Polymetallic sulphide ore flotation process capable of increasing zinc index

A sulfide ore and polymetallic technology, applied in flotation, chemical instruments and methods, cleaning methods using liquids, etc., can solve problems such as increasing electron density, reducing hole concentration, valence and charge state imbalance, etc., to achieve improved Production index, good application effect, effect of expanding utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. This embodiment is only to illustrate the present invention more clearly, rather than limit the present invention.

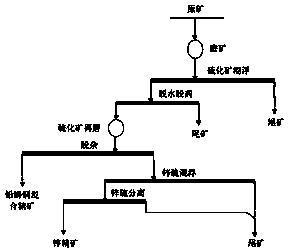

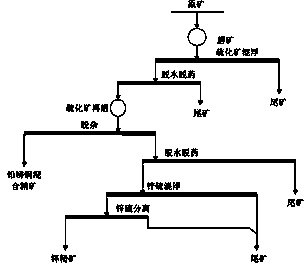

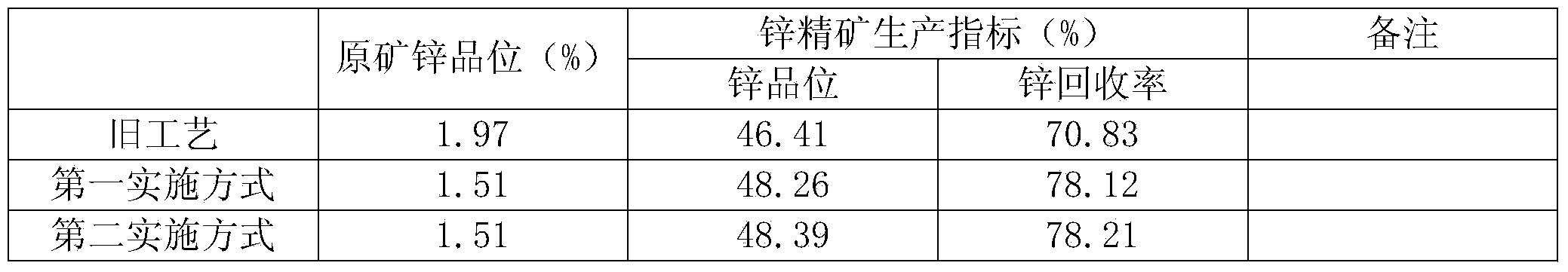

[0037] The beneficiation process (attached) of the first embodiment provided by the present invention is adopted below figure 1 ) to beneficiate the following raw ore:

[0038] A low-grade polymetallic sulfide ore in Guangxi, my country, the ore mainly contains cassiterite, sphalerite, brittle pyrrhotite, pyrrhotite, and pyrite; the gangue minerals are mainly quartz and calcite; the surrounding rock minerals are mainly For limestone and silicified limestone. The ore zinc grade is 1.51%.

[0039] In the first step, after the selected raw ore is crushed and mixed and flotation, the mixed concentrate and some tailings are obtained, and the mixed concentrate is further pre-dehydrated and drug-removed. Dehydration and chemical remova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com