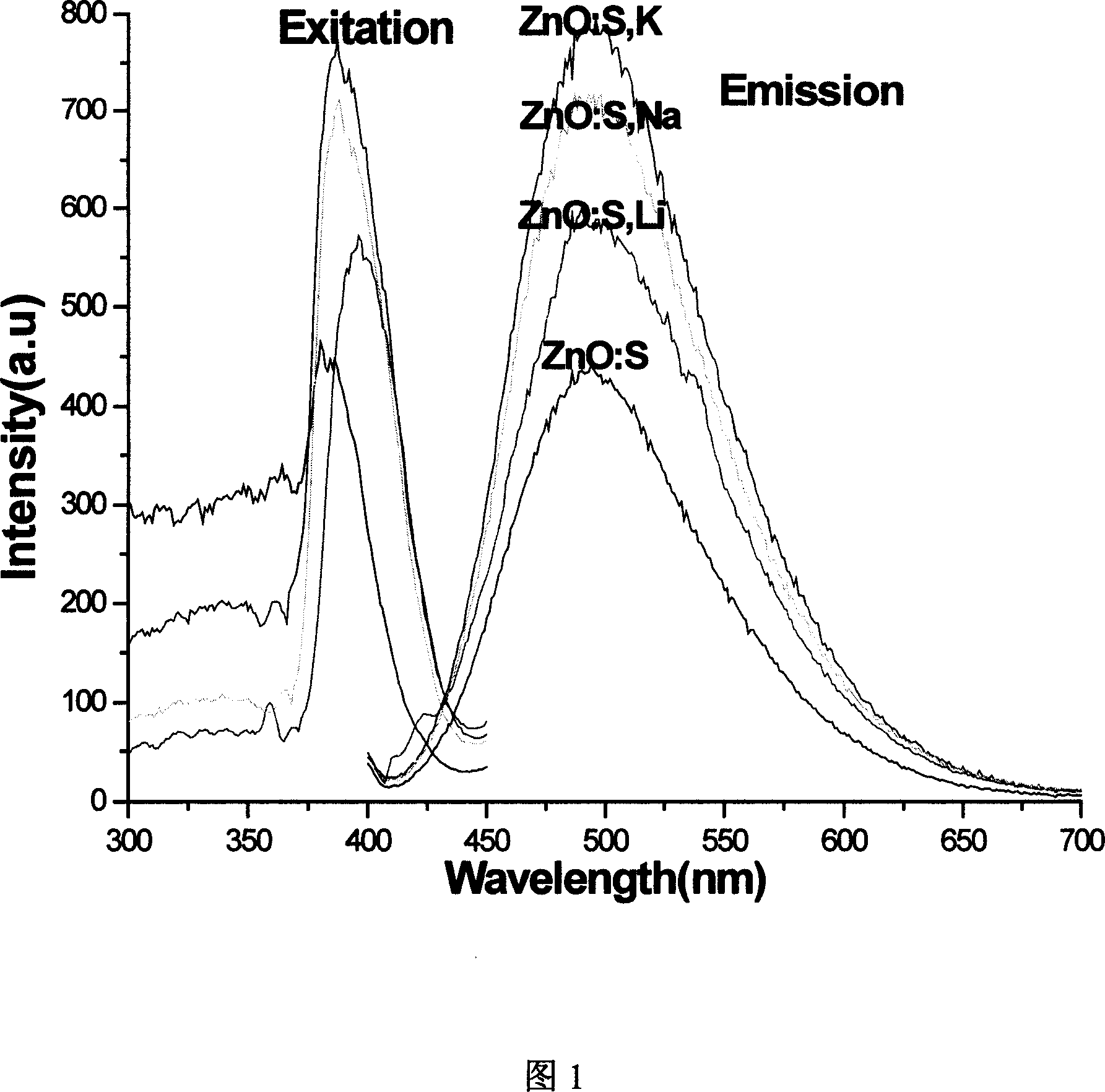

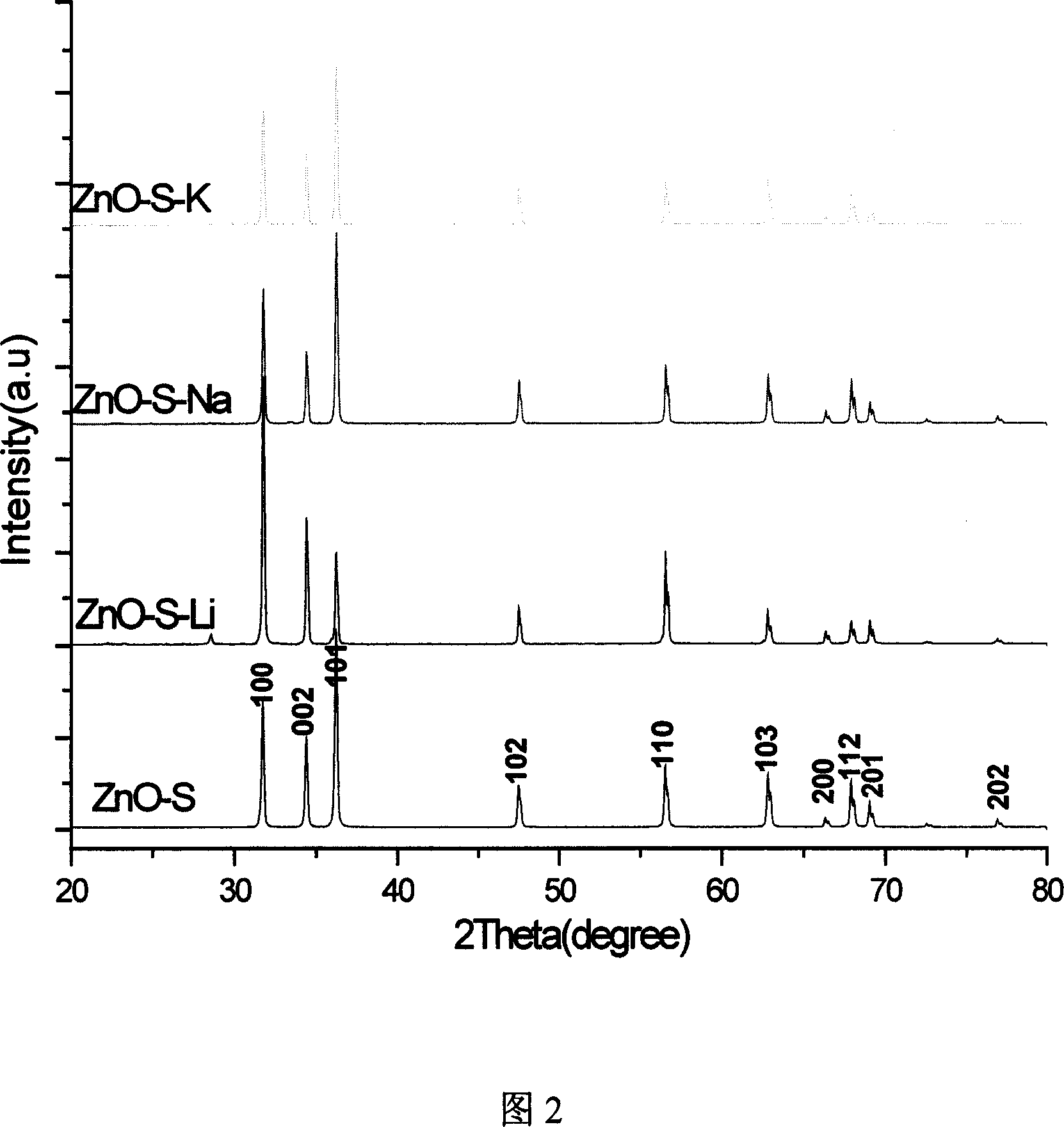

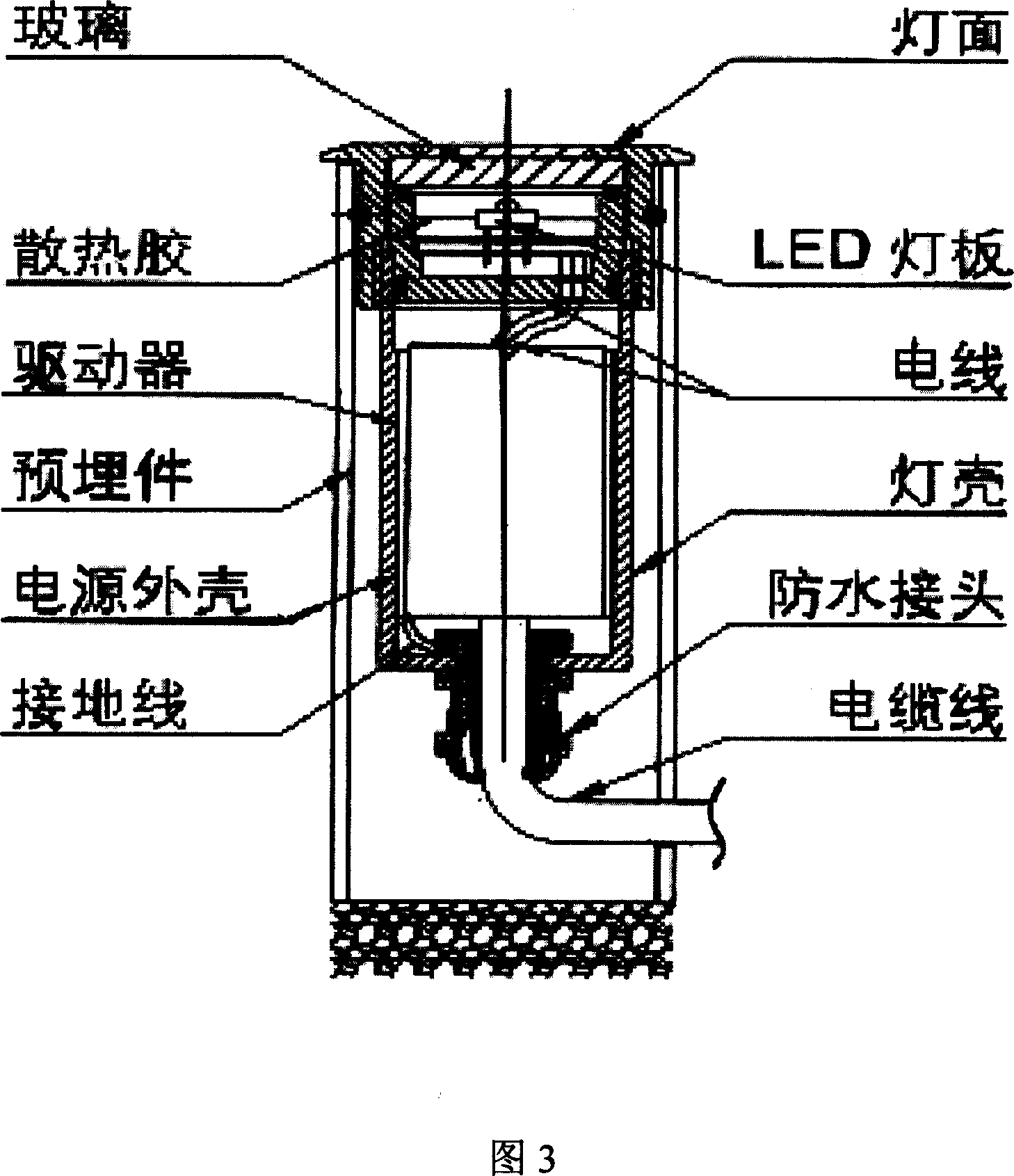

Near-ultraviolet or ultraviolet excited semiconductor luminous material and its preparing method

InactiveCN101024767AStrong absorption capacityStrong launchSolid-state devicesSemiconductor/solid-state device manufacturingRare-earth elementFluorescence

The invention discloses a semiconductor emitting material that is stimulated by near ultraviolet or ultraviolet. The constituents are ZnO: Sx, My and 10-4<=x<=10-2, 0<=y<=0.2. M is selected from Li, Na, K or rare earth of Eu, Tb. When M is Na, it has better emitting effect. The invention also discloses the manufacture method and the performance testing result. The invention has strong absorption near 370-440nm wavelength ultraviolet and blue light zone, and has strong emission between 450-600nm wavelengths. It could be used in LED and LD.

