Comprehensive utilization method of cyanidation tailings

A technology for cyaniding tailings and filter residues, which is applied in the field of metallurgy and can solve problems such as high energy consumption, incomplete treatment, and secondary waste residue pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

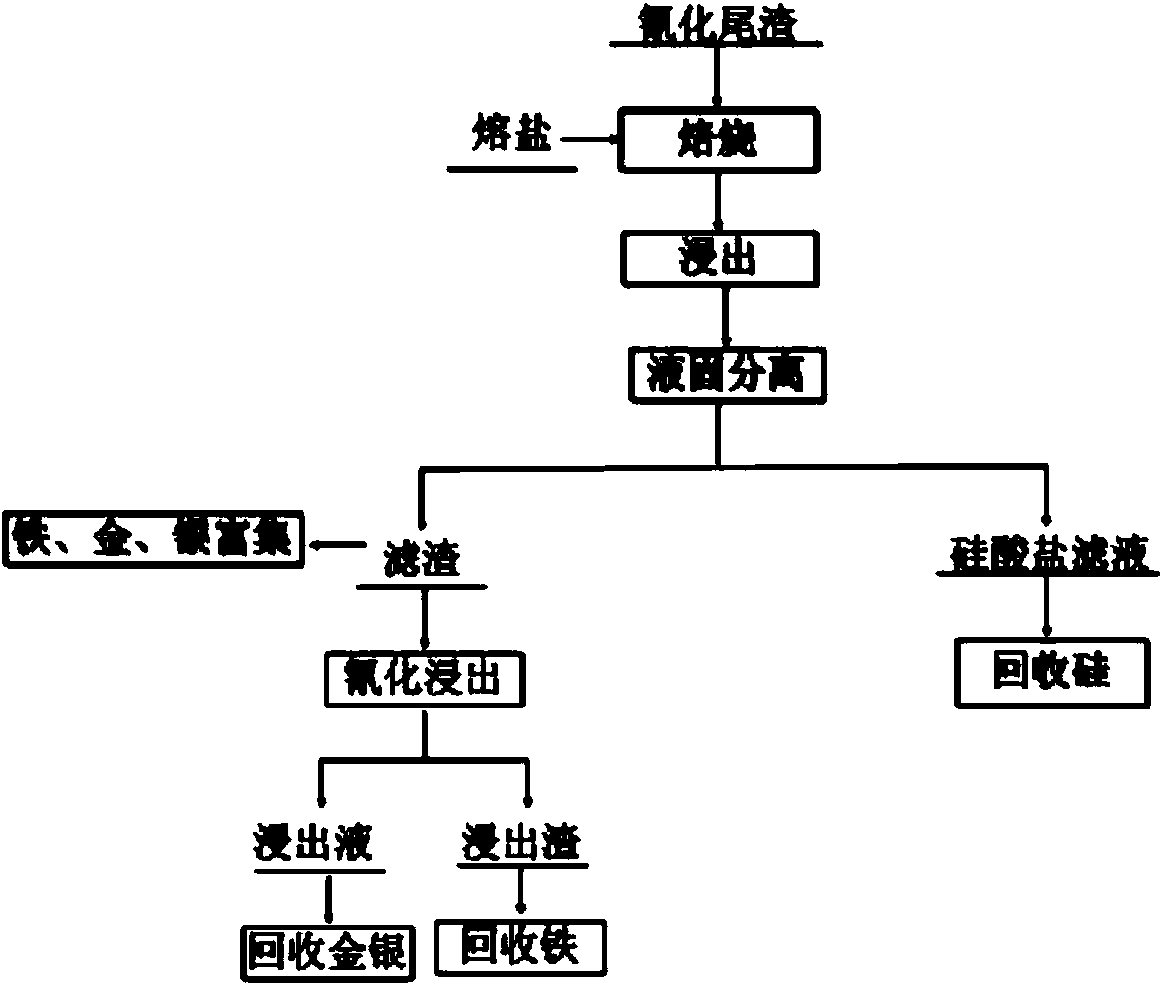

Method used

Image

Examples

Embodiment 1

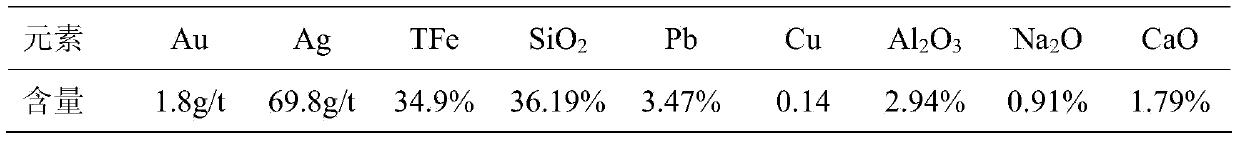

[0029] The molten salt system selected in this example is NaOH-NaCl-NaNO 3 , the molar ratio of each component in the molten salt system is 2:1:1, the molar ratio of Si and Na is 1:2, the cyanide tailings and molten salt are fully mixed and placed in a muffle furnace for roasting, the roasting temperature 700°C, calcination time 1h, water immersion, liquid-solid ratio 4:1, leaching time 20h, the leaching rate of SiO in cyanide tailings after liquid-solid separation reaches 84.5%.

[0030] Carry out conventional cyanide leaching to filter residue (leaching condition is liquid-solid ratio is 5:1, leaching time is 24h, the mass percentage concentration of cyanide (NaCN) is 0.5%), the recoveries of gold and silver are respectively 90.2% and 83.9% , and the TFe grade in the remaining slag reaches 50%, realizing the comprehensive recovery of valuable elements in the cyanide tailings.

Embodiment 2

[0032] Combined with the accompanying drawings, the molten salt system selected in this example is NaOH-NaF-NaNO 3 , the molar ratio of each component in the molten salt system is 2.2:1:1, the molar ratio of Si and Na is 1:5, the cyanide tailings and molten salt are fully mixed and placed in a muffle furnace for roasting, the roasting temperature 200°C, 4 hours after calcination, water immersion, liquid-solid ratio 6:1, leaching time 10 hours, SiO in cyanide tailings after liquid-solid separation 2 The leaching rate reaches 80.4%.

[0033] Carry out conventional cyanide leaching to filter residue, leaching condition is that liquid-solid ratio is 5:1, and leaching time is 24h, and the concentration of cyanide mass percentage is 0.5%, and the recoveries of gold and silver are respectively 81.7% and 79.4%, and TFe in the remaining slag The grade reaches 49%, which can basically realize the comprehensive recovery of valuable elements in cyanide tailings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com