Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Avoid problems such as loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

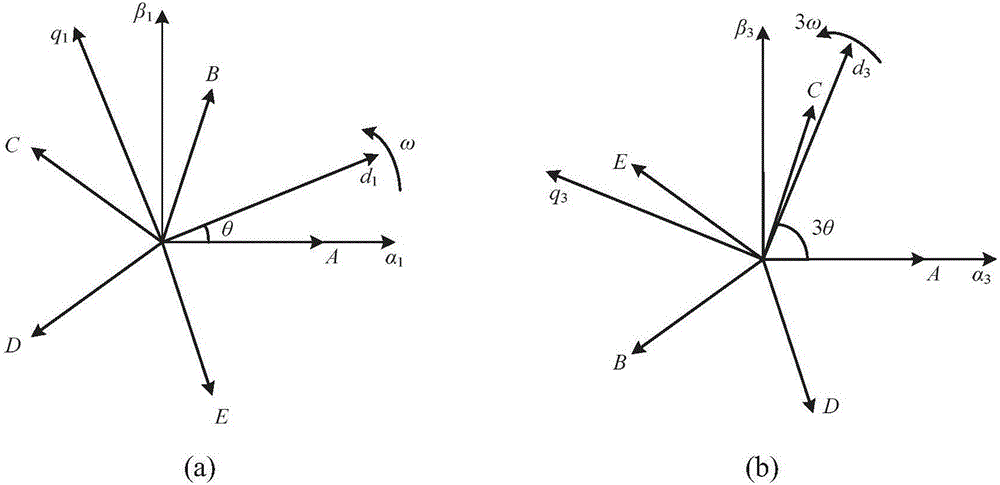

Full-vector control method of five-phase fault-tolerant permanent magnet motor

ActiveCN105119547AAvoid software and hardware changesAvoid selectivityElectronic commutation motor controlVector control systemsCurrent meterControl vector

The invention discloses a full-vector control method of a five-phase fault-tolerant permanent magnet motor. According to the method, a five-phase SVPWM method is adopted when the motor operates normally; after a one-phase open-circuit fault occurs on the motor, the traditional SVPWM method and a current hysteresis control method are combined together to re-construct a post-fault coordinate system; re-distribution and sector reconstruction of space vectors are performed on the reconstructed coordinate system; target vectors are synthetized through re-selection of the space vectors; and therefore, full-vector control on the five-phase fault-tolerant permanent magnet motor can be realized. With the full-vector control method adopted, problems such as hardware variation and loop width selection brought about by the switching of normal five-phase SVPWM to current hysteresis control existing on most current methods can be solved, and tracking performance can be ensured, and torque ripples after open-circuit faults can be effectively restrained.

Owner:东台城东科技创业园管理有限公司

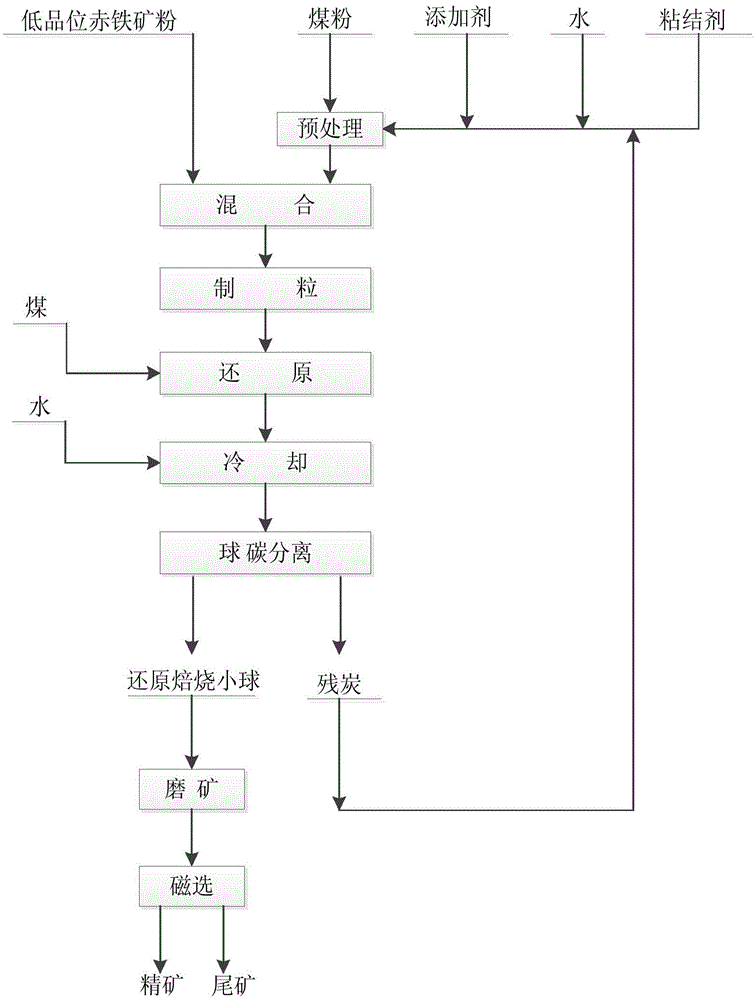

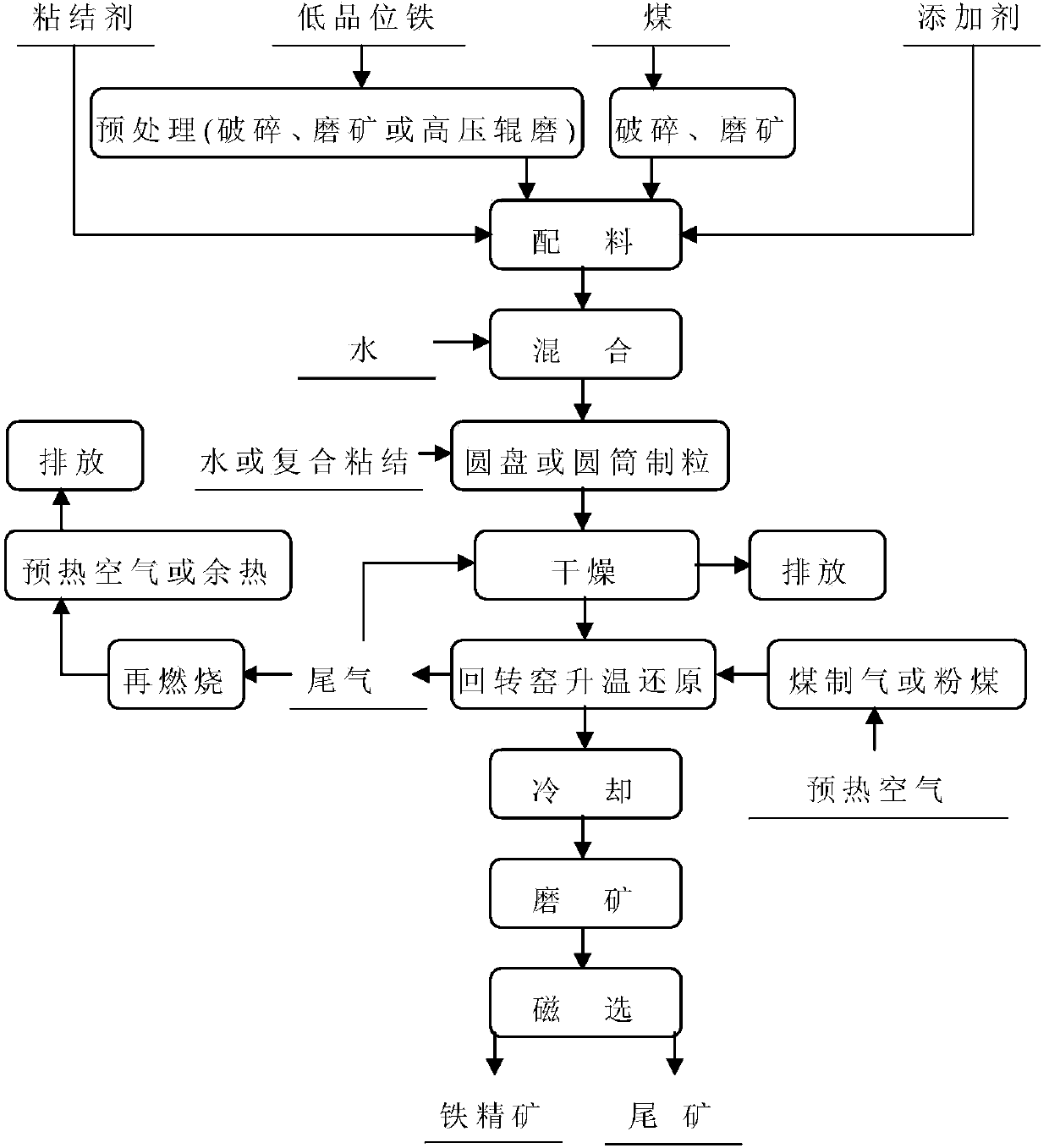

Low-grade iron ore direct reduction method

InactiveCN104862440AAvoid problems such as lossQuick restoreRotary drum furnacesProcess efficiency improvementIron powderResidual carbon

The invention relates to a low-grade iron ore direct reduction method, which comprises: calculating and taking a certain amount of coal powder, an additive, a binder and water by adopting the dry basis mass of iron ore to be treated as reference; uniformly mixing the taken components, and completely wetting to obtain an internal matching coal; uniformly mixing the internal matching coal and iron ore particles to be treated, and granulating to obtain granulated pellets; directly conveying the obtained granulated pellets into a rotary kiln, carrying out drying, pre-heating, and reduction roasting to carry out coal base direct reduction so as to obtain a reduced material, cooling the reduced material in the absence of air, and carrying out dry magnetic separation to obtain the reduced roasting pellets and the residual carbon; and carrying out treatments such as ore grinding and magnetic separation on the reduced roasting pellets to obtain iron concentrate, or carrying out re-grinding and re-magnetic separation to obtain the reduced iron powder, wherein the obtained residual carbon can be recycled. With the method of the present invention, the low-grade iron ore can be effectively treated, the internal matching coal and the additive are used to granulate, the wet pellets enter the kiln, the coal base direct reduction is performed, the magnetic separation is performed to obtain the high-grade iron concentrate or the directly-reduced iron powder, and the method has characteristics of energy saving, high efficiency, and rapidness.

