Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

187results about How to "Good ball forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sintering technology of ferrochrome mineral powder

Owner:CENT SOUTH UNIV

Acid amide-grafted sodium alginate nanometer material, preparation method thereof and use thereof

InactiveCN101565469APromote degradationGood biocompatibilityPharmaceutical non-active ingredientsCarrier-bound/immobilised peptidesChemical synthesisCrystallography

The invention relates to an acid amide-grafted sodium alginate nanometer material, a preparation method thereof and use thereof. The acid amide-grafted sodium alginate nanometer material comprises acid amide having an aliphatic chain and sodium alginate having a molecular weight of less than or equal to 50,000, and is characterized in that a carboxyl group of the sodium alginate is grated with hydrophobic acid amide by a chemical synthesis method for hydrophobic modification so as to form an amphipathic material, namely a modified sodium alginate nanometer material, having both hydrophobicity and hydrophilcity. The acid amide-grafted sodium alginate nanometer material performs self aggregation in deionized water to form nanoparticles, wherein the diameter of the nanoparticles is between 40 and 1,000 nanometers; under a condition of substituted ratio of 2 percent, the mean particle diameter of the nanoparticles is 596.2 nanometers; the medicament-loading rate is up to 40 percent; the medicament entrapment rate is up to 95.1 percent; and the medicament release time is as long as 6 days. The acid amide-grafted sodium alginate nanometer material can be used in a plurality of pharmaceutical fields as a slow release carrier of a plurality of medicaments, particularly hydrophobic medicaments, protein medicaments, polypeptides and vaccines.

Owner:OCEAN UNIV OF CHINA

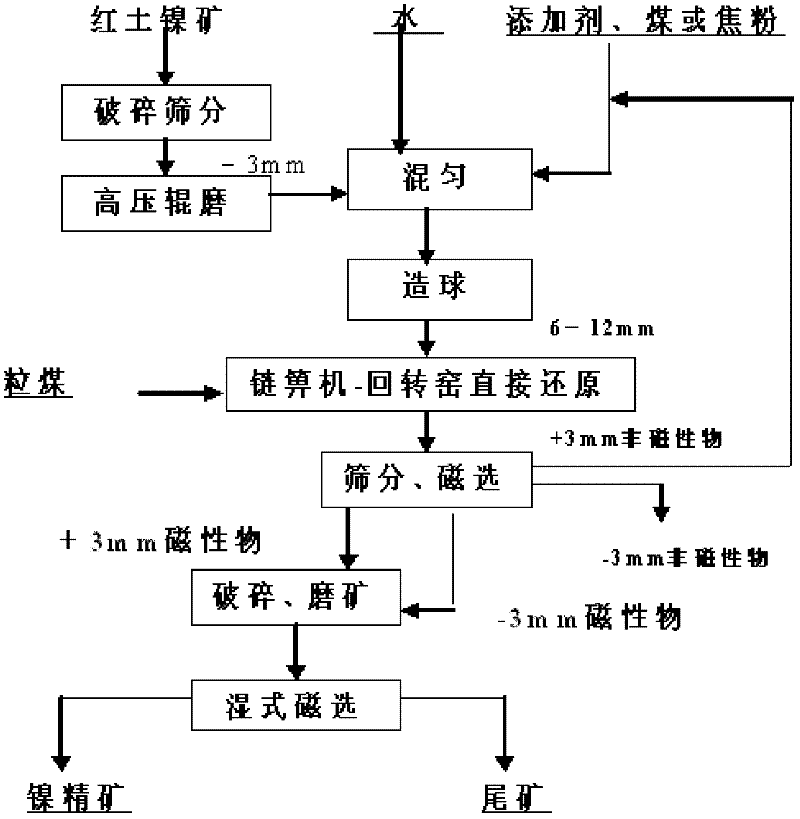

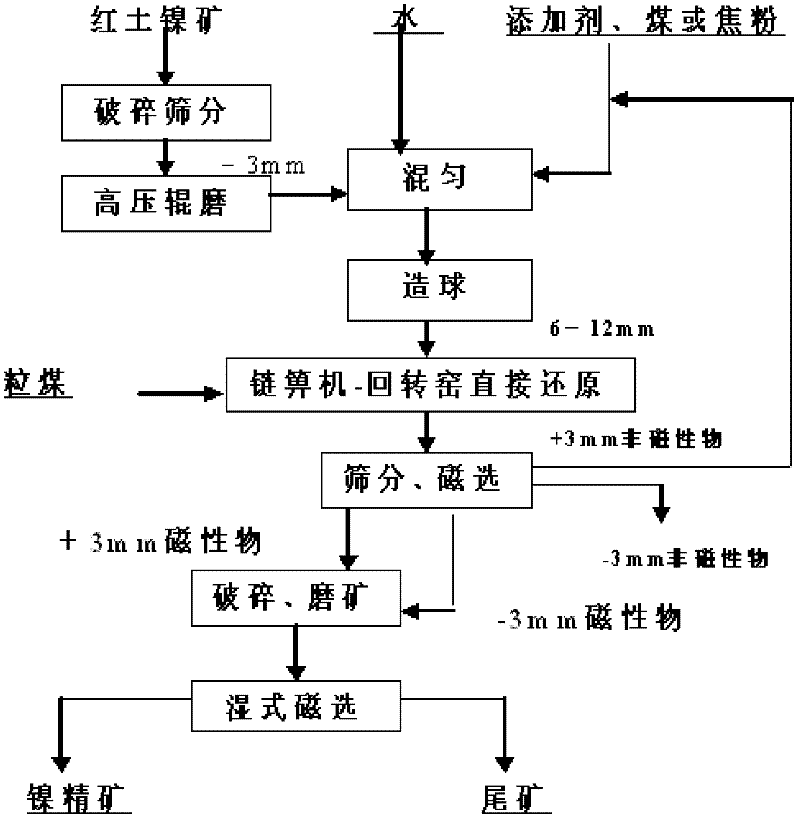

Method for preparing high-nickel concentrate from low-grade red soil nickel ore

InactiveCN102242252ALarge specific surface areaGood ball formingMagnetic separationMass ratioHigh pressure

The invention discloses a method for preparing a high-nickel concentrate from a low-grade red soil nickel ore, which comprises the following steps of: drying the low-grade red soil nickel ore until water content is 13 to 16 percent, crushing to ensure that the size of all particles is less than 3mm, grinding by using a high-pressure roller mill to ensure that particles with the size of less than 0.074mm account for 80 percent and specific surface area is not less than 2,000cm<2> / g, adding 15 to 20 percent of composite binder and 1 to 5 percent of coal powder, and pelletizing by using a disc pelletizer to obtain green pellets with the size of 6 to 16mm; drying and preheating the green pellets on a chain grate for water removal and solidification to ensure that each piece of pellet entering a kiln has the compression strength of over 500N; directly adding the preheated and solidified pellets into a rotary kiln, and reducing at the temperature of between 1,100 and 1,250 DEG C for 60 to 120 minutes by using pea coal as a reducing agent in a mass ratio of the reducing coal to the pellets of 0.8-1.0; and cooling a reduction product, sieving, performing magnetic separation to obtain a magnetic product, crushing, grinding, and performing magnetic separation to obtain the high-nickel concentrate, wherein the composite additive comprises the following components: Na2CO3 and CaO, iron oxide powder, the coal powder and sodium humate in a ratio of (30-60):(20-30):(20-30):(5-10). The method is high in adaptability and nickel recovery rate and suitable for mass production.

Owner:CENT SOUTH UNIV

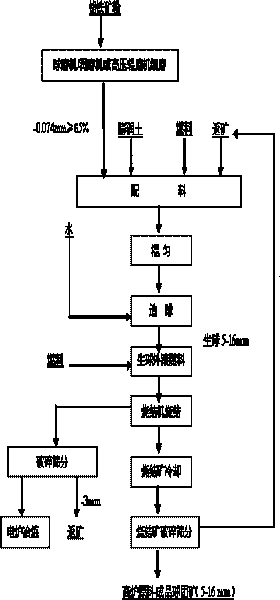

Method for pellet formation using steel-making slurry

InactiveCN1594607ARaw material balling performance improvementReduce the requirement of raw material particle sizePellet FormationWater content

The invention relates to a pelletizing method using sludge of steel production and belongs to pelletizing technology in metallurgy field. The method comprises: adjusting sludge concentration to 10-40%, adding 3-10% (weight percentage) sludge in mixture of iron ore powder and bentonite, continuously spraying it in palletizing disk, The advantage of the method : material sphericity is improved greatly. Bentonite usage can reduce greatly in mixture, which promote the pelletizing quality. Pelletizing disk don't take on sandification. Aqueous sludge can minimize the extra water. The enterprise has electric furnace, open-hearth furnace, revolving furnace and pelletizing line can use the method.