Owner:SHANGHAI NORMAL UNIVERSITY

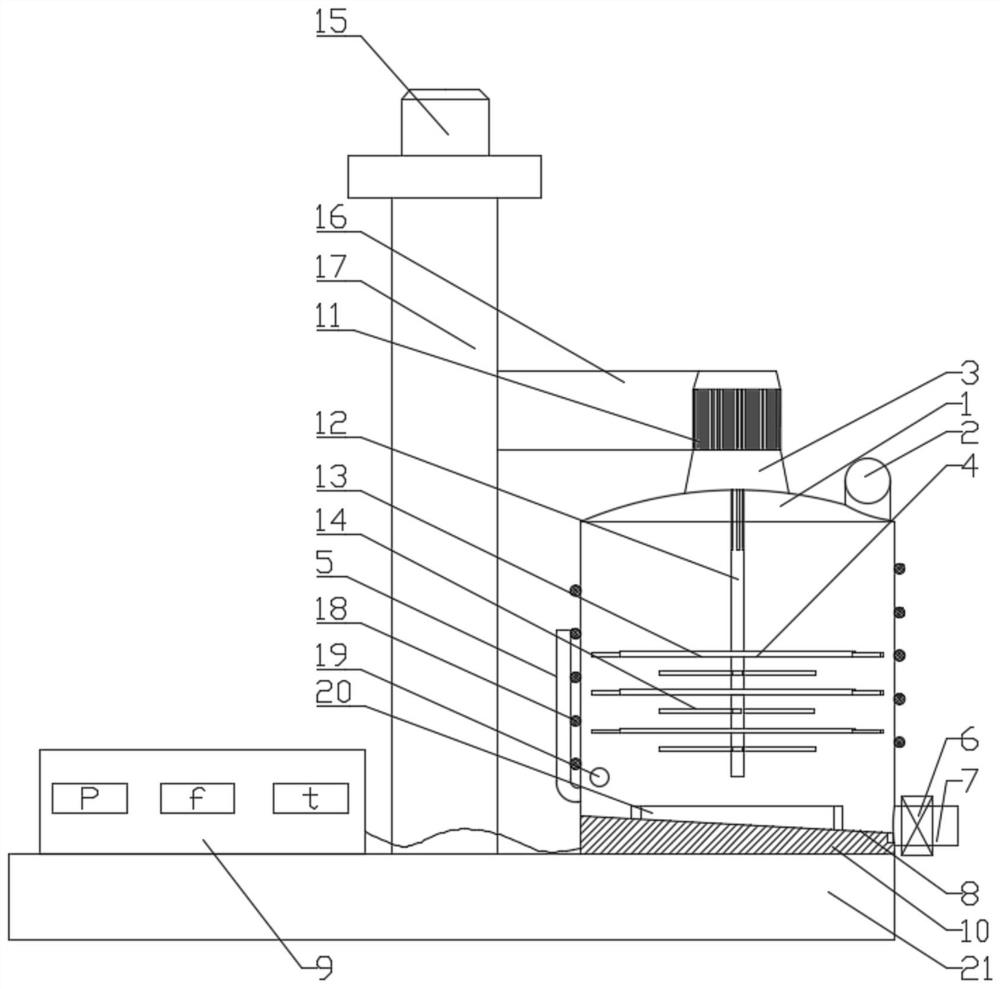

Preparation device of dispersed-phase emulsified oil with ultrafine particle size

ActiveCN111888957AGood for initial mixingUniform particle sizeShaking/oscillating/vibrating mixersTransportation and packagingTemperature controlUltrasonic emulsification

The invention belongs to the related technical field of internal combustion power fuel oil, and discloses a preparation device of dispersed-phase emulsified oil with an ultrafine particle size. The device comprises an emulsifying tank, a stirring mechanism, an ultrasonic emulsifying mechanism, a sliding mechanism and a temperature control mechanism, the tank body of the emulsifying tank is used for containing liquid to be subjected to micronization treatment, the stirring mechanism is arranged in the tank body, and is used for stirring liquid to be subjected to micronization treatment in the tank body, the sliding mechanism is arranged outside the tank body, is connected with the stirring mechanism, and is used for adjusting the height of the stirring mechanism in the tank body, the ultrasonic emulsifying mechanism is arranged below the tank body and is used for sending ultrasonic waves to conduct ultrasonic high-frequency shearing and smashing on the liquid to be subjected to micronization treatment in the tank body, and the temperature control mechanism is used for regulating and controlling the temperature in the tank body so that the requirements for surfactant activity and precise component content can be met; through the invention, the ultrafine particle size of the emulsified oil is realized, the micro-explosion of spray droplets is favorably realized, the oil-gas mixingis promoted, the combustion efficiency is improved, and the emission of harmful gas is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Laser 3D printing method for in-situ synthesized alumina particle reinforced nickel base composite

ActiveCN110976849AEvenly distributedFine particle sizeAdditive manufacturing apparatusTransportation and packagingPhysicsLaser printing

