A kind of processing method of copper-containing gold mud

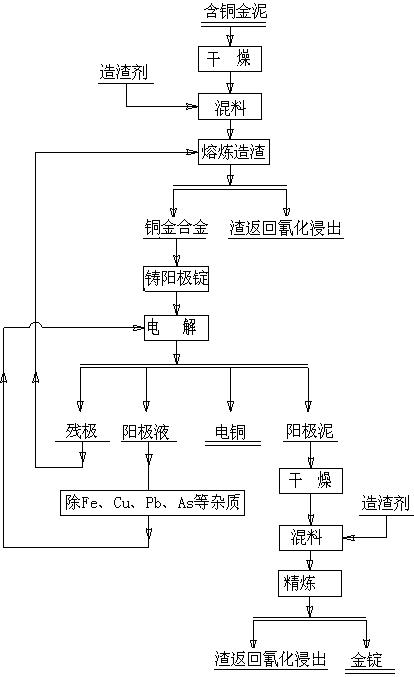

A treatment method and copper-gold technology, applied in the treatment field of copper-containing gold mud, can solve the problems of harsh equipment anti-corrosion requirements, poor production environment, complex equipment, etc., and achieve the effects of reducing the consumption of sulfuric acid, less electrolyte, and shorter process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A copper-zinc ore concentrator in the Najran area of Saudi Arabia, the gold and silver recovery workshop of the plant, applied this method. Put the gold mud after the cake unloading of the zinc powder replacement filter press into the container, and then use the cantilever crane to hoist it to the smelting room on the first floor for storage. ) 2000x1000x500 stainless steel tank. The drying oven adopts RT2-45-9 trolley-type drying furnace with a rated power of 45kw, a rated temperature of 950°C, and a studio size (mm) of 1200x600x400. The gold mud is placed in a stainless steel pan, and there is a pan rack inside the drying furnace. After the gold mud is dried in the furnace, the water content is less than 3%. When the drying furnace is working, turn on the induced draft fan, the power of the induced draft fan is 5kw, and the induced draft fan sucks the indoor air and discharges it into the atmosphere after passing through the water film cyclone dust collector.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com