Resource utilization method of electric furnace bag dusting ash

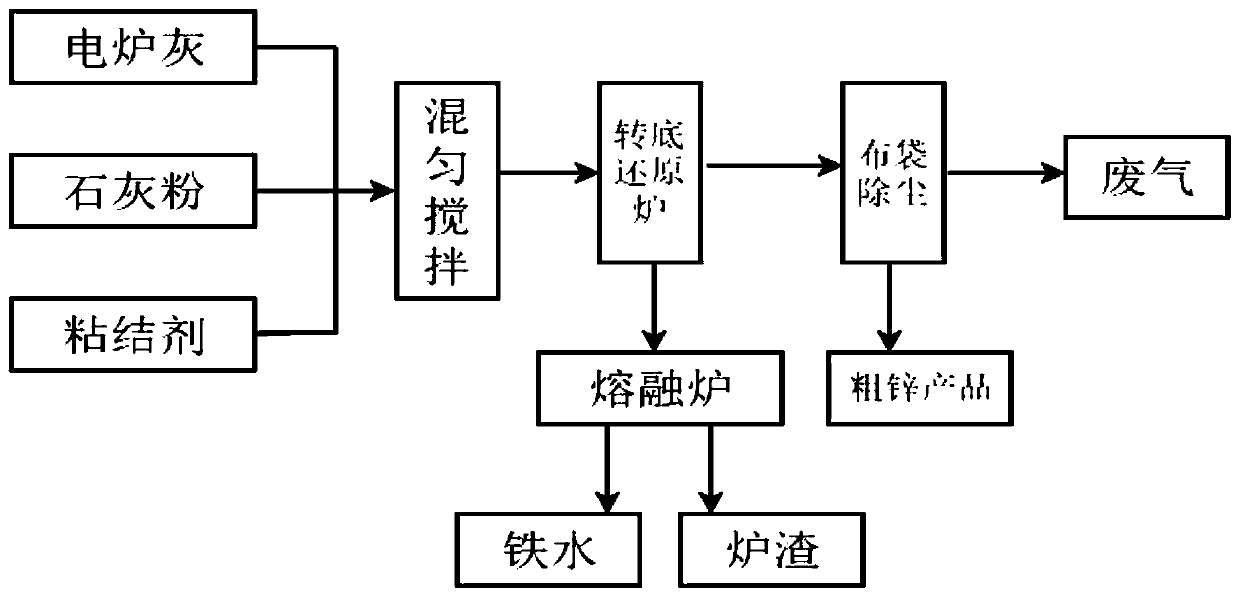

A technology of bag dust removal and resource utilization, which is applied in the direction of furnaces, furnace types, hearth type furnaces, etc., can solve the problems that cannot be completely applied to the current situation of bag dust removal and ash treatment of zinc-containing electric furnaces, and achieves the benefits of comprehensive utilization of resources and production costs. Low, beneficial to the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

