Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78 results about "Zinc products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oysters contain more zinc per serving than any other food, but red meat and poultry provide the majority of zinc in the American diet. Other good food sources include beans, nuts, certain types of seafood (such as crab and lobster), whole grains, fortified breakfast cereals, and dairy products [2,11].

Preparation method of high purity zinc by vacuum distillation

InactiveCN102605194AEasy to operateEasy to separateCrucible furnacesProcess efficiency improvementZinc productsProcess conditions

The invention provides a preparation method of high purity zinc by vacuum distillation, which includes: subjecting zinc material to acid leaching, washing and drying in a distillation furnace, filling a graphite crucible with the zinc material, subjecting the zinc material to vacuum distillation, discharging high purity zinc, and processing high purity zinc products. The preparation method using the zinc material to produce high purity zinc has the advantages that equipment is simple, operation is easy, separation is effective, process conditions are easy to control and impurity index is low, and is applicable to using zinc materials to produce high purity zinc.

Owner:HULUDAO ZINC IND CO LTD

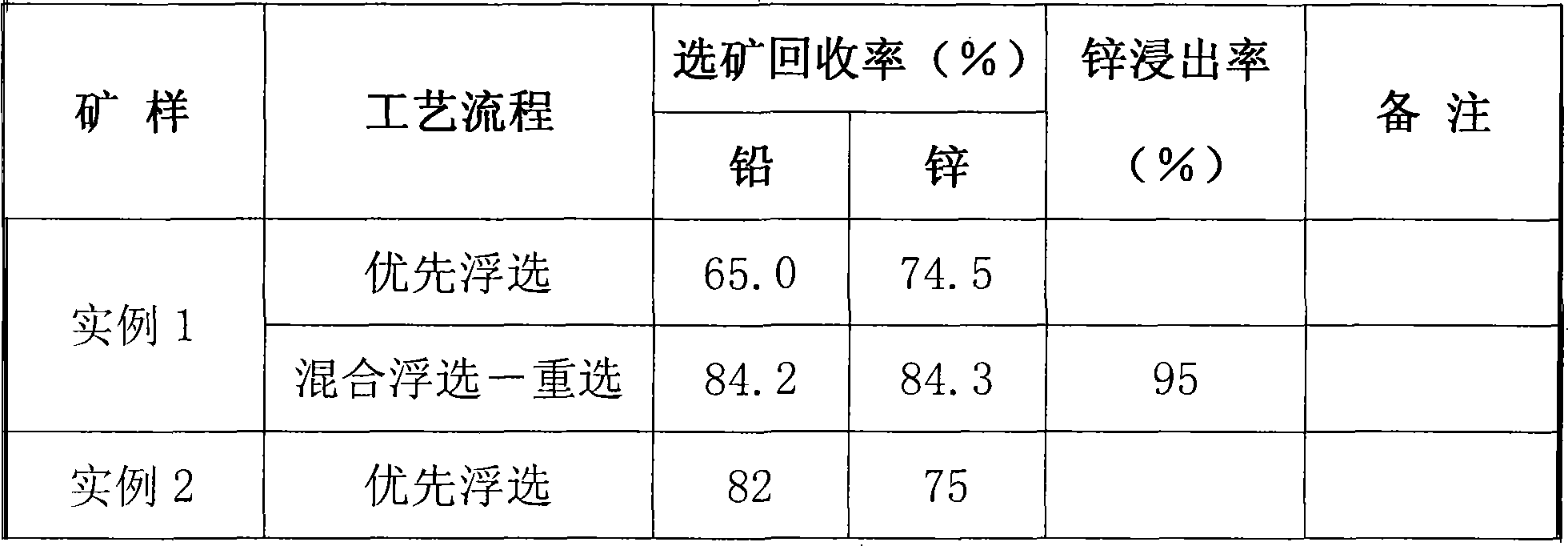

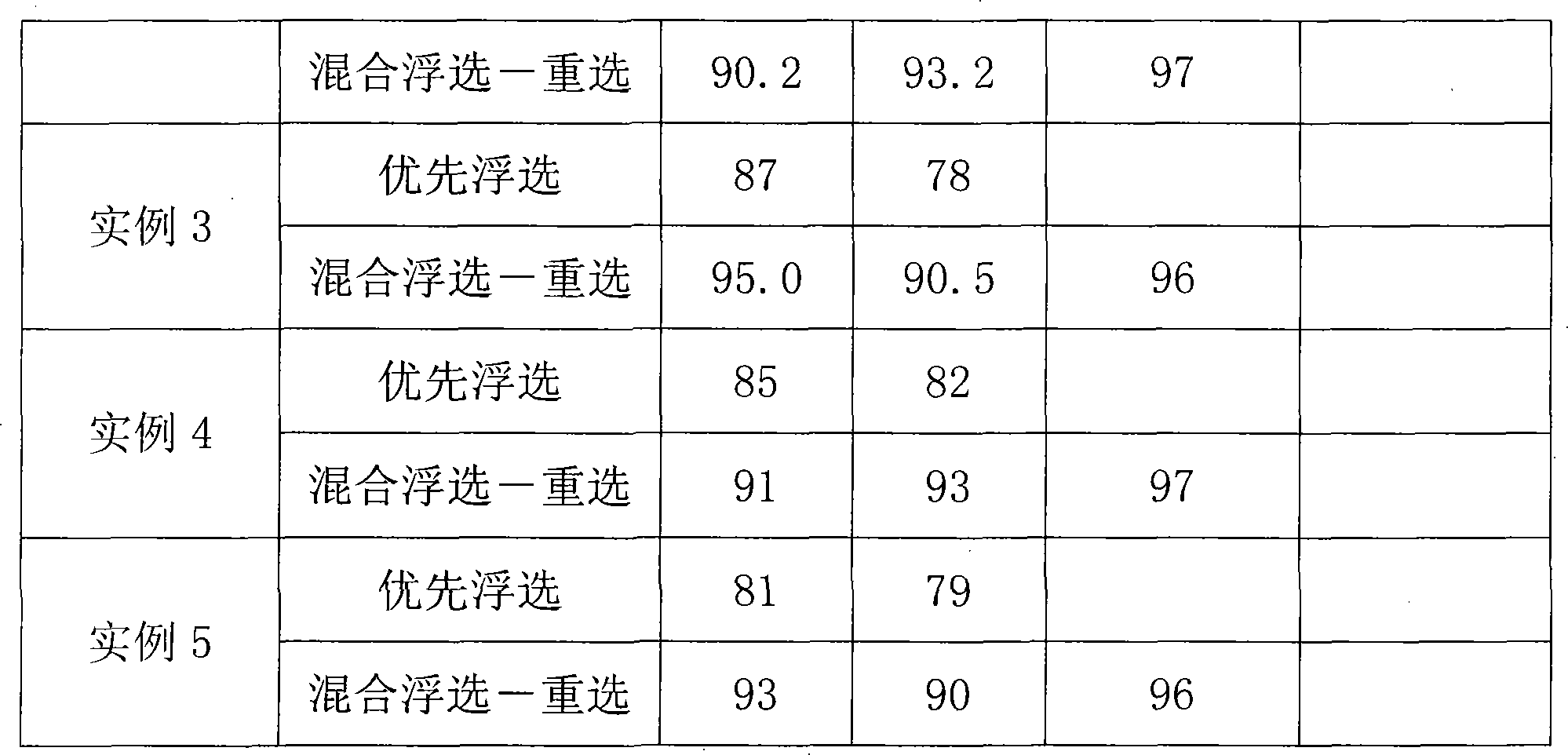

Selecting-smelting method for processing complex hard-washing low ore grade pulmbous sulfide zincium mine