A laser 3D printing method for an in-situ synthesized alumina particle reinforced nickel base composite comprises the steps that firstly, nickel base alloy and pure aluminum powder are subjected to mechanical ball milling, particle size screening is carried out on the powder obtained after ball milling, and a laser 3D printing technological window is initially optimized; a temperature changing curve of a molten pool is recorded regularly with a colorimetric pyrometer, and the average peak temperature T of the temperature curve, the intercept t of the solid phase line and the temperature curveand the average cooling rate Xi of the molten pool are extracted and calculated; and technological parameters are optimized according to the principles that T is higher than or equal to 1.4 Tm and lower than or equal to 1.8 Tm, t is larger or equal to 0.55 s and smaller than or equal to 0.95 s and Xi is larger than or equal to 3.5*103 DEG C / s, and an optimized technological window is obtained, wherein the laser output power is 800-1200 W, the defocusing amount is -2.5 mm, the diameter of a laser spot is 2-3 mm, the scanning speed is 8-14 mm / s, and the powder feeding amount is 12-16 g / min. By means of the laser 3D printing method, in-situ synthesis of alumina particles can be achieved in the forming process, and the mechanical performance of nickel base forming parts can be improved.

Owner:HUNAN UNIV

Industrial public opinion recommendation method and device based on entity extraction and electronic device

ActiveCN112395410AFine particle sizeImprove accuracyNatural language data processingText database queryingNamed-entity recognitionBusiness enterprise

The invention discloses an industrial public opinion recommendation method and device based on entity extraction, and an electronic device method. The method comprises the steps of obtaining industrial public opinion data; identifying entities from the industrial public opinion data based on a named entity identification model; generating a label for the industrial public opinion data according tothe identified entity; and recommending the industrial public opinion data to the user based on the label. The method can effectively solve the existing problems that news is not subdivided to each region of each industry, news processing granularity is relatively coarse, and most of customer groups aim at individual users and cannot meet user requirements of enterprises of different industries.

Owner:北京智源人工智能研究院

Method for preparing YAG-Ce phosphor by using combustion method

InactiveCN104893723AFine particle sizeSimple preparation processMaterial nanotechnologyNanoopticsSolventMuffle furnace

The invention relates to a method for preparing YAG-Ce phosphor by using a combustion method. The method comprises: weighing a cosolvent, a combustion agent, and raw materials for preparing YAG-Ce phosphor; dissolving the raw materials in water; heating to a temperature of 80 DEG C, heating to a temperature of 300 DEG C by using a muffle furnace, carrying out thermal insulation for 3-6 h, carrying out calcining thermal insulation for 3-6 h at a temperature of 800 DEG C, and carrying out water washing or acid washing, suction filtration and drying; and placing the dried precursor under a reducing atmosphere, carrying out calcining thermal insulation for 3-6 h at a temperature of 900-1400 DEG C, cooling, taking out, and screening so as to obtained the required phosphor. According to the present invention, the starch or cellulose powder is adopted as the combustion agent, the combustion method is used to manufacture the YAG-Ce phosphor, the reaction temperature is lowered to about 900 DEG C from the traditional 1400-1700 DEG C, the obtained reaction product has characteristics of regular morphology and good uniformity, the method has characteristics of low temperature synthesis, simple process, low energy consumption, low equipment requirements and the like, and the phosphor has good light-emission intensity and is used for white light LED light source.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Solid phase interface induced precipitation method for preparing nickel oxide, cobalt oxide powder

InactiveCN1699188AFine particle sizeSimple processNickel oxides/hydroxidesCobalt oxides/hydroxidesSolid phasesOxalate

The invention discloses a solid phase interface induced precipitation method for preparing nickel oxide, cobalt oxide powder, which comprises preparing 0.01-2.0mol / L solution from the soluble metal salt of the oxides to be prepared, charging macromolecular dispersing agent by the ratio of cobalt or nickel content of 0.1-1%, weighing oxalic acid or oxalates solid powder by the ratio of 1-1.2 times of metal cobalt or nickel, grinding and sifting, charging in within one time or for several times, controlling the reaction temperature to be 25-90 deg. C, adjusting pH to be 1.0-5.0, agitating at the speed of 100-300 mps, reacting and ageing 0.5-3 hours, producing insoluble metallic oxalate powder, finally 4-12 hours at 350-1000 deg. C, thus metallic oxide powder is prepared.

