Rust prevention packaging method of metallic product

A technology of metal products and packaging methods, applied in the field of anti-rust packaging of metal products, metal parts, and anti-rust packaging of gears, to achieve the effects of good impact resistance, reduced packaging costs, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

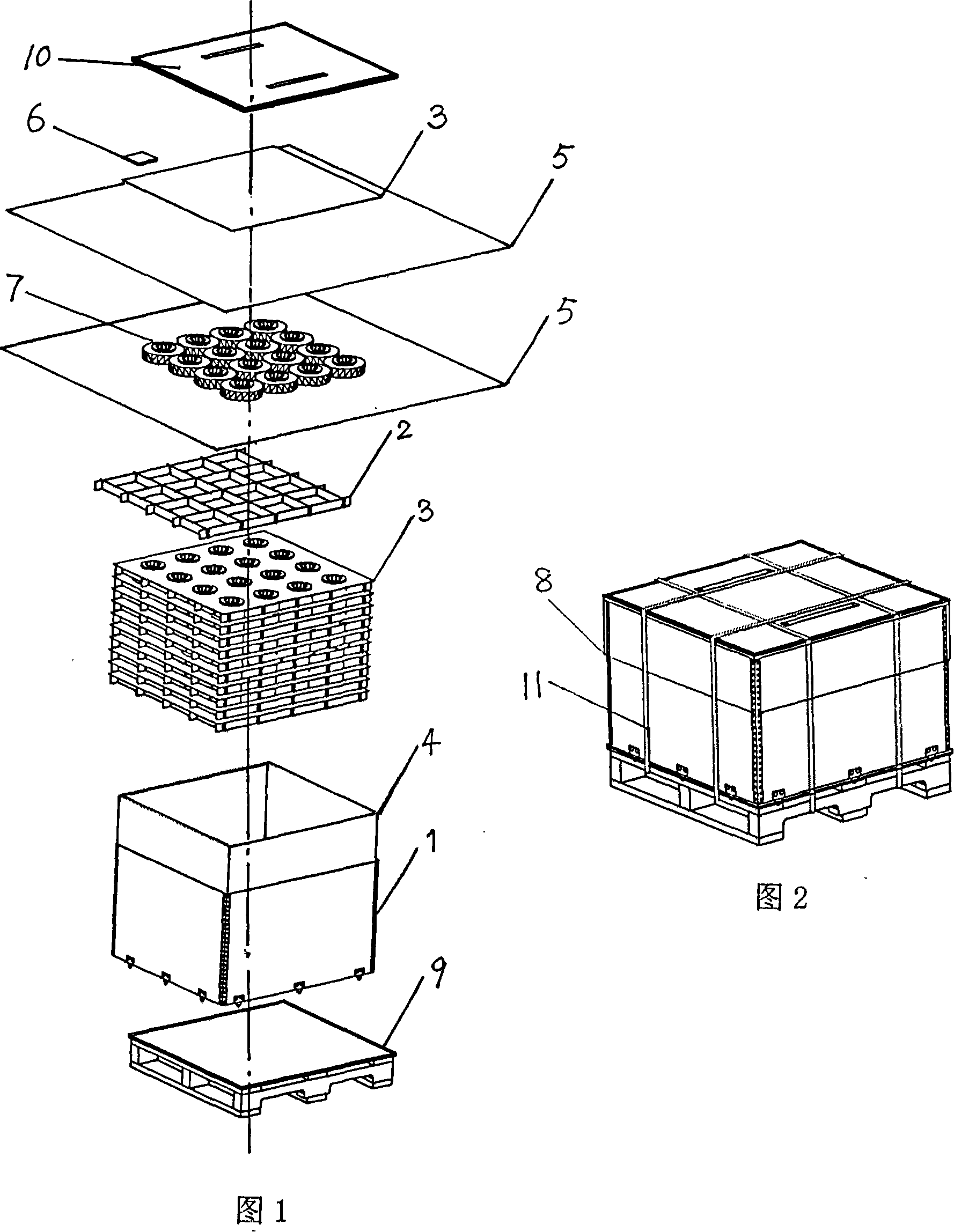

[0047] Embodiment 1: as shown in Figure 1 and Figure 2, the steps of the antirust packaging method for wooden outer packaging metal products are as follows:

[0048] 1) A gas-phase anti-rust bag 4 is arranged inside the wooden box 1;

[0049] 2) Spread the corrugated cardboard 3 and put it into the corrugated cardboard partition 2;

[0050] 3) put in the vapor phase anti-rust film 5;

[0051] 4) Load metal product 7;

[0052] 5) Covering the vapor phase antirust film 5;

[0053] 6) Put corrugated cardboard 3 and desiccant 6;

[0054] 7) tidy up the vapor phase antirust bag 4, and install the wooden upper cover 10;

[0055] 8) Cover the PE rainproof film 8, place it on the wooden pallet 9, and bind the PET plastic-steel belt 11.

