Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

107results about How to "Long anti-rust period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphorus-free water-based metal cleaning agent

The invention relates to a phosphorus-free metal cleaning agent comprising the components of, by weight, 2-20% of a cleaning aid, 1-20% of a surfactant, 1-10% of a chelating agent, 1-20% of an emulsifier, 1-10% of an antirust agent, 0.2-4% of a copper alloy corrosion inhibitor, 1-10% of a penetration agent, 1-6% of a solubilizing agent, 0.1-0.6% of a defoaming agent, and balance of water. The cleaning agent provided by the invention has excellent cleaning capacity, long rust proof period, low foam, long service life, and the like. The cleaning agent is suitable for ferrous metal and non-ferrous metal processing industries. The agent has the advantages of no volatilization, no irritation, no toxic or harmful substance such as nitrite, no damage to health, and no environment pollution.

Owner:SHENYANG PARKERIZING

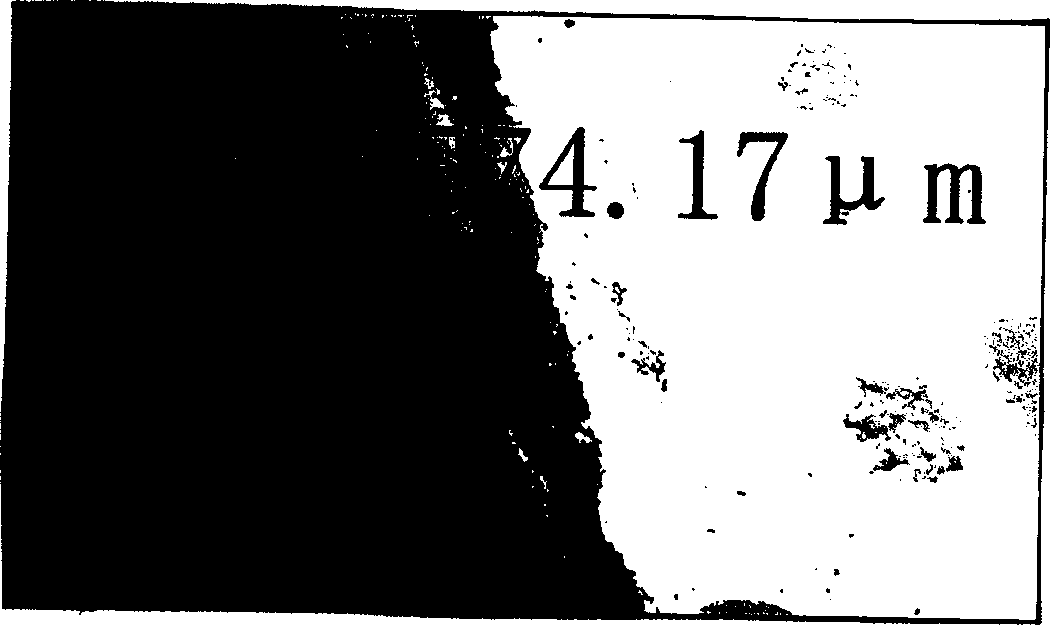

Dewatering antirust oil

A dewatering antirust oil is prepared from mineral oil (85-93 mass%), antirust additive (4-8), dewatering additive (1-5), antioxidizing agent (0.5-2) and other additives (0.1-0.5). Iron and steel objects after treated have their surface adhered with antirust oil film. Its advantages include high dewatering speed (2-5 min) and long antirusting period (1-2 years).

Owner:蔡毓英

All-synthetic grinding fluid

InactiveCN101735881AImprove the lubrication effectLong anti-rust periodPolishing compositionsLubricant compositionPhosphatePolyethylene glycol

The invention provides an all-synthetic grinding fluid, aiming at the problems of poor lubricating property and surface smoothness, low precision, short rust-proof period of the traditional grinding fluid and adverse impact on environment in the discharging process of the traditional grinding fluid. The all-synthetic grinding fluid puts emphasis on comprising the following components in percentage by weight: 0%-15% of extreme-pressure additives, 0%-15% of lubricating agents, 15%-25% of dispersing agents, 15%-25% of surface active agents, 15%-25% of rust-proof components, 0.5%-1% of antifoaming agents, 0.5%-1% of foam suppressors and the balance of water, wherein the extreme-pressure additives and the lubricating agents are one or more than one of polyether, organic carboxylic acid and organic phosphate; the dispersing agents and the surface active agents are one or more than one of JFC, AEO9, polyethylene glycol and diethylene glycol; the rust-proof components are one or more than one of organic carboxylic acid, triethanolamine, diethanol amine, organic molybdenum and sodium borate; and the antifoaming agents and the foam suppressors are one or more than one of organic silicon and the organic phosphate. The invention has good extreme-pressure lubricity, long rust-proof period and small foam without environmental pollution.

Owner:沈阳晟豪化工有限公司

Antirust oil for engine seal

ActiveCN104004573AHumidity and heat resistanceImprove corrosion resistanceLubricant compositionKerosenePolyethylene glycol

The invention discloses an antirust oil for engine seal. The antirust oil comprises, by weight, 81-90 parts of aviation kerosene, 2-3 parts of polyisobutylene, 3-5 parts of lanolin magnesium soap, 2-3 parts of barium stearate, 2-3 parts of allyl polyethylene glycol, 1-2 parts of tert-butyl chromate, 0.6-1 part of N-lauroyl sarcosine sodium, 1-2 parts of polyoxyethylene stearate, 0.8-2 parts of N,N-bis(2-cyanoethyl)formamide, 0.1-0.2 parts of sodium silicate, and 4-6 parts of an antirust aid. The antirust oil has the characteristics of moist heat resistance, corrosion resistance and strong salt spray resistance, is especially suitable for the engine seal, has a long antirust life, can well protect the engine, and prolongs the service life of the engine.

