Process for extracting gold from low-grade, copper-containing and difficultly-treated goldmine ammonia cyanide leaching pulp via electrodeposition

A low-grade technology that is difficult to treat gold ore, applied in the metallurgical industry, can solve the problems of reduced adsorption capacity of regenerated carbon, difficulty in desorption of gold-loaded carbon, and elevated grade of gold-loaded carbon and copper, so as to achieve low production costs and reduce production costs. And the effect of high investment cost and gold recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

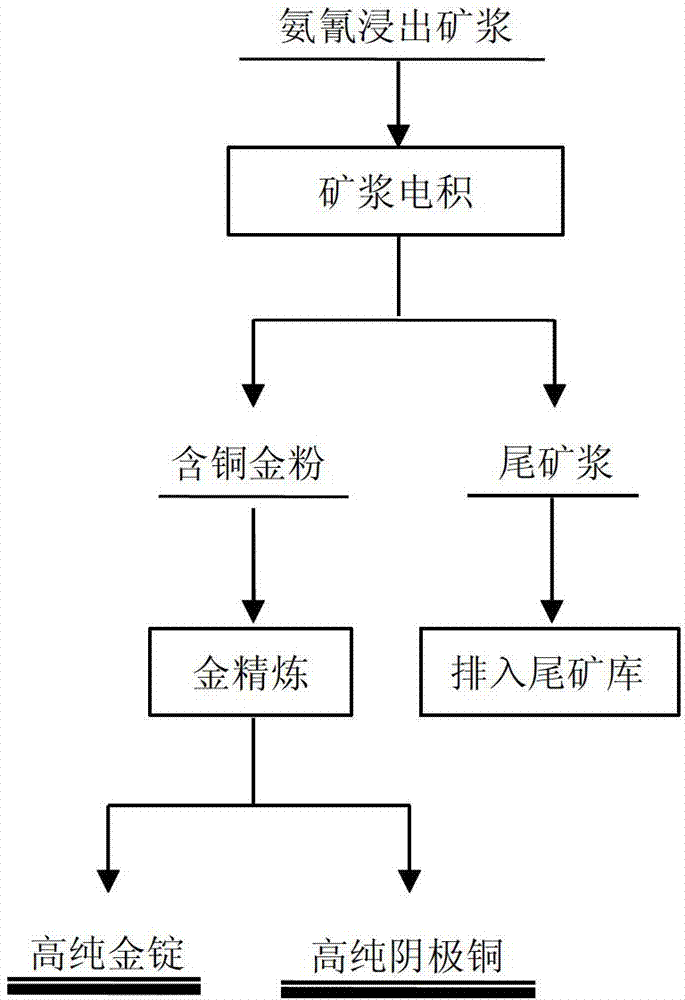

[0022] A low-grade copper-bearing refractory gold ore (gold grade 4.5g / t, copper content 0.70%, containing a large amount of alkaline gangue) is first leached with ammonium cyanide, and after the leaching is completed, the slurry is introduced into the electrolytic tank, and the slurry The concentration is diluted to 15%, the pH value is controlled to be about 12.0, and the electrodeposition of the ore slurry is carried out. The anode is a lead alloy anode, the cathode is a stainless steel plate, and the cathode current density is controlled at 20A / m 2 , electrowinning for 8 hours, the gold concentration in the tailing liquid can be reduced to <0.02mg / L, and the gold grade in the tailings is 0.65g / t. For high-purity gold ingots and high-purity copper cathodes, the recovery rate of gold is 87.29%, and the production cost of gold is 170 yuan / g.

Embodiment 2

[0024] A low-grade copper-bearing refractory gold ore (gold grade 4.5g / t, copper content 0.70%, containing a large amount of alkaline gangue) is first leached with ammonium cyanide, and after the leaching is completed, the slurry is introduced into the electrolytic tank, and the slurry The concentration is diluted to 20%, the pH value is controlled to be about 12.0, and the electrodeposition of the ore slurry is carried out. The anode is a lead alloy anode, the cathode is a stainless steel plate, and the cathode current density is controlled at 15A / m 2 , electrowinning for 6 hours, the gold concentration in the tailing liquid can be reduced to <0.02mg / L, and the gold grade in the tailings is 0.75g / t. For high-purity gold ingots and high-purity copper cathodes, the recovery rate of gold is 85.33%, and the production cost of gold is 160 yuan / g.

Embodiment 3

[0026] A low-grade copper-bearing refractory gold ore (gold grade 4.5g / t, copper content 0.70%, containing a large amount of alkaline gangue) is first leached with ammonium cyanide, and after the leaching is completed, the slurry is introduced into the electrolytic tank, and the slurry The concentration is diluted to 15%, the pH value is controlled to be about 12.0, and the electrowinning of the ore slurry is carried out. The anode is a lead alloy anode, the cathode is a steel wool electrowinning (packed in a cloth bag), and the cathode current density is controlled at 20A / m 2 , electrowinning for 8 hours, the gold concentration in the tailing liquid can be reduced to <0.02mg / L, and the gold grade in the tailings is 0.65g / t. For high-purity gold ingots and high-purity copper cathodes, the gold recovery rate is 87.79%, and the production cost of gold is 168 yuan / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com