Zinc electrolysis anode plate and preparing method thereof

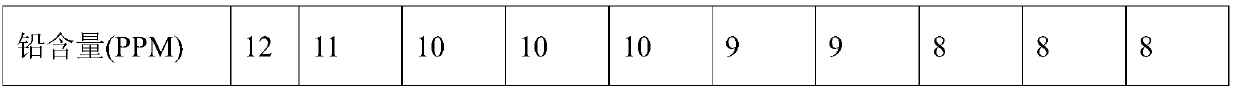

A technology of anode plate and electrolytic zinc, which is applied in the direction of electrodes, anodic oxidation, and electrolytic process, can solve the problems of lower production efficiency, the Pb content of cathode zinc products cannot meet the required standards, and improve the cutting strength, etc. Production efficiency, long cutting interval, and the effect of reducing production intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a method for preparing an anode plate for electrolytic zinc, comprising the following steps:

[0022] Step 1. After the lead substrate is polished and brightened, place it in the sulfuric acid solution of the electrolytic cell and use it as the anode, and another lead alloy plate as the cathode. Under low current density, anodize to obtain dense PbO 2 Anode plate for protective layer;

[0023] Specifically, the lead substrate is made of lead or lead alloy, the sulfuric acid concentration in the sulfuric acid solution is 100-150g / L, and the current density is 20-40A / m 2 , the temperature of the sulfuric acid solution is 20-40°C, the distance between the anode and the cathode is 6-10cm, and the electrolysis time is 4-24 hours.

[0024] Step 2, taking out the anode plate, placing it in the sulfuric acid solution of another electrolytic cell and using it as the anode, another lead alloy plate as the cathode, and electroplating MnO on the anode plate ...

Embodiment 1

[0040] Step 1. After polishing the surface of the new lead substrate obtained by rolling or casting, place it in sulfuric acid solution, use it as the anode in the electrolytic cell, and another lead alloy plate as the cathode. Anodic oxidation to obtain dense PbO 2 The protective layer. The specific method is that the concentration of sulfuric acid used is 150g / L, and the current density is 25A / m 2 , the temperature of the sulfuric acid solution was 30°C, the distance between the anode and the cathode was 8cm, and the electrolysis was performed for 12 hours.

[0041] Step 2, the above-mentioned formed PbO 2 The anode plate of the protective layer is taken out, placed in another electrolytic cell, with it as the anode, and another lead alloy plate is the cathode, and the tank solution is composed of a sulfuric acid concentration of 150g / L, Mn in the sulfuric acid solution 2+ The content is 60g / L, the temperature of the sulfuric acid solution is 90°C, the distance between th...

Embodiment 2

[0054] Step 1. After polishing the surface of the new lead substrate obtained by rolling or casting, place it in sulfuric acid solution, use it as the anode in the electrolytic cell, and another lead alloy plate as the cathode. Anodic oxidation to obtain dense PbO 2 The protective layer. The specific method is that the concentration of sulfuric acid used is 150g / L, and the current density is 40A / m 2 , the temperature of the sulfuric acid solution was 33°C, the distance between the anode and the cathode was 8cm, and the electrolysis was performed for 12 hours.

[0055] Step 2, the above-mentioned formed PbO 2 The anode plate of the protective layer is taken out, placed in another electrolytic cell, with it as the anode, and another lead alloy plate is the cathode, and the tank solution is composed of a sulfuric acid concentration of 150g / L, Mn in the sulfuric acid solution 2+ The content is 70g / L, the temperature of the sulfuric acid solution is 90°C, the distance between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com