Method for treating cyaniding gold extraction waste water

A waste water and chemical treatment technology, applied in the field of smelting, can solve the problems that the waste water cannot be fully returned for use, the treatment process is long, and the cost is high, and the effect of strong treatment adaptability, avoidance of gas pollution, and avoidance of loss can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1: Mix the waste water produced by cyanidation gold extraction of conventional mines with 10% shell composite auxiliary agent aqueous solution for 5 hours, add flocculant anionic polyacrylamide before the mixed solution enters the settling tank, and carry out precipitation, flocculation and precipitation produce suspended solids After settling in the settling tank for 5 hours, it is pumped to the press for filtration, and the press is filtered for solid-liquid separation. After vacuum filtration, the filter cake and filtrate are obtained. The filter cake is sold as copper concentrate for comprehensive recovery, and all the filtrate is returned to the cyanide extractor. Gold system used.

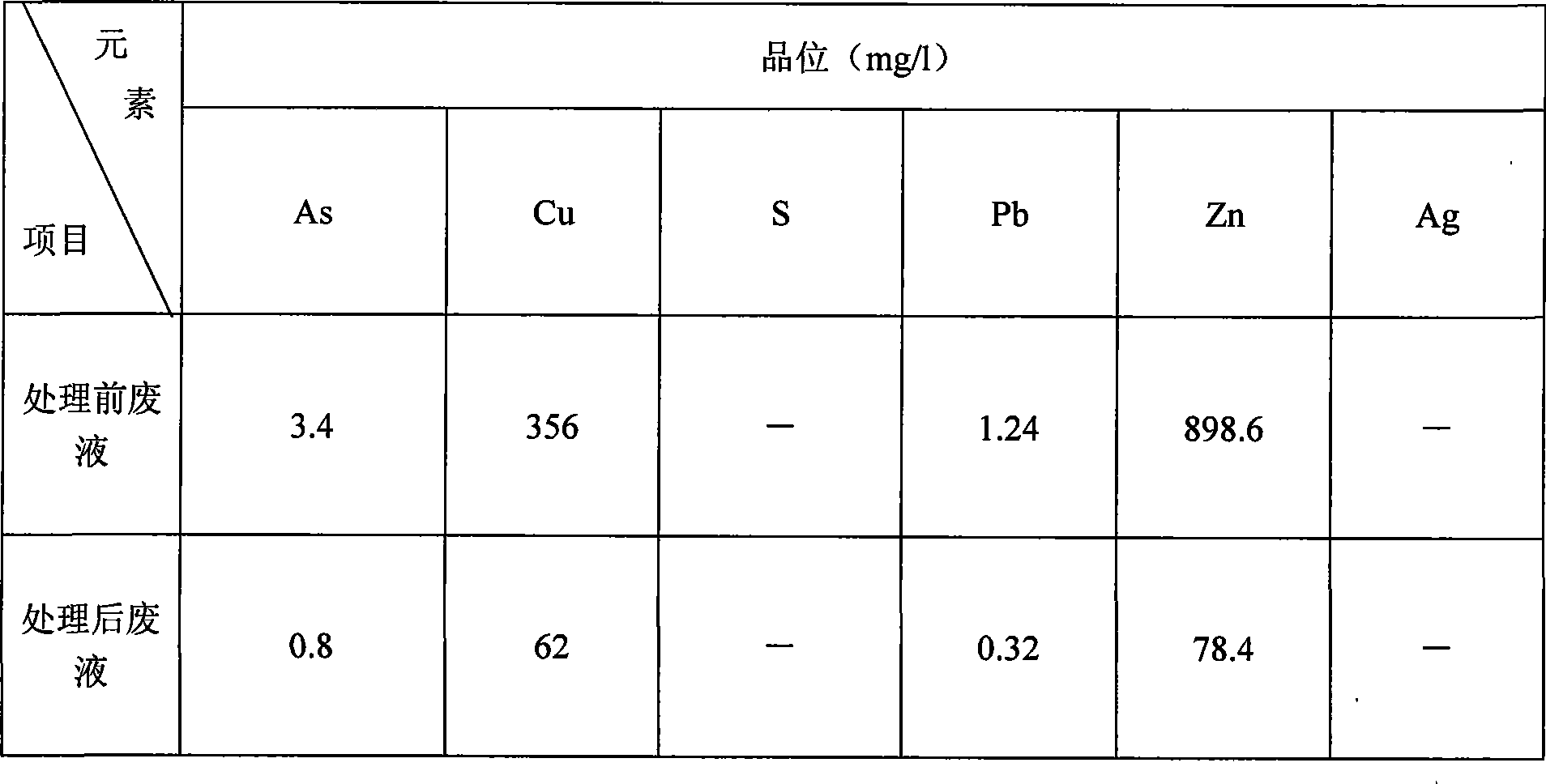

[0012] The relevant elements of the filtrate are tested in Table 1:

[0013] Table 1

[0014]