InactiveCN101245407AHigh recovery rateReduce total usageFlotationProcess efficiency improvementLead smeltingZinc metal

The invention relates to a method for treatment of dressing and smelting low-grade lead-zinc sulphur ore with complex dressing and pertains to the filed of metallurgy. The specific steps of the method comprise that the low-grade lead-zinc sulphur ore with complex dressing is selected, the lead-zinc crude mixed concentrate is obtained by adopting a flotation technique and is then selected by adopting a gravity dressing technique so as to obtain part of lead concentrate and lead-zinc sulphur mixed concentrate; the lead-zinc sulphur mixed concentrate is added with acid to mix slurry after being treated with fine grinding and then done with acid pickling in a high-pressure kettle with high temperature and high pressure and oxygen and then the solid-liquid separation is carried out; leaching solution is used for producing zinc metal by the conventional technique of zinc hydrometallurgy, while leaching slag is used for recycling lead and silver metal with the conventional pyrometallurgical technique of lead smelting. The method of the invention adopts less species of additive medicine and dosage thereof and has higher recovery rate of lead and zinc products and lower production cost; meanwhile, tail water can be directly recycled with benefit for environmental protection. In addition, the smelting process of the method is characterized by shorter process, lower production cost and no smoke emission benefiting environmental protection.

Owner:YUNNAN METALLURGICAL GROUP

Processing method for purified cobalt residues of zinc and manganese hydrometallurgy

InactiveCN105950875AReduce pollutionSimple process controlProcess efficiency improvementManganeseHydrometallurgy

The invention provides a processing method for purified cobalt residues of zinc and manganese hydrometallurgy. The method comprises the following steps that (1) water or a mixture of water and sulfuric acid or a mixture of water and leaching liquid obtained in the step (2) is added into the purified cobalt residues, and the liquid-solid mass ratio is adjusted to be 2-8: 1; and (2) reaction is conducted for 1-8 hours under the atmosphere that the oxygen pressure is 1-2 MPa and the temperature is 110-180 DEG C, and the leaching liquid is obtained. The purified cobalt residues are obtained by purifying zinc and manganese leaching liquid through special reagents, and the special reagents comprise at least one of xanthate, beta-naphthol, sodium dimethyl dithiocarbamate, ziram, SDD and naphthenic acid. The cobalt residues with the high cobalt content have the good processing capacity, and the cobalt rate is as high as 99.95%. The process is simple, the cost is low, and no poisonous gas is generated; and cobalt, zinc, nickel and zinc products can be prepared, and the leached residues mainly comprise carbon and have very high utilization value.

Owner:钟庆文

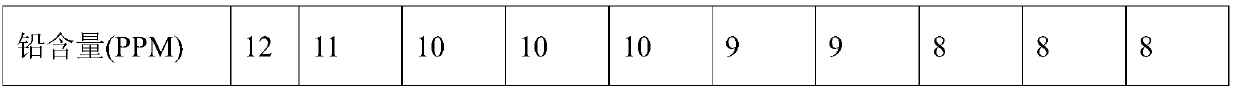

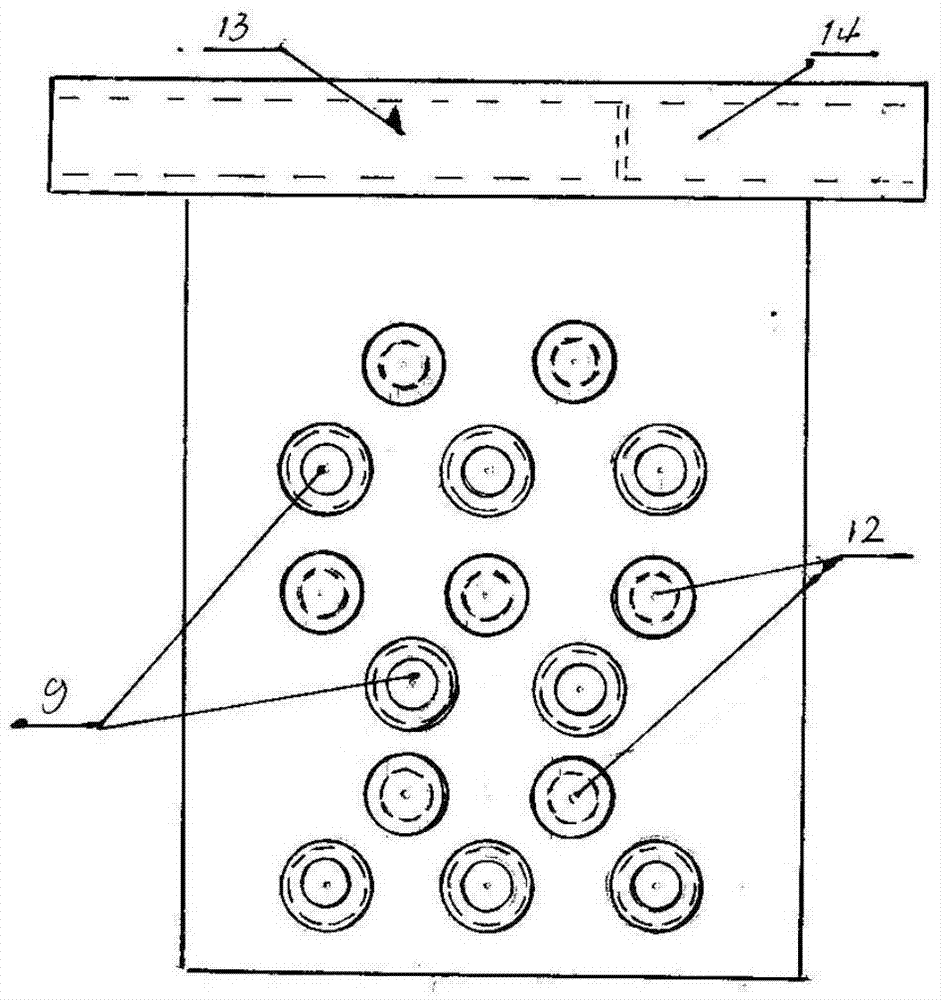

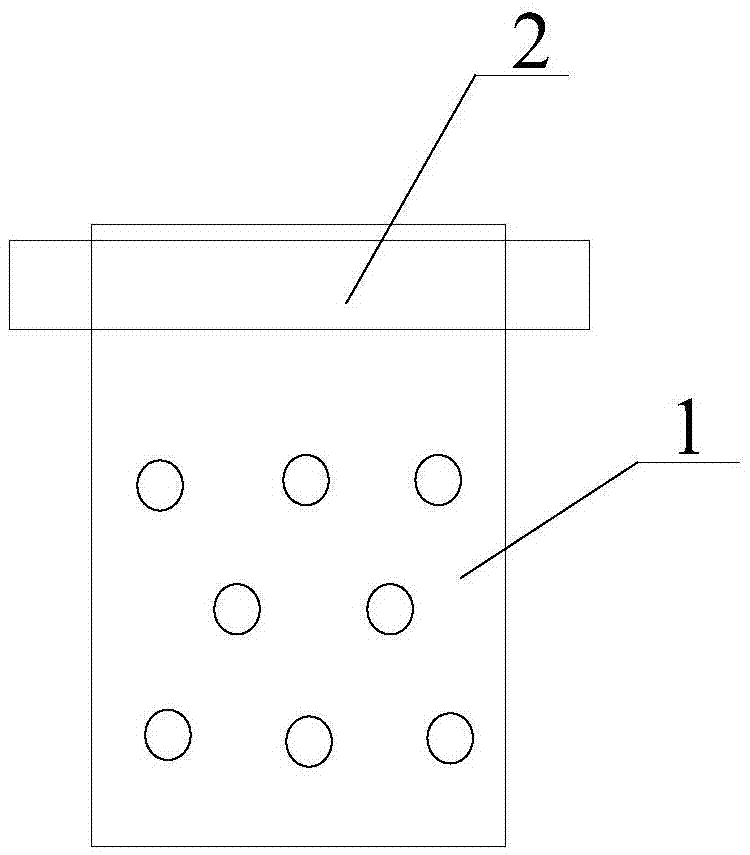

Production method and device of zinc dust

InactiveCN102105608AEasy to controlFine particle sizeCrucible furnacesMethods of productionZinc products