Owner:攀钢集团成都钢铁有限责任公司

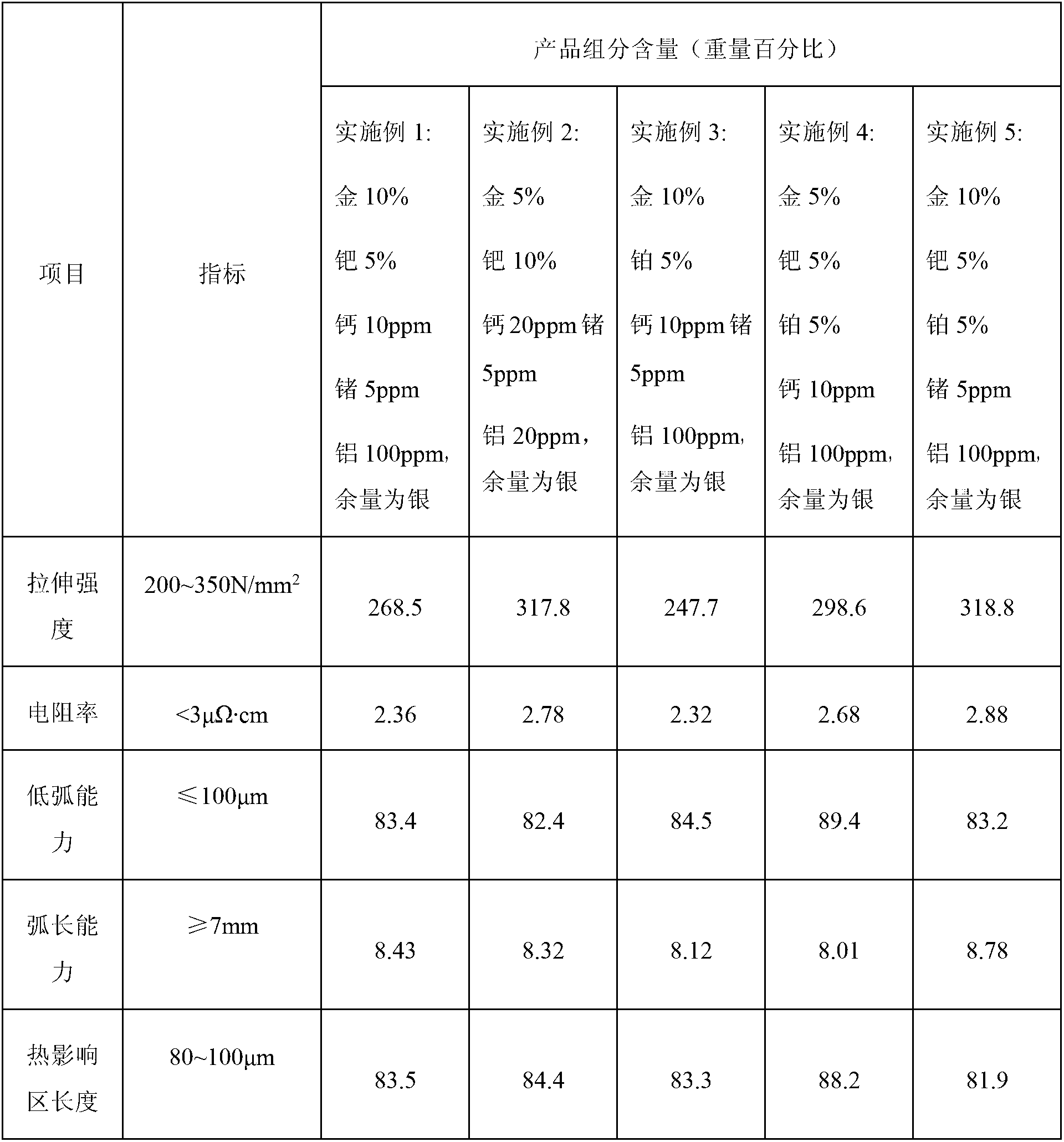

High-end packaging silver alloy bonding wire and method for manufacturing same

ActiveCN102912176AGood ball formingHigh strengthSolid-state devicesSemiconductor/solid-state device manufacturingPlatinumAlloy

The invention discloses a high-end packaging silver alloy bonding wire. The high-end packaging silver alloy bonding wire is characterized by comprising 0.0001%-20% of gold, optional one or more than one of 0.0001%-20% of palladium, 0.0001%-20% of platinum, 0.0001%-0.015% of germanium, 0.0001%-0.015% of calcium and 0.0001%-1% of aluminum, and the balance silver. The invention further discloses a method for manufacturing the high-end packaging silver alloy bonding wire. The high-end packaging silver alloy bonding wire has the advantages of high strength and low hardness and long-arc degree.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

Nano/micron microsphere with superparamagnetism and preparation method

InactiveCN1519866AChange and control sizeAvoid reunionInorganic material magnetismMicrosphereSuperparamagnetism

The invention is specially related to method for preparing nano / micron microsphere with superparamagnetism through silanization. SiO2 with different content and number of layer are utilized to cover surface of Fe3O4 nano granule of new prepared in order to control grain size and avoid agglomeration. Then, under a moderate condition, silanization is carried out for surface of magnetic microsphere with silicon covered so as to obtain superparamagnetism microsphere with functional groups on surface. Grain size is in 30 nm-1000 nm / 1-20 um. Magnetic Fe3O4 is in 0.5-60% (weight percent) of whole microsphere. The invention features of controllable grain size, good sphericity, even magnetism content, and stable physical and chemical performances.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing microcapsule phase change material by using composite emulsifier

InactiveCN103170289AUniform particle size distributionOvercome the problem of air bubbles during stirringHeat-exchange elementsMicroballoon preparationParaffin waxIn situ polymerization

The invention discloses a method for preparing a microcapsule phase change material by using a composite emulsifier, which is used for preparing a microcapsule phase change material by using an in-situ polymerization method with paraffin as the core material and melamine-formaldehyde resin as the wall material. According to the method, firstly an oil-in-water (o / w) latex is prepared under the certain rotation speed with tween-20 and span-80 as the composite emulsifier, then melamine-formaldehyde prepolymer solution is added into the latex, the prepolymer gradually swells and deposits on the surface of the core material, a solid capsule shell is finally formed due to continuous cross linking and polymerization, and the encapsulated-completely phase change material microcapsule is obtained. The microcapsule phase change material prepared according to the method has the particle size of 3-4 mum, and has regular surface morphology, high encapsulation rate and good permeability resistance, and the method is simple and applied to the fields of building energy storage, textile and clothing, military affairs and the like.

Owner:DALIAN UNIV

Carbon nano tube/chitosan mesoporous spherical composite material as well as preparation method thereof

ActiveCN103933949AWon't fall offEasy separationOther chemical processesAlkali metal oxides/hydroxidesCarbon nanotubeSpherical form

The invention relates to a carbon nano tube / chitosan mesoporous spherical composite material as well as a preparation method thereof. The preparation method of the spherical composite material comprises the following steps: (1) carrying out acid treatment and dispersion treatment on carbon nano tube raw materials; (2) preparing a chitosan solution with the degree of deacetylation of 80-100%; (3) adding the carbon nano tube which is treated by the step (1) into the chitosan solution obtained by the step (2), and mixing uniformly so as to a spherical liquid; (4) dissolving alkaline solute into water so as to obtain a solidified liquid; (5) dropwise adding the spherical liquid into the solidified liquid so as to prepare a composite sphere; (6) placing the composite sphere generated by the step (5) into a crosslinking agent solution to crosslink, and stirring so as to obtain a crosslinking composite sphere; (7) refrigerating and drying the crosslinking composite sphere obtain by the step (6) so as to obtain the carbon nano tube / chitosan mesoporous spherical composite material. The carbon nano tube / chitosan mesoporous spherical composite material disclosed by the invention is nontoxic, and has favorable adsorption performance.