Owner:BENGBU HONGAN PRECISION MACHINERY

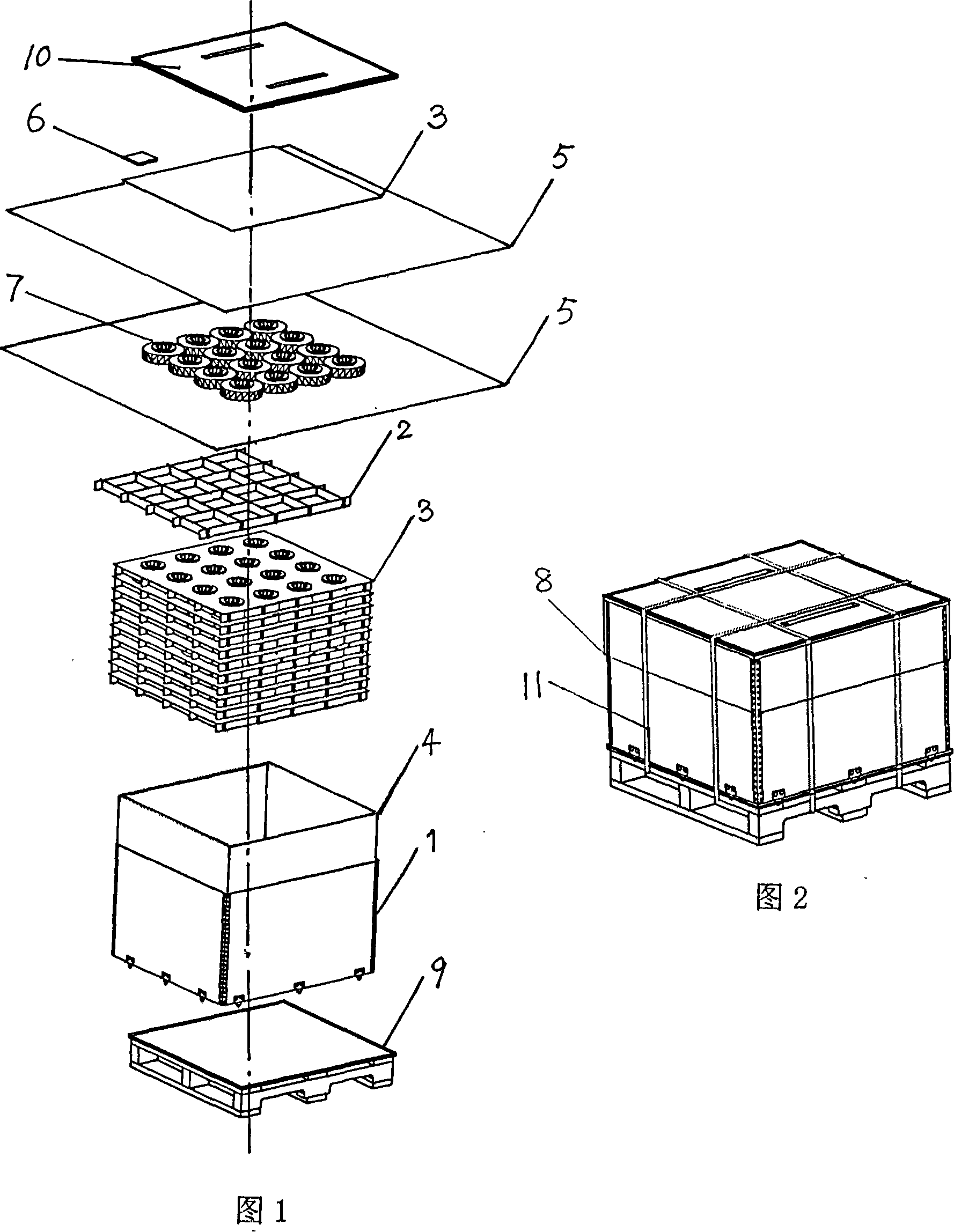

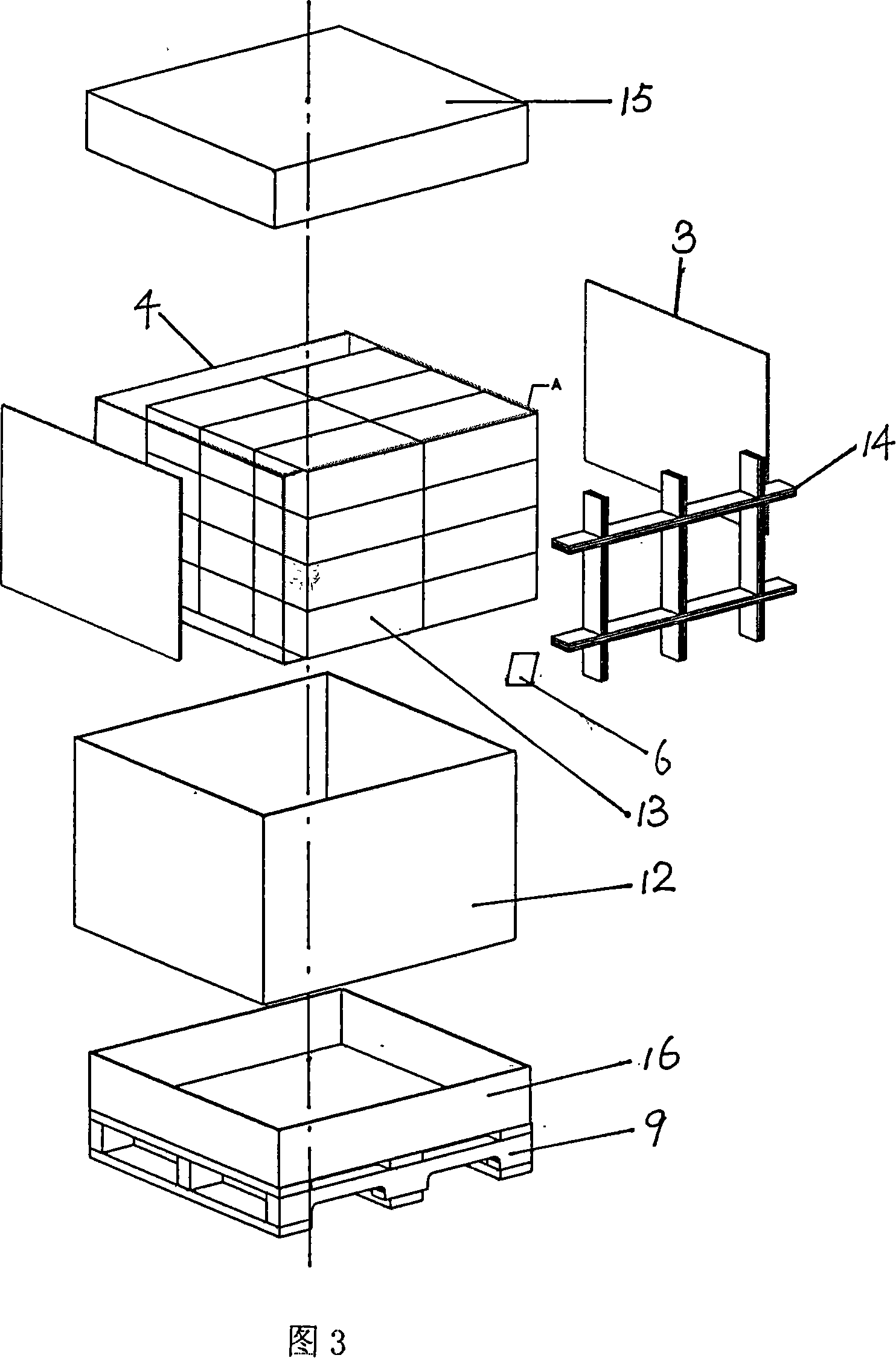

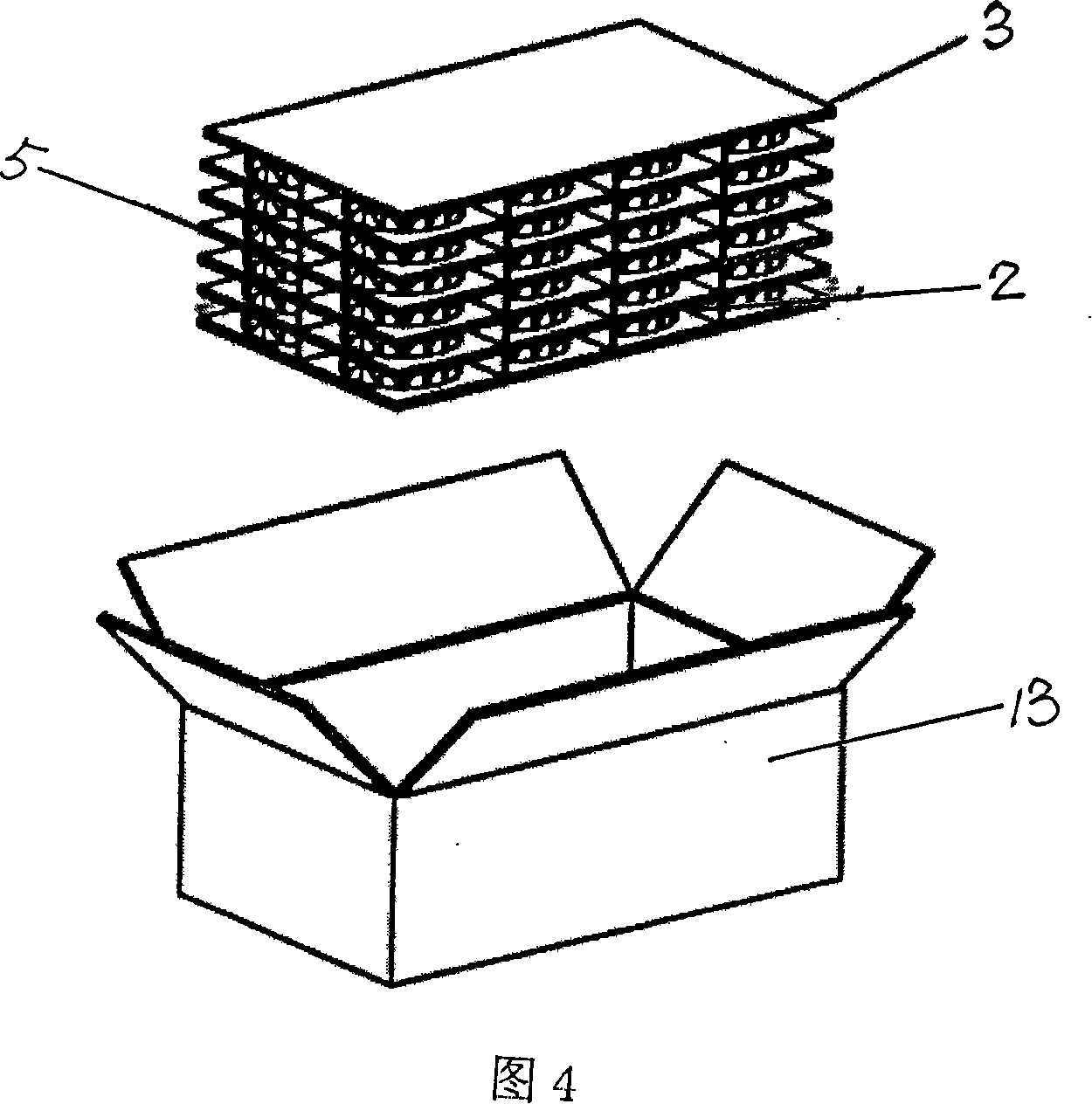

Rust prevention packaging method of metallic product

InactiveCN101108679AAvoid contactPrevent rust and corrosionRigid containersContainers with multiple articlesGas phaseEngineering

The invention belongs to the technology field of the metal product package, in particular to an anti-rust package method of the metal product. The invention solves the problems of poor anti-rust effect or high package cost existing in the anti-rust package of the current metal product. The procedure of the anti-rust package method of the metal product is as follows: an outer package is arranged with gas phase anti-rust bags inside, corrugated boards are rolled out; corrugated paper is added in to separate; gas phase anti-rust films are added; the metal product is filled; the gas phase anti-rust films are covered; the corrugated boards and dryers are added; gas phase anti-rust bags are arranged; the outer package is closed and is externally covered with PE rainproof films and PET is bound. The invention has the beneficial effects of oil-saving, environmental protection, anti rust, firm structure, simple technic, long anti-rust period and high reliability.