Owner:CENT SOUTH UNIV +1

Preparation method capable of modifying nickel-based ternary non-supported catalyst by adding aids PEG and SB powder

InactiveCN106925288AFine particle sizeHigh metal utilizationMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatment productsAmmonium metatungstateNickel based

The invention relates to a preparation method capable of modifying a nickel-based ternary non-supported catalyst by adding aids PEG and SB powder. Two different aids are introduced in the process of preparing a non-supported catalyst by a coprecipitation method and active components and the aids are combined, namely the PEG and the SB powder with different molecular weights are added into a mixed solution of nickel molybdate and ammonium metatungstate to serve as a dispersant surfactant and a dispersant correspondingly. According to the preparation method of the modified non-supported catalyst, the dispersing property of active metal components and the hydrogenation property of the catalyst can be improved effectively, the mechanical strength of the non-supported catalyst is remarkably improved, and the modified catalyst can meet the strict requirement of national standard on the deep desulfurization of diesel after hydrogenation reaction.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Method for directly preparing high-purity white carbon black from fluorine-containing silicon slag

PendingCN110844911AThe process is short and practicalLess investmentSilicaAluminium fluoridesAluminum fluorideAluminium hydroxide

The invention relates to a method for directly preparing high-purity white carbon black from fluorine-containing silicon slag. The method comprises the following steps: homogenizing, pulping and dispersing fluorine-containing silicon slag to disperse aluminum hydroxide powder wrapped by solid white carbon black particles so that the dispersed aluminum hydroxide powder reacts with fluosilicic acidadsorbed by the solid white carbon black to produce a water-soluble aluminum fluoride solution and a solid silicon dioxide material, removing an acid liquor containing aluminum fluoride, and carryingout homogenizing pulping, dispersing and ultrasonic fine washing on the obtained solid silicon dioxide material at least one time until washing water is neutral, and dehydrating and drying the neutralsilicon dioxide material to obtain the high-quality white carbon black. The method is simple, practical and capable of achieving industrial production, the SiO2 content (by dry basis) of the preparedwhite carbon black is greater than or equal to 92%, NSA is greater than or equal to 200 g / m<2>, the particle size is smaller than or equal to 0.044 micrometers, and the total iron content is smallerthan or equal to 0.01%, and other technical indexes all meet or exceed the national industrial standard HG / T3061-2009 requirements of precipitated white carbon black.

Owner:HUANGGANG NORMAL UNIV +1

Composite additive for strengthening middle-high magnesium-type laterite-nickel ore direct reduction and application of composite additive

The invention provides a composite additive for strengthening high magnesium-type laterite-nickel ore direct reduction and an application of the composite additive. The composite additive comprises, by weight, 25-35% of desulphurization gypsum, 20-30% of sodium carbonate, 10-15% of sodium humate, 10-15% of polyacrylamide, 5-10% of coal powder, 5-10% of calcium oxide and 1-5% of iron powder. According to the composite additive for strengthening high magnesium-type laterite-nickel ore direct reduction, high-nickel concentrate can be prepared from high magnesium-type middle-low grade laterite-nickel ore and can be applied to direct reduction of high magnesium-type laterite-nickel ore. The application method of the composite additive comprises the steps that laterite-nickel ore and the composite additive are mixed, and a fresh pellet is obtained through pelletizing; the fresh pellet is dried, so that the fresh pellet is solidified to be a dried pellet, wherein the strength of the dried pellet exceeds 300 N; the dried pellet is placed into a rotary kiln, reduction coal is added into the rotary kiln to conduct segmented reduction, and a reduced product is obtained; and after water quenching and splat cooling are conducted on the reduced product, crushing ball-milling and wet magnetic separation are conducted, and high nickel iron ore concentrate is obtained.