Owner:梁吉 +1

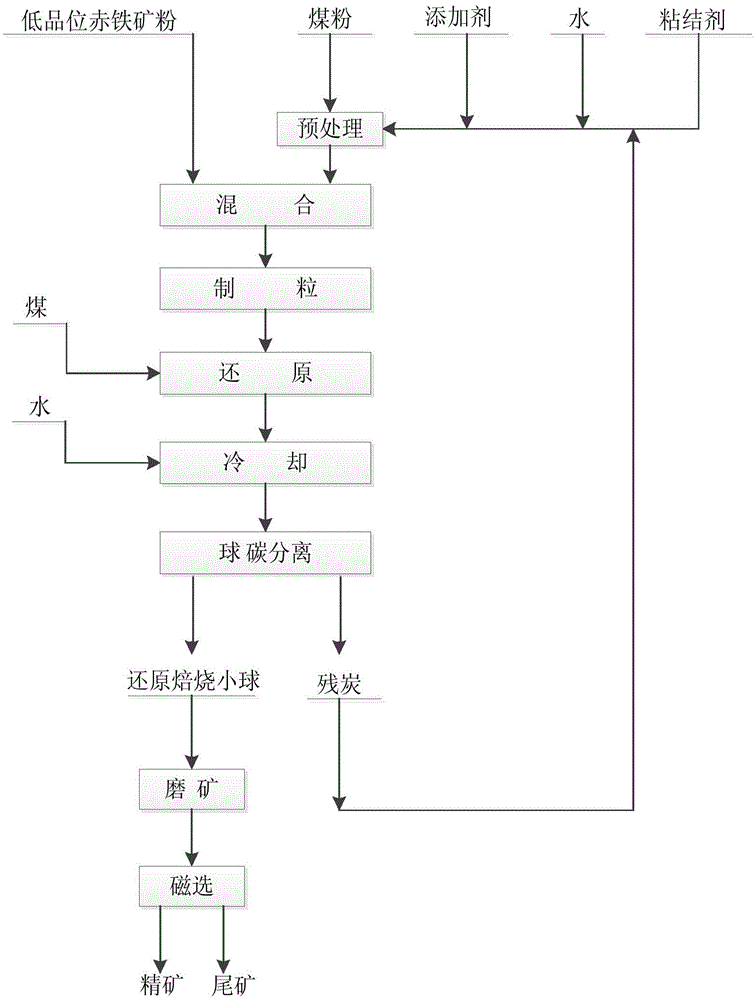

Low-grade iron ore direct reduction method

InactiveCN104862440AAvoid problems such as lossQuick restoreRotary drum furnacesProcess efficiency improvementIron powderResidual carbon

The invention relates to a low-grade iron ore direct reduction method, which comprises: calculating and taking a certain amount of coal powder, an additive, a binder and water by adopting the dry basis mass of iron ore to be treated as reference; uniformly mixing the taken components, and completely wetting to obtain an internal matching coal; uniformly mixing the internal matching coal and iron ore particles to be treated, and granulating to obtain granulated pellets; directly conveying the obtained granulated pellets into a rotary kiln, carrying out drying, pre-heating, and reduction roasting to carry out coal base direct reduction so as to obtain a reduced material, cooling the reduced material in the absence of air, and carrying out dry magnetic separation to obtain the reduced roasting pellets and the residual carbon; and carrying out treatments such as ore grinding and magnetic separation on the reduced roasting pellets to obtain iron concentrate, or carrying out re-grinding and re-magnetic separation to obtain the reduced iron powder, wherein the obtained residual carbon can be recycled. With the method of the present invention, the low-grade iron ore can be effectively treated, the internal matching coal and the additive are used to granulate, the wet pellets enter the kiln, the coal base direct reduction is performed, the magnetic separation is performed to obtain the high-grade iron concentrate or the directly-reduced iron powder, and the method has characteristics of energy saving, high efficiency, and rapidness.

Owner:CENT SOUTH UNIV +1

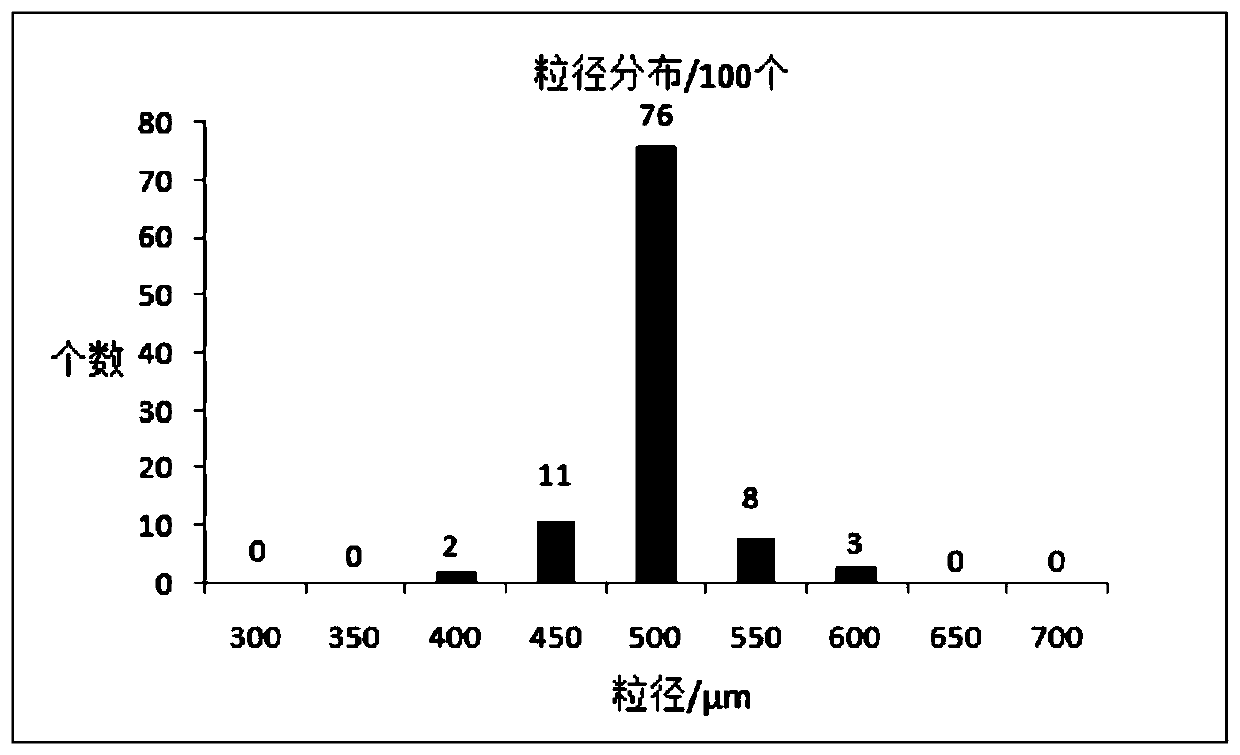

Large-particle-size agarose microspheres and preparation method thereof

ActiveCN109897202AGood ball formingImprove pressure resistanceOther chemical processesAlkali metal oxides/hydroxidesOrganic solventMicrosphere

The invention discloses a preparation method of large-particle-size agarose microspheres, which comprises the steps of providing an agarose solution having the mass concentration of 2-12% as a water phase; providing an organic solvent, in which an emulsifier is dissolved, as an oil phase; dropwise adding the water phase to the oil phase, and stirring to carry out emulsifying; cooling the emulsified mixed liquid for solidifying to obtain the large-particle-size agarose microspheres, wherein the agarose solution is prepared by dissolving at a temperature of 100-150 DEG C for 20-25 min, the emulsifier is one of, or a mixture of more than two of, span 40, span 60, span 80, span 85, tween 20, tween 60 and tween 80, the volume ratio of the water phase to the oil phase is 1:2 to 1:10, stirring speed is 50-1000 rpm, and emulsifying temperature is 50-100 DEG C. The invention also provides large-particle-size agarose microspheres prepared via the preparation method. The large-particle-size agarose microspheres have the particle size range of 400-1000 mu m, and have good pressure resistance, high temperature tolerance and high flow velocity resistance.

Owner:SENHUI MICROSPHERE TECH SUZHOU CO LTD +1

Preparation method based on single crystal copper bonding wire

InactiveCN102280388ALow priceImprove plastic deformationPolycrystalline material growthSemiconductor/solid-state device detailsEpoxyMicrocomputer

The invention discloses a preparation method based on single crystal copper bonding wire. The preparation method of the single crystal copper bonding wire is divided into two steps: (1) using continuous casting single crystal copper rod as the single crystal copper The starting material of the bonding wire, at the same time, the single crystal copper bonding wire is drawn by the drawing equipment driven by the AC servo motor with the microcomputer program control, active wire release, and the pulling force accuracy is less than 1mN; (2) The drawn single crystal copper bond The bonding wire is treated with electroplating precious metal palladium with a surface thickness of 0.5um~1um and an organic epoxy coating with a thickness of 1um for double-layer protection; in this way, a single crystal copper bonding wire with multiple protective coatings is finally obtained. Bonding wire has the advantages of low price, high elongation, good mechanical and electrical properties, and good oxidation resistance.

