Technology for secondary recovery of gold from flotation tailings

A technology for flotation tailings and secondary recovery, applied in the direction of improving process efficiency, can solve the problems of high cost, incomplete reaction, low beneficiation recovery rate, etc., achieve low cost, large processing capacity, and improve beneficiation recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

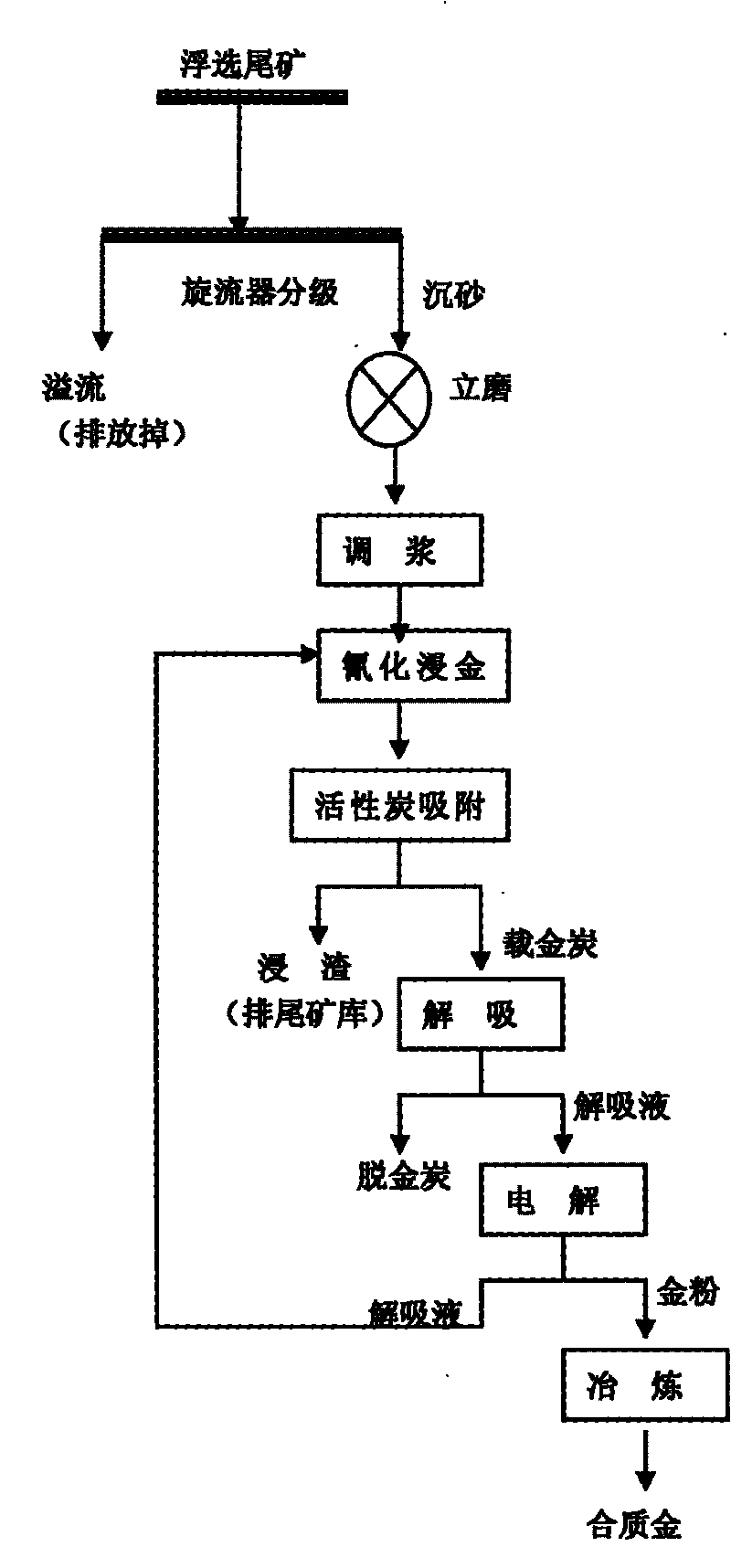

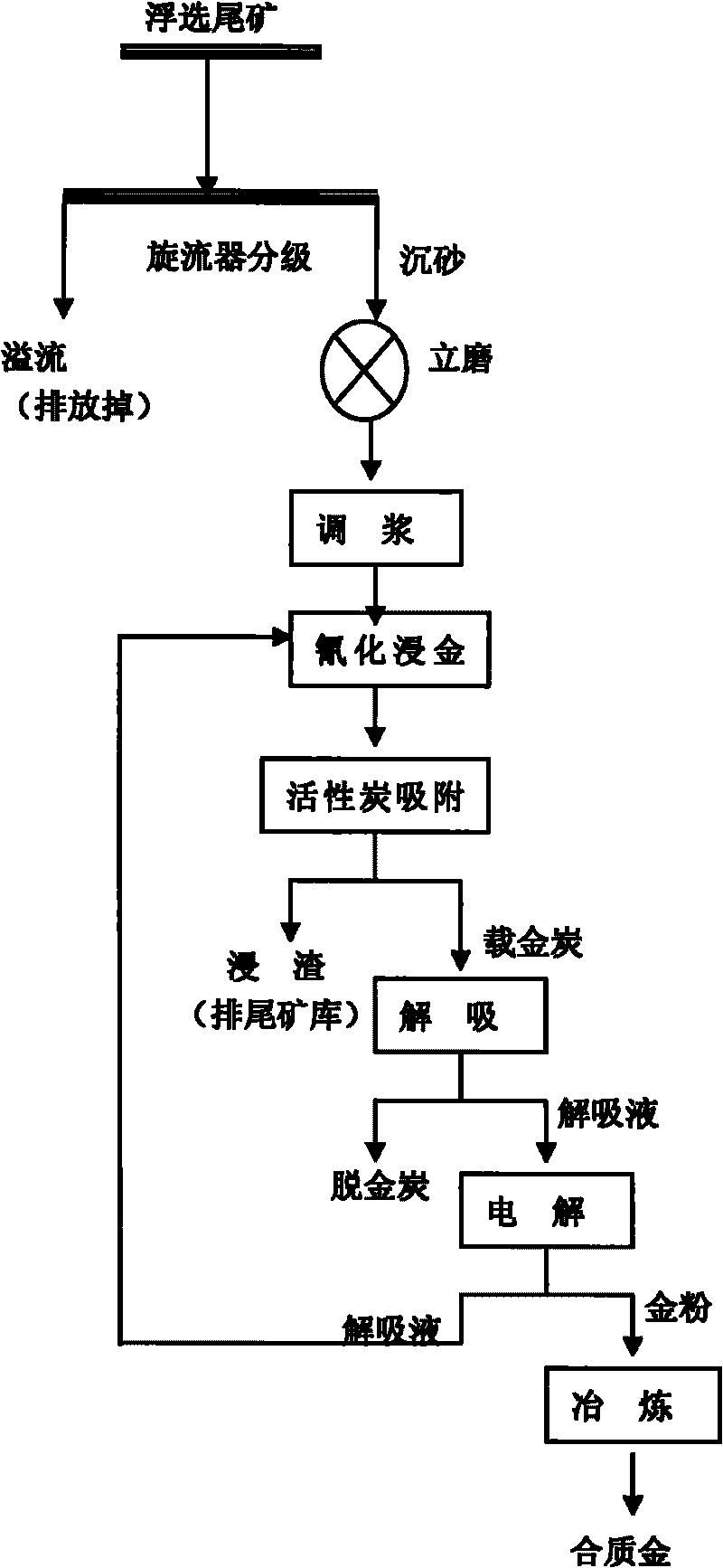

Image

Examples

Embodiment 1

[0019] As shown in the attached figure, the flotation tailings slurry is classified by a cyclone, the overflow is discharged directly, and the swirled out grit is used as raw ore for regrinding until the particle size is -200 mesh and the weight of the ore powder in the total ore powder is 100%. Mineral content is 78%, add calcium hydroxide and water to the ground mineral powder, adjust the pH of the pulp to 10.5, and the weight concentration of mineral powder is 47%, and then add 0.9kg of sodium cyanide per ton of ground mineral powder The amount of sodium cyanide is added to carry out cyanidation gold leaching, the gold leaching temperature is 25°C, and the gold leaching time is 8h. The leached gold is adsorbed by activated carbon, and the gold-loaded carbon obtained after the adsorption is saturated is sent to desorption. The desorption liquid used is the mass concentration prepared by adding water. 2% NaCN and 1% NaOH, the desorption pressure is 0.025Mpa, the desorption tem...

Embodiment 2

