Deeply buried iron mineral resource underground mining and concentrating integration system

A technology of mineral resources and deep burial, applied in underground mining, underground chambers, ground mining, etc., can solve problems such as immature technical solutions and impossibility of implementation, achieve shortening of lifting and filling effects, reduce mining costs, and solve environmental pollution problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

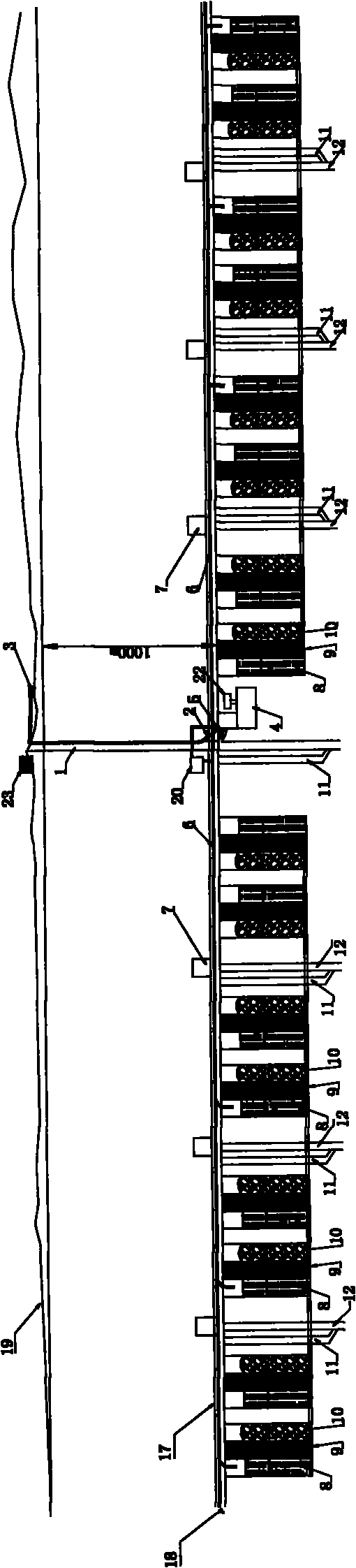

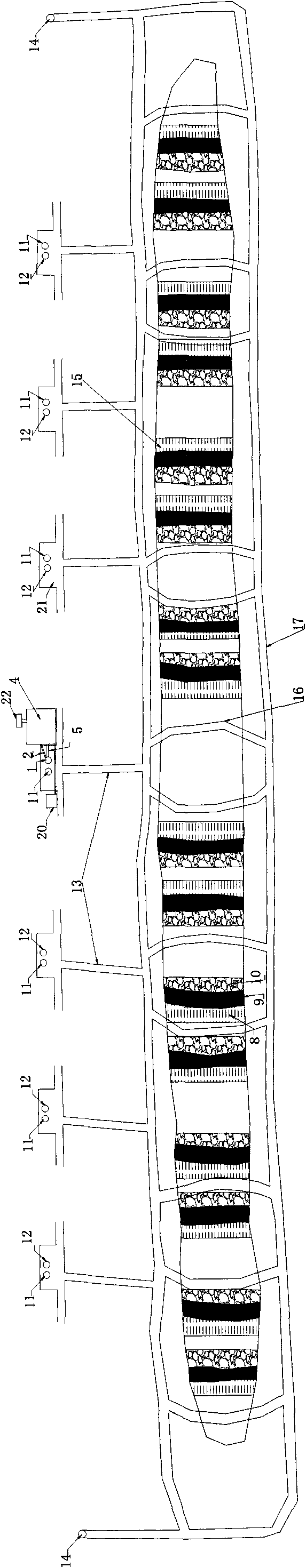

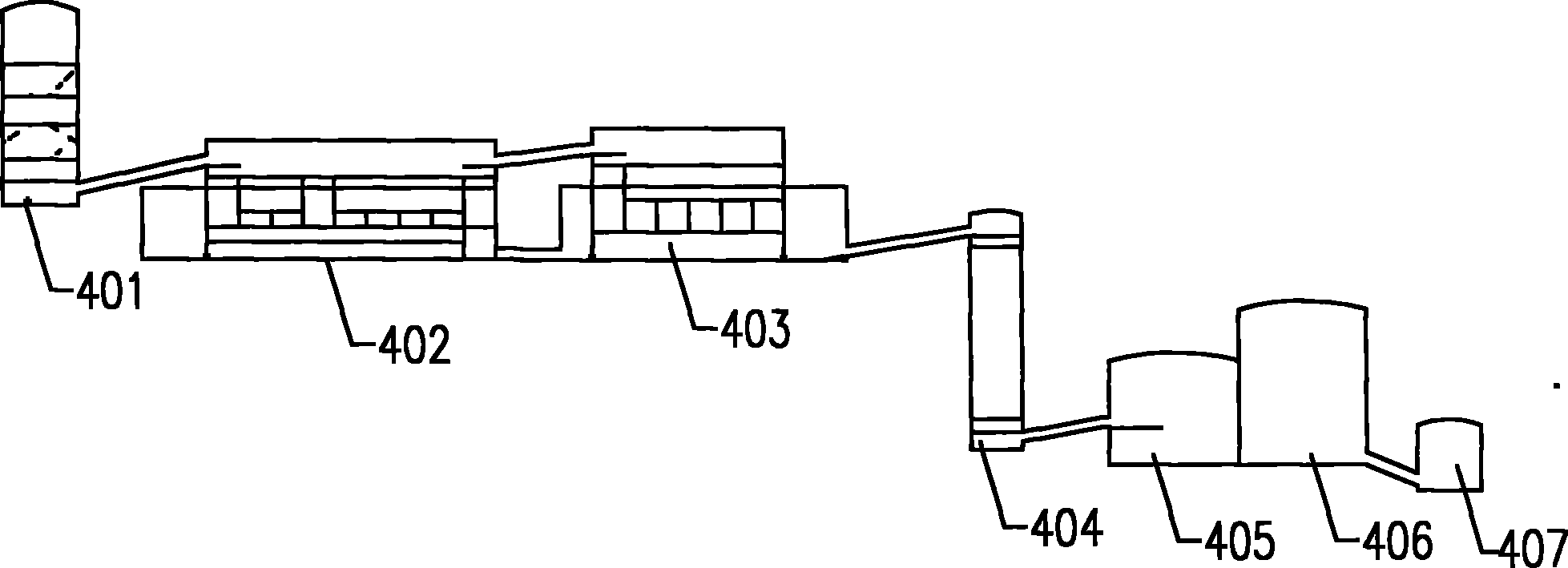

[0023] Example 1. Taking an iron mine in Benxi, my country as an example, the calculated storage capacity is 3.1 billion tons, buried 1000-1400m underground, with a total length of 2000m and a width of 1300m. Based on an annual production capacity of 25 million tons, the integrated system of underground mining and selection is formed, such as figure 1 with figure 2 As shown, in the direction of the vertical ore body, a main lift shaft 1 is set at a position 50m away from the surface movement zone, and a main lift shaft 1 is set in the area 20-300m to the left of the main lift shaft 1 and 20m below the main transportation horizontal roadway 17. Underground concentrator 4, including gyratory chamber 401, conical chamber 402, screening chamber 403, powder ore chamber 404, ball mill chamber 405, sorting chamber 406, product conveying chamber 407, each chamber adopts a plane arrangement, such as image 3 with Figure 4 shown. The design space of the gyratory chamber 401 is 18m...

example 2

[0025] Example 2: Taking the Sijialing Iron Mine in my country as an example, the mineral resource is buried below 600m underground, the ore body is 1000m long and 500m wide, and its reserves are calculated to be 1.6 billion tons. According to the annual production capacity of 10 million tons, the formation of the underground mining and selection integrated system of the present invention is the same as Example 1. The difference is that, in the direction of the vertical ore body and delineated at the position of 30m in the surface movement zone, a main hoisting shaft 1 is set up, and an underground mineral processing plant 4 is set up on the left side of the main hoisting shaft 1 and 40m below the main transportation horizontal roadway 17. The underground mineral processing The space of each chamber in Plant 4 is arranged in a trapezoidal form. Such as Figure 5 with Image 6 shown. The design space of gyratory chamber 401 is 18m×70m×40m, +30m maintenance space, the conical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com