Owner:王一平

Composite additive for preparing hematite concentrate pellet and application thereof

A composite additive for preparing hematite concentrate pellets comprises the following components: humic acid, calcium peroxide, and paigeite. During application, the composite additive is added which has a mass percent of 0.5%-1.6% of the total mass of the hematite concentrates, and the finished product pellets are obtained by pelletization, preheating, and roasting. Compared with pellets prepared by traditional technology, the hematite pellets prepared by the composite additive of the invention have improved falling strength of the green pellets, and compression strength of the finished product pellets; the preheating temperature and roasting temperature suitable for the pellets are reduced; both the preheating time and roasting time are shortened; the TFe grade is increased by 0.8%-1.2%. The composite additive of the invention has reasonable component ratios, is easy to process and manufacture, has a low using amount and a low residual amount, can significantly improve the pelletability of hematite concentrates which are difficult to be palletized, can improve the green pellet quality, has good heat stability, and can effectively reduce the preheating and roasting temperatures and shorten the preheating and roasting time of hematite concentrates. The composite additive of the invention is applicable to the production of oxidized pellets by hematites, and is especially applicable to the production of oxidized pellets by specularites. The composite additive of the invention is applicable to large-scale industrial production.

Owner:CENT SOUTH UNIV

Multi-medicament loaded calcium phosphate cement powder

InactiveCN102114271APromote growthIncrease success rateInorganic non-active ingredientsSkeletal disorderSide effectCo administration

The invention discloses multi-medicament loaded calcium phosphate cement powder. The multi-medicament loaded calcium phosphate cement powder is prepared by directly mixing more than one prophase release medicament, polymer microspheres loaded with a long-term release medicament and calcium phosphate cement powder, or performing precipitation blending on more than one prophase release medicament and an ingredient in the calcium phosphate cement powder and uniformly mixing the obtained product with other ingredients of the calcium phosphate cement powder and the polymer microspheres loaded with the long-term release medicament. The powder is suitable for filling and repairing bone defects with different volumes and different shapes; moreover, the loaded prophase release medicaments and the loaded long-term release medicament can be released for co-administration in different time sequences at local positions of the bone defects; and the powder, through the synergism, enhances therapeutic effect, promotes bone healing, improves the success rate of clinical filling and repair of the bone defects, and can reduce the side effect of the medicaments on organisms and meet the clinical demand on bone filling and repair materials at the same time.

Owner:SOUTHWEST JIAOTONG UNIV

Preparation method of sodium alginate-MOFs composite microsphere for adsorbing heavy metal selenium

InactiveCN108339521AImprove adsorption capacitySimple preparation processOther chemical processesWater contaminantsMicrowaveMicrosphere

The invention discloses a preparation method of a sodium alginate-MOFs composite microsphere for adsorbing heavy metal selenium. The preparation method comprises the steps: adding MIL-101 into a sodium alginate solution, and carrying out stirring; then, adding a CaCl2 water solution, and carrying out a crosslinking reaction to obtain a composite microsphere; and finally, carrying out microwave treatment in a microwave reaction cavity to obtain a sodium alginate-MOFs composite microsphere water body purifying material; the sodium alginate solution refers to a sodium alginate solution having themass percentage concentration of 0.5-3.0% and taking water as a solvent; the stirring refers to the step of carrying out uniform stirring under a room temperature condition by using an electromagnetic stirrer, and then, ultrasonically removing air bubbles; the CaCl2 water solution refers to a CaCl2 water solution having the concentration of 0.05-1.50mol / L and taking water as a solvent; and the microwave treatment refers to the step of carrying out treatment at the power of 300W-1200W for 3-45min. The preparation method has the characteristics such as simple preparation process and conveniencein use.

Owner:ZHEJIANG OCEAN UNIV

Comprehensive sintering method of large-proportion limonite

The invention provides a comprehensive sintering method of large-proportion limonite. The comprehensive sintering method of large-proportion limonite is characterized by comprising the following stepsof (1) preparing the following materials in a mass ratio: 60-75% of limonite powder, 5-10% of imported ore powder, 5-15% of iron ore concentrate powder, 2-5% of dolomite, 2-5% of limestone, 3-5% of quick lime, 5-8% of coke powder and 0-10% of sintered ore minus sieve powder, wherein the total percentage of the components is 100%, and controlling alkalinity to be 1.60-2.0; (2) performing materialmixing for the first time, and controlling moisture to be 5.0-8.5%; (3) performing material mixing for the second time, and controlling moisture to be 6.0-9.5%; (4) performing material distribution: laying bottom materials of which the thickness is 20mm, then laying a sintering material layer of which the thickness is 730-860mm, performing material pressing at edges, and performing water sprayingfor humidifying; and (5) performing sintering so as to obtain sintered ore. Hazardous elements of S and P are effectively reduced, and under the situation of realizing sintering of the large-proportion limonite, fully utilizing limonite resources and reducing cost, high-quality sintered ore can be obtained.

