Large-particle-size agarose microspheres and preparation method thereof

An agarose microsphere, large particle size technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve spherical deformation, wide particle size distribution range, and emulsification effect It can achieve good pressure resistance, narrow particle size distribution and good balling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

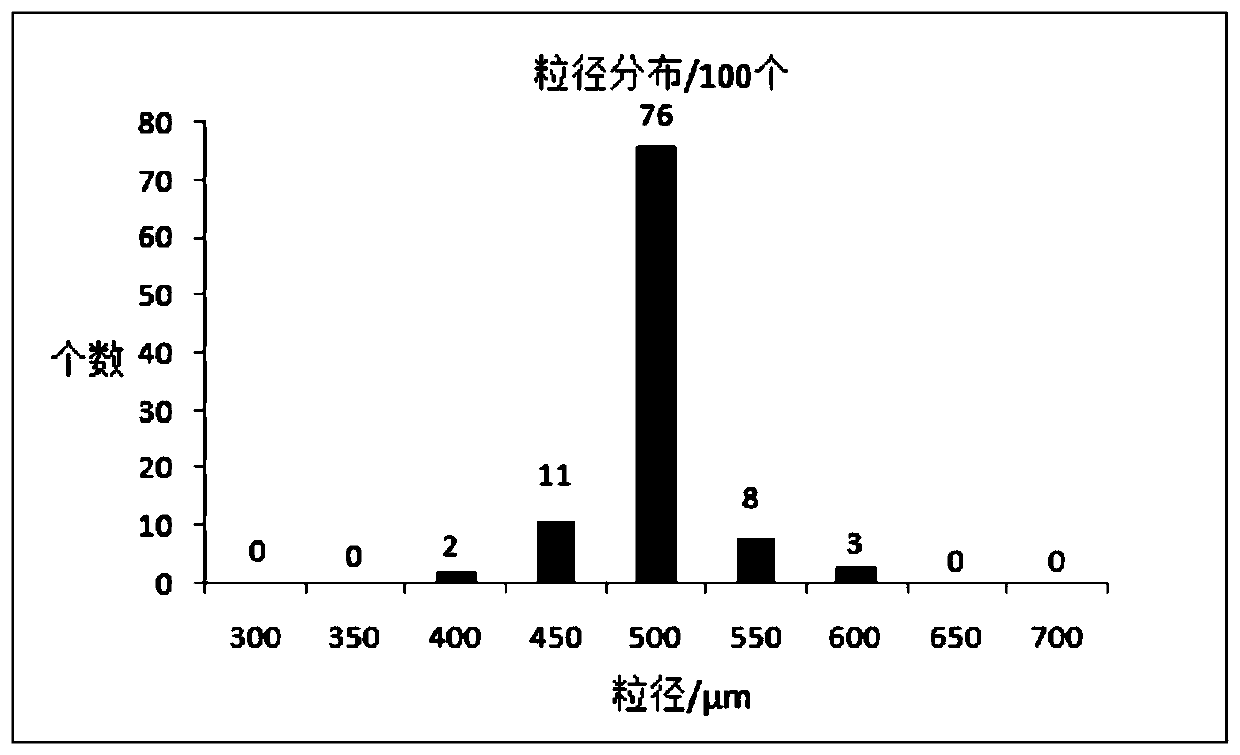

[0032] Example 1: Preparation and crosslinking of liquid paraffin system 500 μm 4% agarose microspheres

[0033] Accurately weigh 32g of agarose powder into 800ml of water, put it into a high-temperature sterilizing pot, set the temperature at 105°C for 60min. Accurately weigh 1.56g of Span 60 and 29.68g of Span 85 in 2400ml of liquid paraffin, dissolve at 75°C, and mix well. After the water phase is sterilized by high temperature, it is taken out and added to the oil phase, the temperature is maintained at 75° C., and the rotation speed is adjusted to 105 rpm. After emulsification for 1 hour, cool down and solidify. Monitor the temperature and keep the rate of temperature drop at 2°C / min. After dropping below 10°C, keep the temperature and cure for 1h. After curing, use petroleum ether, 95% ethanol, and pure water to wash repeatedly. Finally stored in 20% ethanol. The particle size distribution figure of this embodiment product is as figure 1 As shown, the light microsco...

Embodiment 2

[0037] Example 2: Preparation and crosslinking of 800 μm 6% agarose microspheres in toluene system

[0038]Accurately weigh 48g of agarose powder into 800ml of water, put it into a high-temperature sterilization pot, set the temperature at 110°C, and set the time for 120min. Accurately weigh 5.2g of Span 60, 90.8g of Span 80 and 2.5g of Tween 80 in 2400ml of toluene, dissolve at 70°C, and mix well. After the water phase is sterilized by high temperature, it is taken out and added to the oil phase, the temperature is maintained at 70° C., and the rotation speed is adjusted to 150 rpm. After emulsification for 1 hour, cool down and solidify, directly cool down in an ice-water bath, keep the temperature, and solidify for 1 hour. After curing, use 95% ethanol and pure water to wash repeatedly. Finally stored in 20% ethanol. The particle size distribution of the product in this example is as follows Figure 6 shown.

[0039] Accurately weigh 150g of the 800μm 6% agarose micros...

Embodiment 3

[0042] Example 3: Preparation and crosslinking of 500 μm 6% agarose microspheres in liquid paraffin system

[0043] Accurately weigh 48g of agarose powder into 800ml of water, put it into a high-temperature sterilizing pot, set the temperature at 115°C for 60min. Accurately weigh 2.4g of Span 60 and 45.60g of Span 85 in 2400ml of liquid paraffin, dissolve at 75°C, and mix well. After the water phase is sterilized by high temperature, it is taken out and added to the oil phase, the temperature is maintained at 75° C., and the rotation speed is adjusted to 150 rpm. After emulsification for 1 hour, cool down and solidify. Monitor the temperature and keep the rate of temperature drop at 2°C / min. After dropping below 10°C, keep the temperature and cure for 1h. After curing, use petroleum ether, 95% ethanol, and pure water to wash repeatedly. Finally stored in 20% ethanol. The particle size distribution of the product in this example is as follows Figure 7 shown.

[0044] Acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com