A method of production of Zinc dust, which includes melting Zinc products in a melting furnace on a semi-continuous basis, transferring at least a part of the molten Zinc products to a vaporizing furnace, vaporizing the molten Zinc in the vaporizing furnace into Zinc vapour on a substantially continuous basis, transferring Zinc vapour from the vaporizing furnace to a condenser, and condensing the Zinc vapour to form Zinc dust and cycling the Zinc vapour in the condenser and making the Zinc vapour pass through a cyclone type cooler. A Zinc dust production device includes a vertical crucible melting furnace (12), a vertical crucible vaporizing furnace (14), a condenser (18) in fluid flow communication with the vaporizing furnace for receiving Zinc vapour into the condenser, wherein the condenser is provided with a heat exchanger in the form of a vapour cycle system (58).

Owner:ZINCHEM A DIV OF ZIMCO GROUP

Method for extracting valuable metal from seabed multi-metal sulfide mineral coupling complex ore

ActiveCN104785357AReduce consumptionSimple processWet separationPregnant leach solutionSulfur product

The invention discloses a method for extracting valuable metal from seabed multi-metal sulfide mineral coupling complex ore. The method comprises the steps of obtaining leaching liquid containing copper and zinc and leaching slag containing sulfur, gold and silver through catalysis, oxidation and leaching; exacting copper products and zinc products out of the leaching liquid, and exacting sulfur products, gold products and silver products out of the leaching slag. By means of the method, valuable elements including copper, zinc, gold, silver and sulfur in the seabed multi-metal sulfide mineral coupling complex ore can be recycled comprehensively, the method has the advantages that the multipurpose utilization rate is high, the recycling rate is high, the process is simple, the cleanliness is achieved, and energy is saved, and the method is effective in processing new resources in the seabed multi-metal sulfide mineral coupling complex ore.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for extracting zinc from blast furnace gas mud

ActiveCN105087947AShort processing cycleHarm reductionProcess efficiency improvementNitrogen gasShaft furnace

The invention discloses a method for extracting zinc from blast furnace gas mud. The method comprises the steps of drying the gas mud to obtain gas ash, placing screened gas ash in a shaft furnace, introducing nitrogen to the shaft furnace for protection, and heating the shaft furnace to a temperature between 1050 DEG C and 1200 DEG C from room temperature; conducting reduction reaction to obtain gas containing zinc; introducing the gas to a sedimentation chamber for dust removal; obtaining polymorphic zinc mixed gas, and introducing the mixed gas to a coiled cooling pipe to be cooled so that a crude zinc product can be obtained. Through self-reduction reaction of fixed carbon contained in the gas mud at the temperature of 1050-1200 DEG C, the number of procedures is reduced, the gas mud processing cycle is shortened, and production cost is reduced; meanwhile, the requirement for the amount of reduction carbon and heating carbon required by reducing zinc in the gas mud can be met, complete reduction of zinc in the gas mud is guaranteed, and then harm to iron making equipment and iron production caused by zinc existing during gas mud recycling is greatly relieved.

Owner:武汉钢铁有限公司

Anti-corrosive alloy coating for power transmission tower and fastener and preparation process of anti-corrosive alloy coating

ActiveCN103834890ASimple hot-dip plating processShort immersion timeHot-dipping/immersion processesAlloy coatingTower

The invention relates to an anti-corrosive alloy coating for a power transmission tower and a fastener and a preparation process of the anti-corrosive alloy coating. The anti-corrosive alloy coating is prepared by pickling, aided plating, drying, hot dipping, air cooling and other technological processes. The coating comprises the following components: 0.01 to 2.5% of Al, 0.01 to 0.5% of Mg, 0.06 to 2% of Re, 0.02 to 1.5% of Cu, 0.05 to 0.3% of Cr, 0.005 to 0.01% of Nb, 0.005 to 0.01% of Ni, 0.002 to 0.06% of B, and the balance of Zn. The alloy coating is used for prolonging the anticorrosive lifetimes of steel for the power transmission tower and the fastener under a complex salt-spray environment, and prolonging the anticorrosive lifetimes more than 10 times that of an industrial hot galvanizing pure-zinc product on the premise that the thickness of the coating is not increased.

Owner:STATE GRID CORP OF CHINA +2

Preparation method of zinc anode oxidation film layer

The invention belongs to the technical field of the surface treatment of a metal material, and relates to a preparation method of a zinc anode oxidation film layer. The method comprises the following steps of: firstly polishing a substrate through a piece of silicon carbide (SiC) abrasive paper, then ultrasonically washing the surface of the substrate by using the acetone, ethanol and deionized water sequentially, and packaging the substrate with sealing glue to form a square substrate zinc surface; adding cerium chloride, hydrochloric acid, boric acid and citric acid into the distilled water, adequately stirring until all solid substances are dissolved, and adding ethyl orthosilicate to ensure that all substances are adequately dissolved to obtain a prepared electrolyte; and depositing the oxidation film layer on the substrate zinc surface by adopting an anode electro-oxidation technology with the processed substrate as an anode, a platinum niobium wire as a cathode and a saturated calomel electrode as a reference electrode, thus forming the zinc anode oxidation film layer. The preparation process is simple, the cost is low, convenience in operation can be achieved, the repeatability is good, no large-sized expensive equipment is needed, and the prepared film layer can be used for the surface treatment of zinc products or different zinc-coated products.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

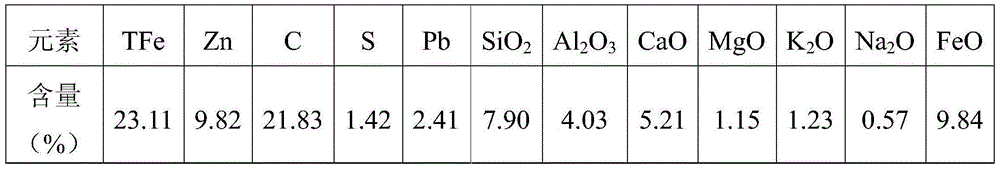

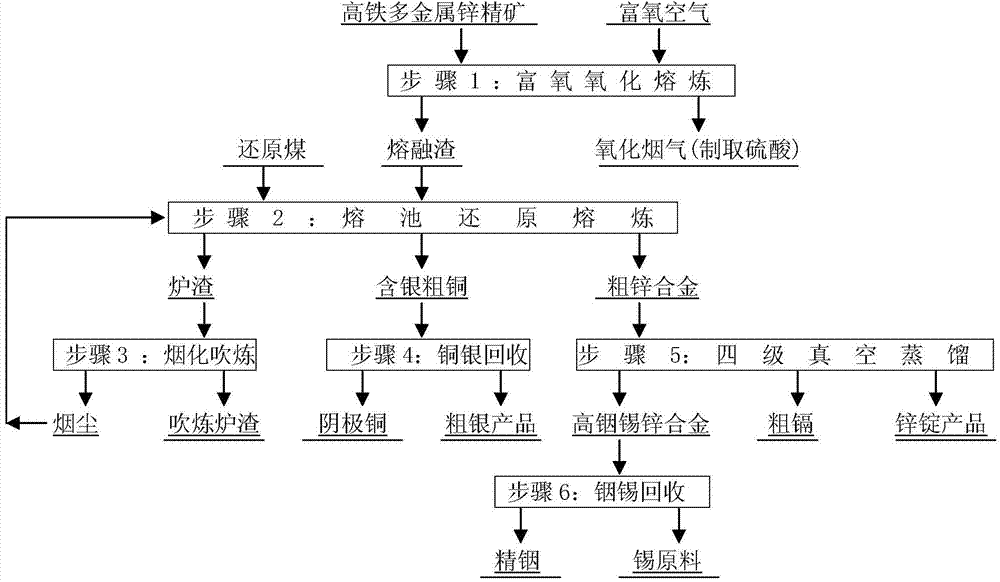

Smelting method of high-iron multi-metal zinc concentrate

ActiveCN103695663AReduce lossesEfficient recyclingPhotography auxillary processesProcess efficiency improvementIndiumDistillation