Owner:CENT SOUTH UNIV

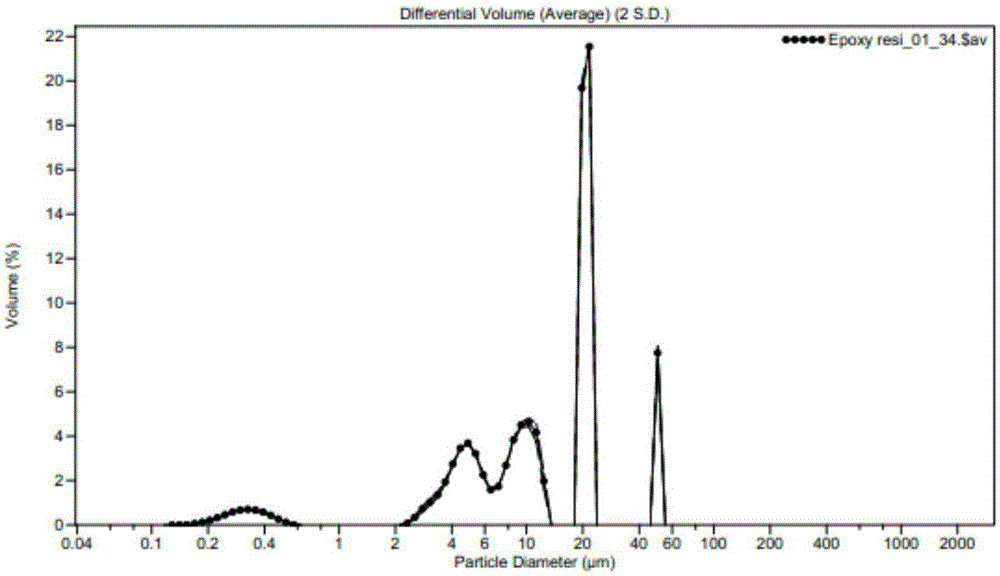

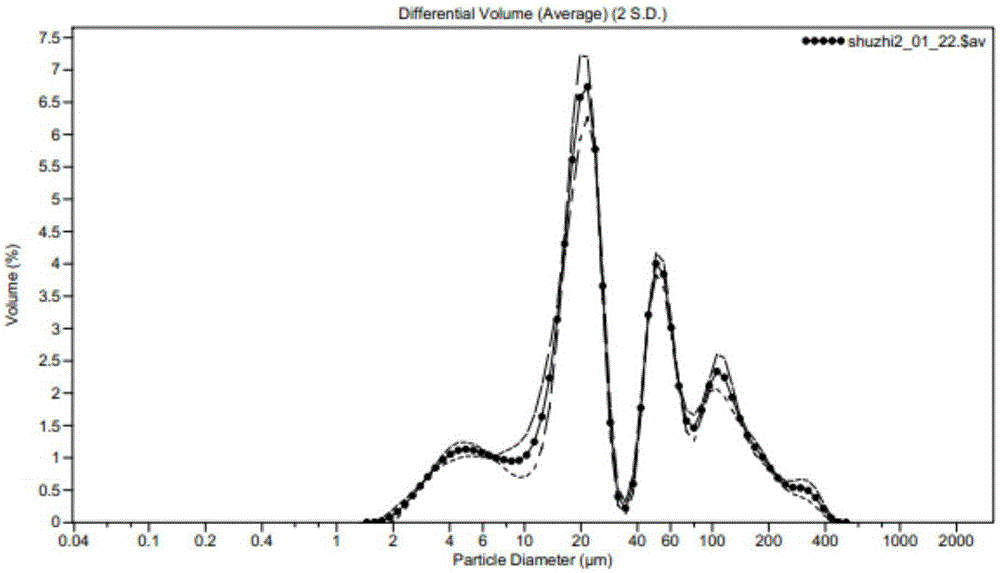

Smashing equipment for smashing of glass fiber composite material or rubber material

ActiveCN105381845ASolve the technical difficulties that are difficult to finely crushImprove crushing efficiencyPlastic recyclingGrain treatmentsGlass fiberDiamond cutting

The invention discloses mashing equipment for smashing of a glass fiber composite material or a rubber material. The equipment comprises a box body; a feeding cavity, a smashing cavity and a discharging cavity are sequentially arranged in the box body in the material conveying direction; a cutter is rotationally connected in the smashing cavity; a conveying belt for conveying materials is disposed in the feeding cavity; the output end of the conveying belt transits to the outer edge of the cutter through a joining plate; a material pressing wheel located above the conveying belt is disposed in the feeding cavity in a sliding mode through an elastic support; a material channel which joins the feeding cavity with the smashing cavity is disposed between the conveying belt and the material pressing wheel. A high-speed motor drives a smashing and cutting mechanism formed by combination of diamond cutting blades to smash strip-shaped and small blocky glass fiber composite material or rubber material at a time, and smashing particle diameter d50 of powder can be controlled to be about 20-30 micrometers. The technical difficulty of finely smashing of recycled materials in the industry is solved, and favorable conditions are created for recycling of the glass fiber composite material and part of the rubber material.

Owner:JIANGSU RUIKANG NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com