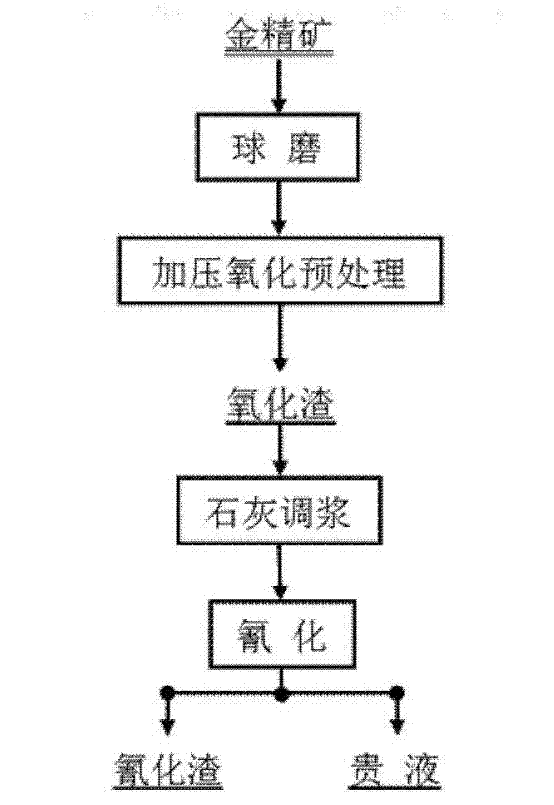

Pressurization, water immersion and oxidation preprocessing cyaniding gold extraction method for difficult-processing gold concentrates

A technology for refractory gold and pressurized water, applied in the field of metallurgy, can solve the problems that the manufacturing process and control technology level of the pressurized oxidation equipment cannot meet the requirements, and achieve the effect of reducing the process cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: The raw gold concentrate comes from a mine of Yunnan Gold Mining Group Co., Ltd. According to mineral analysis, the gold concentrate is a high-sulfur concentrate with a sulfur content of 38.28%. The main chemical composition analysis is shown in Table 1. Ball mill the raw gold concentrate to -0.074mm>90%, add sodium lignosulfonate 2‰, mix water with a liquid-solid ratio of 3:1, under the conditions of a temperature of 130°C, an oxygen partial pressure of 0.6MPa, and a stirring speed of 500rpm , pressurize the ore pulp for 3 hours in the reaction kettle to obtain oxidation slag, the oxidation slag is filtered and washed, mixed with water at a liquid-solid ratio of 2:1, added lime to adjust the slurry to pH = 11, and added potassium cyanide 5‰, The reaction time is 18 hours for cyanidation to extract gold, the precious metal enrichment enters the precious liquid, and the cyanide slag is processed in the next step. The gold content of the precious liquid is 0.0...

Embodiment 2

[0030] Example 2: The raw gold concentrate is a high-sulfur concentrate with a sulfur content of 37.47%. The analysis of its main chemical components is shown in Table 2. The raw gold concentrate is ball-milled to -0.045mm>90%, and sodium lignosulfonate is added at 2‰, and the slurry is mixed with water at a liquid-solid ratio of 6:1. At a temperature of 200°C, oxygen Under the conditions of pressure 1MPa and stirring speed 200rpm, oxidize the ore pulp in the reactor for 4 hours under pressure to obtain oxidized slag, the precious metals are left in the slag, the oxidized slag is filtered and washed, mixed with water at a liquid-solid ratio of 3:1, and added lime Mix slurry to pH=12, add sodium cyanide 2‰, and carry out cyanidation gold extraction after 48 hours of reaction time, the precious metal enrichment enters the solution, and the gold content of the precious solution is 0.015g / L, and the cyanide slag is piled up after being filtered and washed, and the gold The leach...

Embodiment 3

[0031] Example 3: The raw gold concentrate is a high-sulfur arsenic concentrate with a sulfur content of 23.06% and an arsenic content of 5.33%. The main chemical composition analysis of the gold concentrate is shown in Table 3. The raw gold concentrate was ball-milled to a particle size of -0.074mm>80%, and sodium lignosulfonate was added at 2‰, and the slurry was mixed with water at a liquid-solid ratio of 10:1. ℃, oxygen partial pressure 2MPa, stirring speed 450rpm, pressurized oxidation of the ore slurry in the reactor for 5 hours to obtain oxidation slag; the oxidation slag was filtered and washed, mixed with water at a liquid-solid ratio of 5:1, and added lime to adjust the slurry To pH = 12, add sodium cyanide 3‰, the reaction time is 72h to carry out cyanidation gold extraction, the precious metal is enriched into the solution, and the gold content of the precious solution is 0.021g / L. The cyanide slag was stored after being filtered and washed, and the gold leaching...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com