Owner:SHANXI DATONG GEAR GROUP

Synthetic multiple-effect lubricant additive and preparation method thereof

The invention relates to a synthetic multiple-effect lubricant additive and a preparation method thereof and in particular relates to a fully-synthetic multiple-effect lubricant additive which does not contain S and Cl and takes a metal processing lubricant as a main product. The fully-synthetic multiple-effect lubricant additive is a mixture containing glycerol single ricinoleate, a carboxylic acid synthetic ester lubricant, iso-tridecanol polyoxyethylene ether, an antirust agent, amine phosphate, a non-ferrous metal corrosion inhibitor and a carboxyl hexyl-2-cyclohexene-1-octadeca-carbonic acid. The fully-synthetic multiple-effect lubricant additive has the advantages of good wear resistance, good anti-rust performance, good synergy and environmental friendliness. The fully-synthetic multiple-effect lubricant additive is applicable to blending emulsified oil, micro-emulsifying liquid, fully-synthetic metal working fluid, metal rolling liquid and metal molding working fluid as well as lubricating oil products such as water-based fire-resistant hydraulic oil.

Owner:GUANGDONG AOLIDAN IND

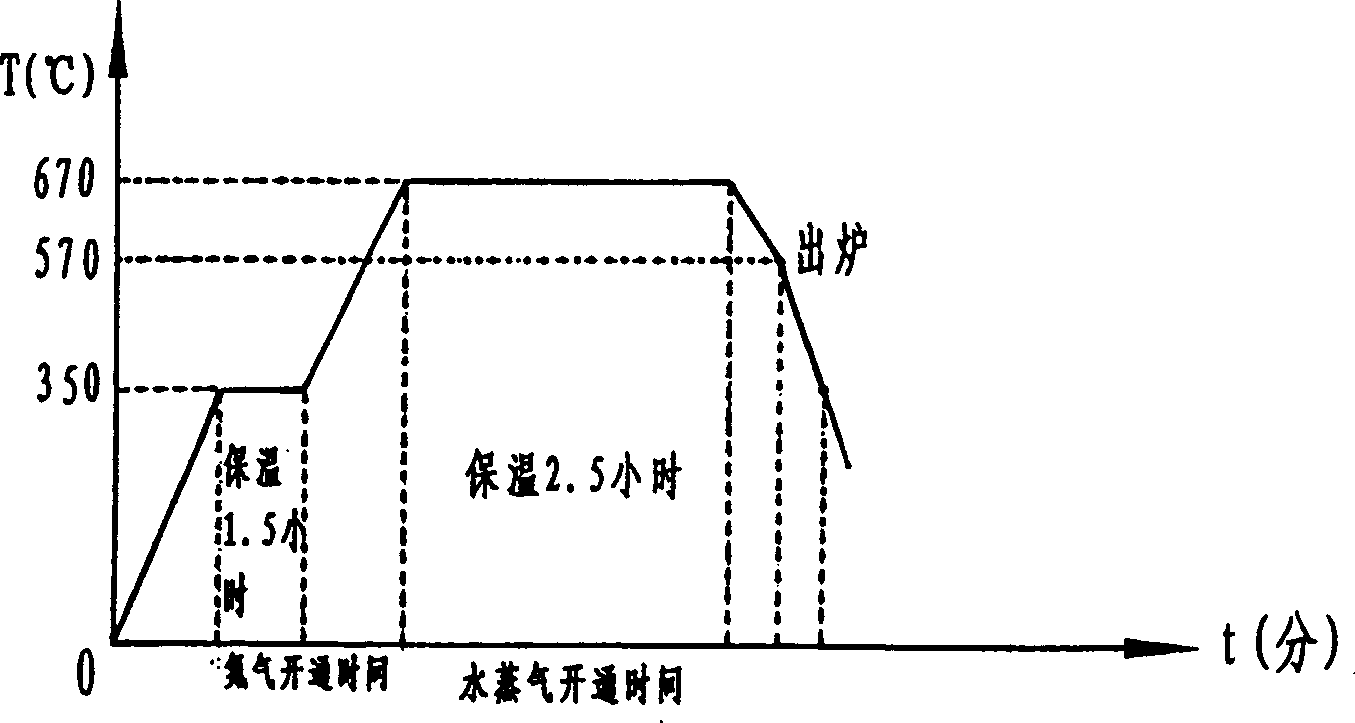

Cast iron exhaust branch pipe having oxidized layer on surface and its surface oxidation method

ActiveCN1904322AImprove rust resistanceImprove reliabilityExhaust apparatusSilencing apparatusFurnace temperatureSteam pressure

The inventive surface oxidizing process of a cast-iron exhaust manifold comprises the following steps of putting the work piece in the steam oxidation treatment furnace; switching on the power supply and starting to raising temperature; turning on the nitrogen valve and leading in the nitrogen while raising temperature and meanwhile going on raising temperature; closing the nitrogen when the temperature reaches the setting one and then leading in steam pressure for a certain time; closing steam when the furnace temperature is lowered to the setting one and then opening the furnace lid and lifting the work piece. By using the above process, a compact ferriferrous oxide film is formed on the surface of the cast-iron exhaust manifold.

Owner:FEILONG AUTO COMPONENTS CO LTD +1

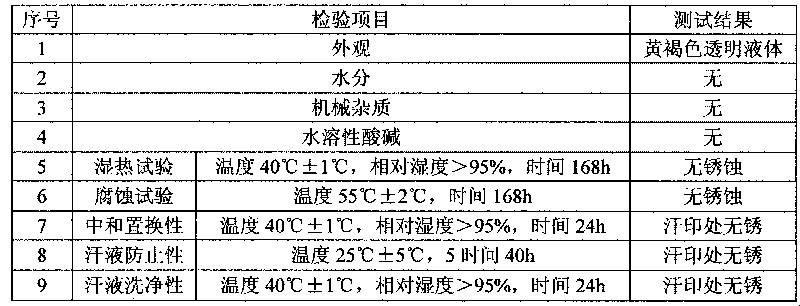

Aqueous antirust agent

The invention discloses an aqueous antirust agent, which comprises the following components in parts by weight: 40 to 50 parts of 1-hydroxybenzotriazole, 35 to 42 parts of 1,2-diethoxyl silyl ethane, 5 to 10 parts of inositol hexaphosphate, 5 to 8 parts of triethylamine, 1 to 4 parts of sodium acetate and 0.02 to 1 part of oxalic acid. According to the aqueous antirust agent, the characteristic of cleanliness of the aqueous antirust agent is ensured; compared with a conventional aqueous antirust agent, the aqueous antirust agent has a good antirust effect, and is stable and long in antirust life.

Owner:珠海市金宜科环保材料有限公司

Thin-layer rust-preventative oil for engine part and method for preparing same

The invention aims to provide thin-layer rust-preventative oil for an engine part and a method for preparing the same. The rust-preventative oil is prepared from the following components in percentage by weight: 2 to 3 percent of petroleum barium sulfate, 4 to 7 percent of barium dinonyl napthalene sulphonate, 0.5 to 0.9 percent of dodecene butane diacid, 0.1 to 0.5 percent of benzotriazole, 1.0 to 5.0 percent of dibutyl phthalate, 3 to 5 percent of polyisobutene and the balance of aviation lubricating oil, wherein the ratio of the two components comprising benzotriazole to dibutyl phthalate is 1:10 to 11.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Gas phase inhibitor special for zinc products

InactiveCN1594657AImprove rust resistanceLong anti-rust periodContainers preventing decayMorpholineGas phase

The invention discloses a vapour phase rust inhibitor VP1-PM special for zinc product and the production method of gas phase rust-preventive packaging material for galvanizing. The said VP1-PM is reaction product of malic Acid with morpholine, has unique gas phase inhibitor action to zinc product. Gas phase rust-preventive paper, gas phase rust-preventive non-woven fabric, framed gas phase rust-preventive paper, framed gas phase rust-preventive non-woven fabric, gas phase rust-preventive plastic film special for galvanizing can apply to long-term seal and temporary rust prevention of all kinds of galvanizing products from galvanizing bolt, screw cap, to heavy galvanizing coiled material, strip and sheet. The said gas phase rust-preventive packaging material for galvanizing has a good effect on rust prevention, long term rust prevention period, which is convenient for usage, and safe.