Owner:CENT SOUTH UNIV +1

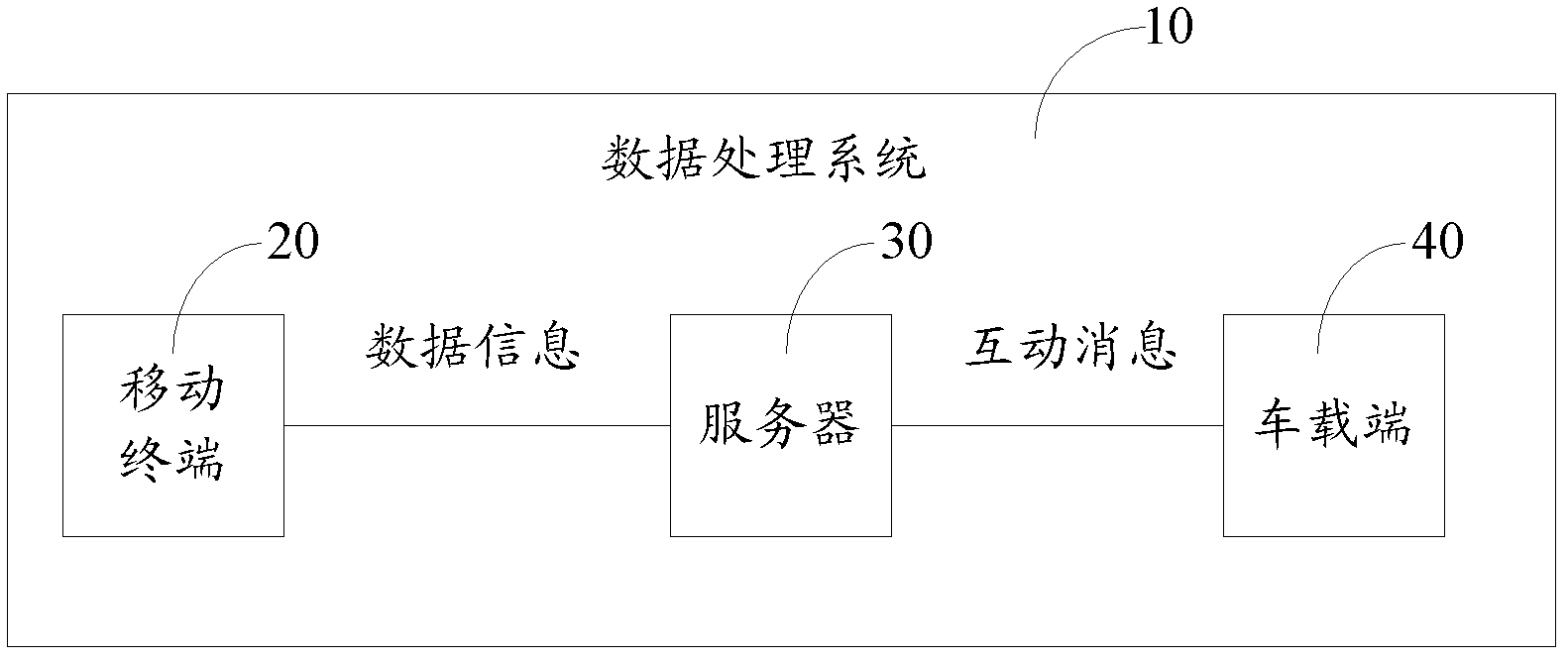

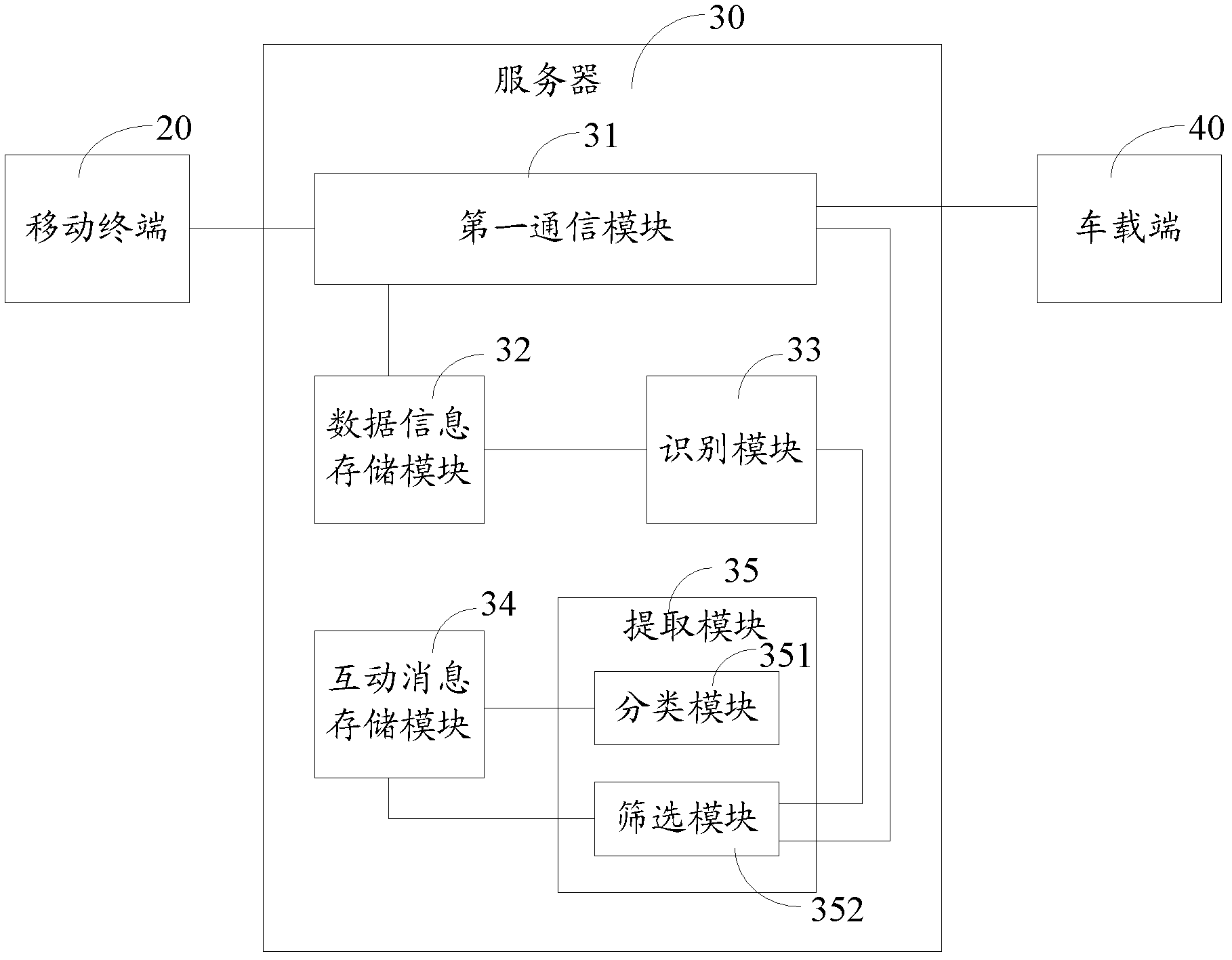

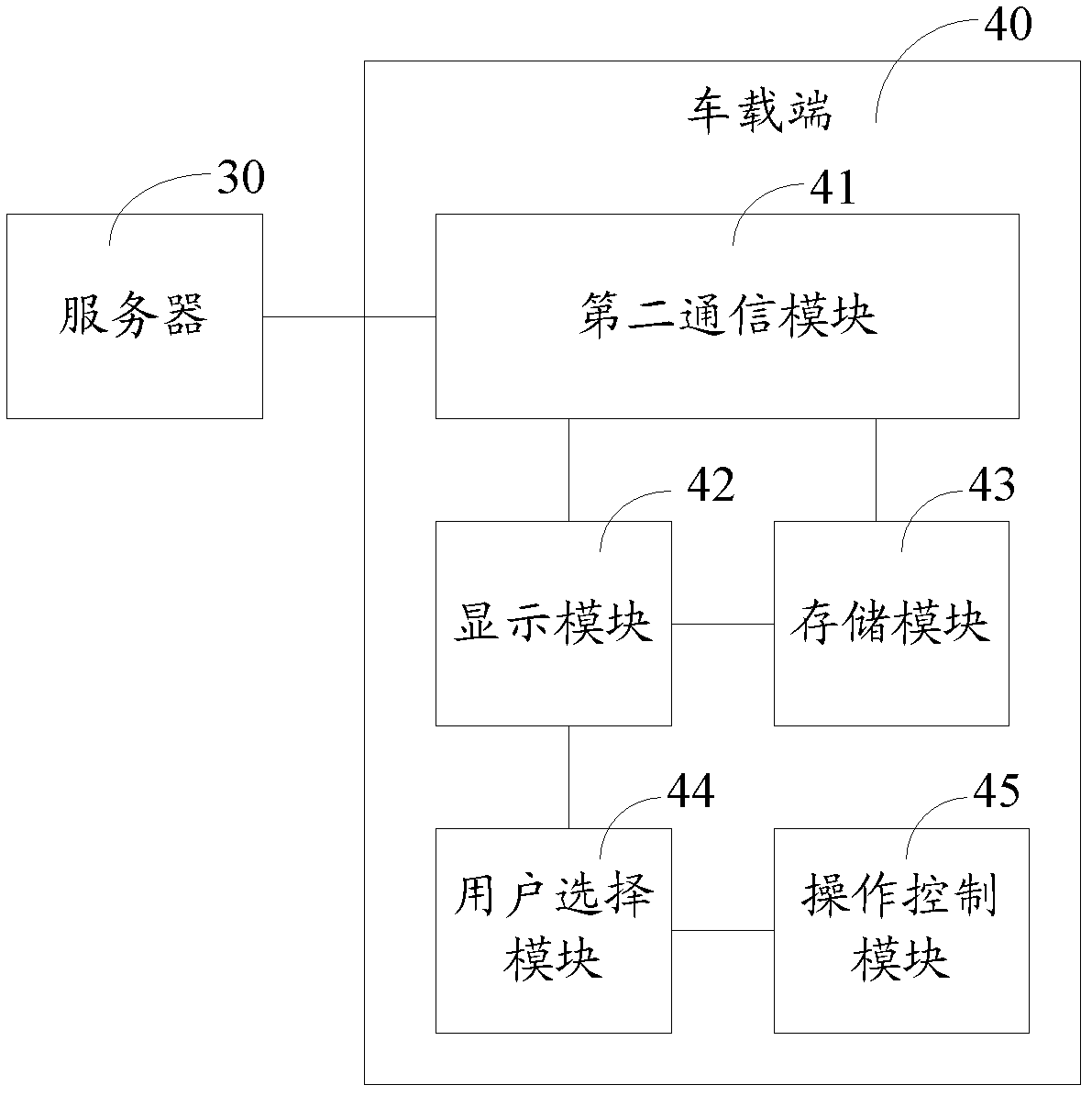

Data processing system and data processing method

ActiveCN103188312ASimplify operation stepsImprove experienceWireless commuication servicesTransmissionData informationData processing

Disclosed are a data processing system and a data processing method. The data processing system comprises a mobile terminal, a server and a vehicle-mounted end, wherein the mobile terminal sends data information to the server, and the server stores the received data information, identifies data request information from the data information, generates corresponding interaction information according to the identified data request information, and sends the interaction information to the vehicle-mounted end. According to the data processing system and the data processing method, a user can directly receive the interaction information sent by the server after the vehicle-mounted end is started, other settings do not need to be carried out on the vehicle-mounted end, and therefore operation procedures of the user are simplified, and experience of the user is improved.