Embodiment 2

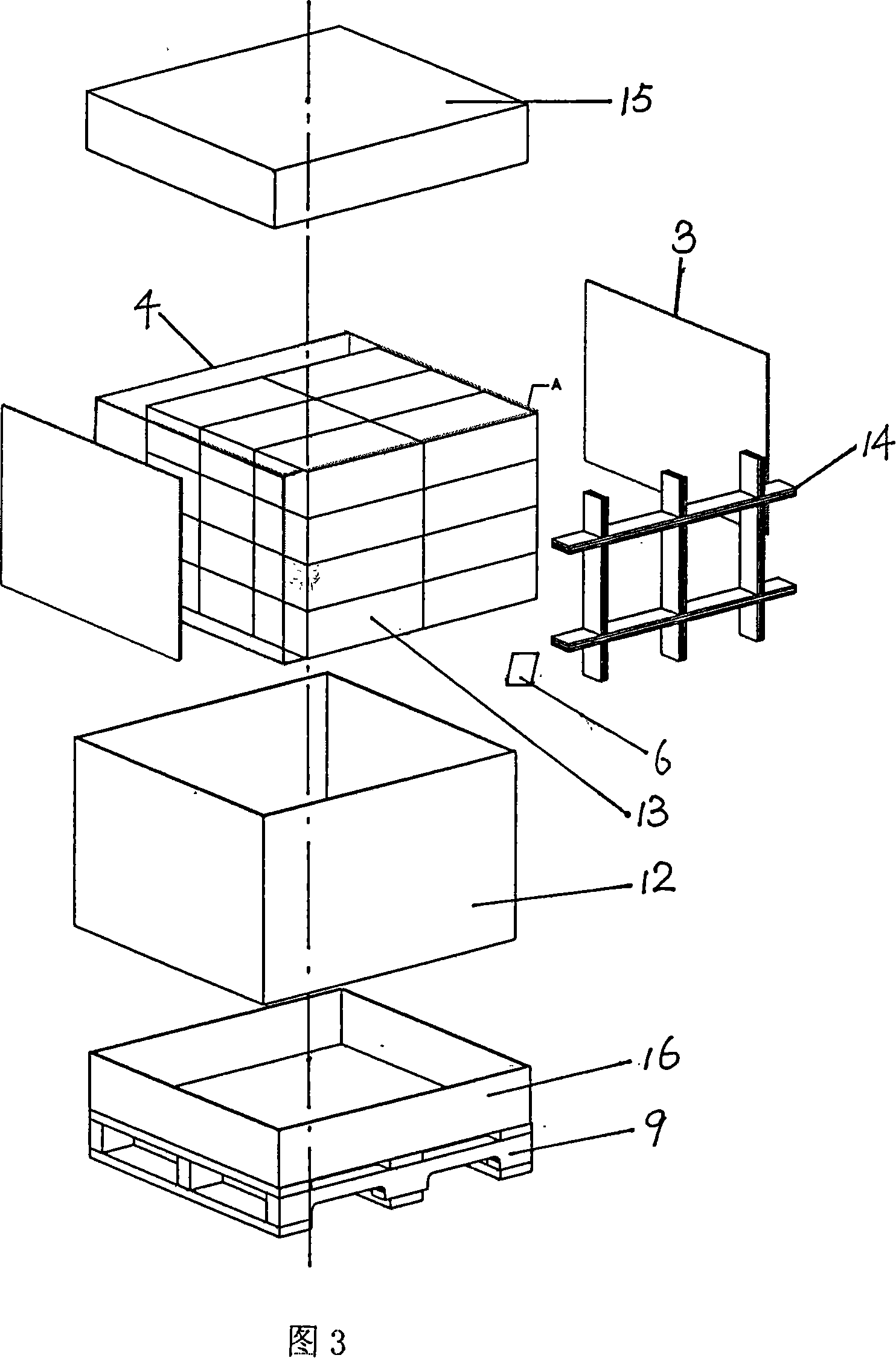

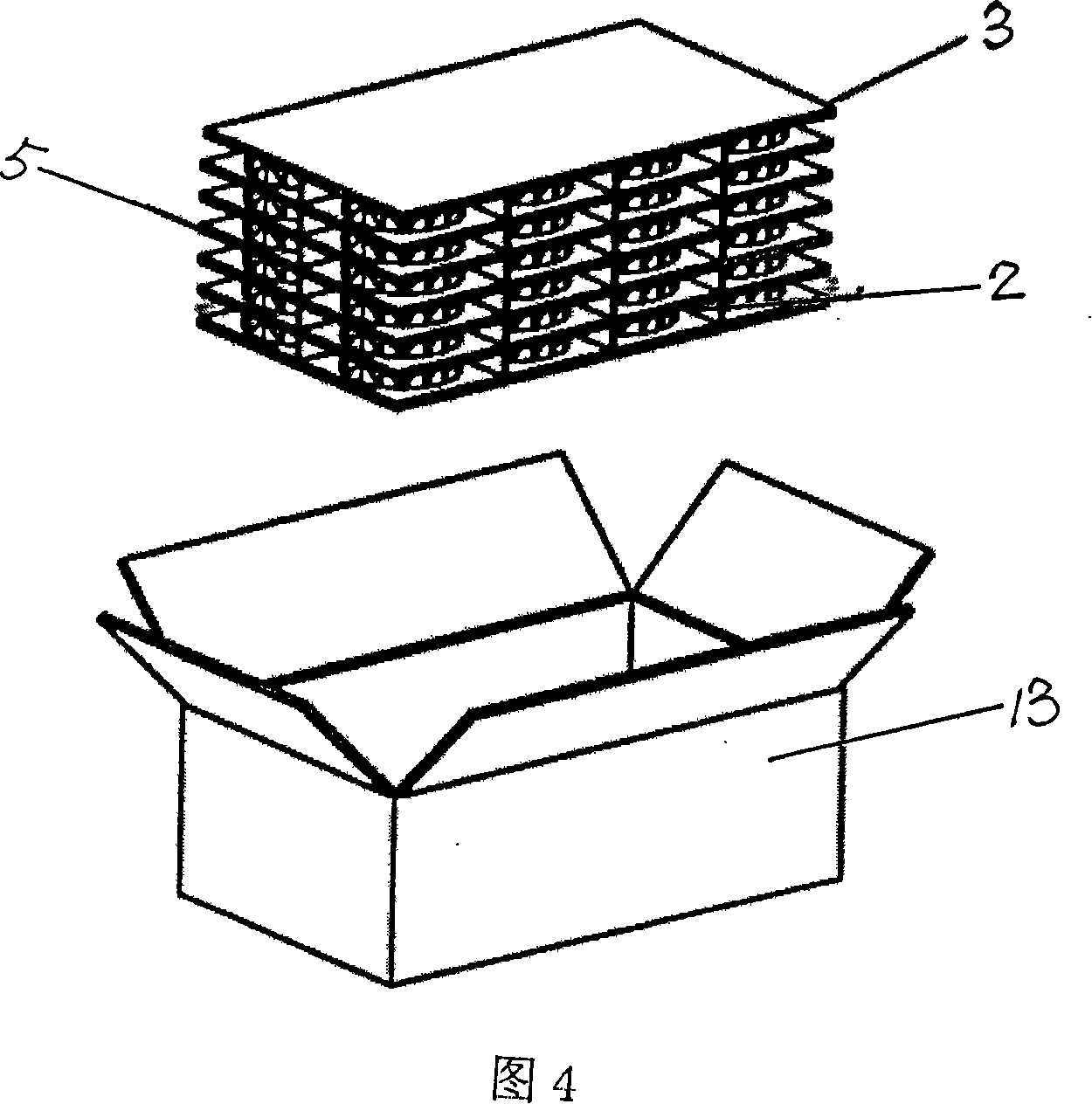

[0056] Embodiment 2: As shown in Figure 3 and Figure 4, the steps of the antirust packaging method for corrugated paper outer packaging metal materials are as follows:

[0057] 1) Put the corrugated cardboard 3 in the small corrugated cardboard box 13, put the corrugated cardboard partition 2, release the vapor phase antirust film 5, put the metal products 7, cover the vapor phase antirust film 5, put the corrugated cardboard 3, and close the corrugated cardboard box 13 ;

[0058] 2) The large corrugated cardboard box 12 is installed on the corrugated paper lower cover 16, and the corrugated cardboard 3, the corrugated paper partition 2 and the desiccant 6 are loaded into the large corrugated cardboard box 12, and then the gas phase antirust bag 4 is loaded, and then several small corrugated cardboard boxes 13 are put into inside;

[0059] 3) tidy up the vapor phase antirust bag 4, and install the corrugated paper top cover 15;

[0060] 4) Cover the PE rainproof film 8, plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com