Owner:WUHAN HONGFU ANTICORROSIVE PACKING CHEM IND

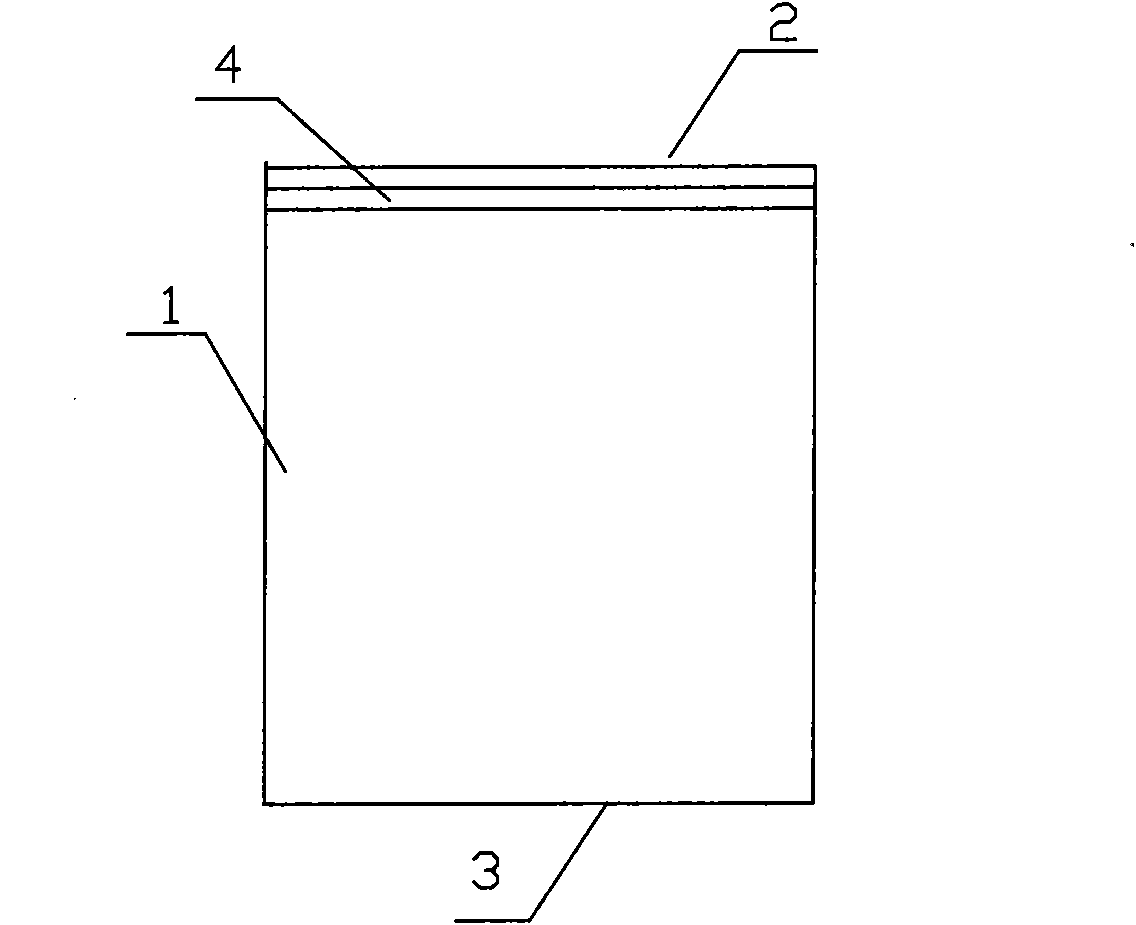

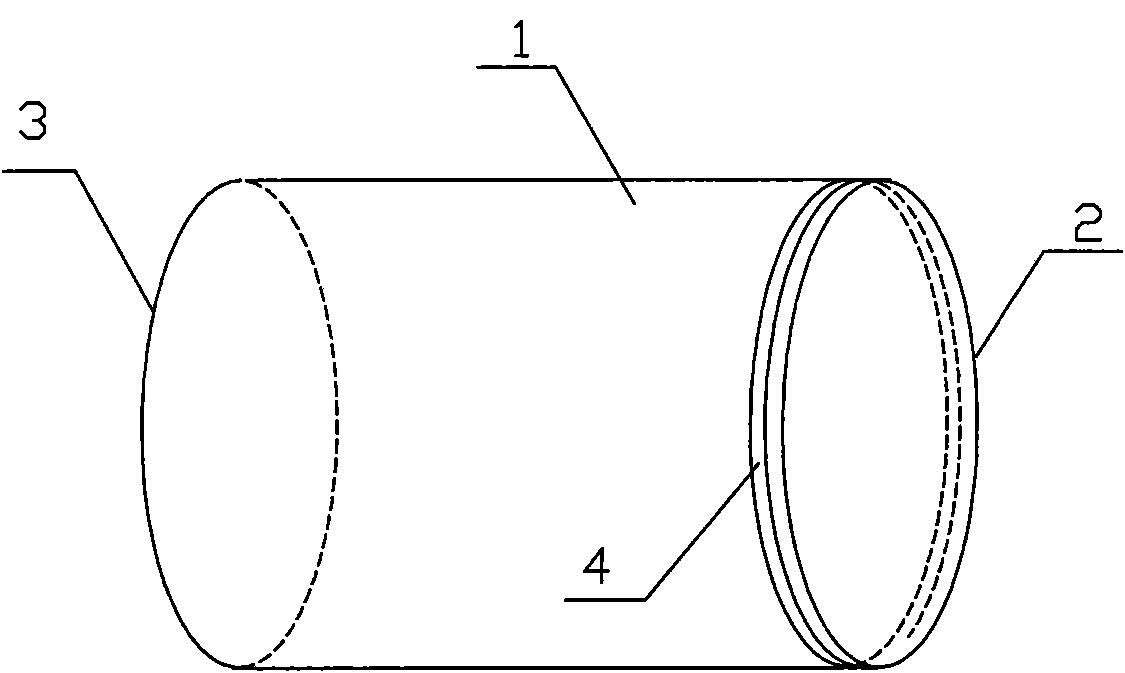

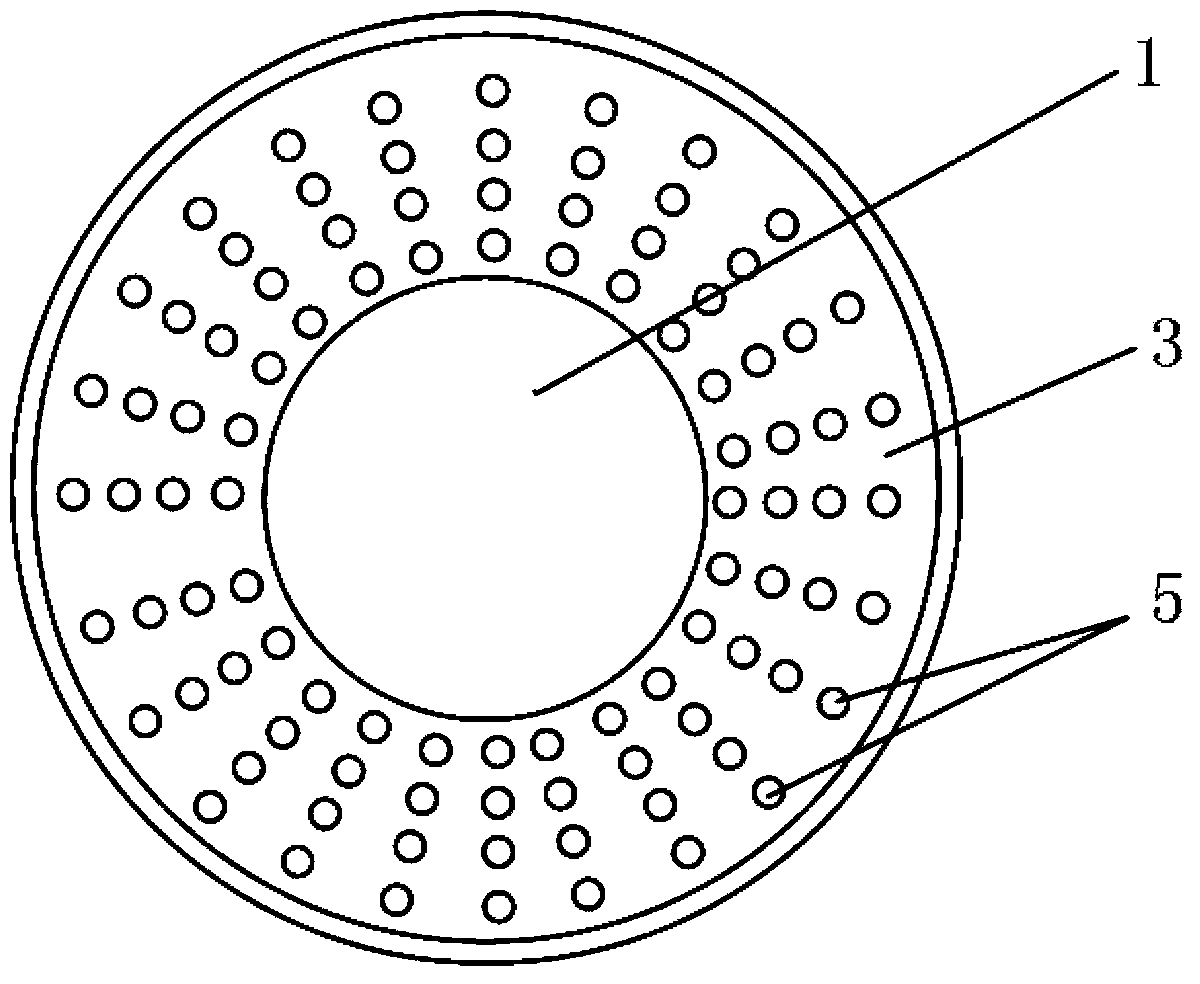

Inward-wound seal packaging bag for ring-shaped cylindrical object and packaging method thereof

InactiveCN102050279ASimple structureEasy to operateFlexible coversWrappersSocial benefitsVolatile corrosion inhibitor

The invention relates to an inward-wound seal packaging bag for ring-shaped cylindrical object and packaging method thereof, which comprises a flexible bag body corresponding to the inner surface and the outer surface of the ring-shaped cylindrical object, wherein two ends of the cylindrical bag body are open, and colloid is arranged at an opening on one side of the bag body; and the outer layer of the flexible bag body is made of plastic film and the inner layer of that is made of gas phase rustproof film coated on the inner wall of the outer layer. The sealing packaging is achieved by the following steps: the bag body is covered on the surface of a steel coil in a manner of aligning the edge of the ring-shaped cylindrical object like the steel coil; the rest of the bag body penetrate out from a ring-shaped hole of the steel coil; and the turned-over edge of the bag body is jointed with the bag opening previously covered on the other side of the steel coil surface via the colloid. In the invention, the VCI (Volatile Corrosion Inhibitor) gas phase rustproof film is used to seal the packaging, and the inner wall and the outer wall of the steel coil are fully coated, so that the sealing is good, the rustproof period is long, the ideal rustproof effect can be obtained, the substantive breakthrough in the rust prevention during the transportation to metal products is achieved, and the economic and social benefits are excellent.