Owner:SHANGHAI PATEO ELECTRONIC EQUIPMENT MANUFACTURING CO LTD

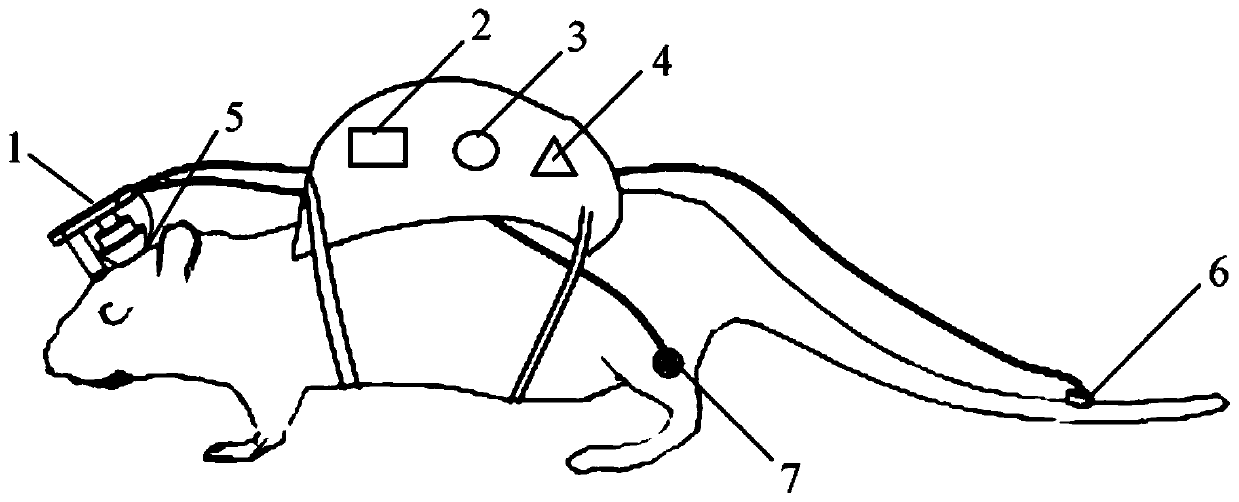

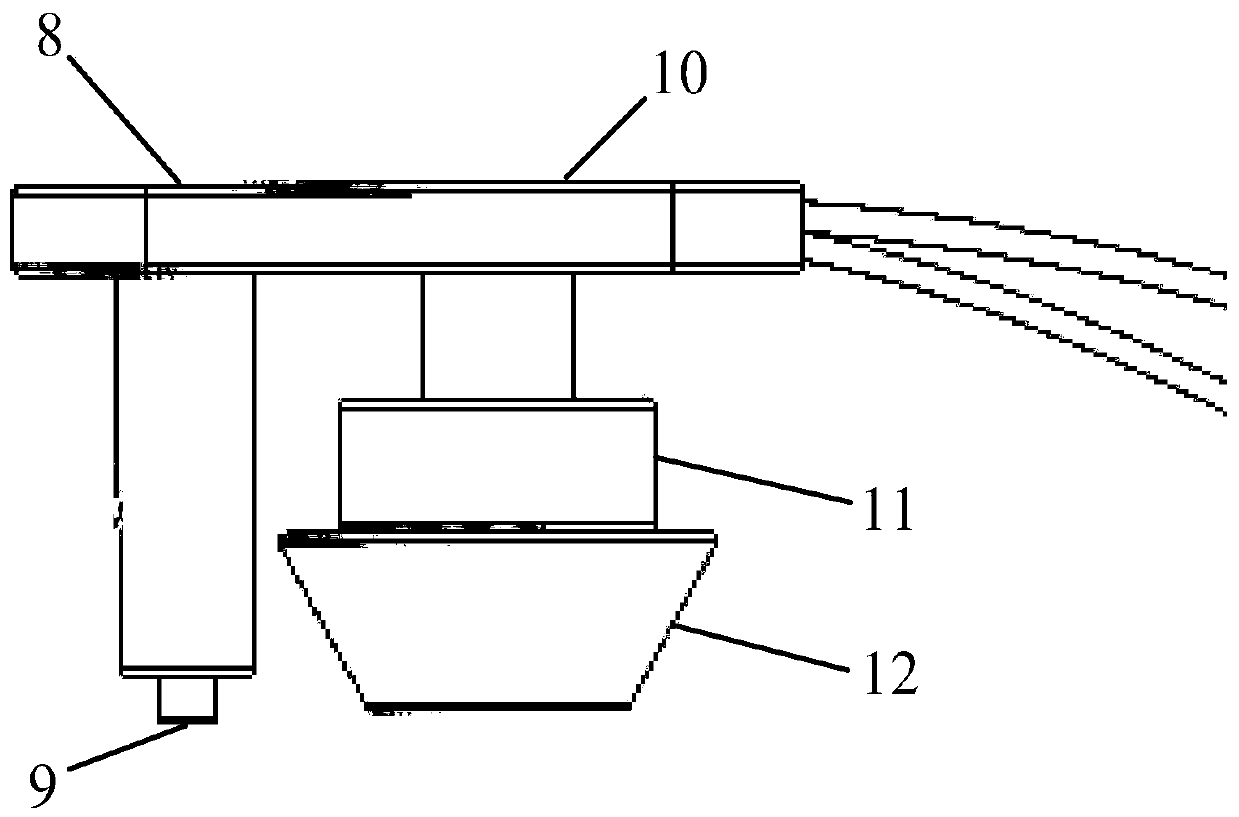

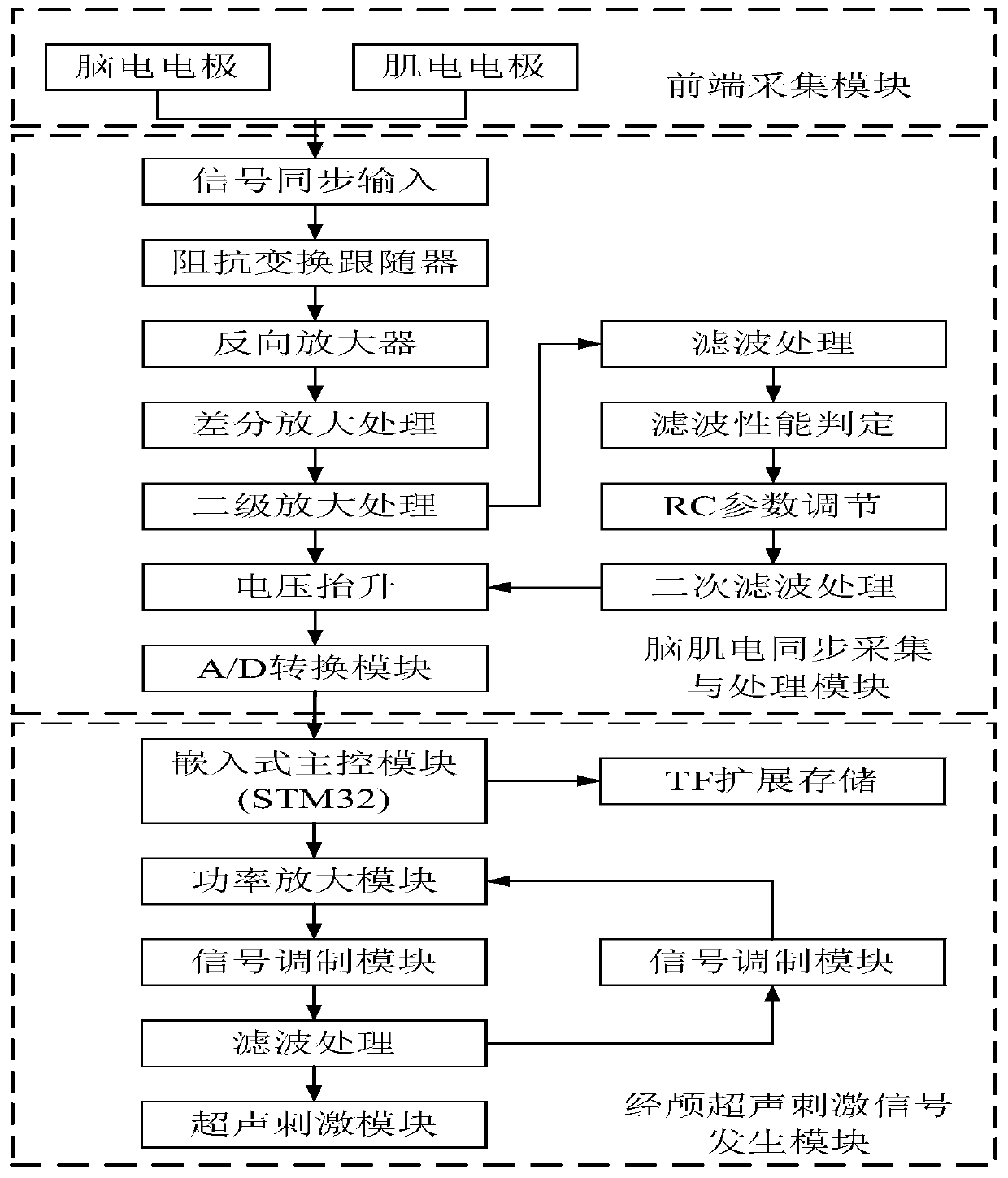

System for transcranial ultrasonic stimulation of mouse and synchronous acquisition of electroencephalogram and electromyogram signals

InactiveCN109924976AReduce volumeStable signalUltrasound therapyDiagnostic recording/measuringSonificationMedicine

The invention discloses a system for transcranial ultrasonic stimulation of mouse and synchronous acquisition of electroencephalogram and electromyogram signals and relates to the field of transcranial ultrasonic stimulation research and synchronous signal acquisition. The system comprises a transcranial ultrasonic stimulation module, a pulse transcranial ultrasonic signal generation module, a brain myoelectric signal acquisition and processing module and a power supply. The device has a series of advantages of stable signal acquisition, strong expansion storage capacity, portability, small size, easiness in operation and the like, and can be effectively applied to real-time synchronous acquisition of electroencephalogram and electromyogram signals of conscious and freely movable mice in transcranial ultrasonic stimulation experiments of various samples. Moreover, the storage module is expanded, and the problems of overlarge storage amount of long-time use data, distortion of wirelesstransmission data and the like are avoided. The system is convenient for subsequent off-line processing of brain myoelectric signals stimulated by transcranial ultrasound, and provides technical support for future mechanism research of transcranial ultrasound stimulation and clinical application of neuromodulation technology.

Owner:YANSHAN UNIV

Wastewater treatment method

ActiveCN103058346AHandling is efficient and stableImprove biodegradabilityWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by oxidationChemistryTreatment effect

The invention provides a wastewater treatment method. Specifically, the method includes: under the effect of a magnetic field, suspending magnetic catalyst particles in wastewater, and conducting a mixing treatment on the wastewater, the magnetic catalyst and an oxidant so as to make the B / C of the treated wastewater larger than equal to 0.3. The wastewater treatment method provided by the invention make the magnetic catalyst particles suspended in the wastewater in the presence of an external magnetic field, and performs catalytic oxidation treatment on the wastewater. With the method, the wastewater treatment effect can be improved significantly, the wastewater treatment effect is stable, and the biodegradability of wastewater can be effectively enhanced.

Owner:CHINA PETROLEUM & CHEM CORP +1

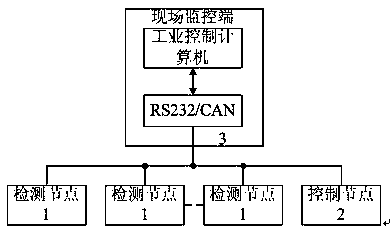

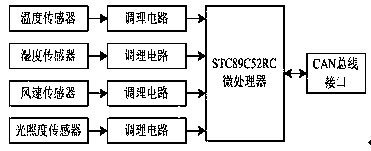

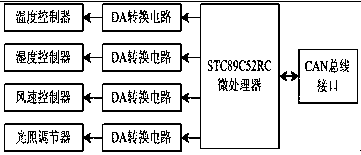

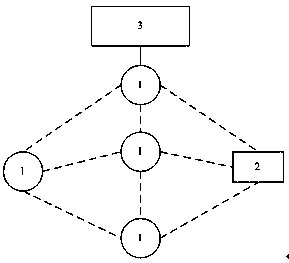

Intelligent tomato greenhouse temperature early-warning system based on minimum vector machine

ActiveCN110119169AImprove forecast accuracyStrong targetingTemperatue controlEarly warning systemControl system

The invention discloses an intelligent tomato greenhouse temperature early-warning system based on a minimum vector machine. The early-warning system is characterized by being composed of a tomato greenhouse environmental parameter acquisition and intelligent prediction platform based on a CAN field bus and an intelligent tomato greenhouse temperature early-warning system. By means of the intelligent tomato greenhouse temperature early-warning system based on the minimum vector machine in the invention, many problems still in the environment in a closed tomato greenhouse due to the reasons ofunreasonable design, backward equipment, incomplete control system and the like in the traditional tomato greenhouse environment can be effectively solved; and furthermore, the control problem that the tomato greenhouse environment temperature is greatly influenced due to the fact that the existing tomato greenhouse environment monitoring system does not monitor and predict the temperature in thetomato greenhouse environment according to the characteristics of nonlinearity and large lag of tomato greenhouse environmental temperature change, large tomato greenhouse area, complex temperature change and the like can be effectively solved.

Owner:淮安润联信息科技有限公司

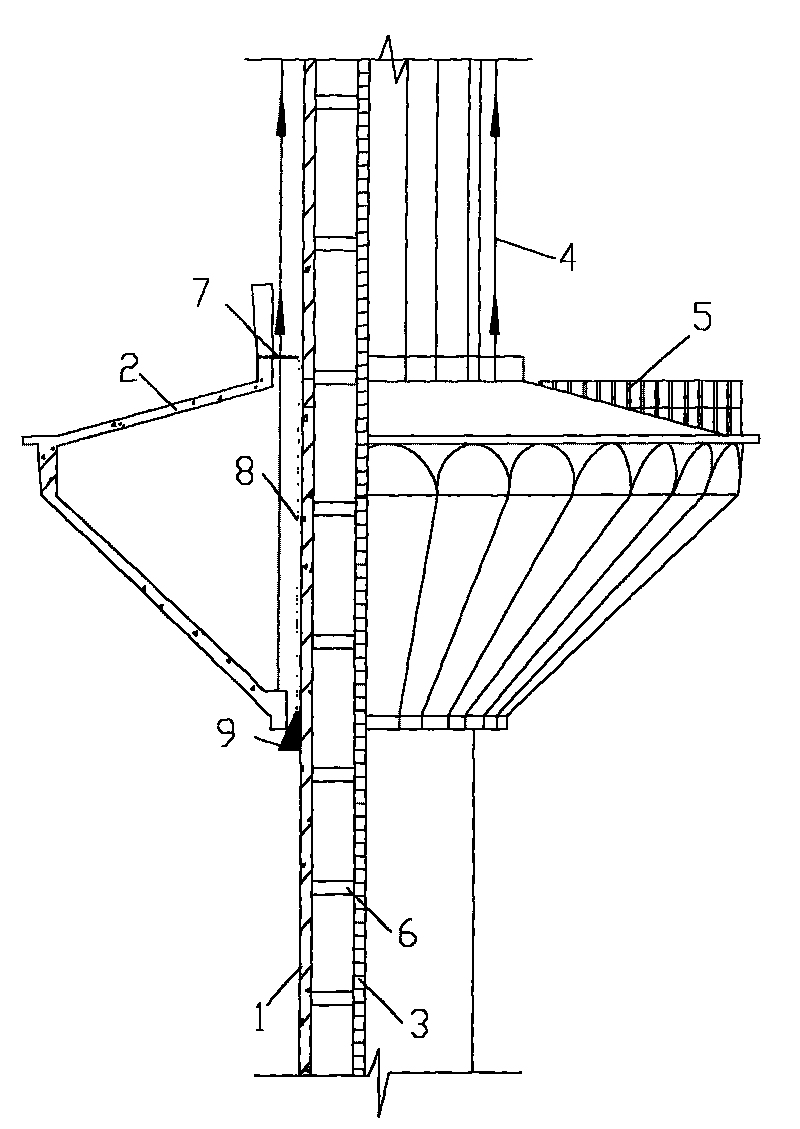

Method for lifting inverted cone shell water tank of reinforced concrete water tower

InactiveCN101736904AAvoid problems such as lossInstallation completed successfullyWater supply tanksBuilding material handlingWire rodReinforced concrete

The invention relates to a method for lifting an inverted cone shell water tank of a reinforced concrete water tower. The method comprises the following steps of: positioning a suspension rod, setting hydraulic equipment in place, primarily lifting the water tank, assembling a suspension wire rod on a support of an upper ring beam of the water tank, and placing lifting steel wedges hanged by steel wires outside a branch cylinder wall, wherein the lifting steel wedges are evenly distributed along the branch cylinder wall at 2,000 millimeter intervals, and tips support the bottom part of the water tank and are arranged in the gap between a lower ring beam and the branch cylinder wall; and when the water tank is lifted, making the steel wedges lifted along with the water tank; hanging suspension feet-hands, fixing the water tank at a high altitude, disassembling the lifting equipment, and casting ring plate concrete. The method fundamentally solves the problem that the water tank swings and bumps the cylinder wall when lifted; when the lifting reinforced bars are broken and the water tank falls off, the lifting steel wedges can fix the water tank on the branch cylinder, so that the huge loss caused by the broken reinforced bar and the falling off of the water tank is avoided; and by the method, the water tank can be stably, safely and quickly lifted up to the designed elevation of the cylinder top. By adopting the method, two hot rolling and two cold rolling 100t safety water towers of the Wuhan Iron and Steel, two continuous casting 200t and 800t water towers of the Wuhan Iron and Steel and the like can be successfully assembled.

