Iron mine pellet raw material preparation method facilitating efficient pelletizing

A technology of raw material preparation and iron ore pellets, which is applied in the field of raw material preparation for iron ore pellet production, can solve problems such as difficult control of moisture content, and achieve the effects of efficient suppression of moisture fluctuations, efficient and stable production, and improved quality of green pellets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

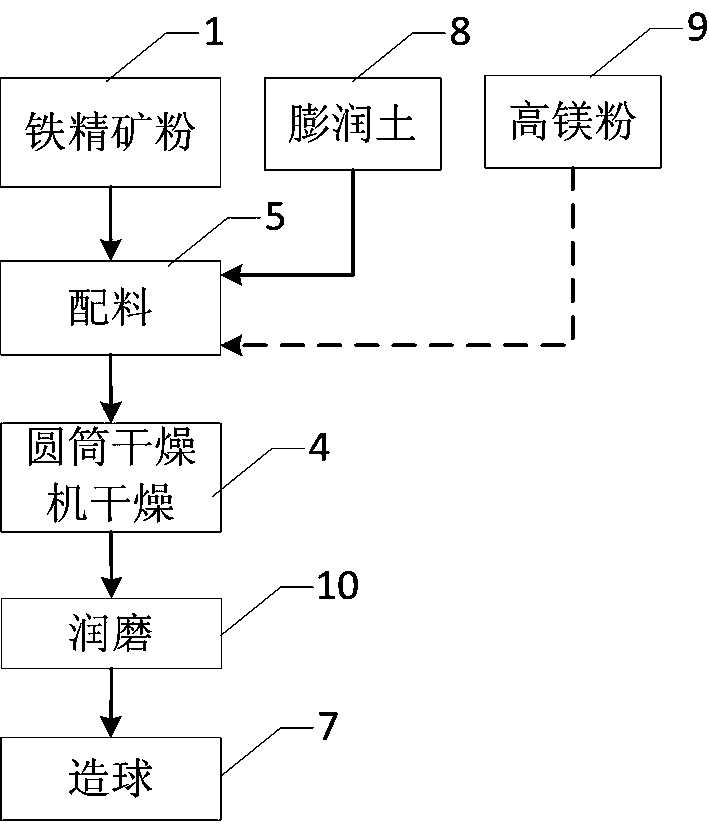

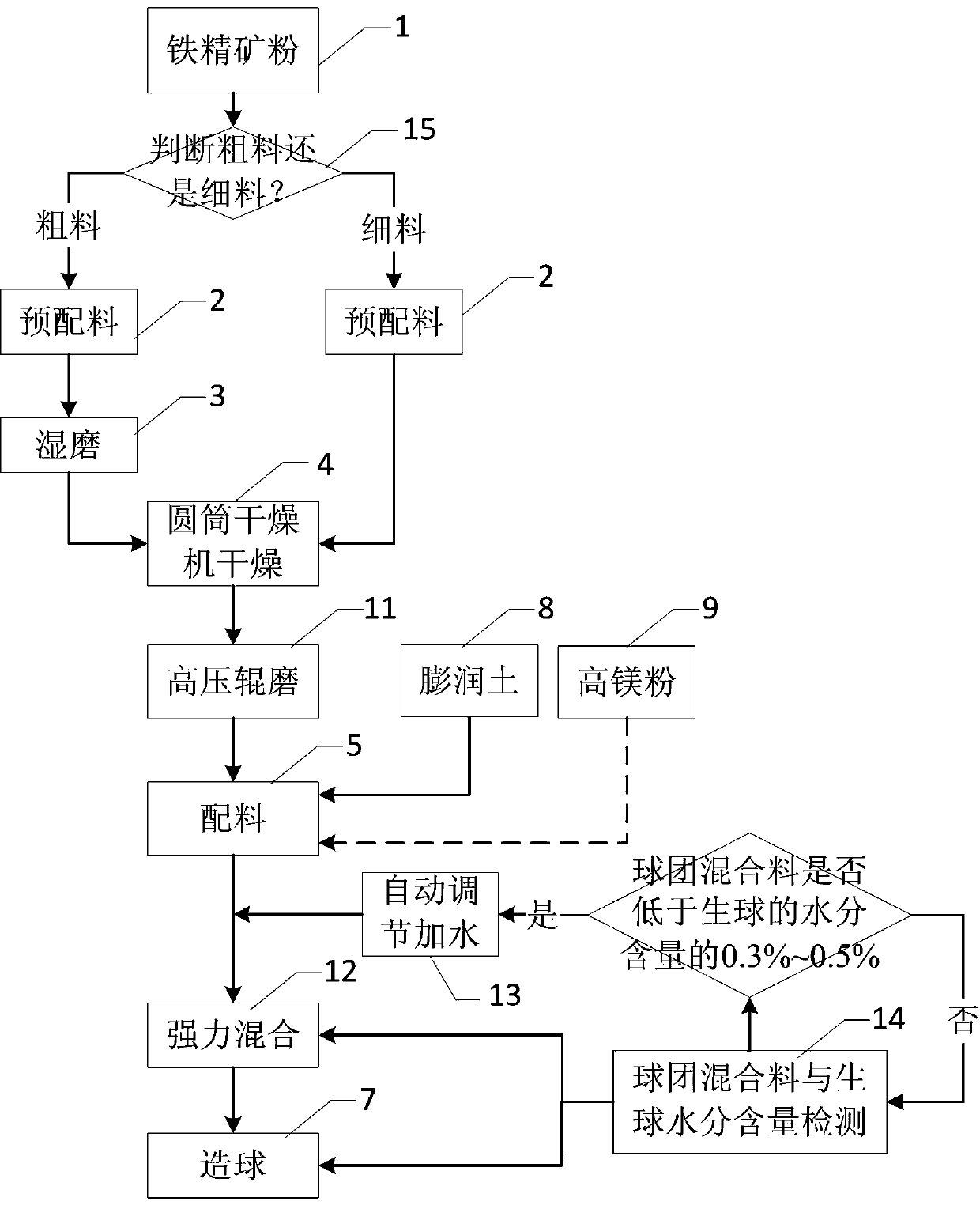

[0055] A method for preparing raw materials for iron ore pellet production that is conducive to efficient pelletizing, comprising the following steps:

[0056] Step 1: first judge whether the iron concentrate powder 1 is a coarse material or a fine material, the iron concentrate powder 1 used in this embodiment is a coarse material, and the particle size of the iron concentrate powder 1 is greater than 0.25mm and the particle content is greater than 10% If it is a coarse material, then the iron ore concentrate powder is pre-mixed 2 and then transferred to step 2 after going through 3 steps of wet grinding.

[0057] Step 2: Dry the iron concentrate powder 1 from the step 1 through a cylinder dryer to control the moisture content of the iron concentrate powder, and then perform high-pressure roller mill 11 through a high-pressure roller mill for pulverization.

[0058] In the wet grinding process, when the grinding particle size is too fine, it is difficult to filter, and when t...

Embodiment 2

[0067] A method for preparing raw materials for iron ore pellet production that is conducive to efficient pelletizing, comprising the following steps:

[0068] Step 1: first judge whether the iron concentrate powder 1 is a coarse material or a fine material. The iron concentrate powder 1 used in this embodiment is a fine material, and the iron concentrate powder 1 has a particle size of less than 0.074 mm and a content greater than 65% , then the iron concentrate powder 1 is directly transferred to step 2 after pre-mixing 2.

[0069] Step 2: The iron concentrate powder 1 from the above step 1 is dried 4 by a cylinder dryer to control the moisture content of the iron concentrate powder, and then crushed through a high-pressure roller mill 14 .

[0070] Various iron concentrate powders are pre-mixed according to a certain ratio, and the drying effect of the iron concentrate powder without adding bentonite, high-magnesium powder, etc. in the cylinder dryer is obviously improved, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com