Owner:UNICHEM APPLIED MATERIALS SHANGHAI

Non-phosphorus water-based metal cleaner

The invention discloses a non-phosphorus water-based metal cleaner which is prepared from raw materials, namely, isodecanol polyoxyethylene ether, 1,3-butanediol, dodecanedioic acid, petroleum barium sulfonate, water, modified siloxane defoaming agent, sylvite, fatty alcohol polyoxyethylene ether, p-tertiary butyl benzoic acid, triazine polycarboxylic acid compounds, fatty alcohol-polyoxyethylene ether, benzyl alcohol fatty alcohol polyoxyethylene ether, isoundecanol polyoxyethylene ether, butyl cellosolve, n-hexane, glycol, glycerol, fatty alcohol-polyoxyethylene ether, fatty alcohol-polyoxyethylene ether, alkyl polymers or blocked polyether, castor oil polyoxyethylene ether, succinic acid derivative, boric acid, petroleum sodium sulfonate, imidazoline, methyl triazole, polyoxyethylene ether, fatty alcohol alcoxyl compounds, triazole, ether carboxylic acid organic chelating agents and the like. The non-phosphorus water-based metal cleaner is excellent in cleaning capability, long in anti-rusting period, low in foam, long in service life and applicable to ferrous metal and non-ferrous metal processing industry.

Owner:CHANGSHU TIANHE MACHINE EQUIP MFR

Gas-phase antirust dispersing body

The invention discloses a gas-phase antirust dispersing body, which belongs to the technical field of gas-phase corrosion inhibitors and metal protection. The dispersing body comprises an outer protection box, an air-permeable packaging material and a gas-phase antirust corrosion inhibitor; a gas-phase antirust protection agent is arranged inside the outer protection box after being coated with the air-permeable packaging material; the outer protection box is provided with a plurality of air holes; the air-permeable packaging material can be packaging materials such as high-permeability paper and air-permeable nonwoven fabric; the gas-phase antirust corrosion inhibitor consists of 1 to 10 percent of sodium nitrite, 10 to 30 percent of ammonium benzoate, 10 to 30 percent of triazole and 10 to 30 percent of sodium benzoate. The gas-phase antirust dispersing body is convenient and simple to use, takes effect for a long time, is novel and attractive and can be widely applicable to the corrosion protection of metal products in an airtight space.

Owner:沈阳防锈包装材料有限责任公司

Milky rust-proof liquid and preparation method thereof

ActiveCN103469210ALong anti-rust periodImprove stabilityMaterials scienceSODIUM DODECYL BENZENE SULFONATE

The invention provides a milky rust-proof liquid which comprises the following components in parts by weight: 10 to 30 parts of machine oil, 5 to 10 parts of barium petroleum sulfonate, 2 to 4 parts of iron naphthenate, 1 to 3 parts of fatty acid salt, 1 to 4 parts of sodium dodecyl benzene sulfonate, 2 to 5 parts of triethanolamine oleate, 2 to 6 parts of OP-10, 0.2 to 0.8 part of rosin resin, 0.1 to 0.5 part of polyacrylate, 1 to 3 parts of silicone oil and 10 to 15 parts of water. The milky rust-proof liquid provided by the invention has the advantages of long rust-proof life, good stability, nontoxicity, no abnormal odor, low cost and the like.

Owner:WUJIANG JUNDA ELEVATOR PARTS

Reactive type water-based metal grinding fluid and preparation method thereof

InactiveCN101812366ANo pollution in the processNo pollution, no harm to human bodyLubricant compositionWater basedMetal working fluid

The invention relates to a water-based metal grinding fluid and a preparation method thereof. The water-based metal grinding fluid comprises the components of sodium tetraborate, boric acid, a solvent, triethanolamine, a sodium salt with slow release function, a corrosion inhibitor, a water-based defoamer, preservative and deionized water. The grinding fluid greatly improves the machining precision and the surface finish quality of a workpiece, and effectively eliminates surface sewages of the workpiece. Through practical application tests by many enterprises, the use effect of the grinding fluid achieves the engineering level of an imported fully synthetic water-based grinding fluid, and the water-based metal grinding fluid can be used for effectively replacing an imported high-grade fully synthetic water-based metal grinding fluid, thereby greatly lowering the production cost of grinding machining.

Owner:BEIJING CARL RES INST FOR CHEM IND

Non-toxic efficient rust-proof oil

InactiveCN106398842ANo pollution in the processImprove rust resistanceLubricant compositionParaffin waxRosin

The invention discloses non-toxic efficient rust-proof oil which is prepared from the components of, by weight, 10-20 parts of castor oil, 3-8 parts of lanolin magnesium soap, 10-15 parts of paraffin wax, 1-5 parts of antioxidant, 8-15 parts of oil soluble gas phase corrosion inhibitor, 4-10 parts of sodium molybdate, 10-15 parts of film-forming agent, 8-12 parts of lauric acid, 5-15 parts of nanosilicon dioxide, 10-20 parts of petroleum sodium sulfonate, 1-4 parts of polyacrylate and 5-10 parts of rosin-polythylene oxide ester. According to the non-toxic efficient rust-proof oil, the preparation technology is simple, the preparation process is environmental-friendly and free of pollution, the rust-proof effect of the prepared rust-proof oil is good, the rust-proof period is long, and no pollution is caused to the environment; besides, the surface of a workpiece can be prevented from being scratched, and the workpiece quality is guaranteed.

Owner:MAANSHAN NIUZE TECH SERVICE

Anti-high temperature oxidation long-acting antirust composite epoxy powder paint for automobile chassis and preparation method thereof

InactiveCN106519914AExcellent curabilityGood dispersionFireproof paintsAnti-corrosive paintsEpoxyMicrosphere

The invention discloses an anti-high temperature oxidation long-acting antirust composite epoxy powder paint for automobile chassis and a preparation method thereof. The protonated graphene-polypyrrole composite powder added into the paint can significantly improve the corrosion resistance of the system, and has good reaction activity, can effectively combine with resinite to reach a good toughening and reinforcement effect, and the added aluminum tripolyphosphate / polymethyl methacrylate microsphere is a novel antirust filler with good dispersibility, makes up for the disadvantages of the traditional filler adding way, and more uniform and stable antirust effect can be achieved. According to the invention, all the raw materials in the formula are effectively combined to prepare the composite epoxy powder paint with the advantages of fast curing speed, good film-forming effect, high film strength and long antirust cycle finally, and the composite epoxy powder paint has good application prospects in the field of chassis rust protection.

Owner:TONGLING SIDE TECH

Ultra-thin antirust oil and preparation method thereof

InactiveCN109385325ARaw materials are readily availableSimple preparation processLubricant compositionWaxLANOLIN DERIVATIVES

The invention discloses an ultra-thin antirust oil. The ultra-thin antirust oil comprises, by weight, 10-15 parts of machine oil, 50-70 parts of solvent oil, 5-15 parts of barium petroleum sulfonate,2-3 parts of carboxylate, 2-3 parts of a lanolin derivative, 0.5-1 part of a corrosion inhibitor, 2-3 parts of a solubilizing agent and 1-2 parts of oxidized wax. According to the invention, the raw materials for preparation of the ultra-thin antirust oil are simple and easily available; preparation process is simple; and the prepared ultra-thin antirust oil has low viscosity, a light color, a long antirust period and water replacement capability, and is suitable for promotion in industrial fields.