Owner:KUNMING UNIV OF SCI & TECH

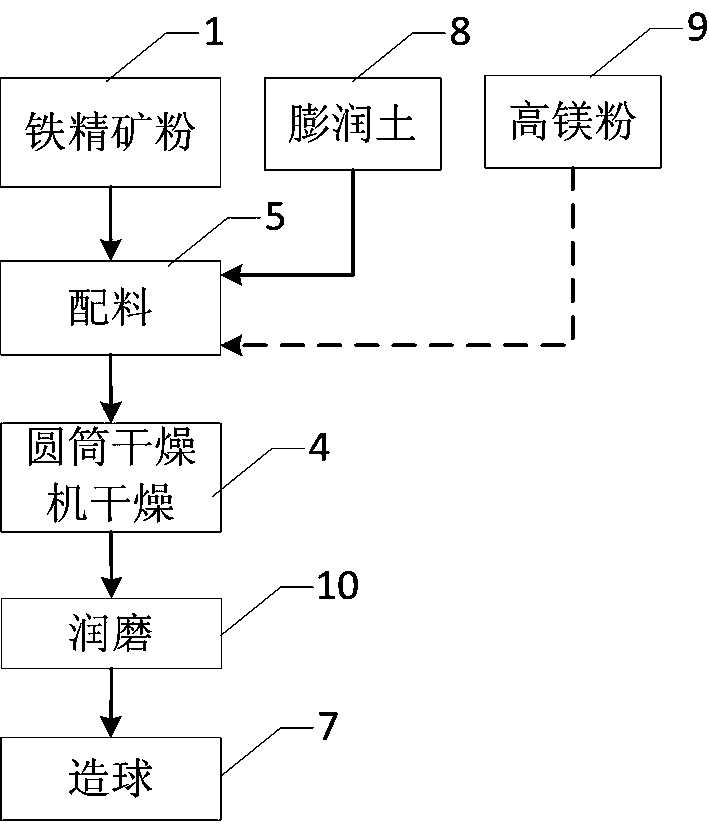

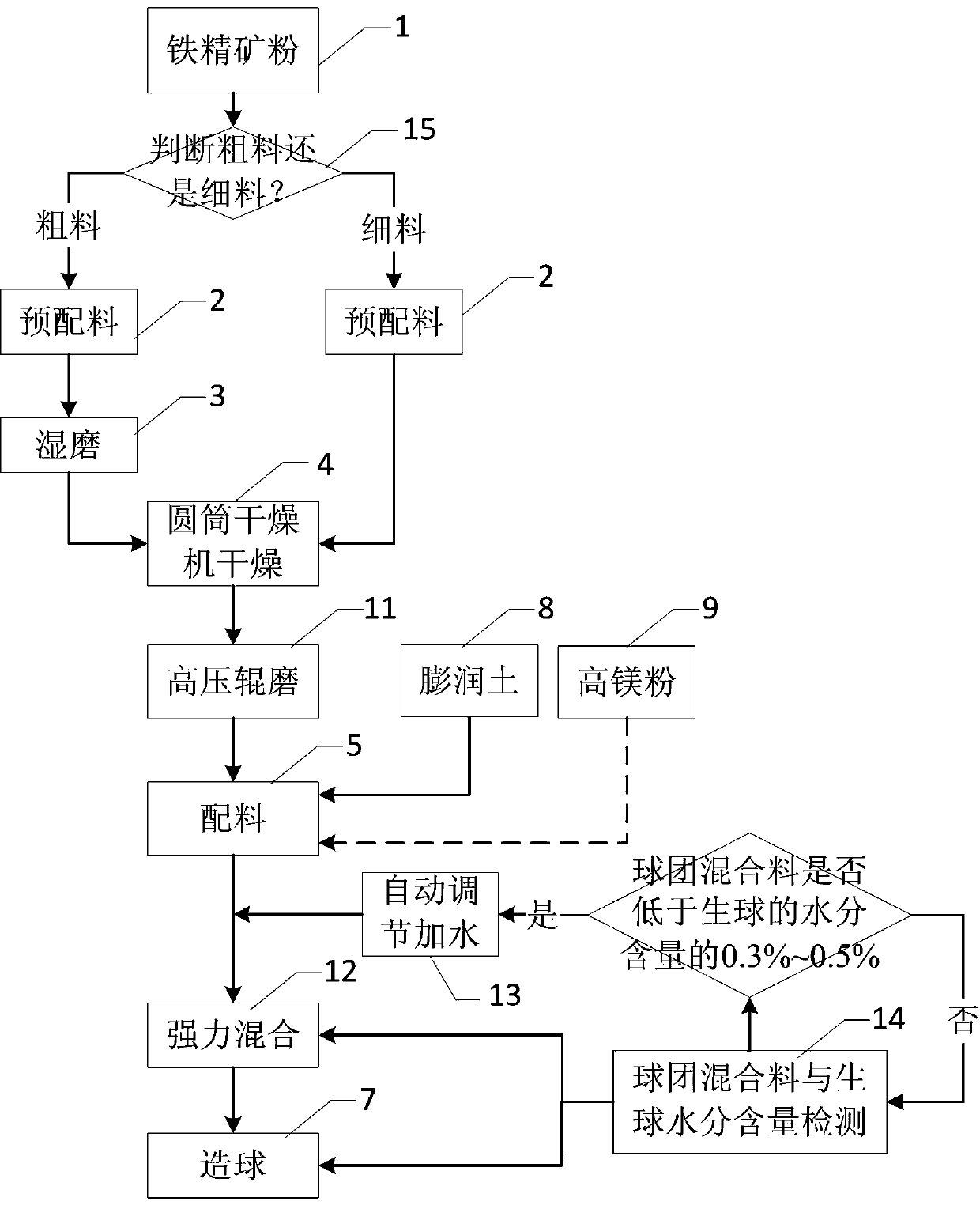

Iron mine pellet raw material preparation method facilitating efficient pelletizing

The invention relates to the field of research of pellet mine manufacturing techniques of the iron and steel metallurgy industry, in particular to an iron mine pellet raw material preparation method facilitating efficient pelletizing. The method includes the steps that whether iron concentrate fines are coarse materials or fines is judged, if the iron concentrate fines are the coarse materials, the iron concentrate fines are subjected to wet grinding after pre-dosing; the iron concentrate fines are dried and smashed by a high pressure rolling mill; the iron concentrate fines after smashing aremixed with bentonite and the like to obtain a pellet mixture through intensive mixing; the pellet mixture enters a pelletizer to be subjected to pelletizing to obtain pelletizing green-balls; and thewater content of the pelletizing mixture before entering the pelletizer and the water content of the pelletizing green-balls are separately detected, the pelletizing mixture before entering the pelletizer is automatically regulated and intensively mixed with water, and the pelletizing mixture water content range is controlled below 0.3%-0.5% of the green-ball suitable water content. According tothe iron mine pellet raw material preparation method facilitating efficient pelletizing, the technical problem that the water content of production raw materials is difficult to control in the preparation process is solved, and the strength and the production efficiency of pelletizing green-balls are improved.

Owner:ANYANG IRON & STEEL

Cu2+-EDTA-Fe3O4 magnetic grain, preparation method and application

ActiveCN105032310AUniform particle size distributionGood dispersionPeptide preparation methodsInductances/transformers/magnets manufactureSuperparamagnetismAdsorption effect

The invention belongs to the technical field of superparamagnetism functional materials, and discloses a Cu2+-EDTA-Fe3O4 magnetic grain with the surface decorated with a large number of copper ions, a preparation method of the Cu2+-EDTA-Fe3O4 magnetic grain, and application of the Cu2+-EDTA-Fe3O4 magnetic grain in the bio-medical field. The Cu2+-EDTA-Fe3O4 magnetic grain is particularly suitable for separating histidine proteins. The magnetic grain is prepared through the following steps of preparing an EDTA-Fe3O4 magnetic grain through a hydrothermal method, adding the EDTA-Fe3O4 magnetic grain to a water-soluble copper salt solution, and obtaining the Cu2+-EDTA-Fe3O4 magnetic grain through chelation. The magnetic grain is spherical and high in dispersibility and has the grain size of about 150 nm and the magnetic saturation of 69 emu / g. Through the strong coordination of Cu2+ with which the surface of the grain is decorated and histidine residues on surfaces of hemoglobin, the superhigh adsorption capacity is achieved for hemoglobin, the adsorption capacity can reach 1250 mg / g, no obvious adsorption effect is achieved for serum albumin, excellent selectivity is expressed, and the removal efficiency is larger than 90%.

Owner:SOUTH CHINA NORMAL UNIVERSITY

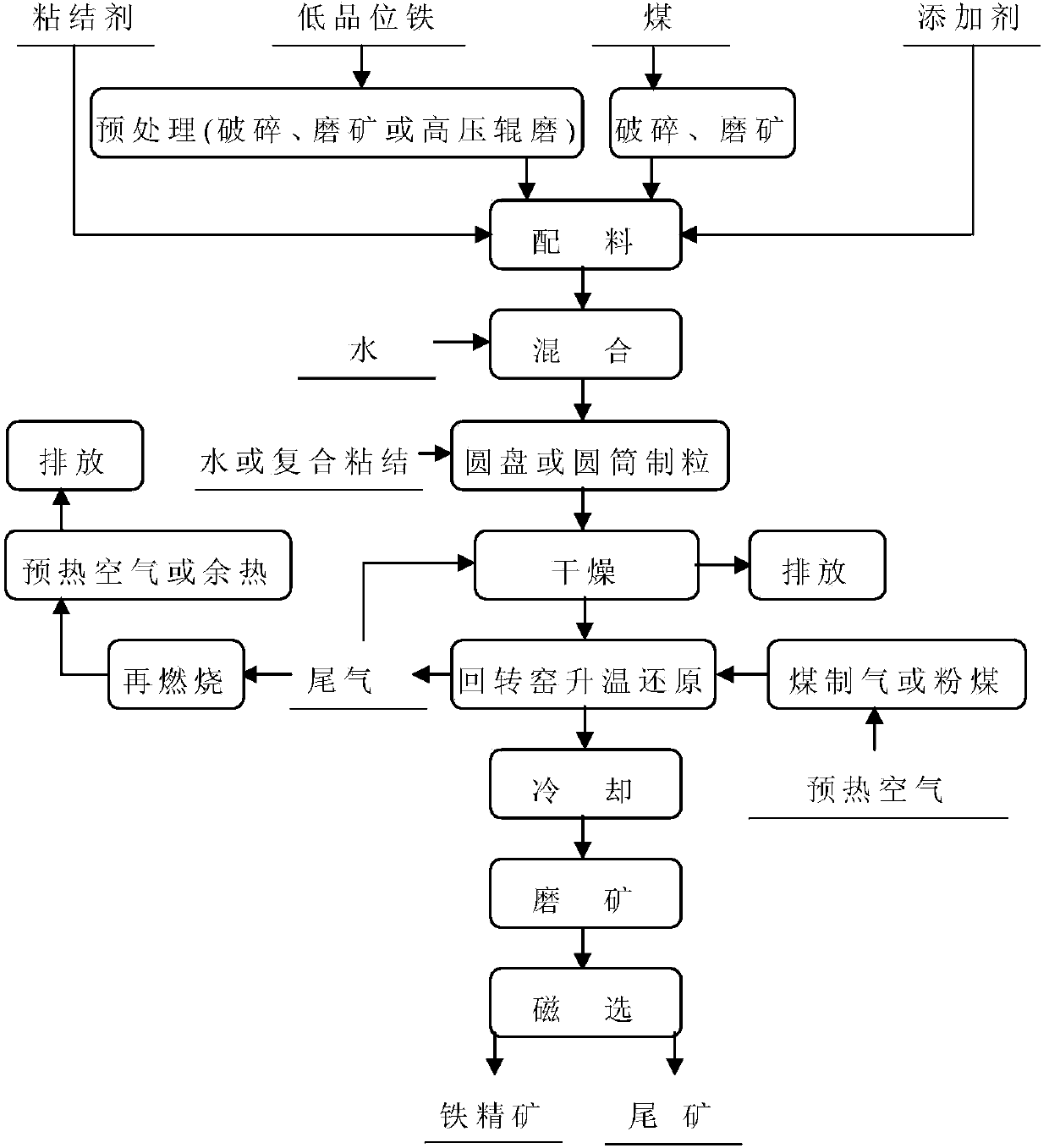

Method for improving grade of low-grade iron ore

ActiveCN103993166AAvoid problems such as lossGood ball formingProcess efficiency improvementClay mineralsLower grade