[0024] As shown in the attached figure, the flotation tailings slurry is classified by a cyclone, the overflow is discharged directly, and the swirled out grit is used as raw ore for regrinding until the particle size is -200 mesh and the weight of the ore powder in the total ore powder is 100%. Mineral content is 75%, add calcium hydroxide and water to the ground mineral powder, adjust the pH of the slurry to 10, and the weight concentration of the mineral powder is 45%, and then add 0.6kg of sodium cyanide per ton of ground mineral powder The amount of sodium cyanide is added to carry out cyanidation gold leaching, the gold leaching temperature is 20°C, and the gold leaching time is 6 hours. The leached gold is adsorbed by activated carbon, and the gold-loaded carbon obtained after the adsorption is saturated is sent for desorption. The desorption solution used is the mass concentration prepared by adding water. 2% NaCN and 1% NaOH, the desorption pressure is 0.025Mpa, the de...

Embodiment 3

[0026] As shown in the attached figure, the flotation tailings slurry is classified by a cyclone, the overflow is discharged directly, and the swirled out grit is used as raw ore for regrinding until the particle size is -200 mesh and the weight of the ore powder in the total ore powder is 100%. Mineral content is 80%, add sodium hydroxide and water to the ground mineral powder, adjust the pH of the slurry to 11, and the weight concentration of mineral powder is 50%, and then add 1.2kg of sodium cyanide per ton of ground mineral powder The amount of sodium cyanide is added to carry out cyanidation gold leaching. The gold leaching temperature is 30°C and the gold leaching time is 10h. The leached gold is adsorbed by activated carbon. After the adsorption is saturated, the gold-loaded carbon obtained is sent for desorption. 2% NaCN and 1% NaOH, the desorption pressure is 0.025Mpa, the desorption temperature is 130°C, the desorption solution obtained after desorption is electrolyz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com