Cyanide leaching device for gold ore

A technology for cyanide leaching and gold mines, which is applied in the field of mining and metallurgical engineering, can solve the problems of limited suction speed, large space occupation, inability to meet the oxygen consumption of gold electrochemical reaction and adsorption oxygen consumption, etc., to achieve enhanced cyanide The effect of chemical leaching process and improving leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

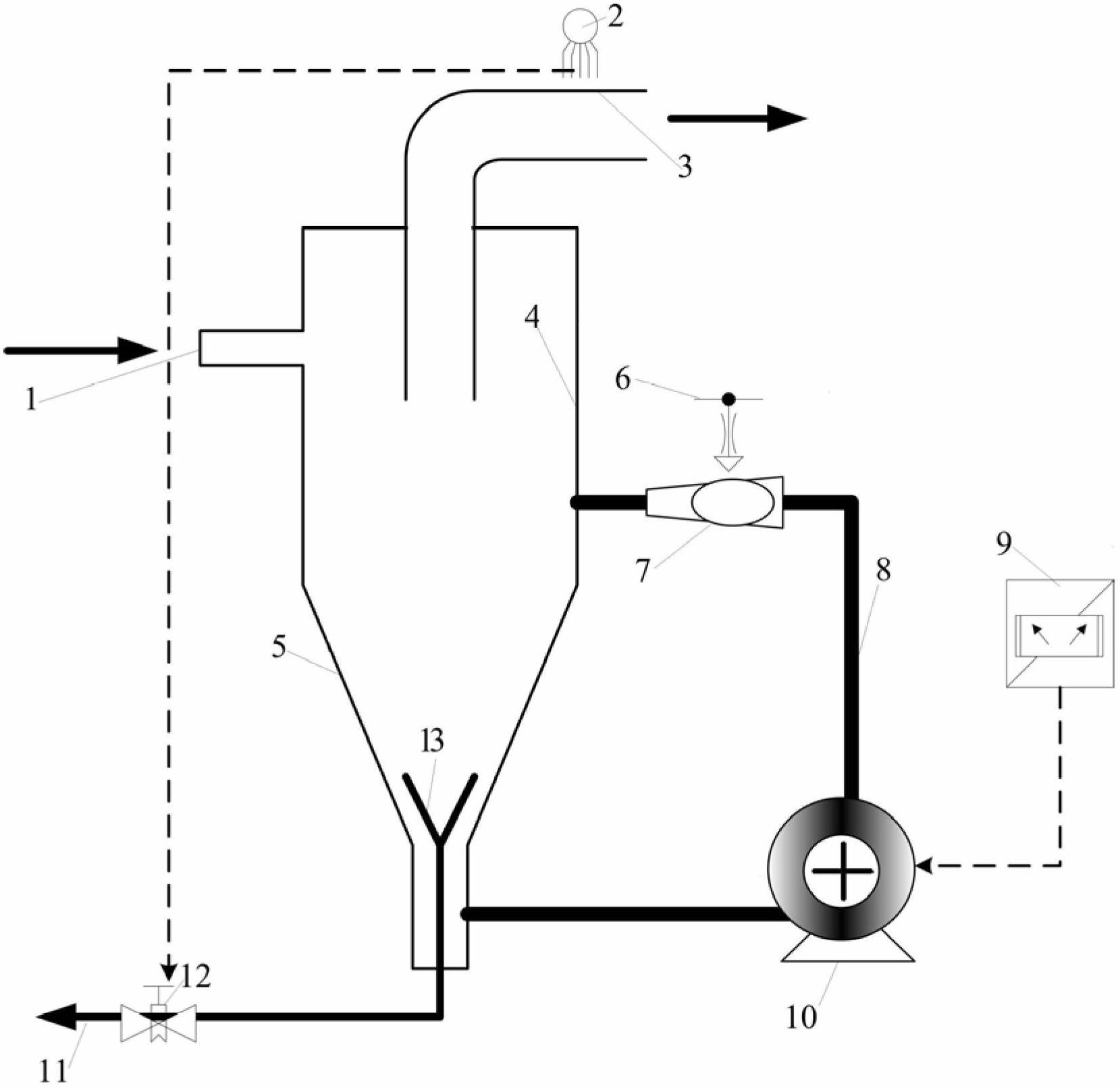

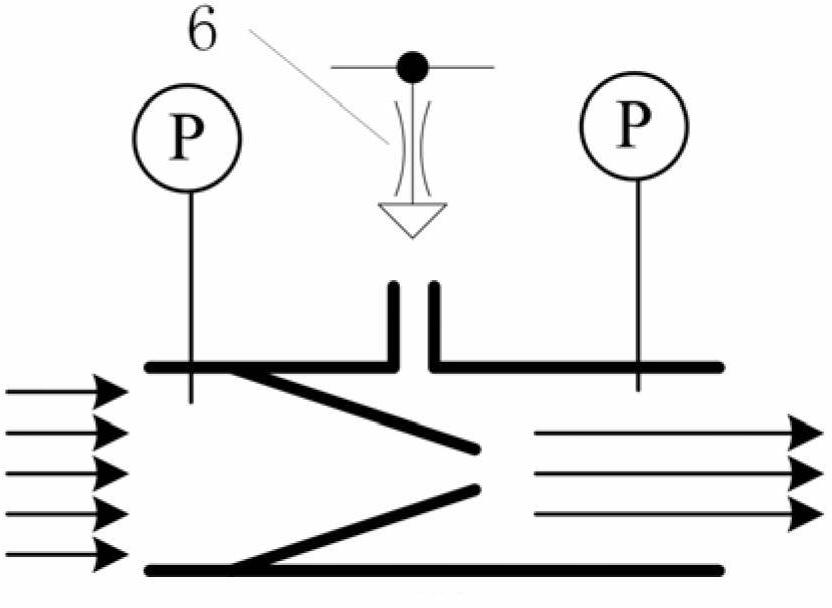

[0023] see figure 2 , 3, 4, the present invention comprises the cyclone leaching column that the upper end is a cylinder 4, the lower end is a cone 5, and the top and side walls of the cylinder 4 are respectively provided with an overflow ore discharge port 3 and an ore feed port 1, The ore inlet 1 is tangent to the cylinder 4, the lower end of the cone 5 is provided with a separation bottom cone 13, and the lower end of the separation bottom cone 13 is connected to the sand discharge outlet 11, and the cavity formed by the separation bottom cone 13 and the inner wall of the cone 5 The pipeline is connected to the circulation pump 10, the circulation pipeline 8, and the bubble generator 7 in turn. The outlet of the bubble generator 7 is connected to the cylinder 4 through the through hole on the side wall of the cylinder 4. The bubble generator 7 passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com