Embodiment 2

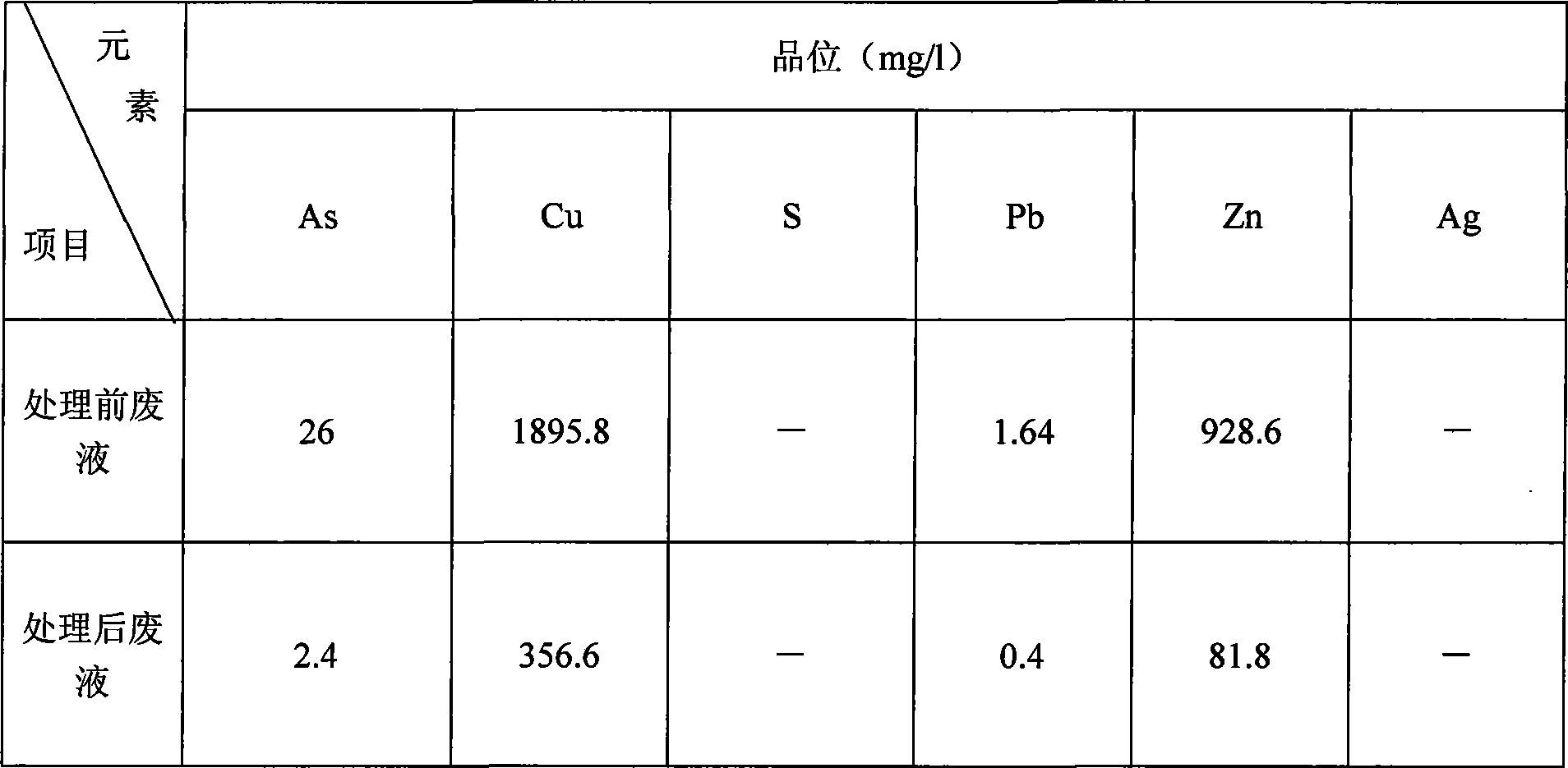

[0015] Example 2: Mix the wastewater containing copper and arsenic cyanide gold extraction with 10% shell composite auxiliary agent aqueous solution for 6 hours, add flocculant anionic polyacrylamide before the mixed solution enters the settling tank, and carry out precipitation, flocculation and precipitation produce Suspended matter, after settling in the settling tank for 4 hours, is pumped to the press for filtration, and the press is filtered for solid-liquid separation. After vacuum filtration, the filter cake and filtrate are obtained. The filter cake is sold as copper concentrate for comprehensive recovery, and all the filtrate is returned to cyanide. It is used by chemical gold extraction system. The relevant element assay of the filtrate is shown in Table 2:

[0016] Table 2

[0017]

Embodiment 3

[0018] Example 3: Mix the wastewater containing copper and arsenic cyanide gold extraction with 10% shell composite auxiliary agent aqueous solution for 4 hours, add flocculant anionic polyacrylamide before the mixed solution enters the settling tank, and carry out precipitation, flocculation and precipitation produce Suspended matter, after settling in the settling tank for 6 hours, is pumped to the press for filtration, and the press is filtered for solid-liquid separation. After vacuum filtration, the filter cake and filtrate are obtained. The filter cake is sold as copper concentrate for comprehensive recovery, and all the filtrate is returned to cyanide. It is used by chemical gold extraction system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com