The invention provides a method for improving the grade of low-grade iron ore. The method comprises the following steps: respectively pretreating low-grade iron ore and coal, adding coal dust and an additive according to a certain proportion and preparing small balls with particle sizes of 3 to 8 mm by using a disc or drum balling machine after the content of treated iron ore and coal with a particle size of 0.074 mm is more than 50%, wherein clay minerals in the low-grade iron ore are used as a binder, or a small amount of binders like bentonite is added and uniformly mixed with treated iron ore and coal; and drying the prepared balls with a belt or cylindrical dryer, carrying out reduction by using a rotary kiln and then successively carrying out cooling and magnetic separation so as to obtain high-grade iron ore concentrate. With the method, low-grade iron ore can be effectively treated, the high-grade iron ore concentrate is obtained through granulation of the coal and the additive, direct reduction and magnetic separation, and the characteristics of energy conservation, high efficiency and rapidness are obtained.

Owner:CENT SOUTH UNIV +2

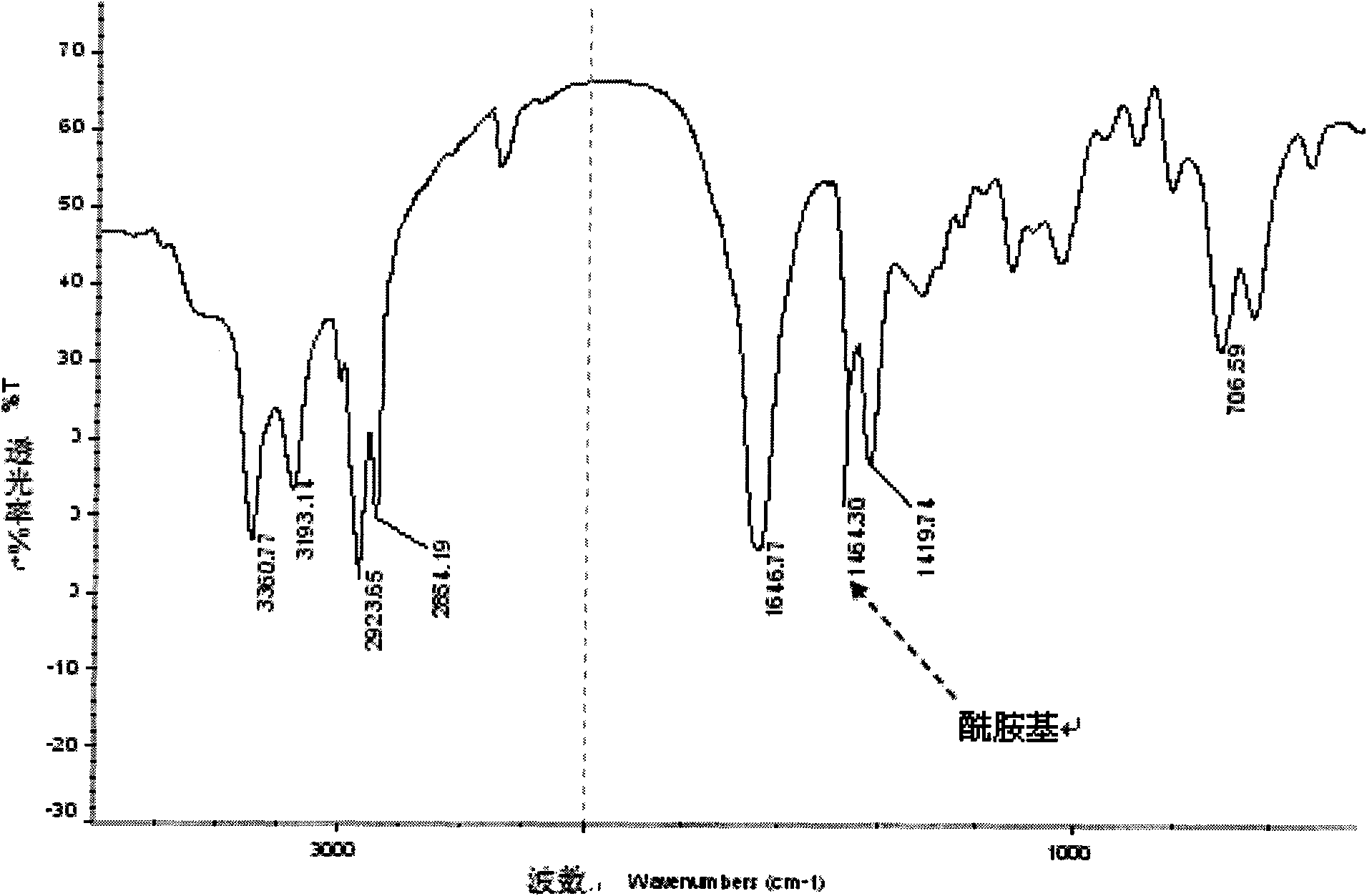

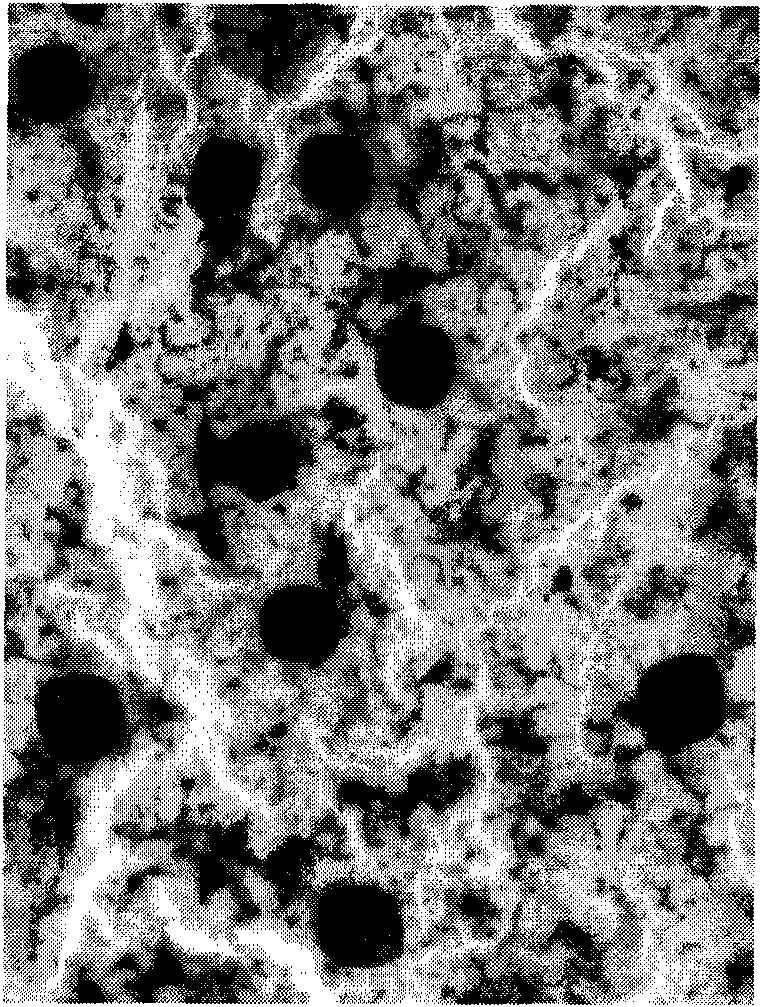

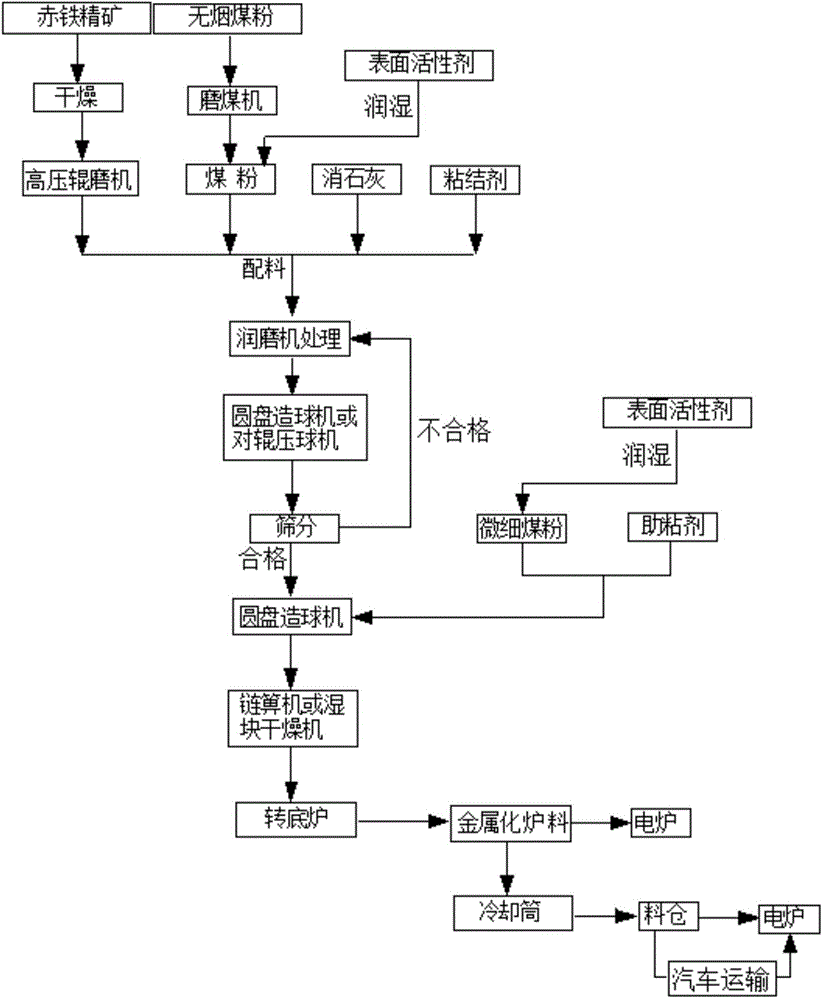

Technology for producing metal furnace burden for high-quality electric furnace by coal-based method

The invention discloses a technology for producing a metal furnace burden for a high-quality electric furnace by a coal-based method, and belongs to the field of direct iron ore concentrate reducing technologies. The technology comprises the following steps: (1) blending: drying hematite concentrates, then performing mechanical activation, grinding anthracite powder, and blending and mixing the hematite concentrates, the anthracite powder, slaked lime and an adhesive; (2) balling or ball pressing: balling or pressing the mixed raw materials in the step (1) to obtain pellets or blocks; (3) mixture wrapping: wrapping the produced pellets or blocks with a layer of mixture consisting of the anthracite powder, the slaked lime and polyacrylamide powder; (4) drying and reduction: drying the pellets or blocks wrapped with the mixture in the step (3), and then putting the pellets or blocks into a rotary hearth furnace. The metal furnace burden produced by the technology can directly meet the requirement on electric furnace production and is used for partially replacing waste steel for the electric furnace.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Method for utilizing sulfate slag and red mud comprehensively

The invention discloses a method for utilizing sulfate slag and red mud comprehensively. The method comprises the steps that the sulfate slag and the red mud are mixed with a reducing agent so as to obtain a mixed material; roasting is carried out on the mixed material so as to obtain a reduced iron product; the reduced iron product is separated so as to obtain iron powder. By the utilization of the method, the two metallurgical solid waste resources, namely the red mud and the sulfate slag are utilized comprehensively, so that the iron product with good indexes is obtained.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Leadless tin-base soft solder