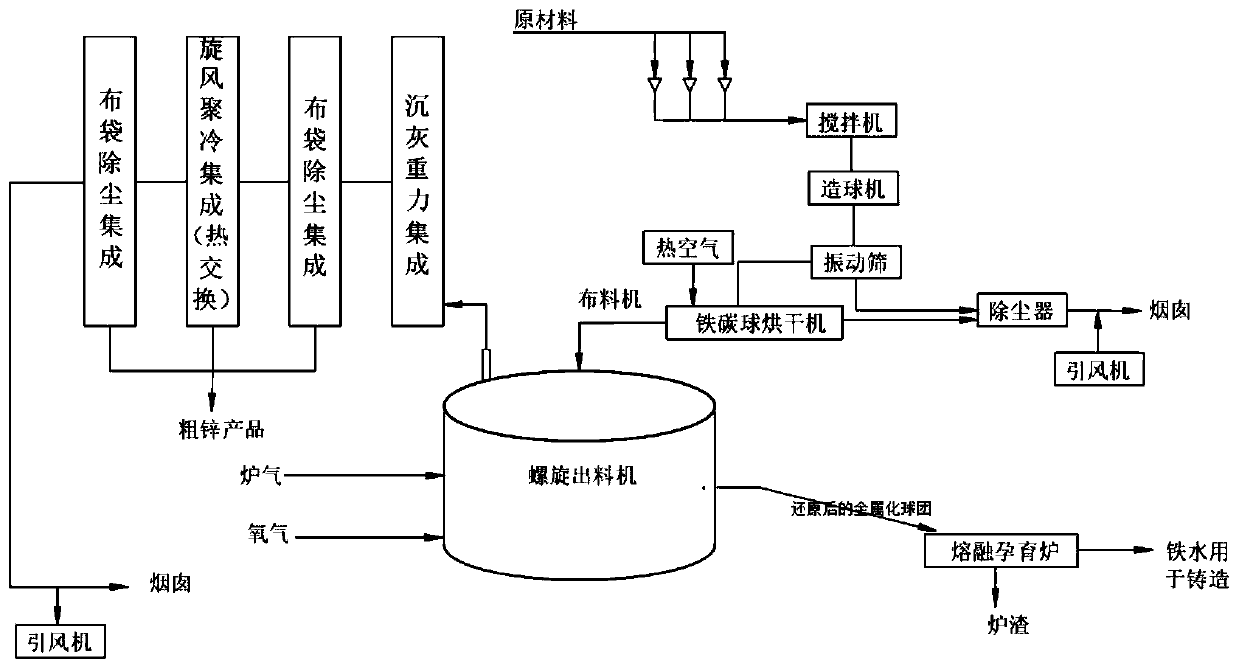

Method used

Image

Examples

Embodiment 1

[0031] A method for resource utilization of electric furnace bag dust removal ash, comprising the following steps:

[0032] a) Mix electric furnace bag dust, coke powder and 901 glue, the amount of carbon powder added is 15% of the mass of electric furnace bag dust, and the amount of 901 glue is 10% of the mass of electric furnace bag dust. Stir at a speed of min for 20 minutes, stir evenly, put it into a pelletizing machine for pelletizing, and obtain semi-finished iron-carbon pellets.

[0033] b) Naturally curing the finished semi-finished iron-carbon spheres for 5 days, or drying the semi-finished iron-carbon spheres at an ambient temperature of 105°C for 4 hours; making the semi-finished iron-carbon spheres have a compressive strength of 1000-1800N / piece.

[0034] c) The dried iron-carbon balls are placed in a rotary bottom reduction furnace for heating and reduction. Control the temperature of the rotary bottom reduction furnace at 1200°C and keep it warm for 30 minutes t...

Embodiment 2

[0039] A method for resource utilization of electric furnace bag dust removal ash, comprising the following steps:

[0040]a) Mix the electric furnace bag dust removal ash, coke powder and 42.5 ordinary silicon cement (more than 80% of the particle size is 200 mesh). It is 9% of the mass of the electric furnace bag dedusting ash, and water with 10% of the mass of the electric furnace bag dedusting ash is added, stirred at a speed of 200r / min for 8 minutes, stirred evenly, and put into a pelletizing machine for pelletizing to obtain semi-finished iron carbon balls.

[0041] b) Naturally curing the finished semi-finished iron-carbon spheres for 7 days, or drying the semi-finished iron-carbon spheres at an ambient temperature of 110°C for 4 hours; making the semi-finished iron-carbon spheres have a compressive strength of 1000-1800N / piece.

[0042] c) Put the dried iron-carbon spheres into the rotary bottom reduction furnace for heating and reduction. Control the temperature of t...

Embodiment 3

[0047] A method for resource utilization of electric furnace bag dust removal ash, comprising the following steps:

[0048] a) Mix the electric furnace bag dust removal ash, coke powder and 42.5 ordinary silicon cement (more than 80% of the particle size is 200 mesh), the amount of coke powder added is 10% of the mass of the electric furnace bag dust removal ash, and the amount of 42.5 ordinary silicon cement It is 9% of the mass of the electric furnace bag dedusting ash, and water with 10% of the mass of the electric furnace bag dedusting ash is added, stirred at a speed of 60r / min for 25min, stirred evenly, put into a pelletizing machine for pelletizing, and semi-finished iron carbon pellets are obtained.

[0049] b) Naturally curing the finished semi-finished iron-carbon spheres for 7 days, or drying the semi-finished iron-carbon spheres at an ambient temperature of 105°C for 4 hours; making the semi-finished iron-carbon spheres have a compressive strength of 1000-1800N / piec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com