The invention relates to a smelting method of a high-iron multi-metal zinc concentrate. The method comprises the following steps: performing oxygen-enrichment oxidation melting on a zinc concentrate containing 14% to 20% of Fe, 0.03% to 0.10% of In, 0.2% to 0.6% of Cu, 0.2% to 0.6% of Cd, 0.005% to 0.02% of Ag, 0.1% to 0.2% of Sn and 40% to 50% of Zn so as to generate an oxidized flue gas and molten slags; preparing the oxidized flue gas into sulfuric acid; performing reduction smelting on the molten slags in a smelting pool so as to generate a crude zinc alloy, crude copper containing silver and slags; blowing the slags so as to obtain smoke dust and blown slags; returning the smoke dust to be subjected to reduction smelting; selling the blown slags in a market; extracting the copper and the silver from the crude copper containing silver; and performing four-stage distillation on the crude zinc alloy entering an electric-heating graphite vacuum furnace so as to generate a pyrogenic distilled zinc product, a crude cadmium product and a high-indium-tin zinc alloy which is used for extracting indium and tin. The method is reasonable in process, good in comprehensive recovery, high in production efficiency, low in production cost and clean and environmentally friendly in production process.

Owner:LAIBIN CHINA TIN SMELTING

Process for removing chloride fromiznc electrolytic solution by using silver hydroxide

InactiveCN1936036AMake full use of the dechlorination effectLow production costPhotography auxillary processesProcess efficiency improvementPregnant leach solutionSulfate

The invention relates to a technology to deprive chlorine from zinc electrolytic solution by silver hydroxide. It includes the following steps: using zinc oxide as raw material to form zinc sulfate leach solution that contains chlorine over 200mg / L, adding silver hydroxide into the solution, whisking for 30 minutes, after qualifying, filtering the solution, and the filtrate could be used to produce deposition zinc product, the leached residue is silver oxide that could be recycled.

Owner:YUNNAN AOSIDI INDAL

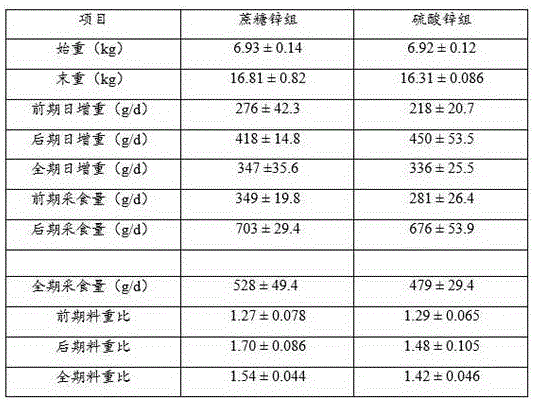

Method for preparing tannin chelate zinc feed additive

InactiveCN102106481AHigh yieldRaw materials are easy to getAnimal feeding stuffAccessory food factorsAcetic acidTrace element

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

Method for recovering and treating zinc-containing dust through blast furnace slag sensible heat

InactiveCN105838876AFull recoveryIncreasing energy efficiencyRecycling and recovery technologiesSlagProduct gas

The invention belongs to the field of comprehensive utilization of resources and relates to a method for recovering and treating zinc-containing dust through blast furnace slag sensible heat. The zinc-containing dust in a steel plant serves as a main raw material, a certain amount of a reducing agent, a bonding agent, a fluxing agent and water are added, and after sufficient mixing is conducted, a mixture is pressed into balls through a ball press; the balls are sent to a furnace slag retention room after being dried and cured; zinc-containing dust blocks are subjected to a self-reducing reaction through the furnace slag sensible heat; crude-zinc products are recovered through a gas dust removing device; and residual furnace slag is treated through a traditional furnace slag treatment technology. By means of the technology of the method, the zinc-containing dust different in component in the steel plant can be treated, and the zinc element in the dust can also be sufficiently recovered while the C resource in the dust is utilized.

