Gold extraction technique method for low-grade refractory gold ores

A process method and low-grade technology, applied in the direction of improving process efficiency, etc., can solve problems such as difficult to apply and difficult gold concentrate, and achieve low production cost, low cost, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

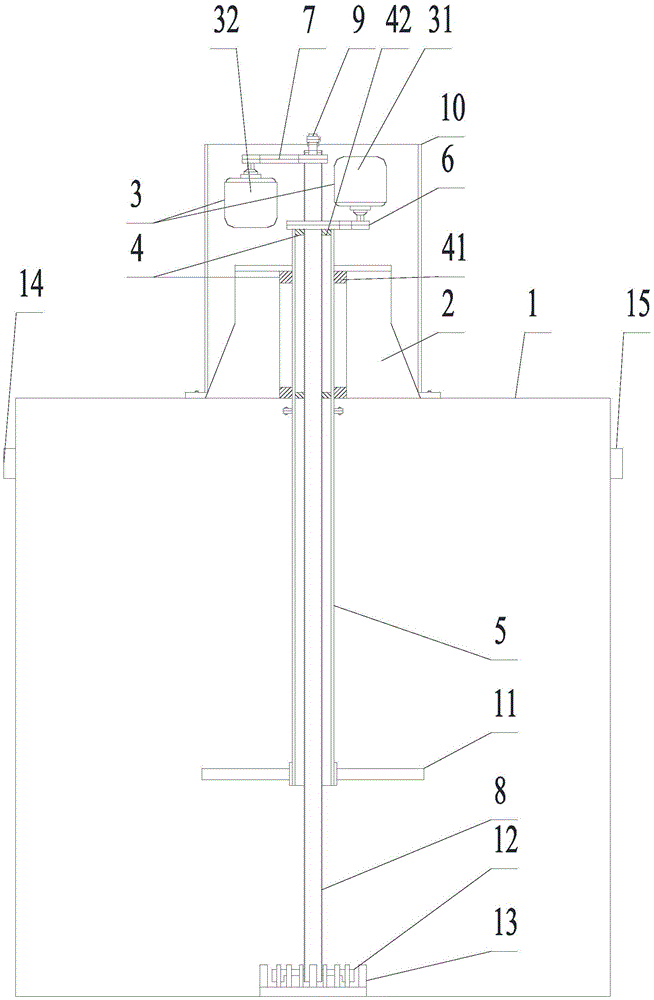

[0066] a kind of like Figure 13 The gold extraction process of the low-grade refractory gold ore of the present invention shown, may further comprise the steps:

[0067] (1) Finely grind the above-mentioned raw ore containing fine-grained sulfide-coated gold; the fine grinding is to adopt a micron-level ultra-fine stirring mill (such as the technical solution disclosed in No. ZL201010558281.4 Chinese Patent), and the grinding concentration is 50% , Grinding fineness D90=9.27μm;

[0068] (2) Add the finely ground raw ore into the intensified agitation and aeration reaction device of the present invention, and at normal pressure and 50° C., feed air and stir to carry out pre-oxidation; the oxidant is air, and the flow rate is 0.10 m 3 / h, the liquid-solid ratio of pre-oxidation, alkali treatment and leaching is 2:1, and the pre-oxidation time is 24 hours;

[0069] (3) Add calcium oxide to the above-mentioned pre-oxidized ore pulp for sufficient alkali treatment; the dosage of...

Embodiment 2

[0072] a kind of like Figure 13 The gold extraction process of the low-grade refractory gold ore of the present invention shown, may further comprise the steps:

[0073] (1) Finely grind the above-mentioned raw ore containing fine-grained sulfide-coated gold; the fine grinding is to adopt a micron-level ultra-fine stirring grinder, the grinding concentration is 50%, and the grinding fineness D90=9.27 μm;

[0074] (2) Add the finely ground raw ore into the intensified stirring aeration reaction device of the present invention, and at normal pressure and 100° C., feed oxygen and stir to carry out pre-oxidation; the oxidant is oxygen, and the flow rate is 0.20 m 3 / h, the liquid-solid ratio of pre-oxidation, alkali treatment and leaching is 5:1, and the pre-oxidation time is 4 hours;

[0075] (3) Add calcium oxide to the above-mentioned pre-oxidized ore pulp for sufficient alkali treatment; the dosage of calcium oxide is 20kg / t, the pH value is 11-12, and the alkali treatment t...

Embodiment 3

[0078] a kind of like Figure 13 The gold extraction process of the low-grade refractory gold ore of the present invention shown, may further comprise the steps:

[0079] (1) Finely grind the above-mentioned raw ore containing fine-grained sulfide-coated gold; the fine grinding is to adopt a micron-level ultra-fine stirring grinder, the grinding concentration is 50%, and the grinding fineness D90=9.27 μm;

[0080] (2) Add the finely ground raw ore into the intensified agitation and aeration reaction device of the present invention, and at normal pressure and 10° C., feed air and stir to carry out pre-oxidation; the oxidant is air, and the flow rate is 0.10 m 3 / h, the liquid-solid ratio of pre-oxidation, alkali treatment and leaching is 2:1, and the pre-oxidation time is 24 hours;

[0081] (3) Add calcium oxide to the above-mentioned pre-oxidized ore pulp for sufficient alkali treatment; the dosage of calcium oxide is 10.35kg / t, the pH value is 11-12, and the alkali treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com