Owner:MCC SHIJIU CONSTR

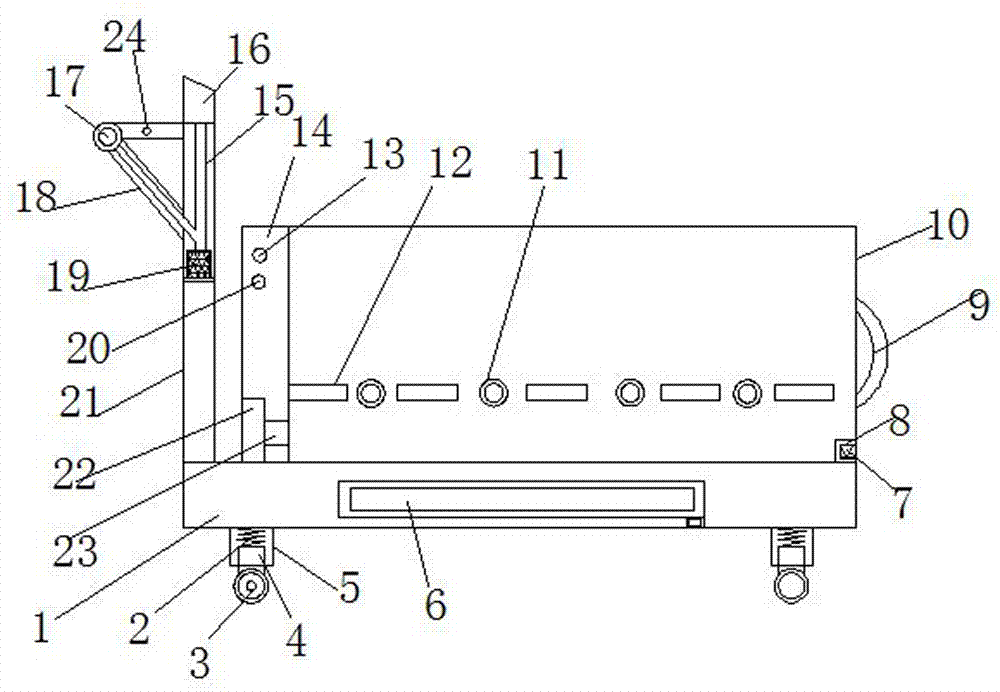

Computer peripheral transport vehicle

InactiveCN107416001AImprove working comfortImprove work efficiencySupporting partsVentilationPeripheralEngineering

The invention discloses a computer peripheral transport vehicle. The computer peripheral transport vehicle comprises a base and a supporting plate, wherein spring sleeves are respectively mounted at the left end and the right end of the bottom of the base; a spring is mounted in each spring sleeve; the bottom of each spring is fixedly connected with a corresponding supporting rod; an universal wheel is mounted at the bottom of each supporting rod; and a supporting frame is mounted at the left end of the upper part of the base. According to the computer peripheral transport vehicle disclosed by the invention, a plurality of sets of plastic cement grooves are formed in the bottom of the supporting plate, so that computer display screens are effectively fixed, and swinging in the transportation process is avoided; the magnetic property of each magnetic block A is the same as that of a corresponding magnetic block B, so that the supporting plate is effectively limited, and the problem that a conventional limiting block is damaged is solved; the tail end of a wind transporting pipe A is connected with a wind outlet pipe, so that in a hot summer, a user can perform heat dissipation through blowing, working comfortableness of the user is improved, and the working efficiency is improved; and the computer peripheral transport vehicle is practical and is suitable for wide popularization and usage.

Owner:合肥锦和信息技术有限公司

Method for improving grade of low-grade iron ore

ActiveCN103993166AAvoid problems such as lossGood ball formingProcess efficiency improvementClay mineralsLower grade

The invention provides a method for improving the grade of low-grade iron ore. The method comprises the following steps: respectively pretreating low-grade iron ore and coal, adding coal dust and an additive according to a certain proportion and preparing small balls with particle sizes of 3 to 8 mm by using a disc or drum balling machine after the content of treated iron ore and coal with a particle size of 0.074 mm is more than 50%, wherein clay minerals in the low-grade iron ore are used as a binder, or a small amount of binders like bentonite is added and uniformly mixed with treated iron ore and coal; and drying the prepared balls with a belt or cylindrical dryer, carrying out reduction by using a rotary kiln and then successively carrying out cooling and magnetic separation so as to obtain high-grade iron ore concentrate. With the method, low-grade iron ore can be effectively treated, the high-grade iron ore concentrate is obtained through granulation of the coal and the additive, direct reduction and magnetic separation, and the characteristics of energy conservation, high efficiency and rapidness are obtained.

Owner:CENT SOUTH UNIV +2

Tomato greenhouse environmental parameter intelligent monitoring device based on ANFIS neural network

ActiveCN110119086AImprove forecast accuracyGood nonlinear approximation capabilityAdaptive controlMoistureWireless sensor networking

The present invention discloses a tomato greenhouse environmental parameter intelligent monitoring device based on an ANFIS neural network. The intelligent monitoring device is composed of a wirelesssensor network-based tomato greenhouse environmental parameter intelligent detection platform and a tomato greenhouse yield intelligent early warning system. According to the tomato greenhouse environmental parameter monitoring and regulation platform established by the present invention, the problem that the tomato greenhouse yield cannot be predicted and early warned according to the impact of tomato soil moisture on the tomato greenhouse yield in the prior art is effectively solved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Green pepper greenhouse environment intelligent monitoring system based on subtractive clustering classifier

ActiveCN110083190AStrong correlationImprove forecast accuracyProgramme controlMeasurement devicesEarly warning systemIntelligent lighting

The invention discloses a green pepper greenhouse environment intelligent monitoring system based on a subtractive clustering classifier. The intelligent monitoring system is characterized by comprising a green pepper greenhouse environment parameter detection platform based on a wireless sensor network and a green pepper greenhouse yield intelligent early warning system. In the prior art, only adevice is adopted for monitoring the green pepper greenhouse environment parameter, and green pepper greenhouse yield cannot be warned according to green pepper greenhouse environment temperature andsunlight. The green pepper greenhouse environment intelligent monitoring system solve the above problem.

Owner:威海晶合数字矿山技术有限公司

Agricultural heavy metal polluted farmland soil remediation system

ActiveCN112974497ANo human laborSave human effortWithdrawing sample devicesContaminated soil reclamationInformation processingInformation analysis

The invention discloses an agricultural heavy metal polluted farmland soil remediation system, which is characterized in that the system comprises a soil quality detection system; the soil quality detection system comprises a fixed monitoring unit and a mobile detection unit; the soil quality detection system is connected with an information management system through wireless data, the information management system comprises an information processing center, and the information processing center comprises an information analysis center and a data storage library connected with the information analysis center and the soil quality detection system; the information management system is connected with a soil remediation system through wireless data, and the soil remediation system comprises vehicle-mounted soil remediation equipment; according to the invention, a real-time soil information map is made through the fixed and mobile detection monitoring terminal and the information processing center, an optimal soil remediation scheme is selected by means of accurate and timely data, and rapid, accurate and efficient remediation treatment on the soil polluted by heavy metals is realized by using a specially designed soil remediation device.

Owner:河南鸣皋智能科技有限公司

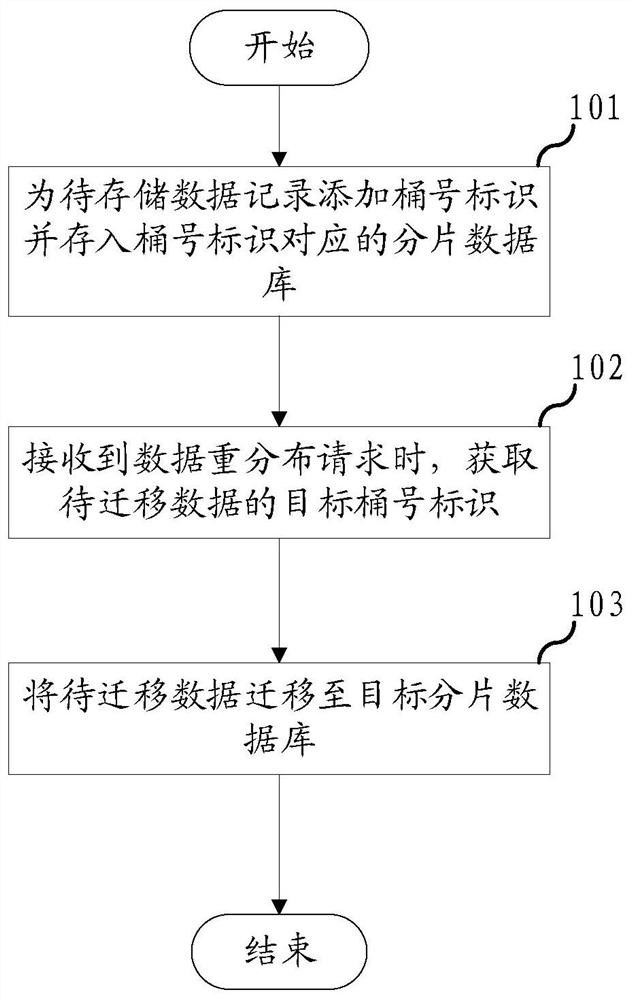

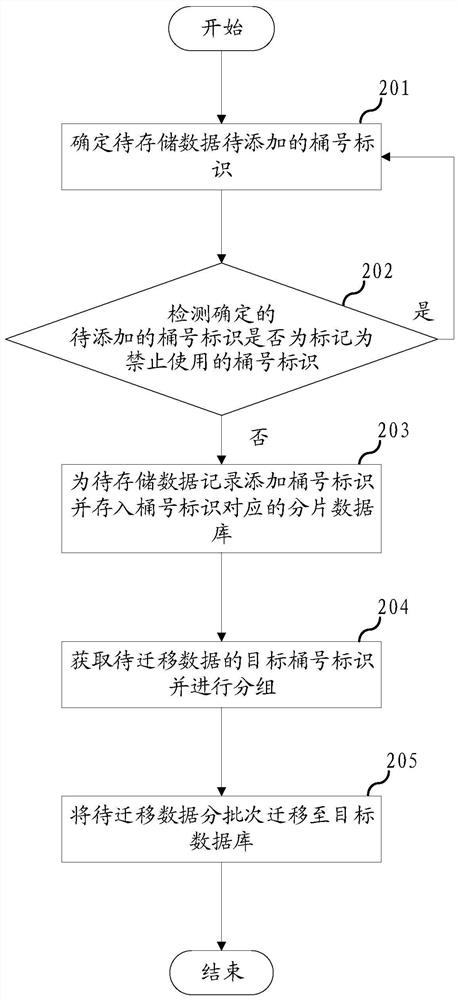

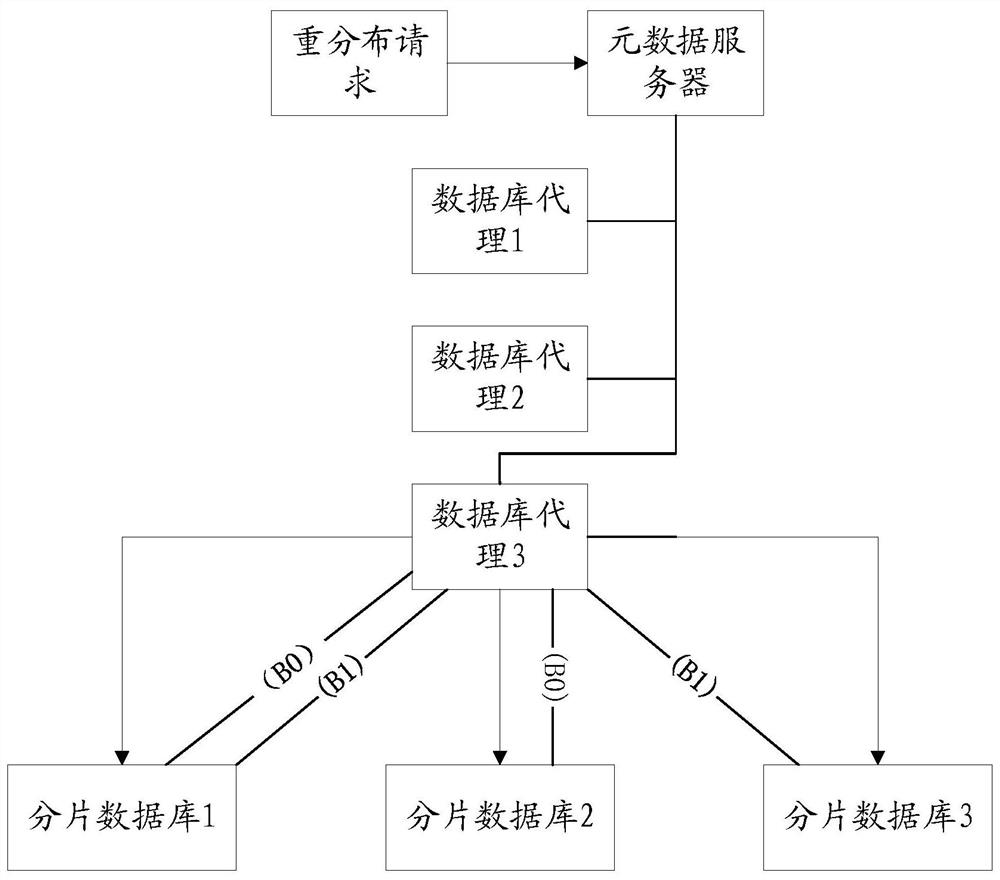

Data redistribution method, electronic equipment and storage medium

ActiveCN112765262AImprove scalabilityAvoid hot spotsDatabase distribution/replicationTransmissionData migrationData records

The embodiment of the invention relates to the field of communication, and discloses a data redistribution method, electronic equipment and a storage medium. The method comprises the following steps: adding a bucket number identifier for a to-be-stored data record, and storing the data record to a fragmentation database corresponding to the bucket number identifier of the data record according to a preset corresponding relationship between the bucket number identifier and the fragmentation database; in response to the data redistribution request, obtaining a target bucket number identifier of to-be-migrated data; and migrating the to-be-migrated data to the target fragmented database according to the target bucket number identifier, and logically performing partition storage on the data, so that the expansibility of redistribution of a large amount of data is improved, the hot spot problem caused by overlarge data volume due to limitation of a physical partition is avoided. The system reliability is improved. The data migration is carried out by taking the data record corresponding to the bucket number identifier as the basic unit, so that the performance and the quality of the data migration are ensured, the influence on services is reduced, and the availability of data redistribution is improved.