Owner:UNIV OF SCI & TECH BEIJING

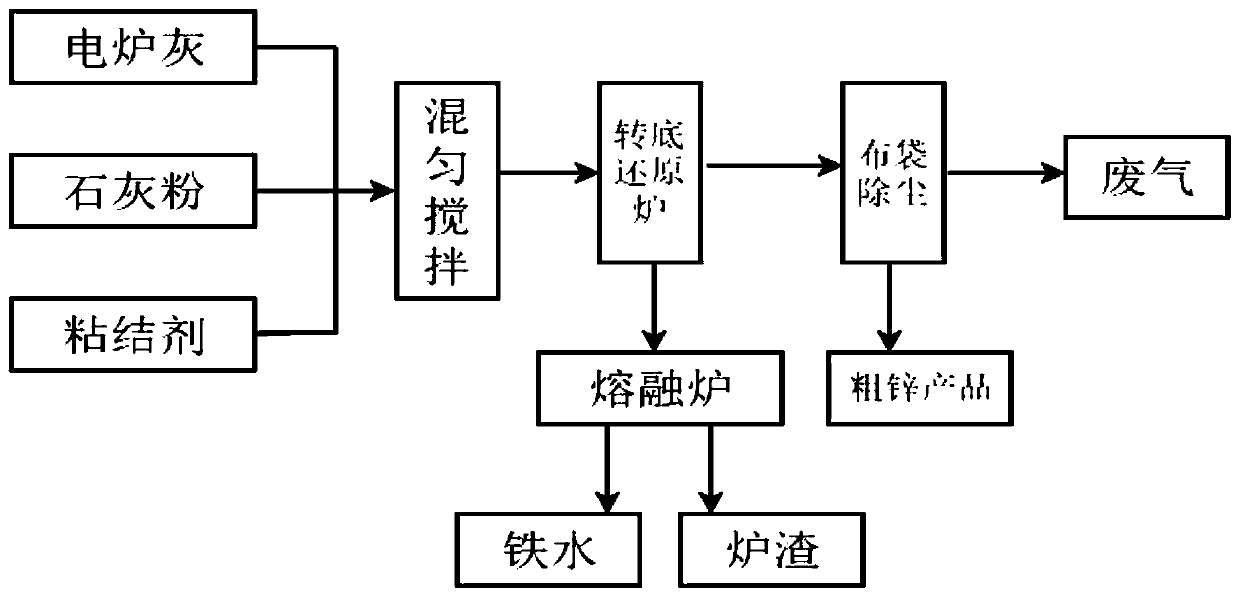

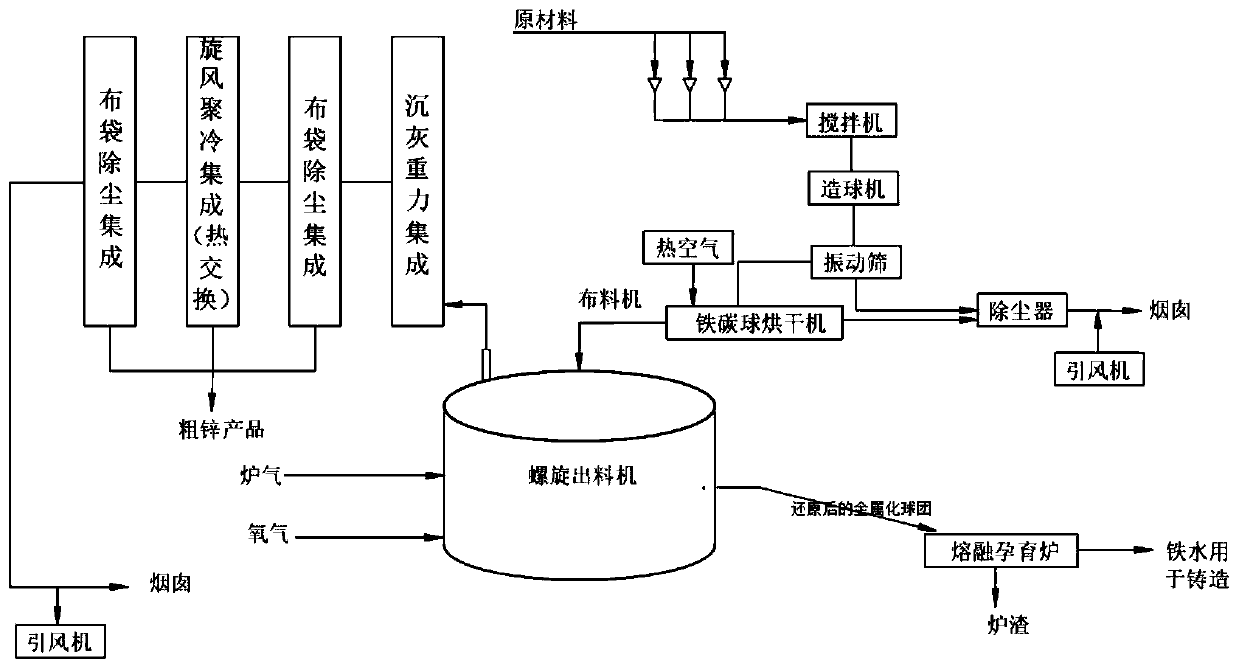

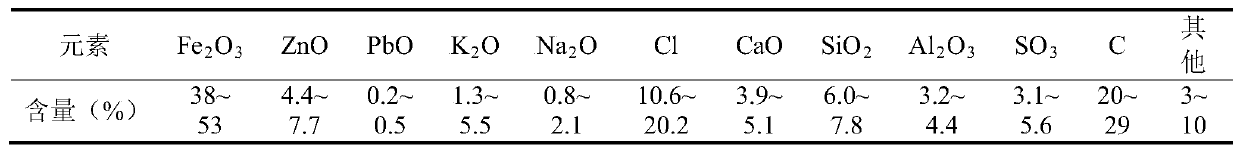

Resource utilization method of electric furnace bag dusting ash

InactiveCN110055410ANo emissionsAchieve recyclingGlass making apparatusProcess efficiency improvementSlagResource utilization

The invention provides a resource utilization method of electric furnace bag dusting ash. The resource utilization method of the electric furnace bag dusting ash comprises the following steps that a)adding a reducing agent, a binder and water into the electric furnace bag dusting ash, uniformly stirring is performed, and putting the mixture into a pelletizing machine for pelletizing to obtain a semi-finished iron carbon ball; b) naturally curing the prepared semi-finished iron carbon ball or drying the prepared semi-finished iron carbon ball at 105-110 DEG C; and c) putting the dried iron carbon ball into a rotary-bottom reduction furnace for heating and reducing, controlling the temperature of the rotary-bottom reduction furnace to be 1100-1400 DEG C, carrying out heat preservation for 25-45 minutes, collecting volatile smoke dust and reducing furnace slag, and collecting the collected smoke dust as a crude zinc product. According to the method, the zinc element is reduced by using the electric furnace bag dusting ash, the zinc element is subjected to air re-oxidation, then the purpose of extracting and recovering the zinc element is achieved, heavy metal indexes of residual slagafter zinc extraction reach the national waste discharge standard, and the goal of zero emission treatment of solid waste is realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A method for treating zinc smoke

The invention provides a method for treating zinc blast furnace smoke and electric furnace smoke, comprising: treating the zinc smoke by strongly basic NaOH solution to react the Zn, ZnO with the NaOH and generate a soluble compound as a liquid phase; reacting Fe, oxide of the Fe, C, SiO, Al2O3, CaO or the like with the NaOH and staying the reaction product into the solid phase; separating the liquid and the solid via filtering and cleaning, wherein, the solid phase filter cake contains the solid phase filter cake containing Fe, oxide of the Fe, C, SiO, Al2O3, CaO or the like, is recovered into a sinter to reuse; the liquid phase containing the Zn soluble compound is neutralized by H2SO4 to convert the Zn into Zn(OH)2 precipitation, thereby obtaining the Zn(OH)2 filter cake after filtering and cleaning to be used for producing the other zinc product; the filtrate as Na2SO2 solution can be used to recover the Na2SO2.

Owner:史汉祥

Method for preparing organic zinc by means of calcium analysis reactive crystallization

The invention discloses a method for preparing organic zinc by means of calcium analysis reactive crystallization, which includes: adding terephthalic acid and water and / or filtrate in a reactor, and then adding sodium hydroxide to lead the terephthalic acid to dissolve into terephthalic acid sodium solution, wherein the filtrate is mother solution after centrifugal separation of organic zinc; adding saturated lime milk suspension to enable separation by crystallization of terephthalic acid calcium; adding saturated sodium zincate solution to enable separation by crystallization of terephthalic acid zinc on a terephthalic acid calcium carrier; and centrifuging, wherein filtrate which is sodium hydroxide solution is used for allocation of terephthalic acid sodium solution in next batch, so that an organic zinc product is obtained by rinsing and drying a centrifuged product. By the aid of the method, discharge of waste water containing inorganic salt such as sodium chloride and / or sodium sulfate and the like is avoided, the sodium hydroxide contained in centrifuged mother solution can be used for allocation of the terephthalic acid sodium solution in next batch, and consumption of the sodium hydroxide is reduced.

Owner:EAST CHINA UNIV OF SCI & TECH

Technical method for recycling potassium, sodium and zinc from blast furnace bag ash

The invention relates to a technical method for recycling potassium, sodium and zinc from blast furnace bag ash. The raw material of the method is the blast furnace bag ash, and the method aims to realize recycling of potassium, sodium and zinc and cyclic utilization of iron-containing slag in a steel plant. The method comprises the process of recycling potassium and sodium through water washing,the process of reducing and volatilizing zinc and the process of recycling zinc through a wet method. The method specifically includes the steps that after the blast furnace bag ash is subjected to water washing, a filtrate containing potassium chloride and sodium chloride is obtained, and the filtrate saturated with potassium chloride or sodium chloride is purified and subjected to fractional crystallization to obtain KCl and NaCl products; the filtrate not saturated with potassium chloride or sodium chloride is subjected to the water washing step again, after the water washing residues are dried, the water washing residues, a reduction agent and an adhesive are evenly mixed and granulated according to a certain mass ratio, then high-temperature reduction and volatilization of zinc are carried out in a reduction device, and the iron-containing slag is recycled in the steel plant; and zinc-rich dust recycled in a flue gas recycling system is leached, purified and electrolytically deposited to obtain metal zinc products, and electrolyte is recycled in the leaching step. According to the process flow, high-value utilization of the blast furnace bag ash and cyclic utilization of the blast furnace bag ash in the steel plant are simultaneously realized, and energy conservation and emission reduction of steel enterprises are promoted.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

Distillation furnace for directly preparing high-purity zinc products from hot galvanizing slag

The invention discloses a distillation furnace for directly preparing high-purity zinc products from hot galvanizing slag, belonging to a zinc product preparation device in the nonferrous metallurgy industry. The distillation furnace is provided with a melting section, an evaporation section and a rectifying section in turn, wherein the melting section and the evaporation section are arranged horizontally, and the rectifying section is arranged vertically; one end of the melting section is provided with a raw material inlet, the other end of the melting section is communicated with the evaporation section, and the outlet of the evaporation section is communicated with the inlet of a silicon carbide tray arranged in the rectifying sections through a connection channel; and the outlet of the silicon carbide tray is communicated with a condenser on the outside of the furnace body through a zinc vapor duct. The distillation furnace integrates the advantages of the horizontal zinc distillation furnace and the tower type zinc distillation furnace and is suitable for the treatment of zinc-containing high-iron materials such as hot galvanizing slag and hard zinc; and a certain of service life can be ensured and the distillation furnace is suitable for the industrial productions of high-purity zinc powder and zinc ingots.