Owner:上海洁安精细化工有限公司

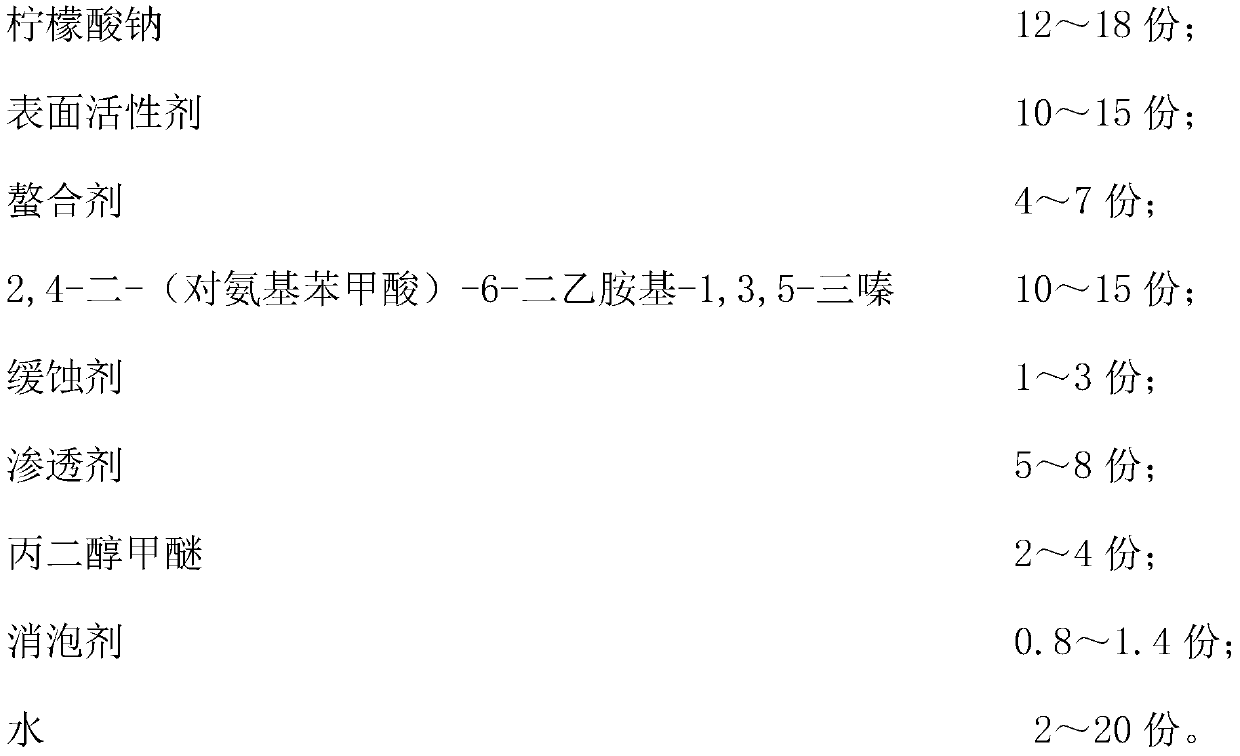

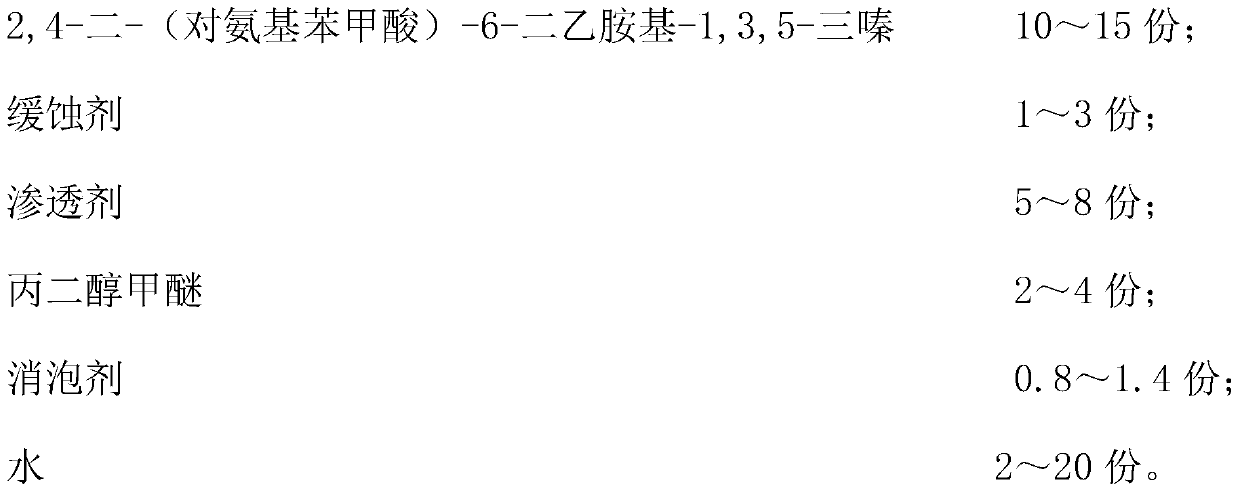

Phosphorus-free cleaning agent

InactiveCN110564522ANo service lifeNo long service life, at the same time, no volatileInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsP-Aminobenzoic acidTriazine

The invention discloses a phosphorus-free cleaning agent. The phosphorus-free cleaning agent comprises the following components in parts by weight: 12-18 parts of sodium citrate; 10-15 parts of a surfactant; 4-7 parts of a chelating agent; 10-15 parts of 2,4-di-(p-aminobenzoic acid)-6-diethylamino-1,3,5-triazine, 1-3 parts of a corrosion inhibitor; 5-8 parts of a penetrating agent; 2-4 parts of propylene glycol monomethyl ether; 0.8-1.4 parts of a defoaming agent; and 2-20 parts of water. The phosphorus-free cleaning agent disclosed by the invention has the advantages of excellent cleaning capacity, a long antirust period, good stability, long service life, no volatilization and no irritation.