Owner:金篆信科有限责任公司

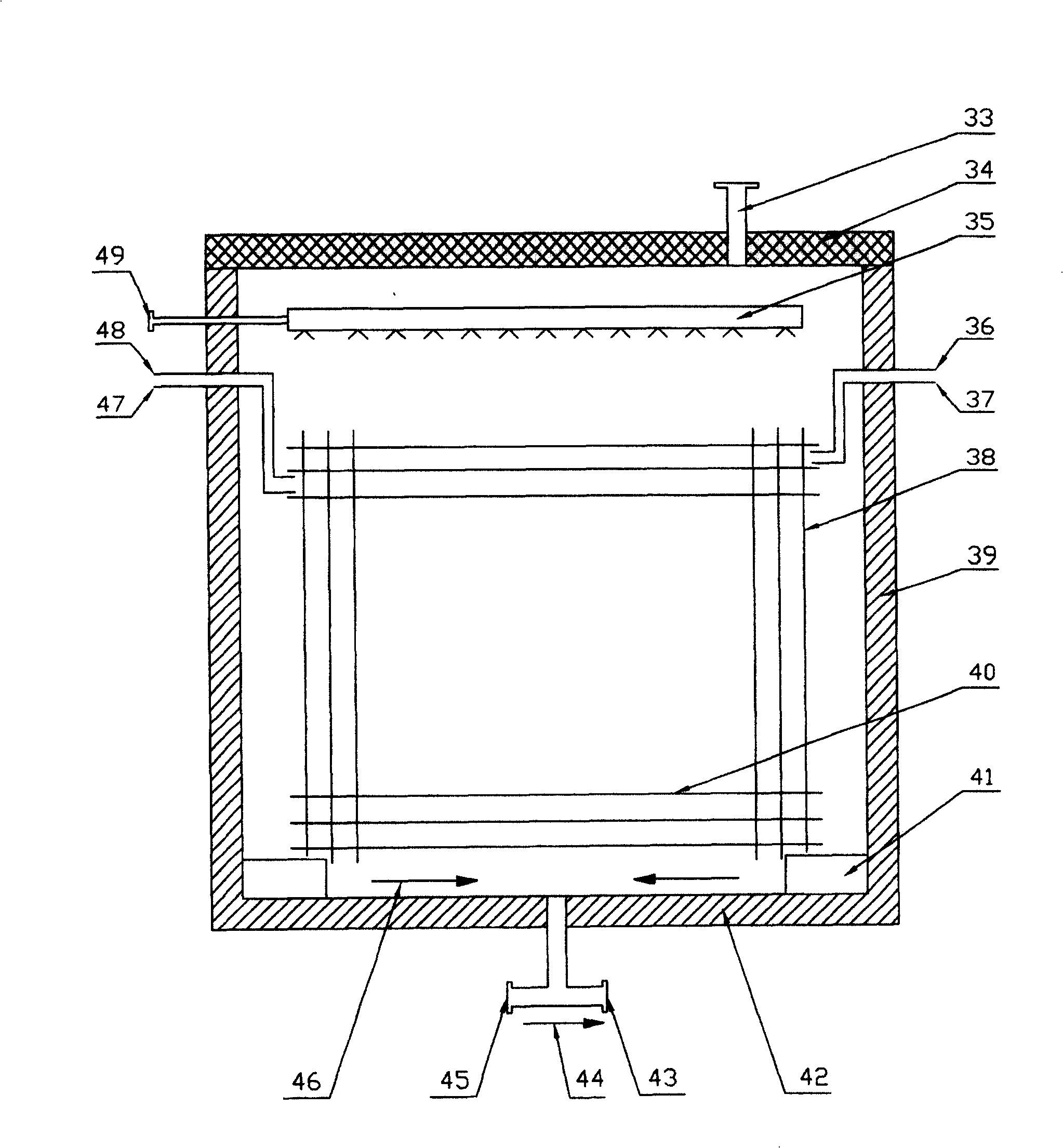

Concentration method of graduate freezing interface

InactiveCN100450572CAvoid lostAvoid problems such as lossClimate change adaptationSolution crystallizationIce waterDevice form

The present invention relates to a method capable of utilizing closed heat pump circulation technique to implement high-effective energy-saving interfacial progressive freeze concentration. Said method includes 7 working steps of feeding aqueous solution, concentrated solution transfer and discharge, thawy water transfer and discharge, washing ice layer, heat pump circulation, auxiliary refrigeration and central control, and includes a system device formed from 7 subsystems and two icing water tanks which are communicated to implement aqueous solution interfacial progressive freeze concentration.

Owner:QINGDAO UNIV

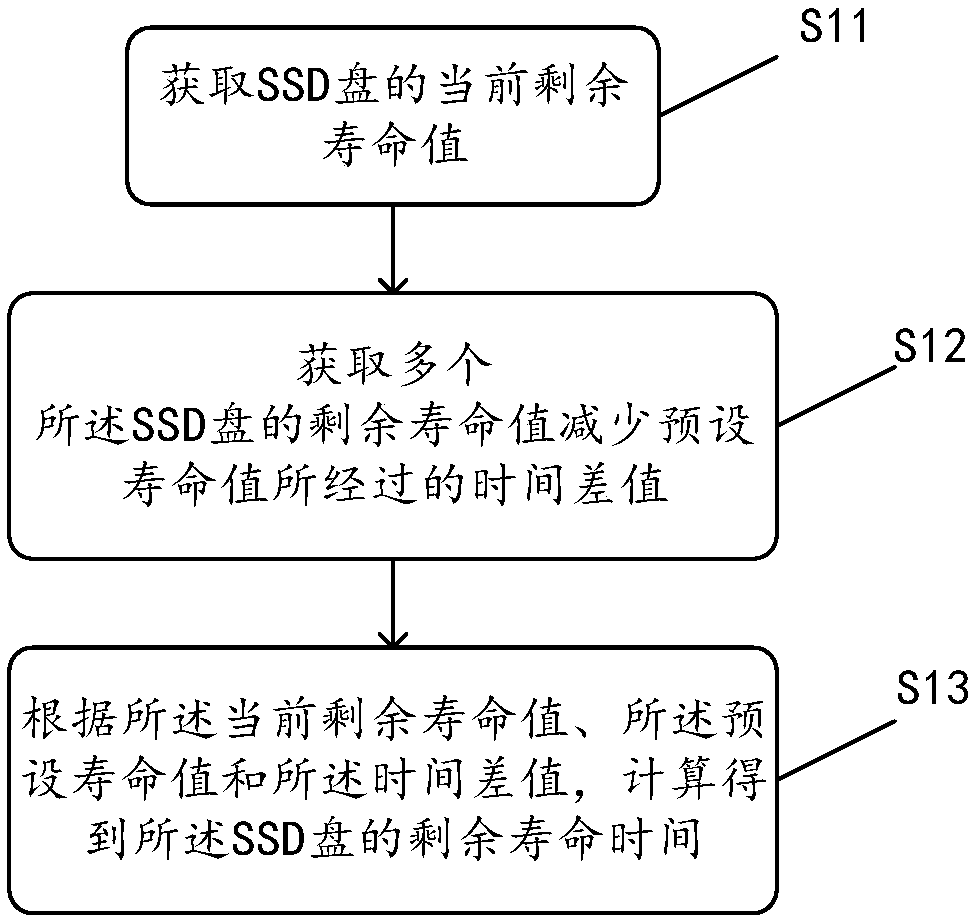

Method, device and equipment for estimating remaining life of SSD

InactiveCN107895588AShorten the time differenceAvoid problems such as lossRead-only memoriesData lossTime difference

The invention discloses a method for estimating the remaining life of an SSD. The method realizes effective use of the current remaining life of an SSD and comprises acquiring the current remaining life of an SSD and a time difference of reduction of remaining lives of multiple SSDs by a preset life value, and calculating the remaining life of the SSD according to the current remaining life, the remaining life and the time difference so that the remaining life of the SSD is estimated and a data loss is effectively avoided. The invention also provides a device, equipment and computer-readable storage medium for estimating the remaining life of an SSD.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

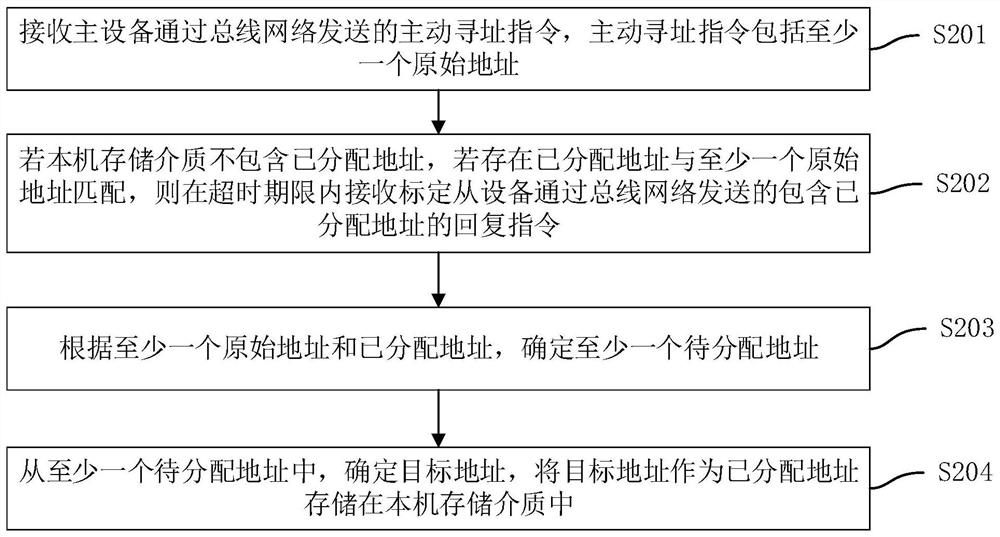

Address allocation method

ActiveCN112272243ASimple processAvoid problems such as lossEnergy efficient computingBus networksBusComputer engineering

The invention discloses an address allocation method. A current slave device executes the following steps of receiving an active addressing instruction sent by a master device through a bus network, the active addressing instruction comprising at least one original address; if the local storage medium does not contain the allocated address, receiving a reply instruction which is sent by the calibration slave equipment through the bus network and contains the allocated address within the timeout period; determining at least one to-be-allocated address according to the at least one original address and the allocated address; and determining a target address from the at least one to-be-allocated address, and storing the target address as an allocated address in a local storage medium. According to the address allocation method provided by the invention, the target address is automatically determined without adding dialing equipment, cost is effectively reduced, the determination process is simple and efficient, and the address allocation method is suitable for all to-be-allocated slave equipment and has good compatibility.

Owner:SHENZHEN KEXIN COMM TECH

'Increasing, returning, reducing, combining' carbon-fixing and discharge-reducing fertilizing method in Allium fistulosum and wheat crop rotation

InactiveCN106961987AAvoid lostAvoid problems such as lossFertilising methodsPlant cultivationAgricultural scienceHectare

The invention provides an 'increasing, returning, reducing, combining' carbon-fixing and discharge-reducing fertilizing method in Allium fistulosum and wheat crop rotation, and belongs to the technical field of agricultural fertilizing. Based on the existing problem in the cultivation mode of the Allium fistulosum and wheat crop rotation, the nutrient demand and distribution of two harvest crops at different stages within one year are considered, and the technical mode of 'increasing, returning, reducing, combining' carbon-fixing and discharge-reducing is formed. Compared with the conventional technology of farmers, the fertilizer input cost is saved about 1120 yuan per hectare; the Allium fistulosum average yield is increased by 7800 kg / hm<2> in one season; the wheat average yield is increased by 280 kg / hm<2> in one season; the average yield rate of two seasons is up to 13%; the year yield is increased by 16% per hectare; the discharge of N2O is reduced by 24.4%; 0-20 cm soil layer is solidified by 2.26t C / hm<2>; the total nitrogen rain-washing ratio is reduced by 19.4%; the technical supports for the improvement of cultivated land soil organic matter, the discharge-reducing of agricultural greenhouse gases, and the sustainable development of agriculture are provided for China.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Private cloud access method and device based on VPN

ActiveCN106130864AAvoid problems such as lossEasy to operateNetworks interconnectionAccess methodPassword

The invention discloses a private cloud access method and device based on a VPN. The method comprises the steps of obtaining a login request of a client to private cloud, and analyzing the login request to obtain a private cloud account, a private cloud password and a private key; generating a VPN account and a VPN password matching with the private cloud account; carrying out identity verification by employing the VPN account, the VPN password and the private key; establishing connection between the client and a private cloud server through the VPN if the identity verification is successful; and logging in the private cloud server by employing the private cloud account and the private cloud password. Through application of the method and the device, when a user employs cloud service through a VPN server, the VPN can be logged in automatically through the VPN server only by inputting the private cloud account and the private cloud password, and therefore, the login operation is simplified. According to the method provided by the embodiment, the user does not need to store the private key in advance, when the user attempts to log in the private cloud, the newest private key is sent to the client by the VPN server, and therefore, the problem of missing the private key can be avoided.