Owner:BGRIMM ADVANCED MATERIALS SCI & TECH

Gas phase inhibitor special for zinc products

InactiveCN1594657AImprove rust resistanceLong anti-rust periodContainers preventing decayMorpholineGas phase

The invention discloses a vapour phase rust inhibitor VP1-PM special for zinc product and the production method of gas phase rust-preventive packaging material for galvanizing. The said VP1-PM is reaction product of malic Acid with morpholine, has unique gas phase inhibitor action to zinc product. Gas phase rust-preventive paper, gas phase rust-preventive non-woven fabric, framed gas phase rust-preventive paper, framed gas phase rust-preventive non-woven fabric, gas phase rust-preventive plastic film special for galvanizing can apply to long-term seal and temporary rust prevention of all kinds of galvanizing products from galvanizing bolt, screw cap, to heavy galvanizing coiled material, strip and sheet. The said gas phase rust-preventive packaging material for galvanizing has a good effect on rust prevention, long term rust prevention period, which is convenient for usage, and safe.

Owner:WUHAN HONGFU ANTICORROSIVE PACKING CHEM IND

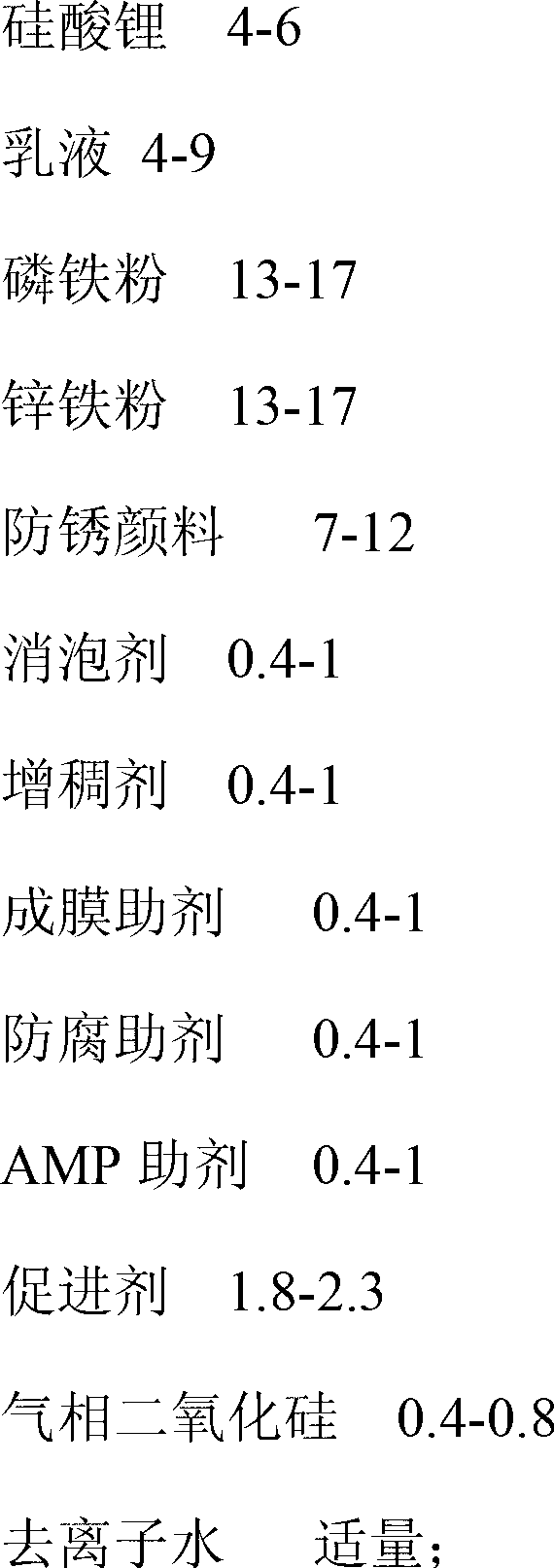

Zinc powder-free water-based primer

ActiveCN102993885AImprove performanceAddress health hazardsAnti-corrosive paintsGas phaseSilicon dioxide

The invention relates to a zinc powder-free water-based primer. The zinc powder-free water-based primer comprises the following components in parts by weight: 4-6 of lithium silicate, 4-9 of emulsion, 13-17 of ferrophosphorus powder, 13-17 of zinc-iron powder, 7-12 of antirust pigment, 0.4-1 of defoaming agent, 0.4-1 of thickening agent, 0.4-1 of film forming aid, 0.4-1 of anticorrosive aid, 0.4-1 of AMP aid, 1.8-2.3 part of accelerant, 0.4-0.8 of fumed silica and a right amount of deionized water. The zinc powder-free water-based primer has the advantages that the secondary rust removal problem caused by zinc powder is eliminated, and the health hazards on constructors and the pollution on environments are eliminated by using water for replacing an organic solvent. The adhesive force of the zinc powder-free water-based primer is obviously superior to that of an inorganic zinc product under the condition of unsatisfactory surface treatment.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Method for recovering zinc from waste electrogalvanizing mud cake containing zinc

ActiveCN105543500AHigh recovery rateReduce recycling costsProcess efficiency improvementRecovery methodProper treatment

The invention discloses a method for recovering zinc from a waste electrogalvanizing mud cake containing zinc. The method comprises the steps that a proper treatment method and a proper treating agent are selected according to the chemical properties of main elements of a solid product, namely the mud cake containing zinc, of electrogalvanizing waste water; a treatment process comprising the step of acid leaching, the step of evaporation, concentration and oxidization, the step of replacement treatment, the step of secondary oxidization, the step of neutralizing and the step of drying and forging is conducted, and optimization operation is conducted in each step; and a zinc product of zinc oxide is finally obtained. The recovery rate of zinc is greatly increased compared with a traditional recovery method; the recovery cost is low, the technique is simple, wastewater discharge is avoided, and new pollution is avoided; the method has both environmental protection value and economic value.