InactiveCN101134272AGood ball formingImprove surface qualityWelding/cutting media/materialsSoldering mediaElectronic industryMaterials science

The no-lead Sn-base soft solder for preparing BGA tin ball consists of Ag 1.1.5-5.0 wt%, Cu 0.3-0.9 wt%, RE 0.001-0.2 wt%, Ge 0.001-0.2 wt%, and Sn for the rest. Or, it consists of Ag 2.1.5-5.0 wt%, Cu 0.3-0.9- wt%, RE 0.001-0.2 wt%, Ge 0.001-0.2 wt%, Bi 0.05-1.5 wt%, and Sn for the rest. The present invention is suitable for no-lead assembling and packaging in electronic industry.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL

Preparation method of cross-linked chitosan resin

InactiveCN102989421AGood ball formingImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesParaffin oilsPolyresin

The invention discloses a preparation method of a cross-linked chitosan resin. The method provided by the invention comprises reaction liquid preparation, resin producing, and resin pretreatment. Main steps comprise: (a) a chitosan solution is prepared and is added into paraffin; (b) a stirring device is started and a resin producing reaction is carried out; (c) obtained resin is filtered, washed, and is subjected to an impurity-removing treatment; and (d) the resin is pretreated. With the method provided by the invention, cross-linked chitosan resin with excellent pelletization performance and relatively high adhesion performance can be prepared.

Owner:王然

Preparation method for immobilization particle used for reducing activated sludge

ActiveCN104762291AFully contactedGood ball formingMicroorganism based processesOn/in organic carrierBacillus licheniformisActivated sludge

The invention provides a preparation method for an immobilization particle used for reducing activated sludge. The preparation method comprises the following steps: uniformly mixing fermentation broths of corresponding strains according to a weight ratio of Bacillus subtilis to Bacillus cereus to Bacillus megaterium to Bacillus licheniformis to Bacillus pumilus of 4-6: 4-6: 6-9: 5-7: 4; preparing bacterial powder from the above mentioned mixed bacterial liquid through spray drying; and preparing the immobilization particle by using a PVA-saturated boric acid method. By using an immobilization method, high-efficiency sludge degrading bacterial strains are embedded, so the concentration of the sludge degrading bacterial strains participating in a reaction can be greatly increased, the bacterial strains are vulnerable to loss and dying, have longer action time and obviously improved antitoxin capability and tolerance, solid-liquid separation can be easily realized, and secondary pollution is small.

Owner:天津北洋百川生物技术有限公司

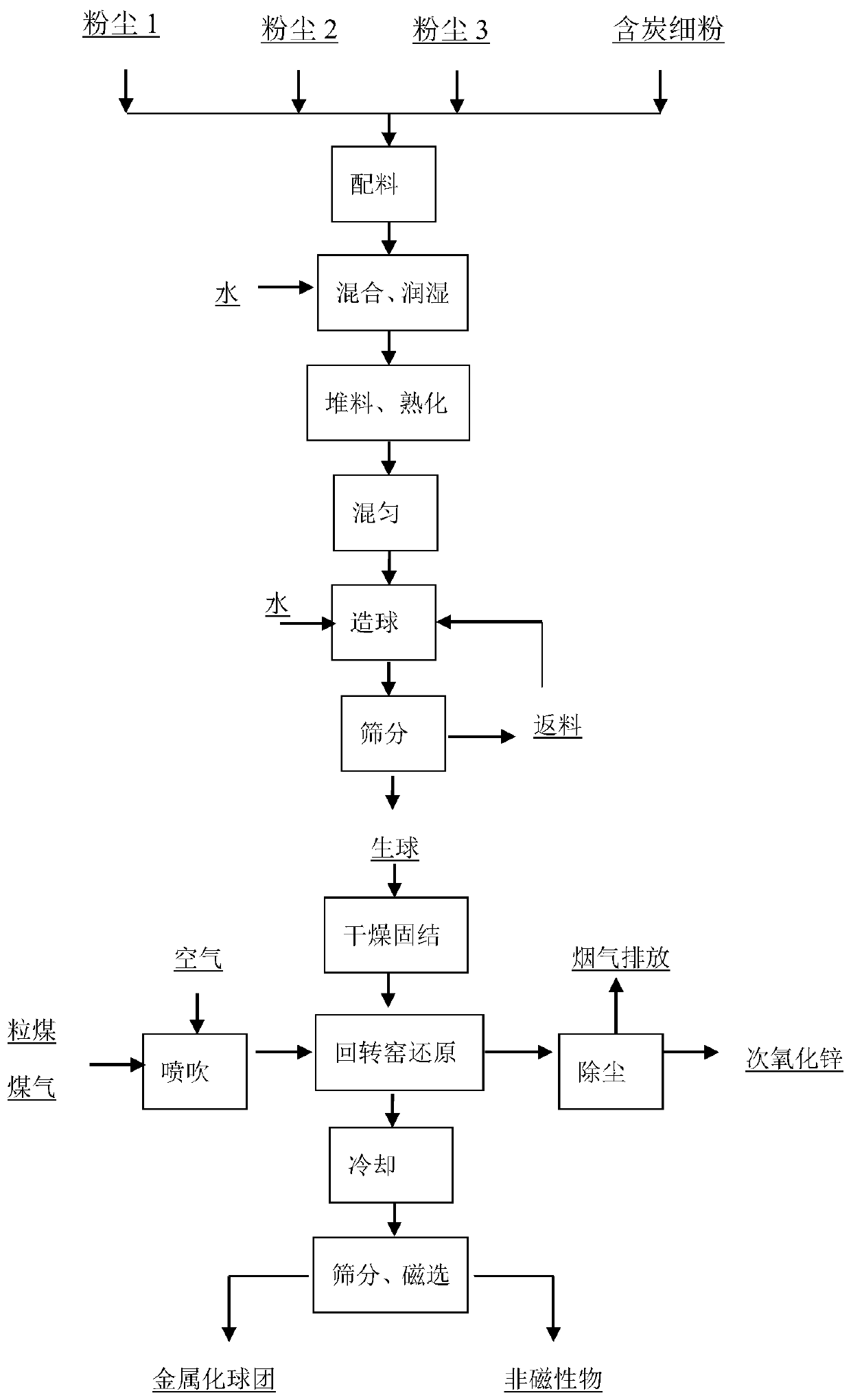

Preparation method of zinc-containing dust pellet

ActiveCN110317949AOvercoming the characteristics of weak ball formationGood ball formingRotary drum furnacesProcess efficiency improvementMixed materialsCompressive strength