Owner:BEIJING GUODIANTONG NETWORK TECH CO LTD +4

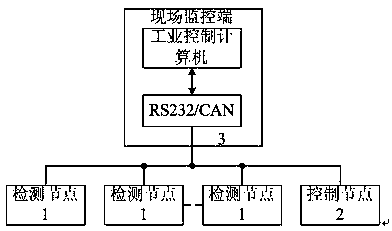

Cucumber greenhouse temperature intelligent detection device based on LVQ neural network

ActiveCN110119767AImprove forecast accuracyStrong targetingMeasurement devicesForecastingGreenhouseMonitoring system

The invention discloses a cucumber greenhouse temperature intelligent detection device based on an LVQ neural network. The cucumber greenhouse temperature intelligent detection device is characterizedby comprising a cucumber greenhouse environment parameter acquisition platform based on a CAN bus and a cucumber greenhouse temperature intelligent monitoring system. The device effectively solves the problem that the existing cucumber greenhouse monitoring system does not intelligently monitor and predict the temperature of the cucumber greenhouse environment according to the characteristics ofnonlinearity and large lag of the temperature change of the cucumber greenhouse environment, large area and complex temperature change of the cucumber greenhouse and the like, so that the regulation and control of the temperature of the cucumber greenhouse environment are greatly influenced.

Owner:合肥名龙电子科技有限公司

Charging pile with fingerprint recognition and payment system

PendingCN110015023AAccurate identificationUnique identificationCharging stationsCharacter and pattern recognitionFeature extractionImaging processing

The invention discloses a charging pile with a fingerprint recognition and payment system. The charging pile comprises a fingerprint image collecting module, an image processing module, a control module, a communication module, a local data storage module, a back-end server and a MCU. Firstly, the image processing module preprocesses fingerprint images collected by the fingerprint image collectingmodule to make the images more clear, then the fingerprint images are subjected to feature extraction through a fingerprint feature point extraction algorithm based on binary images, extracted feature information is compared with fingerprint information preset in the local data storage module or the back-end server, a successful comparison signal or a failed comparison signal is output, and a control circuit triggers or closes a charging circuit of the charging pile according to the comparison results. Compared with the prior art, the charging pile has the beneficial effects that in the process of using the charging pile by a user, an electric vehicle can be charged easily and conveniently without carrying secret keys such as an RFID card, and meanwhile, safety and reliability in the using process are also improved.

Owner:浙江智充电力科技有限公司

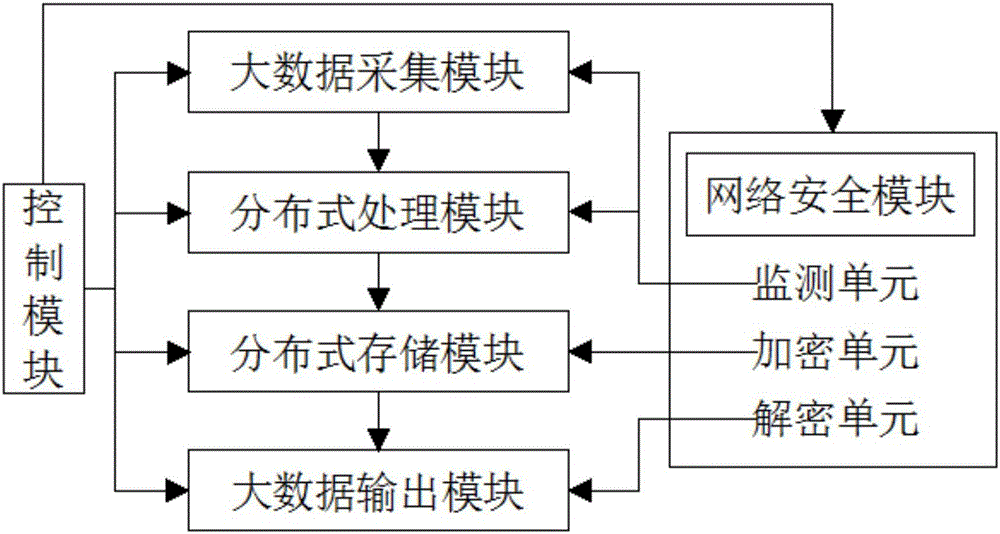

Big data implementation system based on network security

InactiveCN106845276AImprove integrityReduce memory usageDigital data protectionData integrityResource utilization

The invention discloses a big data implementation system based on network security. The big data implementation system comprises a control module, a big data acquisition module, a distributed processing module, a distributed storage module, a big data output module and a network security module. The output end of the control module is connected with the input ends of the big data acquisition module, the distributed processing module, the distributed storage module, the big data output module and the network security module respectively. The big data acquisition module, the distributed processing module, the distributed storage module and the big data output module are connected in sequence. The network security module comprises a monitoring unit, an encryption unit and a decryption unit. The big data implementation system can rapidly and effectively organize and analyze obtained big data based on network security utilizing the distributed processing module. Compared with existing big data implementation system, the big data implementation system has the advantages that the processing efficiency and resource utilization rate are high and data integrity and confidentiality are good in the processing process, and is worthy of popularization.