Owner:南通好汉邦新材料科技有限公司

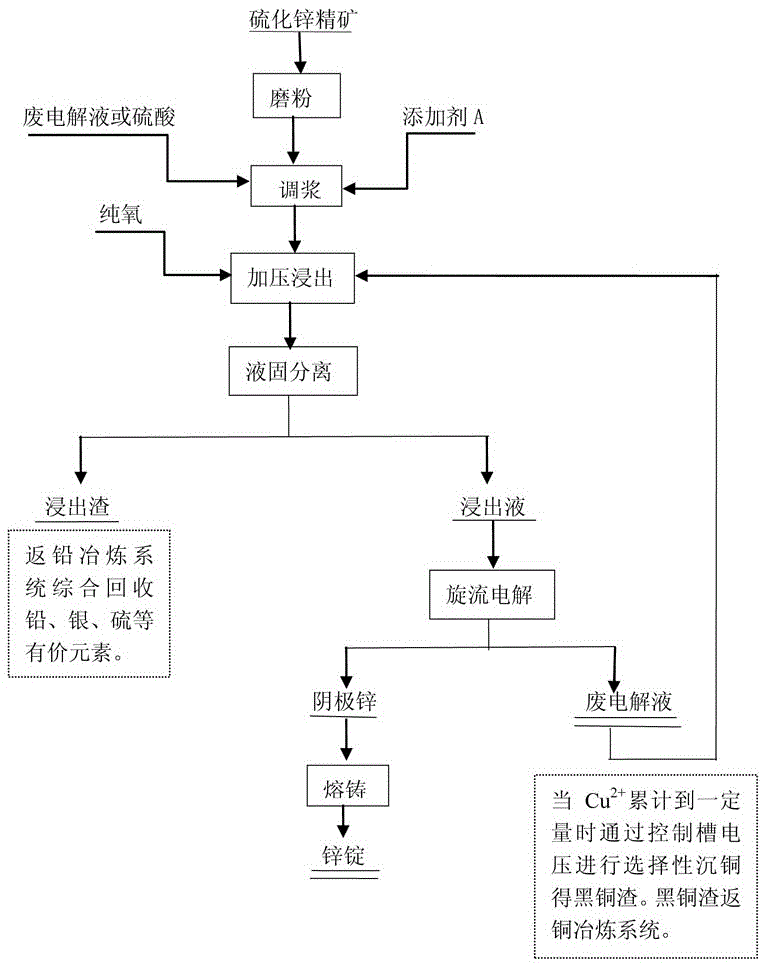

Technology for efficiently and selectively separating zinc in zinc sulfide concentrate

ActiveCN105603186ANo pollution in the processAdaptablePhotography auxillary processesProcess efficiency improvementElectrolysisSlag

The invention discloses a technology for efficiently and selectively separating zinc in zinc sulfide concentrate. The technology includes the steps that the zinc sulfide concentrate serves as a raw material and is wetly ground, then the wetly-ground concentrate and sulfuric acid or waste electrolyte are mixed into a slurry and poured into a high-pressure kettle for leaching, an adjusting agent A is added, pure oxygen is led in, the proper final acidity is controlled, and most Fe and most As in the zinc sulfide concentrate enter slag in the hematite mode, the iron vitriol mode and the ferric arsenate salt mode. Leached liquid is subjected to acidity regulation to be directly electrolyzed in a rotational flow mode, zinc in the leached liquid is extracted, and an electric zinc product meeting the national standard can be obtained. According to the technology, the traditional purification working procedure is omitted, the technological process and a device are simplified, the technology is simple, operation is easy and convenient, energy consumption is reduced, the leaching rate and the recovery rate of the zinc are increased, resources are saved accordingly, and cost is reduced.

Owner:XIANGNAN UNIV +1

Zinc electrolysis anode plate and preparing method thereof

ActiveCN109680301AAvoid corrosionReduce Pb contentAnodisationPhotography auxillary processesElectrolysisAlloy

The invention discloses a preparing method of a zinc electrolysis anode plate. The preparing method comprises the following steps that firstly, under low current density, anode oxidization is conducted, and a dense PbO2 protection layer anode plate is obtained; secondly, electroplating of an MnO2 protection layer is conducted on the anode plate; thirdly, by mass percent, 20-30% of an Mn(NO3)2 solution is prepared; and fourthly, a chemical MnO2 deposition layer is generated on the anode plate, the fourth step is repeatedly conducted 2-5 times, and the zinc electrolysis anode plate is obtained.The invention further provides the zinc electrolysis anode plate. The preparing method of the zinc electrolysis anode plate and the zinc electrolysis anode plate have the following beneficial effectsthat an electrolytic zinc product with the extremely low Pb content can be obtained at the beginning of production; the current efficiency is improved, the production intensity is lowered, and the production efficiency is improved; and dissolving of Pb alloy materials is effectively prevented, the service life is longer, and the lead content in product zinc is lower.

Owner:湘西土家族苗族自治州质量检验及计量检定中心

Method for absorbing sulfur dioxide in sintering flue gas using blast furnace smoke as absorbing agent

The invention relates to a method for absorbing sulfur dioxide in sintering gases by taking blast furnace flue gases as an absorbing agent. The blast furnace flue gas is made into blast furnace pulp by water and washing liquid or filter liquor returned to the filter washing process, the pulp is fully contacted with the sintering gas in sulfur dioxide absorbing equipment, and filled with air for oxidation, and the pH value of the pulp after desulfurization is controlled; the reaction product is filtered and washed, the filter cake containing ferriferous oxide F2O3, FeO and C which do not take part in the reaction, CaSO4 newly generated and the like is taken as an ironmaking material and returns to a sintering machine, the washing liquid and the filter liquor are returned to prepare the blast furnace pulp, and when the concentration of Zn<++> in the filter liquor meets a required value, the filter liquor is taken to be processed into zinc products. The method has the advantages of reducing the emission of sulfur dioxide, separating zinc which causes adverse effects on ironmaking from the blast furnace flue gas, making Fe, C and Zn in the blast furnace flue gas fully utilized, and killing two birds with one stone.

Owner:史汉祥

Molding of die-cast product and method of

InactiveUS20100032123A1Inhibition formationMelt-holding vesselsMolten metal pouring equipmentsMolten stateHot runner

A system and method of preventing surface imperfections of die-cast products with the method comprising the steps of loading a volume of molten zinc from a source of molten zinc into a chamber of a dispenser station, dispensing the molten zinc from the dispenser station through a hot runner and into a mold cavity, continually maintaining the molten zinc in a molten state from the source of molten zinc to the mold cavity, interrupting the flow of the molten zinc to the mold cavity, following the contraction of the molten zinc in the mold cavity as the molten zinc solidifies therein; and removing the solidified die-cast zinc product from the mold cavity.

Owner:RATTE ROBERT W

Method for removing arsenic and recovering valuable metal from ilmenite smoke dust

ActiveCN109306408AAchieve enrichmentSolve problems that are difficult to separate efficientlyProcess efficiency improvementZinc hydroxideSlag

The invention discloses a method for removing arsenic and recovering valuable metal from ilmenite smoke dust. The method comprises the steps of leaching ilmenite smoke dust through strong alkali to obtain a leaching solution containing arsenate and zincate and iron-containing leaching slag; adding benzyl chloride to the leaching solution to convert arsenate into benzyl-arsine; then adding a particle carrier for adsorbing the benzyl-arsine; fully floating and separating to obtain benzyl-arsine salt; neutralizing the floating separating liquid core, and separating out a zinc hydroxide product; adding water to the iron-containing leaching slag; stirring and mixing the slurry; and then adding a flocculating agent and a collecting agent for floating and separating so as to obtain iron ore concentrate. With the adoption of the method, the purpose of removing arsenic is achieved, and moreover, iron and zinc products can be recovered, so that the resource comprehensive utilization of the ilmenite smoke dust can be realized; and the method is simple, quick, efficient, and low in cost and meets the industrial production.

