Process of comprehensively recovering various metals from limonite

A technology for limonite and metal, applied in the field of comprehensive recovery of polymetals, can solve problems such as poor effect and weak magnetic properties, and achieve the effect of increasing the economic benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The raw ore iron grade is 46.88wt%, gold grade is 0.40g / t, silver grade is 12.45 g / t, copper grade is 0.24wt%, lead content is 0.68wt%, and zinc content is 1.06wt%.

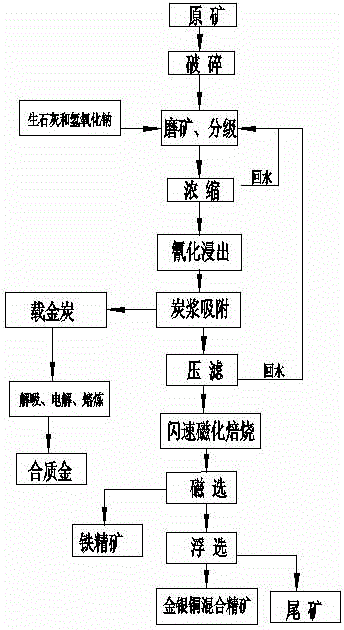

[0021] Such as figure 1 Shown, a kind of technique that comprehensively recovers multiple metals from limonite comprises the following steps:

[0022] (1) Crushing: crush 1200 tons of limonite to -10mm;

[0023] (2) Grinding and grading: The raw ore after crushing is wet-grinded. During the grinding process, a mixture of quicklime and sodium hydroxide with a mass ratio of 2:3 is added to control the pH value of the pulp at 10, and the graded overflow The fineness is -200 mesh and the content accounts for 80wt%;

[0024] (3) Concentration: The ore pulp is concentrated and dehydrated to control the concentration of the ore pulp at 40wt%, and the return water is returned to the grinding and classification operation;

[0025] (4) Cyanide leaching: the pulp enters the carbon slurry operation, and the con...

Embodiment 2

[0032] The raw ore iron grade is 46.88wt%, gold grade is 0.40g / t, silver grade is 12.45 g / t, copper grade is 0.24wt%, lead content is 0.68wt%, and zinc content is 1.06wt%.

[0033] Such as figure 1 Shown, a kind of technique that comprehensively recovers multiple metals from limonite comprises the following steps:

[0034] (1) Crushing: crushing 1500 tons of limonite to -10mm;

[0035] (2) Grinding and grading: The raw ore after crushing is wet-grinded. During the grinding process, a mixture of quicklime and sodium hydroxide with a mass ratio of 2:3 is added to control the pH value of the pulp at 11, and the graded overflow The fineness is -200 mesh and the content accounts for 80wt%;

[0036] (3) Concentration: The ore pulp is concentrated and dehydrated to control the concentration of the ore pulp at 45wt%, and the return water is returned to the grinding and classification operation;

[0037] (4) Cyanide leaching: the pulp enters the carbon slurry operation, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com