Method for extracting zinc from blast furnace gas mud

A technology for blast furnace gas mud and gas ash, which is applied in the field of recovery and treatment of ironmaking tailings, can solve the problems of high exhaust gas temperature, prolonged production kiln period and high production cost, and achieves overcoming large equipment, reducing production cost and shortening Effects of processing cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

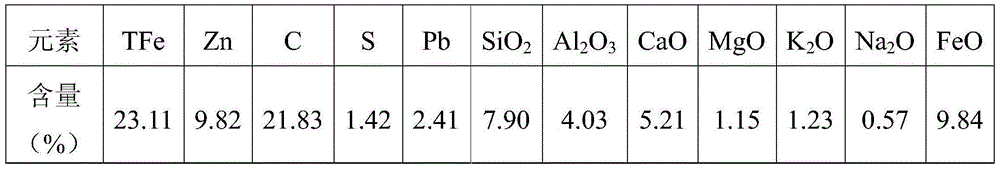

[0051] A method for dezincification from blast furnace gas mud, comprising the following steps:

[0052] 1) Insulate and bake the gas mud at a temperature of 150°C for 2 hours to obtain gas ash, and measure the fixed carbon content in the gas ash to be 21.83%;

[0053] 2) sieving the gas ash obtained in step 1) to obtain gas ash with a particle size less than 10 mm;

[0054] 3) Put the sieved gas ash in the shaft furnace, and the flow rate into the shaft furnace is 0.20m 3 / h of nitrogen protection, and the shaft furnace starts from room temperature and raises the temperature to 1100°C at a rate of 5°C / min; 3 / h of compressed air for 20 minutes of reduction reaction, after the reaction is completed, the compressed air is turned off, and the flow rate is 0.20m again 3 Nitrogen protection for / h; Simultaneous reduction reaction to obtain zinc-containing gas;

[0055] 4) Step 3) The gas containing zinc is discharged from the shaft furnace together with the gas under the action...

Embodiment 2

[0058] A method for dezincification from blast furnace gas mud, comprising the following steps:

[0059] 1) Insulate and bake the gas mud at a temperature of 150°C for 2 hours to obtain gas ash, and measure the fixed carbon content in the gas ash to be 22.15%;

[0060] 2) sieving the gas ash obtained in step 1) to obtain gas ash with a particle size less than 10 mm;

[0061] 3) Put the sieved gas ash in the shaft furnace, and the flow rate into the shaft furnace is 0.20m 3 / h of nitrogen protection, and the shaft furnace starts from room temperature and raises the temperature to 1150°C at a rate of 5°C / min; 3 / h of compressed air for 20 minutes of reduction reaction, after the reaction is completed, the compressed air is turned off, and the flow rate is 0.20m again 3 Nitrogen protection for / h; Simultaneous reduction reaction to obtain zinc-containing gas;

[0062] 4) Step 3) The gas containing zinc is discharged from the shaft furnace together with the gas under the action...

Embodiment 3

[0065] A method for dezincification from blast furnace gas mud, comprising the following steps:

[0066] 1) Insulate and bake the gas mud at a temperature of 150°C for 2 hours to obtain gas ash, and measure the fixed carbon content in the gas ash to be 22.15%;

[0067] 2) sieving the gas ash obtained in step 1) to obtain gas ash with a particle size less than 10 mm;

[0068] 3) Put the sieved gas ash in the shaft furnace, and the flow rate into the shaft furnace is 0.20m 3 / h of nitrogen protection, and start the shaft furnace from room temperature, and raise the temperature to 1200°C at a rate of 5°C / min; 3 / h of compressed air for 30 minutes of reduction reaction, after the reaction is completed, the compressed air is turned off, and the flow rate is 0.20m again 3 Nitrogen protection for / h; Simultaneous reduction reaction to obtain zinc-containing gas;

[0069] 4) Step 3) The gas containing zinc is discharged from the shaft furnace together with the coal gas under the ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com