Owner:CENT SOUTH UNIV

Comprehensive utilization method for complex multi-metal material containing copper, zinc and the like

InactiveCN106282572AIncrease concentrationEasy to separateZinc oxides/hydroxidesZinc sulfidesPregnant leach solutionVulcanization

The invention relates to a comprehensive utilization method for a complex multi-metal material containing copper, zinc and the like. The complex multi-metal material containing copper, zinc and the like is treated to be non-vulcanized, an ammonia process is used for leaching metal elements such as copper and zinc conducting complexation with ammonia; after a leaching agent is purified and subjected to impurity removing, zinc powder is added, valuable metal ions such as copper are replaced, a residual zinc-ammonia complex solution is then used for reproducing a zinc product, various kinds of valuable metal are separated and concentrated into tailings or oxidizing slag or replacement slag or vulcanization slag, replaced elementary copper and the residual zinc-ammonia complex solution correspondingly; and a high-grade non-vulcanized copper material and / or a non-vulcanized zinc material with the copper content higher than 2% and / or the zinc content higher than 10% are / is added, so that the concentration of copper and zinc in the leaching agent is improved. According to the comprehensive utilization method, the problem that the complex material containing lead, copper, zinc and the like is difficultly singly separated during flotation is solved, the method can be suitable for copper and zinc materials low in grade, the leaching rate is 80% or higher, and the content of manufactured products such as copper sponge and zinc oxide is also 97% or higher.

Owner:李果

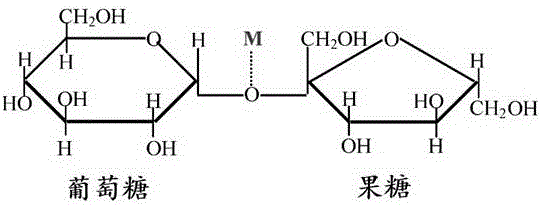

Preparation method for saccharose zinc complex

ActiveCN106188200AAchieve reuseMeet the requirements of green chemistrySugar derivativesAccessory food factorsFiltrationWastewater

The invention discloses a preparation method for saccharose zinc complex. Saccharose and heptahydrate are subjected to a complex reaction, and a saccharose zinc solution is obtained; then, the saccharose zinc solution is cooled and filtered, filter residues and filtrate are obtained, ethanol water is added into the filtrate, complex precipitates, precipitate is subjected to centrifugal suction filtration and vacuum drying to be dried, and a pure saccharose complex zinc product is obtained; the zinc ion concentration of the filter residues is detected, according to the molar ratio being 1:4 of saccharose and zinc ions, saccharose and heptahydrate continue to be added, waste water obtained after centrifugal suction filtration is returned to a reaction kettle to serve as mother liquid for dissolving saccharose, a circular reaction is conducted, and saccharose zinc continues to be generated. In the process of preparing the saccharose zinc, no resources are wasted, the production cost is reduced, and the production efficiency is improved. The obtained saccharose zinc has the advantages of being safe, efficient and high in cost performance and can be applied to production of animal feed with comprehensive nutrition.

Owner:南宁市泽威尔饲料有限责任公司

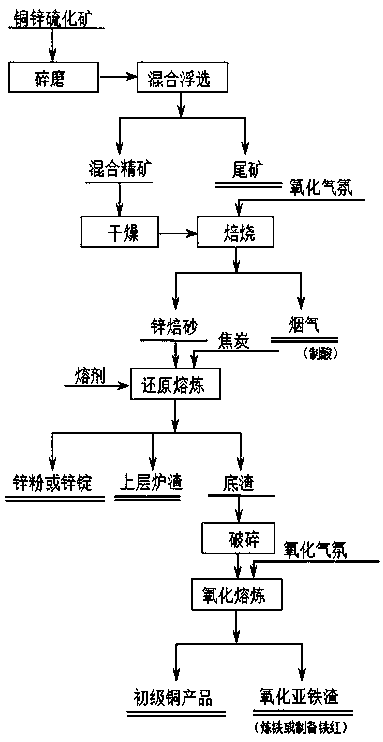

Dressing and smelting combination method for copper-zinc sulfide ores difficult to treat

InactiveCN107805721AHigh recovery rateLess fixed investmentRotary drum furnacesCrucible furnacesSmelting processFerrous

The invention discloses a dressing and smelting combination method for copper-zinc sulfide ores difficult to treat and belongs to the field of dressing and smelting. The dressing and smelting combination method for the copper-zinc sulfide ores is used for solving the problems that flotation separation of the copper-zinc sulfide ores is difficult, the traditional dressing and smelting process is long, and the treatment cost is high. Firstly, the copper-zinc sulfide ores are treated through the processes of ore crushing, ore grinding and mixing flotation, and thus mixed flotation concentrates are obtained; then, roasted zinc is obtained after drying and oxidation roasting, coke and slag forming constituents are added for reduction smelting, thus a zinc product, smelted upper-layer slag and smelted bottom slag are obtained, the upper-layer slag is directly used for being sold or used as paving stone, and copper in the bottom slag is enriched preliminarily; and finally, the bottom slag issubjected to selective oxidation smelting at the temperature of 1350-1550 DEG C, thus a primary copper product and ferrous oxide slag are obtained, and the ferrous oxide slag is directly used for ironsmelting or dye manufacturing. The dressing and smelting combination method provides a new method for clean utilization of the copper-zinc sulfide ores difficult to treat, the total recycling rate ofcopper is 80%-90%, and the total recycling rate of zinc is 82%-92%, and the method is short in process, environmentally friendly, and good in industrializing application prospect.

Owner:KUNMING UNIV OF SCI & TECH

Smelting method of high-iron multi-metal zinc concentrate

ActiveCN103695663BReduce lossesEfficient recyclingPhotography auxillary processesProcess efficiency improvementIndiumDistillation

The invention relates to a smelting method of a high-iron multi-metal zinc concentrate. The method comprises the following steps: performing oxygen-enrichment oxidation melting on a zinc concentrate containing 14% to 20% of Fe, 0.03% to 0.10% of In, 0.2% to 0.6% of Cu, 0.2% to 0.6% of Cd, 0.005% to 0.02% of Ag, 0.1% to 0.2% of Sn and 40% to 50% of Zn so as to generate an oxidized flue gas and molten slags; preparing the oxidized flue gas into sulfuric acid; performing reduction smelting on the molten slags in a smelting pool so as to generate a crude zinc alloy, crude copper containing silver and slags; blowing the slags so as to obtain smoke dust and blown slags; returning the smoke dust to be subjected to reduction smelting; selling the blown slags in a market; extracting the copper and the silver from the crude copper containing silver; and performing four-stage distillation on the crude zinc alloy entering an electric-heating graphite vacuum furnace so as to generate a pyrogenic distilled zinc product, a crude cadmium product and a high-indium-tin zinc alloy which is used for extracting indium and tin. The method is reasonable in process, good in comprehensive recovery, high in production efficiency, low in production cost and clean and environmentally friendly in production process.

Owner:LAIBIN CHINA TIN SMELTING

Manufacturing method of novel electricity-saving composite anode plate for copper-zinc electrolysis and electrodeposition

InactiveCN106995929AImprove conductivityLower cell voltagePhotography auxillary processesProcess efficiency improvementElectrolysisZinc products

The invention belongs to the field of metallurgy, and particularly relates to a manufacturing method of a novel electricity-saving anode plate special for copper-zinc electrolysis and electrodeposition. A plate body is a three-layer plate, the middle layer of three layers of anode plates is a copper, aluminum and titanium alloy and titanium coated titanium sheet, one plate serves as the middle layer, lead plates are arranged on the two faces of the outer layer, and three layers of metal plates are overlaid and compounded to be manufactured into the integrated composite anode plate. The above three layers of overlaid metal polar plates are manufactured into the integrated composite anode plate capable of being used in production chains in a long-acting manner through the manufacturing method that through holes are formed in a drilling or punching manner, lead rivets are additionally mounted , and stacking staggered pressing embedded riveting is carried out, and therefore the novel anode plate with the best electrolysis and electrodeposition electricity-saving effect is achieved when copper and zinc products are produced through an electrolysis and electrodeposition method.

Owner:胡桂生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com