Owner:HUNAN UNIV OF FINANCE & ECONOMICS

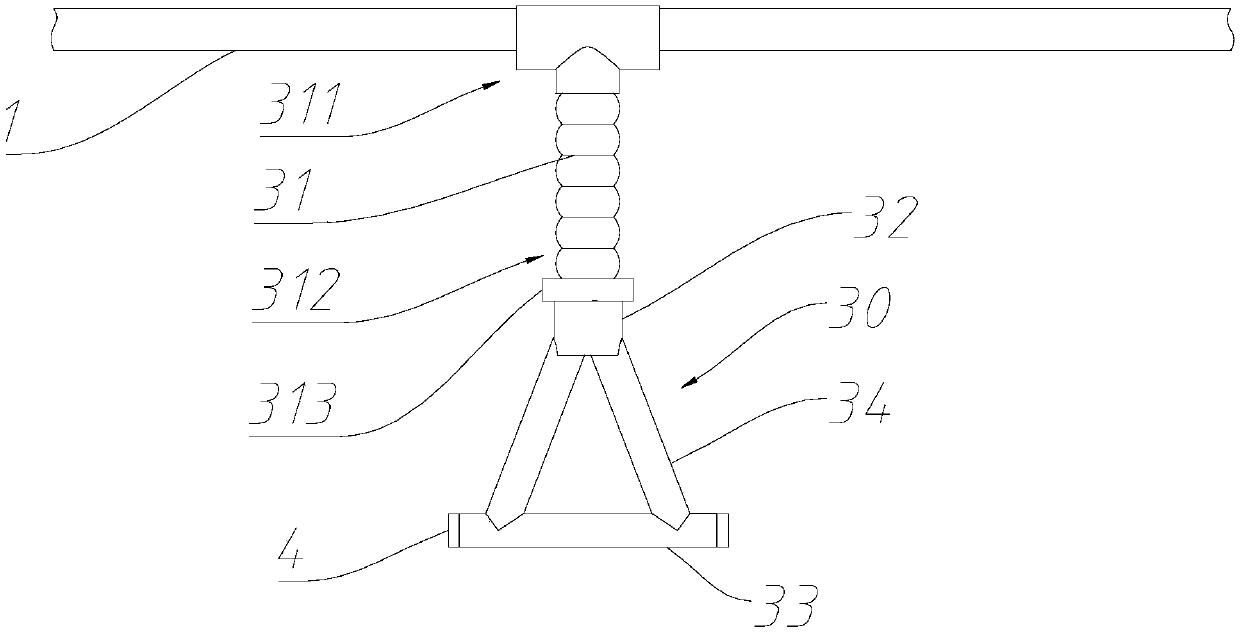

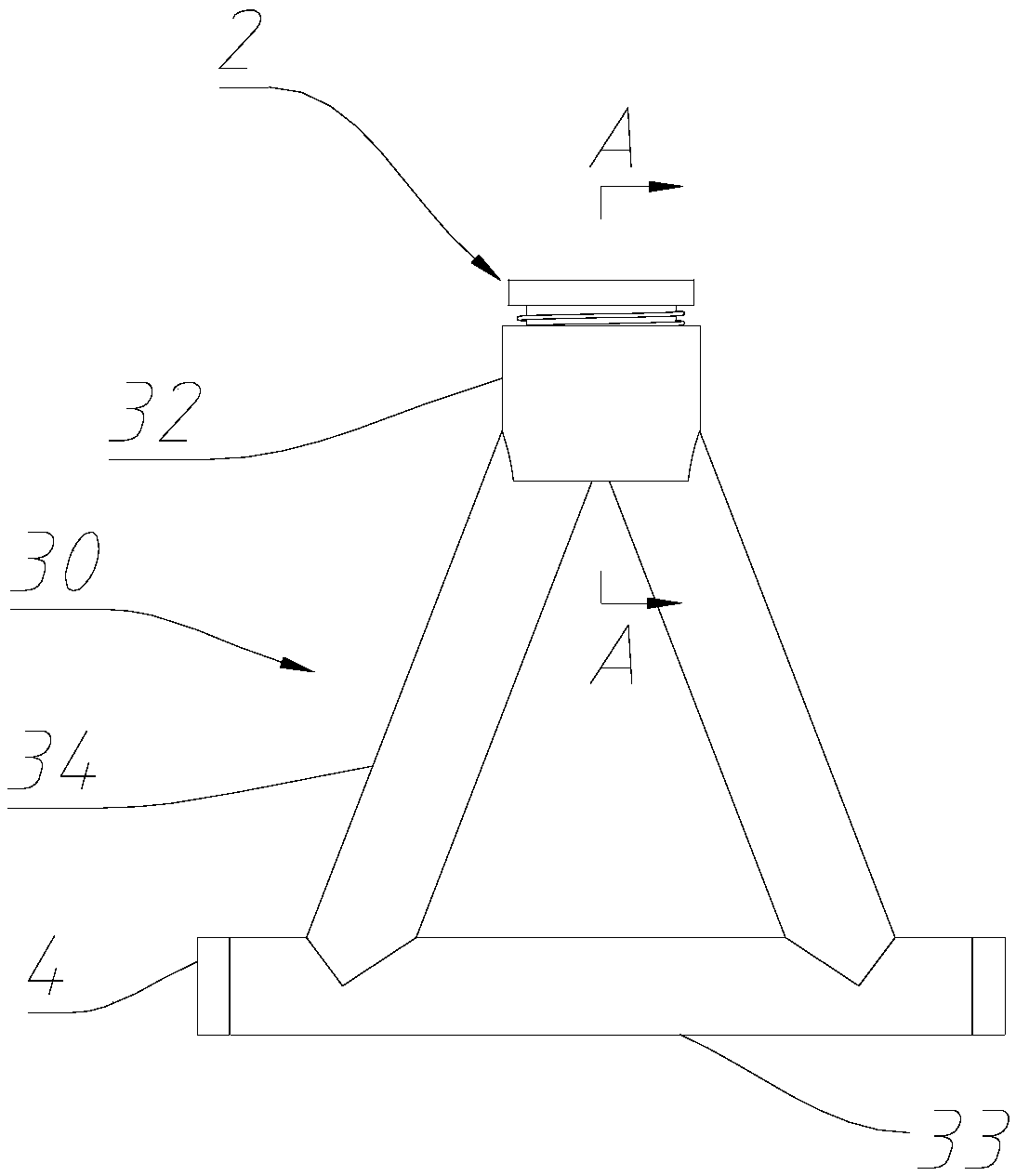

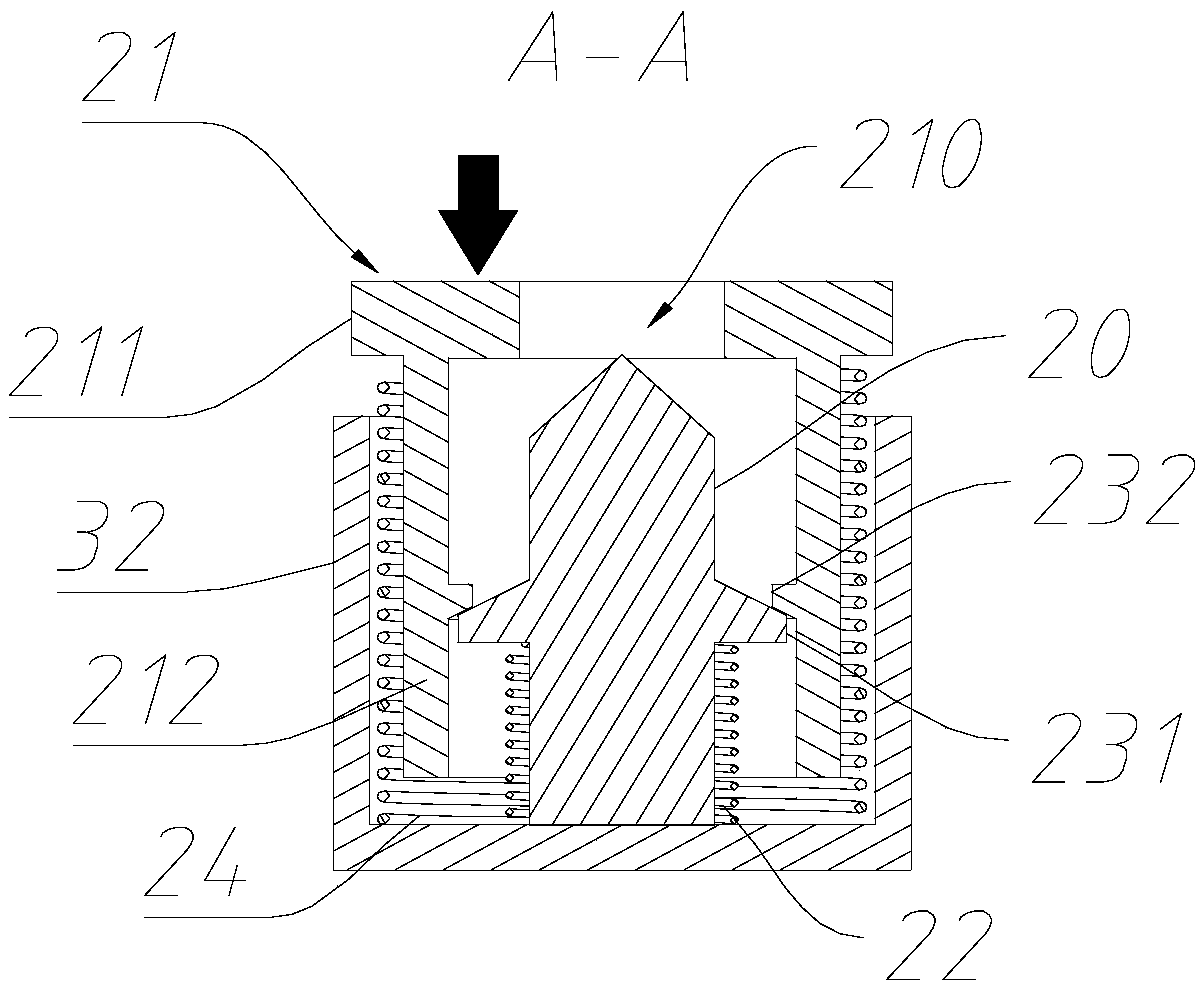

Emergency device and public transport means

ActiveCN111319535ADoes not affect the manufacturing basePrevent fallingVehicle arrangementsRailway componentsArchitectural engineeringMechanical engineering

The invention relates to an emergency device and a public transport means. The emergency device comprises an escape hammer mechanism (2) and a handle; the handle comprises a lifting ring (30) and a flexible connecting piece (31); the lifting ring (30) comprises a lifting ring main body (32) and a connecting seat (32) which are connected with each other; the flexible connecting piece (31) comprisesa first end (311) and a second end (312) which are opposite to each other, wherein the first end (311) is used for being connected with a grab rail (1), the second end (312) is detachably connected with the connecting seat (32); and the escape hammer mechanism (2) is arranged in the connecting seat (32). By means of the above technical schemes of the invention, effective emergency measures can beprovided, and disorder and treading events are avoided.

Owner:BYD SEMICON CO LTD

Durable lubricating and friction-reducing slide plate for bridge support

PendingCN110835887ALong-lasting slow-release lubrication effectPlay the role of lubrication and friction reductionBridge structural detailsBridge materialsPolymer scienceSlide plate

The invention relates to a durable lubricating and friction-reducing slide plate for a bridge support. The composite slide plate is formed by compounding a wear-resistant material and a slow-release friction-reducing material, the wear-resistant material is a non-metal wear-resistant sliding plate formed by a polymer-based polymer material, a pit or a groove is formed in the surface of the non-metal wear-resistant sliding plate, and the slow-release friction-reducing material is formed in the pit or the groove in the surface of the non-metal wear-resistant sliding plate; the slow-release friction-reducing material is compose of a carrier material, an adsorption material, a lubricating material and a stabilizer; the slow-release friction-reducing material comprises the following componentsin percentage by weight of 30%-60% of the carrier material, 5%-20% of the adsorption material, 10%-40% of the lubricating material and 10%-20% of the stabilizer. The composite sliding plate has the characteristics of strong bearing capacity, small friction coefficient, excellent wear resistance and long effective lubrication time.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

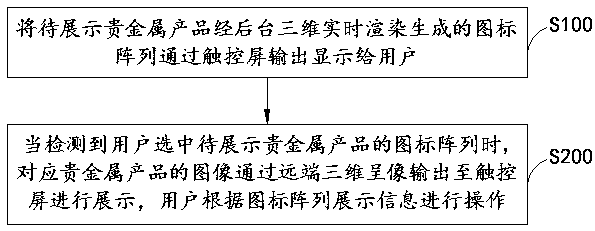

Precious metal product displaying method and apparatus

InactiveCN108196745AEasy to understandImprove convenienceInput/output processes for data processingComputer scienceWear and tear

The present invention provides a precious metal product displaying method, and belongs to the technical field of product display, in order to solve wear and tear caused by displaying the physical objects of the existing precious metal products. The technical scheme is as follows: outputting an icon array generated through 3D background real-time rendering on the to-be-displayed precious metal products to users via the touch screen, wherein the icon array comprises thumbnail icons, call consultation icons, purchase icons of a plurality of precious metal products; when detecting that the user selects a certain icon in the icon array of the to-be-displayed precious metal products, outputting the image corresponding to the precious metal product to the touch screen through the remote three-dimensional image for displaying, so that the user can observes the precious metal products, or automatically call a remote customer service, or use the touch screen to purchase products that are being viewed in a facilitated manner. According to the method provided by the present invention, the true appearance of the precious metal products can be vividly displayed to the user, the user can fully understand the details of the precious metal products in a facilitated manner, and the loss of the products can be avoided. The present invention also provides a displaying apparatus that achieves the same purpose.

Owner:INSPUR FINANCIAL INFORMATION TECH CO LTD

Commodity transaction device and method based on blockchain system and readable storage medium

A commodity transaction method based on a blockchain system comprises the steps: providing a commodity shelving and purchasing interface so that a manufacturer can shelve commodity content through thecommodity shelving interface and a consumer can initiate commodity transaction through the commodity purchasing interface; when a consumer initiates a commodity transaction, controlling each node inthe blockchain system to verify the commodity transaction; when the node verifies the commodity transaction successfully, broadcasting a verification passing message to a blockchain system; when the node receives a verification passing message exceeding a first preset number, storing the name and the number of the commodities purchased by the consumer, so that the consumer can obtain the purchasedcommodities from the access provider; and updating the name and quantity information of the commodity owned by the consumer according to the commodity taking information of taking the commodity fromthe access provider by the consumer. The invention further provides a commodity transaction device based on the blockchain system and a computer readable storage medium. According to the invention, the problems of user information leakage, capital loss and the like can be avoided to the greatest extent.

Owner:FU TAI HUA IND SHENZHEN +1

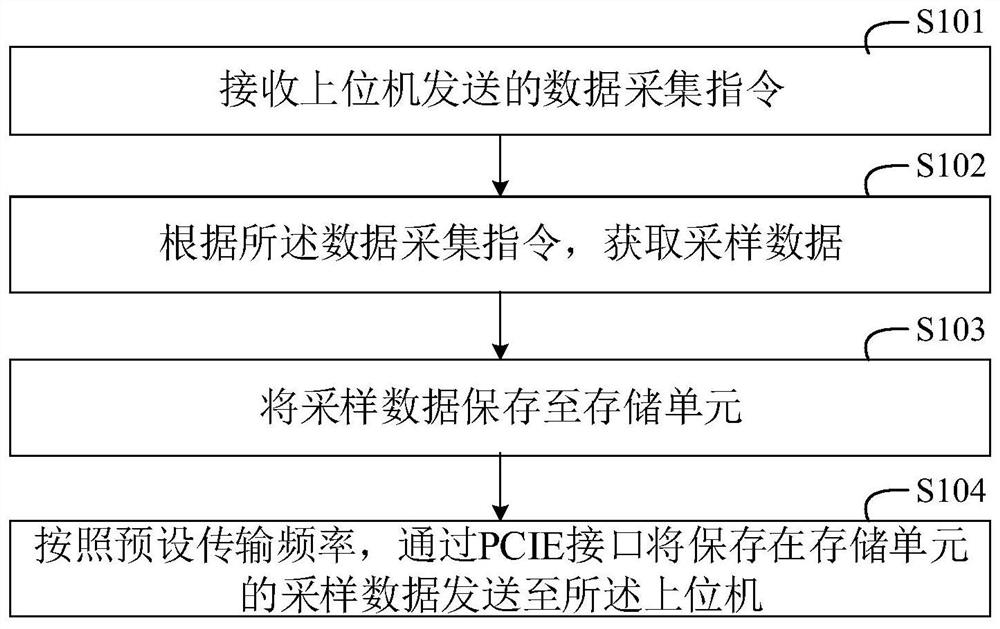

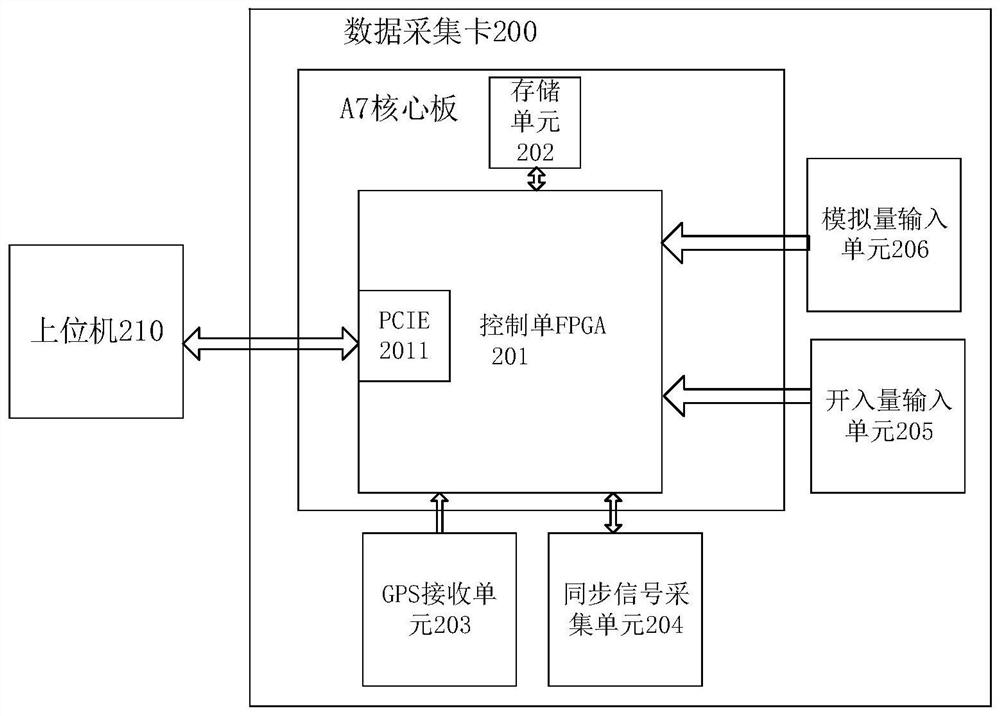

Data acquisition method and device and data acquisition card

PendingCN112988646AAvoid data lossImprove reliabilityElectric digital data processingStorage cellEngineering

The invention discloses a data acquisition method and device and a data acquisition card. The data acquisition method is applied to a data acquisition card of an oscillograph, and comprises the following steps: receiving a data acquisition instruction sent by an upper computer; acquiring sampling data according to the data acquisition instruction; storing the sampling data to a storage unit; and sending the sampling data stored in the storage unit to the upper computer through a PCIE interface according to a preset transmission frequency. According to the embodiment of the invention, when the oscillograph collects data, adjustment can be carried out according to the sampling rate and the storage depth based on the storage unit, the PCIE transmission rate can be adapted, data processing can be completed in time, and the problems of data loss and the like can be avoided as much as possible.