Owner:NANTONG KEXING CHEM

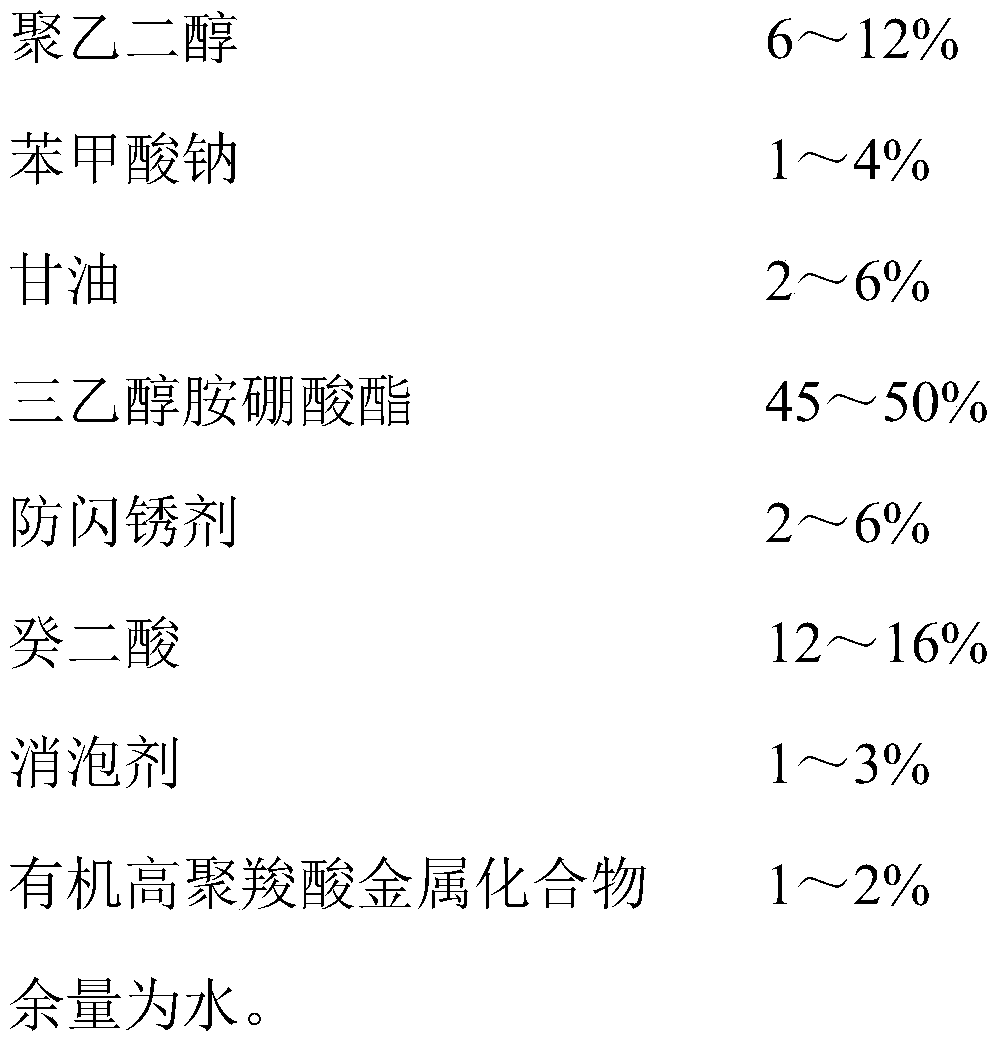

Long-acting water-based antirust agent and preparation method thereof

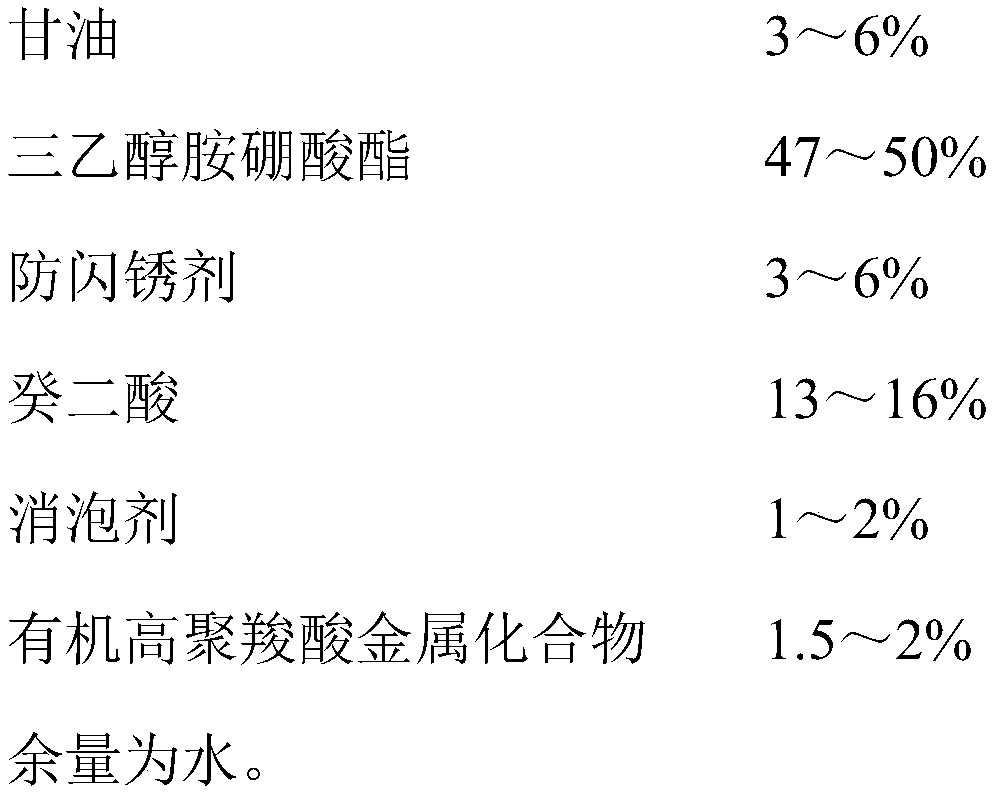

The invention provides a long-acting water-based antirust agent, and aims to overcome the defects in the prior art. The long-acting water-based antirust agent comprises the following components of, byweight, 6-12% of polyethylene glycol, 1-4% of sodium benzoate, 2-6% of glycerol, 45-50% of triethanolamine borate, 2-6% of an anti-flash rust remover, 12-16% of sebacic acid, 1-3% of a defoaming agent, 1-2% of an organic high-polycarboxylate metal compound and the balance water. The water-based antirust agent can be widely applied to rust prevention during procedures of steel materials, cast iron, mechanical parts, alloy steel product assemblies and materials, and the advantages of being long in rust prevention period, convenient to clean, good in stability, not prone to decomposition at a high temperature and long in indoor storage period are achieved.

Owner:青岛亚东精细化学品有限公司

Anti-rust oil used for instrument

The invention discloses anti-rust oil used for an instrument. The anti-rust oil comprises, by weight, 40-60 parts of base oil, 20-30 parts of zinc naphthenate, 25-35 parts of lanolin, and the balancing being vaseline. The anti-rust oil overcomes the problems in the prior art. By using the anti-rust oil provided by the invention, the instrument has a good anti-rust effect and a long anti-rust period. Loss of enterprises is reduced. The anti-rust oil has high practicality and is suitable for wide application in related industries.

Owner:HAIAN GUOLI CHEM

Sponge with gas phase rust-proof layer and pressure-sensitive adhesive for multiple metal and its production method

InactiveCN1730587ASimple production processReduce manufacturing costFilm/foil adhesivesGas phaseIsoprene

The present invention provides a multiple-metal gaseous phase rust-proofing pressure-sensitive adhesive sponge comprises an upper layer, a middle layer and a lower layer, the middle layer is a sponge layer, the upper layer is a hot melt adhesive, the lower layer is gas phase rust-preventing agent, its preparing process comprises, mixing phenylethene, butadiene or isoprene blocked copolymer, white oil or naphthenic oil, rosin or terpene resin, anti-oxidant, cyclohexylamine benzoate, amine benzoate and benzene-triazole, squeezing to obtain gas phase rust-preventing pressure-sensitive adhesive, (2) mixing starch gum liquid, cyclohexylamine benzoate, amine benzoate, benzene-triazole and grinding, (3) coating the hot melt pressure-sensitive adhesive and the gas phase antirusting agent homogeneously onto the two surfaces of sponge for air drying.

Owner:刘永余

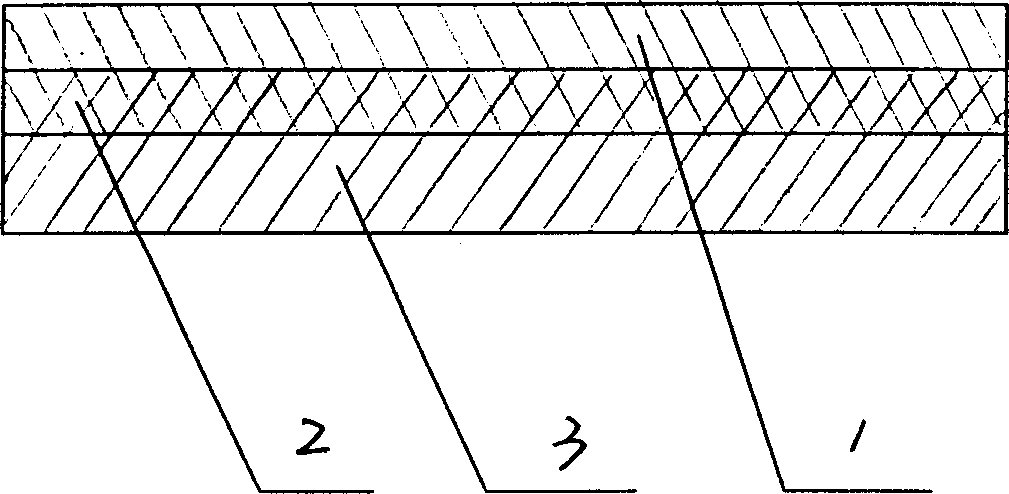

Multi-layer co-extrusion volatile rust-proof film

ActiveCN102310608ALong anti-rust periodBarrier seepageSynthetic resin layered productsPlastic filmCo extrusion

The invention relates to a multi-layer co-extrusion volatile rust-proof film, belonging to the field of plastic films. To solve the technical problem of short rust-proof time at low temperature in the current volatile rust-proof film, the multi-layer co-extrusion volatile rust-proof film is provided. The multi-layer co-extrusion volatile rust-proof film provided by the invention has a multi-layer structure. The multi-layer co-extrusion volatile rust-proof film is in a three-layer, five-layer or seven-layer structure, wherein the multi-layer co-extrusion volatile rust-proof film is in a three-layer structure including A / B / G from inside to outside; or the multi-layer co-extrusion volatile rust-proof film is in a five-layer structure including A / B / D / B / G, A / B / C / B / G or A / B / C / D / G from inside to outside; or the multi-layer co-extrusion volatile rust-proof film is in a seven-layer structure including A / B / C / D / C / B / G or A / B / C / D / E / F / G from inside to outside. The rust-proof effect of the multi-layer co-extrusion volatile rust-proof film provided by the invention can be up to 10-20 years.

Owner:包头市恒瑞新材料科技有限公司

Environment-friendly multi-effect type cooling liquid for testing engine

InactiveCN108949119AImprove rust resistanceExcellent vapor phase rust resistanceHeat-exchange elementsWater jacketStain

The invention discloses environment-friendly multi-effect type cooling liquid for testing an engine. The environment-friendly multi-effect type cooling liquid comprises the following components in percentage by mass: 8-10% of a ferrous metal antirusting agent, 2-3% of a non-ferrous metal antirusting agent, 15-20% of organic amine, 3-5% of a vapor-phased corrosion inhibitor, 5-8% of all-purpose cellosolve, 0.1-0.2% of a defoaming agent and the balance of deionized water, wherein the total percentage is 100%. The environment-friendly multi-effect type cooling liquid disclosed by the invention has the beneficial effects that the anti-rusting property and the vapor-phased anti-rusting property are excellent, no corrosion to metals under high temperature is achieved, the anti-rusting property is stable, the cleaning property is excellent, oil-stain impurities in a water jacket of the engine can be effectively cleaned, condensation of steam is prevented from rusting an inner cavity, the engine can be protected from being corroded, the anti-rusting period is long (up to more than 90 days), residual liquid and other engine antifreezing liquids have excellent compatibility, and after addition of a proper amount of the antifreezing agent, the cooling liquid can be used as the engine antifreezing liquid and is safe and environment-friendly.