The invention provides a preparation method of a zinc-containing dust pellet. The preparation method comprises the following steps of S1, carrying out burdening , mixing the blast furnace cloth bag ash, the steel-making ladle furnace ash, the steel-making converter smoke dust and other zinc-containing dust with the carbon-containing fine powder to obtain a mixture; S2, carrying out pretreatment, adding water into the mixture obtained in the step S1 for wetting, and piling up and curing after wetting; S3, adding a composite binder into the cured mixture, and carrying out uniformly mixing to obtain a uniform mixture; S4, carrying out pelletizing on the uniformly mixed material prepared in the step S3 to obtain a green pellet; and S5, drying the green pellet in the step S4 to obtain the zinc-containing dust dry pellet. The dry pellet has the advantages of high compressive strength and good reducibility, the metallization rate is high in the direct reduction process, the dezincification effect is good, and the preparation method solves the technical problems that an existing zinc-containing dust pellet is easy to break and pulverize in the reduction process.

Owner:CENT SOUTH UNIV

Preparation method of magnetic immobilized enzyme

InactiveCN104560940AResponsiveness to strong magnetic fieldsQuick and Easy EnrichmentOn/in organic carrierOn/in inorganic carrierMagnetic responseOperational stability

The invention provides a preparation method of a magnetic immobilized enzyme, relating to a preparation method of a novel carrier PVP-DB-171 (polyvinylpyrrolidone-vinyltrimethoxysilane) / SiO2 / Fe3O4. The invention aims to solve the problem that the free enzyme is sensitive to the reaction environment and can not be recovered and the problems of high production cost and the like, and thus, the free enzyme is immobilized in the nano magnetic carrier PVP-DB-171 / SiO2 / Fe3O4. The magnetic immobilized enzyme is an enzyme with magnetic response characteristic and has operational stability; and the nano immobilized enzyme is uniformly dispersed in the liquid phase. The magnetic response performance can be utilized to achieve the goal of completely separating the immobilized enzyme from the reaction medium. The active recovery rate of the finally obtained immobilized enzyme is 85%; and the enzyme activity after 10 times of repeated use is kept at 70% above.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Novel binder for metallurgical pellets

The invention belongs to metallurgical raw materials and pretreatment technology, and in particular relates to a novel binder for metallurgical pellets. The novel binder for the metallurgical pellets consists of the following components in part by weight: 100 parts of natural calcium-based bentonite, 2 to 5 parts of sodium carbonate and 1.1 to 2.0 parts of sodium cellulose, wherein the natural calcium-based bentonite is natural calcium-based bentonite with montmorillonite content of more than 54 percent. The preparation method comprises the following steps of: adding 2 to 5 weight parts of sodium carbonate into 100 weight parts of natural calcium-based bentonite for sodium treatment, drying until the moisture content is below 12 percent, performing ore grinding until the ore with granularity of less than 43 microns is over 90 percent, adding 1.1 to 2.0 weight parts of sodium cellulose, and stirring and uniformly mixing to prepare the novel binder for the metallurgical pellets. The pellet forming property of green pellets can be effectively improved, the cracking temperature of the green pellets is improved, the metallurgical property of pellet ore is improved, and the binder has the effects of increasing the yield and reducing the consumption for the production of the pellet ore.

Owner:ANSTEEL GRP MINING CO LTD

Method for preparing monodisperse nanosphere medicine carrier

ActiveCN102091042AGood size uniformityGood monodispersityPowder deliveryPharmaceutical non-active ingredientsUltrafiltrationWater soluble

The invention discloses a method for preparing a monodisperse nanosphere medicine carrier, which comprises the following steps: dissolving poly(lactic-co-glycolic acid) in organic solvent to form an organic phase; dissolving emulsifier in distilled water to form a water phase; under the synergistic effect of ultrasound and stirring and in an ice water bath, adding an organic phase into a water phase according to a volume ratio to obtain oil-in-water emulsion; continuously stirring the emulsion at normal temperature for 4 to 20 hours, and removing organic solvent; and performing low-speed centrifugation to remove aggregate, subjecting supernate to ultrafiltration, refrigeration, centrifugation and washing to obtain the monodisperse nanosphere medicine carrier. In the monodisperse nanospheres, the spherical shape is regular, the particle size is between 100 and 500 nanometers, the size is controllable and the specifications are uniform. The monodisperse nanospheres are suitable for coating and carrying various water soluble or liposoluble medicines and have the advantages of biodegradability, controlled medicine release and the like.

Owner:广州智焜生物科技有限公司

'Funnel'-shaped three-dimensional cell aggregation and culture chip and preparation method thereof

PendingCN108795751AGood ball formingPhotomechanical apparatusTissue/virus culture apparatusEngineeringSoft lithography

The invention provides a 'funnel'-shaped three-dimensional cell aggregation and culture chip and a preparation method thereof. The chip is provided with a 'funnel'-shaped recessed array structure, andthe upper half portion of the funnel-shaped structure is a trapezoidal pyramid while the lower half portion of the funnel-shaped structure is a cylinder or a cuboid. According to a preparation process of the chip, a template which has a funnel-shaped structure is obtained by two soft lithography technologies including oblique exposure and vertical exposure at first, then a polydimethylsiloxane chip is prepared by the template, and when ultraviolet exposure is carried out by soft lithography, the upper half portion and the lower half portion of the funnel-shaped structure are separately prepared by two exposure methods. After the chip is inoculated with cells, because an inclined side wall is arranged on the top of a funnel-shaped recess in the chip, cells are forced to be aggregated to the bottom of the funnel-shaped recess and then are aggregated into cell groups or cell balls.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Ironmaking oxidized pellet additive

The invention discloses the globe group chemic additive used in the mine, it is the powder duplicating mix compound. The granularity exceeds 200 items, the team element (the weight percent): the adding adhesive is 30-50%; the adding oxygen activator is 10-25%; the intensifying reagent is 10-25%; the carrier is 30-50%. The produced additive has not Si, AL, K, Na element which are harmful for the piddling. It can replace fully the expanding moist soil in producing the ball and is need to depress the quality of the globe group mine, the request of the quality can be reached and exceeded with the adding of the 0.4-0.6% additive in the globe group material, the ability of the metallurgy under the high temperature in the globe group material can be improved highly. The function of the additive exceeds the function of the expanding moist soil highly.

Owner:刘虎生

Collagen-polyvinyl alcohol embolism microspheres loaded with iodine 131 and preparation method thereof

ActiveCN111229139ARadioactive shortImprove distributionSurgeryMicroballoon preparationPolyvinyl alcoholMicrosphere

The invention discloses collagen-polyvinyl alcohol embolism microspheres loaded with iodine 131 and a preparation method thereof. The preparation method comprises the following steps: firstly, carrying out a crosslinking reaction on polyvinyl alcohol and type I collagen to prepare collagen-polyvinyl alcohol embolism microspheres, and then carrying out radioactive iodine 131 labeling on the collagen-polyvinyl alcohol embolism microspheres to obtain iodine 131-collagen-polyvinyl alcohol embolism microspheres. The embolism microspheres prepared by the invention not only can slow down the growth speed of tumors and prolong the longest lifetime of patients, but also have the advantages of small specific gravity, easiness in perfusion, long half-life period and capability of releasing gamma raysfor imaging monitoring, do not need expensive activation equipment, and are beneficial to reducing the cost.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com