Comprehensive treatment method of waste lithium iron phosphate battery

A lithium iron phosphate battery, comprehensive treatment technology, applied in the direction of phosphate, phosphorus oxyacids, phosphorus compounds, etc., can solve the problems of acid consumption, leaching liquid containing impurities and high-salt wastewater, etc., achieve high recovery rate, solve resource recovery Exploitation problem, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

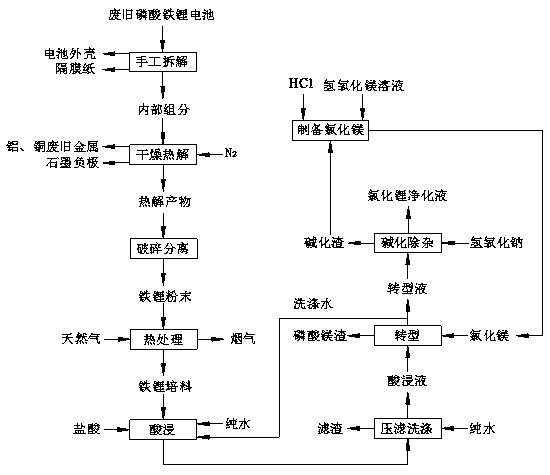

[0028] see figure 1 , the present invention provides a technical solution: a comprehensive treatment method for waste lithium iron phosphate batteries, comprising the following steps:

[0029] S1: Manual dismantling, after manually tearing the packaging paper of the waste lithium iron phosphate battery, cut the shell of the waste lithium iron phosphate battery, and after separation, the battery shell, internal components and separator paper are obtained;

[0030] S2: dry pyrolysis, transfer the internal components to the heating furnace and pass through the N 2 Protection, control the heating temperature to 600 °C, and continue heating for 1.5 hours to obtain aluminum and copper scrap metal, graphite negative electrode and pyrolysis products;

[0031] S3: Breaking and separating, transferring the pyrolysis product to a fine jaw crusher, and obtaining iron-lithium powder after complete crushing;

[0032] S4: heat treatment, transfer the iron-lithium powder to a natural gas co...

Embodiment 2

[0040] see figure 1 , the present invention provides a technical solution: a comprehensive treatment method for waste lithium iron phosphate batteries, comprising the following steps:

[0041] S1: Manual dismantling, after manually tearing the packaging paper of the waste lithium iron phosphate battery, cut the shell of the waste lithium iron phosphate battery, and after separation, the battery shell, internal components and separator paper are obtained;

[0042] S2: dry pyrolysis, transfer the internal components to the heating furnace and pass through the N 2 protection, control the heating temperature to 700 °C, and continue heating for 2.0 h to obtain aluminum and copper scrap metals, graphite negative electrodes and pyrolysis products;

[0043] S3: Breaking and separating, transferring the pyrolysis product to a fine jaw crusher, and obtaining iron-lithium powder after complete crushing;

[0044] S4: heat treatment, transfer the iron-lithium powder to a natural gas comb...

Embodiment 3

[0052] see figure 1 , the present invention provides a technical solution: a comprehensive treatment method for waste lithium iron phosphate batteries, comprising the following steps:

[0053] S1: Manual dismantling, after manually tearing the packaging paper of the waste lithium iron phosphate battery, cut the shell of the waste lithium iron phosphate battery, and after separation, the battery shell, internal components and separator paper are obtained;

[0054] S2: dry pyrolysis, transfer the internal components to the heating furnace and pass through the N 2 protection, control the heating temperature to 800 °C, and continue heating for 2.5 h to obtain aluminum and copper scrap metals, graphite negative electrodes and pyrolysis products;

[0055] S3: Breaking and separating, transferring the pyrolysis product to a fine jaw crusher, and obtaining iron-lithium powder after complete crushing;

[0056] S4: heat treatment, transfer the iron-lithium powder to a natural gas comb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com