Owner:HUBEI CHENGXIANG TECH

Carbon steel material rust-preventative oil and preparation method thereof

InactiveCN102925262AImprove corrosion resistanceImprove bindingLubricant compositionLanolinSorbitan Monooleate

The invention discloses a carbon steel material rust-preventative oil and a preparation method thereof. The carbon steel material rust-preventative oil comprises 90-95 parts of conduction oil, 0.5-1 part of calcium stearate, 0.6-0.8 part of sodium benzoate, 2-3 parts of dinonynalphthalene sulfonic acid barium, 0.4-0.6 part of dodecenylsuccinic acid, 1-1.5 parts of sorbitan monooleate, and 0.5-1 part of lanolin magnesium soap. When in use, the rust-preventative oil is sprayed on the surfaces of carbon steel materials by electrostatic spraying equipment. According to the technical scheme of the carbon steel material rust-preventative oil and the preparation method thereof which are disclosed by the invention, the rust-proof life is long, the binding capacity is good and the rust-proof effect is good.

Owner:TIANJIN UNIV

Rust prevention treatment solution for transmission case inner walls

InactiveCN104233254ANo residueNo pollution in the processMetallic material coating processesFatty alcoholSodium hydroxide

The invention discloses a rust prevention treatment solution for transmission case inner walls, which is composed of the following components in percentage by weight: 8-10% of oxalic acid, 7-9% of triethanolamine, 5-7% of citric acid, 6-8% of sodium petroleum sulfonate, 5.5-6.5% of fatty alcohol polyethenoxy ether, 3-5% of ammonium molybdate, 2-4% of sodium benzoate, 1.5-2.5% of sodium hydroxide, 2-4% of industrial alcohol, 1.5-3.5% of ethylene glycol and the balance of water.

Owner:无锡杨市表面处理科技有限公司

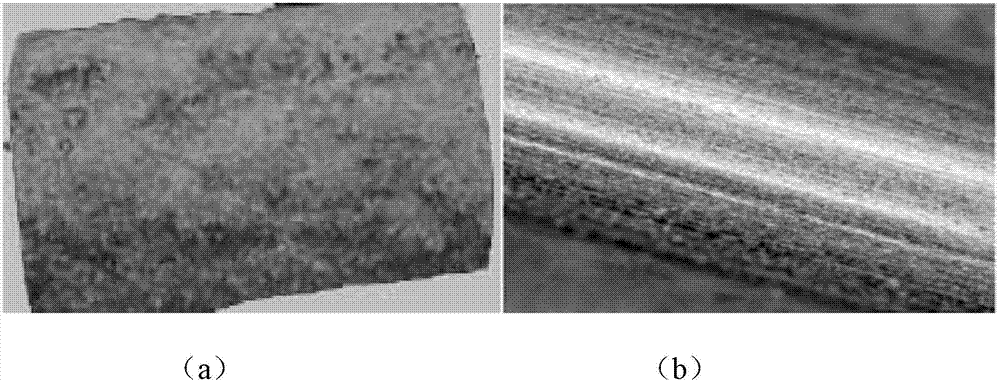

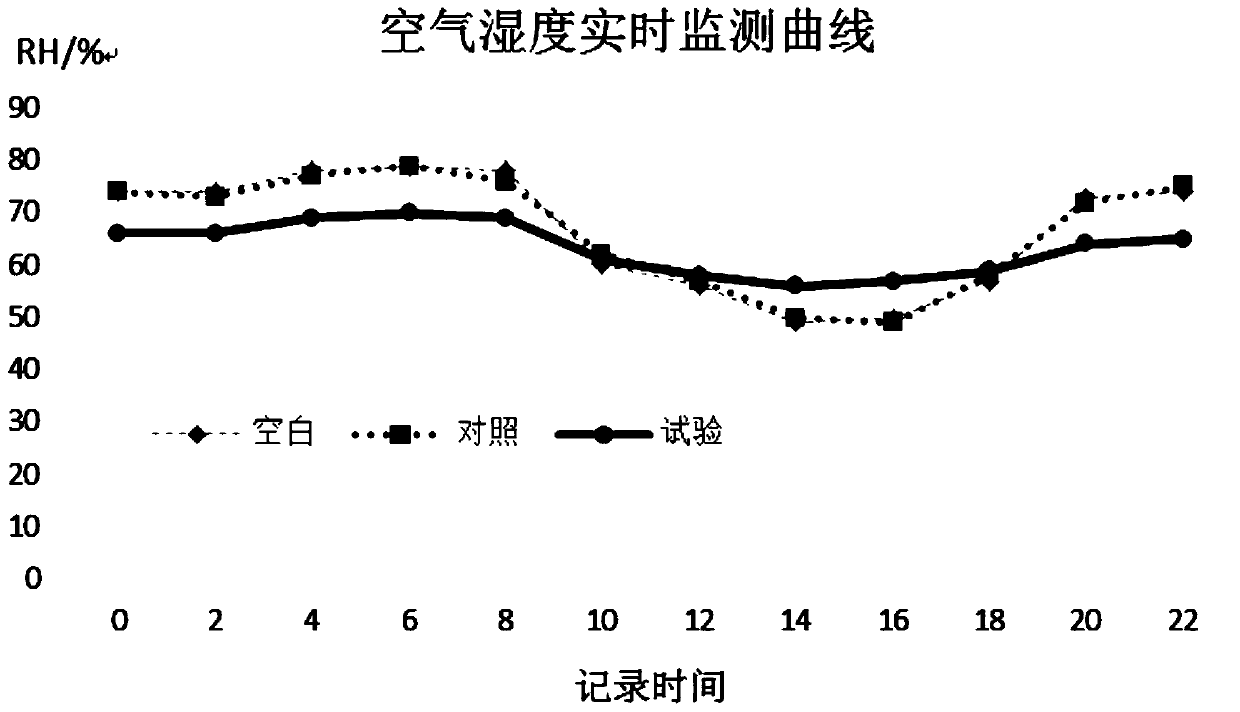

Preparation method of humidity regulating and release controlling type gas phase inhibitor

InactiveCN111172543AWith air humidity adjustment functionControl moisture contentGas phasePhysical chemistry

The invention discloses a preparation method of a humidity regulating and release controlling type gas phase inhibitor. The preparation method comprises the following steps that step 1, a pure gas phase inhibitor is added to deionized water, and heating for dissolution is conducted; step 2, the temperature keeps unchanged, and a cosolvent with the volume of 0.2-2 times of the volume of the deionized water is added, so that the pure gas phase inhibitor is completely dissolved; step 3, a porous hygroscopic material is heated to the same temperature; step 4, under stirring, the dissolved gas phase inhibitor solution is added to a porous carrier which is heated to the same temperature, and even stirring is conducted; and step 5, drying of low temperature and vacuum is conducted on the mixtureevenly stirred, and all the cosolvent is removed to obtain the humidity regulating and release controlling type gas phase inhibitor. According to the preparation method, the gas phase inhibitor prepared has the function of adjusting the environmental humidity, and the volatilization speed of VCI can be controlled.

Owner:STATE GRID ZHEJIANG PINGHU POWER SUPPLY +3

Rust-protection oil for instrument

The invention discloses rust-protection oil for an instrument. The rust-protection oil comprises the following components in parts by weight: 40-60 parts of base oil, 20-30 parts of barium petroleum sulfonate, 12-18 parts of wool fat and 8-12 parts of transformer oil. According to the rust-protection oil for the instrument, the problems in the prior art are solved, and by utilizing the rust-protection oil, the rust-protection period of the instrument is long; the surface of the instrument can be protected, and the loss of an enterprise is reduced; and the rust-protection oil is strong in practicability and is suitable for wide use in relevant industries.

Owner:QIDONG TIANDI MACHINERY MFG

Anti-rust oil for sealing and storage of parts

InactiveCN103374446AImprove rust resistanceLong anti-rust periodLubricant compositionSulfonateEngineering

The invention discloses an anti-rust oil for sealing and storage of parts. The anti-rust oil is composed of, by weight, 30-40 parts of petroleum sodium sulfonate, 20-30 parts of zinc naphthenate and 25-35 parts of burning oil, the balance being industrial vaseline. The anti-rust oil solves the problems in the prior art. The anti-rust oil has good anti-rust effects and long anti-rust period, reduces loss for companies, has strong practicability, and is suitable for wide application of related industries.

Owner:QIDONG TIANDI MACHINERY MFG

Emulsified-type metal antirust agent

InactiveCN106191832ASalt spray anti-rust periodGood anti-rust effectMetallic material coating processesChemistryN-butyl acrylate

The invention provides an emulsified-type metal antirust agent. The emulsified-type metal antirust agent comprises, by weight, 1-5 parts of monobasic acid, 4-10 parts of dibasic acid, 2-6 parts of tribasic acid, 4-10 parts of monoethanolamine, 2-6 parts of diethanol amine, 40-50 parts of triethanolamine, 10-20 parts of polyacrylate, 20-30 parts of butyl acrylate, 10-20 parts of tricresyl phosphate, 30-50 parts of olefin succinic acid, 20-30 parts of dodecyl phenyl succinic acid, 30-40 parts of Octadecylamine N-oleoyl Sarcosinate and 600-700 parts of water. The emulsified-type metal antirust agent is resistant to salt mist, long in rust-proof life and good in rust-proof effect. The rust-proof life can reach 1-4 months. Moreover, the source of the raw materials is wide, production cost can be effectively reduced, and the emulsified-type metal antirust agent is particularly suitable for large-scale industrial production.

Owner:施美

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com