Owner:PONOVO POWER

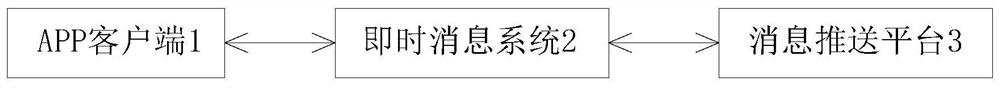

Simple and light message real-time pushing system and implementation method thereof

PendingCN111901227AAvoid unreachableAvoid problems such as message loss after network disconnection and reconnectionData switching networksPush technologyMobile end

The invention discloses a simple and light message real-time pushing system and an implementation method thereof. The invention belongs to the technical field of mobile internet instant message pushing. The system comprises an APP client, an instant message system and a message pushing platform. The APP client communicates with the instant message system through a wireless network according to a full duplex communication mode, and the instant message system communicates with the message pushing platform through the wireless network according to the full duplex communication mode. The APP client is a user mobile device APP, and the instant message system is a back-end server system for providing communication service. According to the simple and light message real-time pushing system and the implementation method thereof, the problems that the message cannot be reached after the mobile terminal is recycled or the message is lost after network disconnection and reconnection are avoided,and a message pushing platform can be provided to ensure that the message can be reached necessarily under any condition, the service docking is simple, the service is light and fast, and the messageis reached necessarily in real time.

Owner:ZHUHAI JIAMI TECH CO LTD

Charging and discharging control method and device of energy storage system, controller and energy storage system

PendingCN114156968AAvoid equipment wear and tearAvoid problems such as lossCircuit monitoring/indicationSecondary cells charging/dischargingCharge and dischargeControl engineering

The invention relates to a charging and discharging control method and device of an energy storage system, a controller and the energy storage system. After the set target charging and discharging power is obtained, the corresponding actual charging and discharging power is determined according to the operating state, operating parameters and other factors of the energy storage system, so that the situation that the charging and discharging power does not meet the system state can be avoided, and parts such as a battery are protected; and the operation of the energy storage converter is controlled according to a stepped charging and discharging strategy, that is, the energy storage converter only operates according to a certain percentage of the actual charging and discharging power at the beginning and then operates according to the complete actual charging and discharging power, so that the problems of equipment loss and the like caused by soaring of the power within a short time can be avoided.

Owner:GREE ELECTRIC APPLIANCES INC

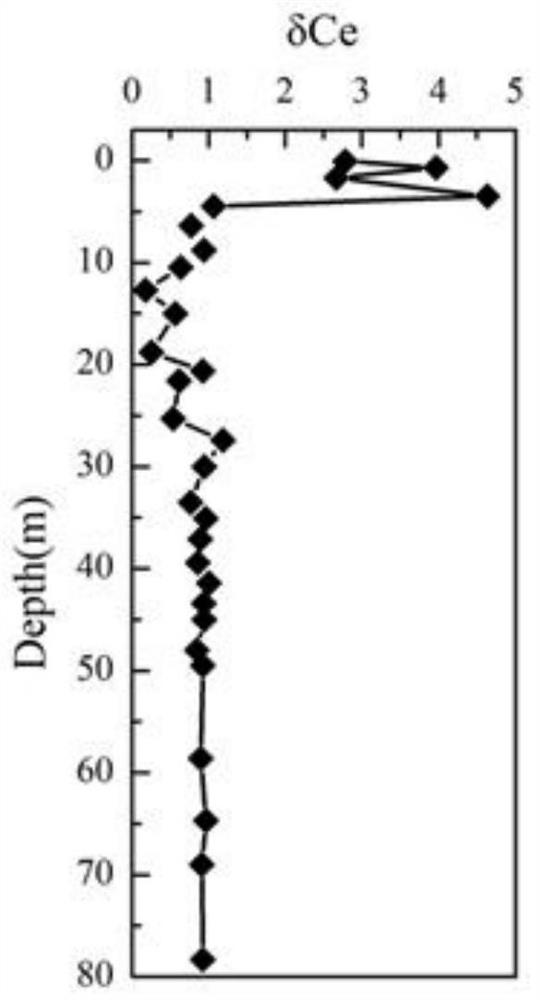

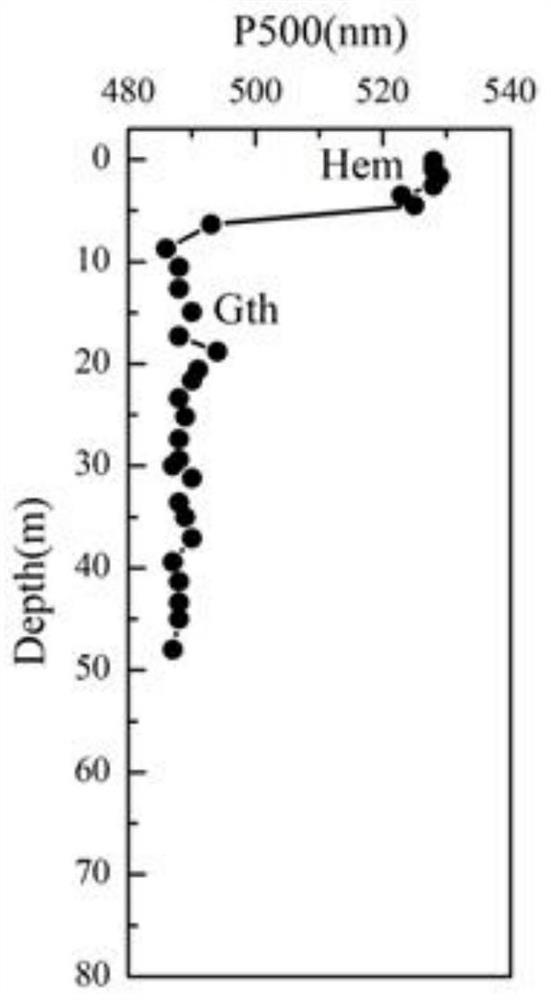

Method for predicting weathering crust ion adsorption type rare earth deposit layer position through ancient phreatic water level

ActiveCN111678882AAvoid owlsAvoid problems such as lossMaterial analysis by optical meansRare-earth elementWave band

The invention discloses a method for predicting a weathering crust ion adsorption type rare earth deposit layer position through an ancient phreatic water level. A sample of the weathering crust is collected for trace element analysis and visible light-near infrared reflectance spectrum analysis; the change of Ce content in the weathering crust whole rock, namely deltaCe, and the absorption peak position of a visible light-near infrared reflection spectrum capable of representing the relative content of hematite-goethite in a wave band (P500) of 480-530 nm are calculated; the boundary line where deltaCe in the weathering crust is sharply changed from positive to negative and P500 is remarkably reduced is the ancient phreatic water level of the weathering crust, and the rare earth element rich ore layer in the weathering crust is distributed below the ancient phreatic water level. The precision of delineating the ore body and evaluating the ore deposit reserves of the rich ore layer ofthe weatheringion adsorption type rare earth ore deposit is further improved, and the purpose of efficiently utilizing rare earth resources in weathering crust ion adsorption type rare earth ore deposit prospecting exploration work is achieved.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

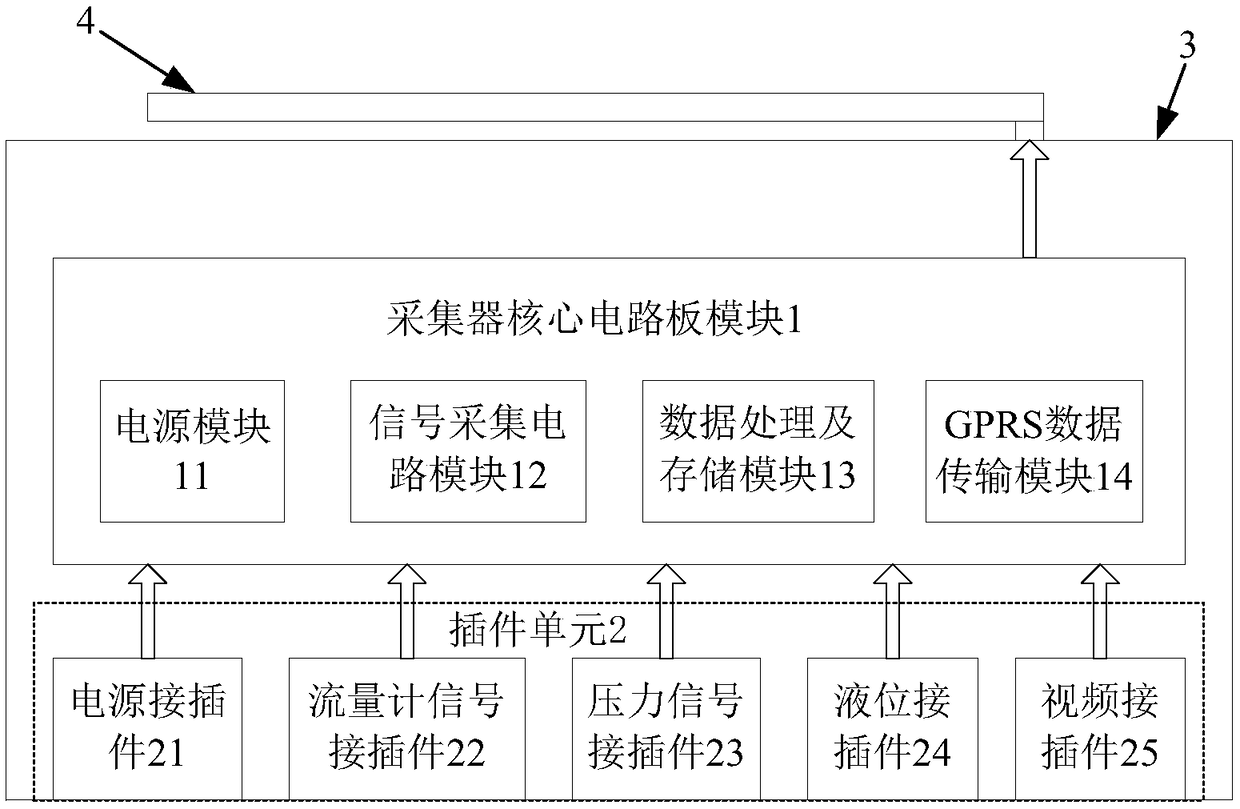

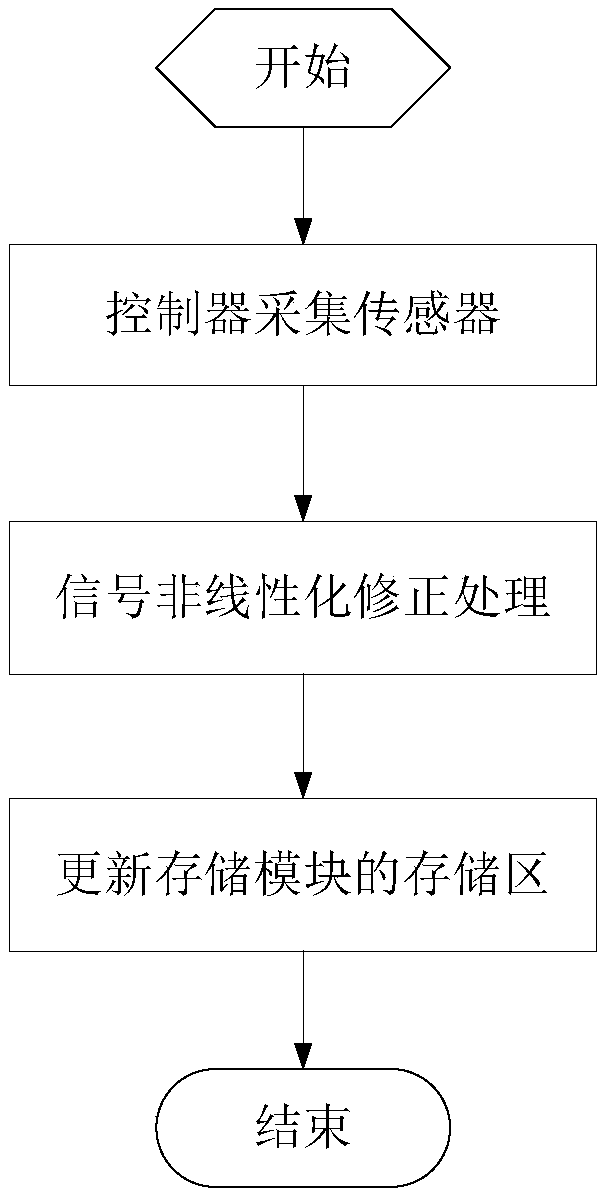

Integrated water shut-off and profile control data acquisition unit and data processing method thereof

InactiveCN109191817AReal-time transmissionConvenient and flexible useTransmission systemsData acquisitionData transmission

The invention provides an integrated water shut-off and profile control data acquisition unit, which comprises an acquisition unit core circuit board module and a plug-in unit; the acquisition unit core circuit board module is formed by integrating multiple sub-function modules, each sub-function module at least comprises a power module, a signal acquisition circuit module, a data processing and storage module and a GPRS data transmission module; the signal acquisition circuit module is used for performing data acquisition with a sensor connected with a signal acquisition connector, performingnonlinear stage processing and conversion on data of an acquisition channel, and storing the data to a database of the data processing and storage module. The invention also provides a data processing method. According to the integrated water shut-off and profile control data acquisition unit, multiple signal acquisition connectors are adopted, and different sensors can be combined according to different requirements, so that the data acquisition unit is flexible and convenient in use on the whole, realizes real-time transmission of video data, is simple in system and is plug and play unit.

Owner:北京普赛斯智能科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com