Treatment method of heavy metal wastewater

A treatment method and technology for wastewater treatment, applied in water/sewage treatment, special compound water treatment, water/sludge/sewage treatment, etc., can solve the problems of slow precipitation, increased sludge production, and difficult recovery of heavy metals, etc. Achieve the effect of favorable recovery and fast settling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: A treatment method for heavy metal wastewater

[0047] The influent nickel-containing wastewater with a nickel concentration of 600mg / L is added to sodium sulfide solution, and the nickel-containing wastewater and sodium sulfide solution are reacted in the SBR reactor or reaction tank to generate particulate matter. The molar ratio of nickel and sulfur is used It is 1:1.2, stir for 5 minutes, and let stand for 2 hours.

[0048] It accelerates the rapid precipitation of small particles and other substances under the entrapment of particles, and realizes the evolution of wastewater treatment after standing.

Embodiment 2

[0049] Example 2: A treatment method for sequential batch heavy metal wastewater

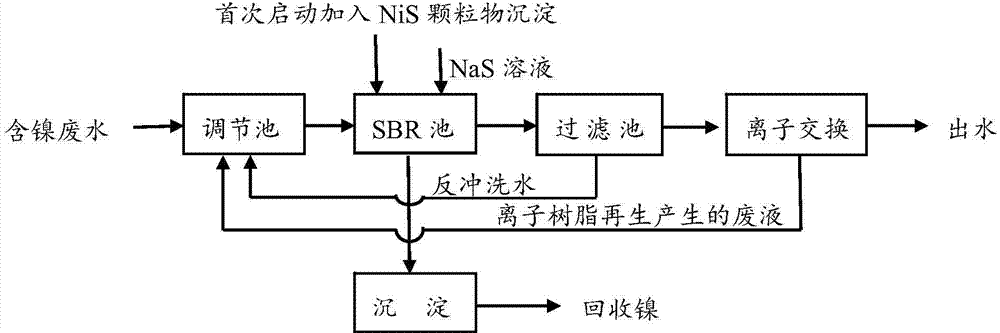

[0050] The influent nickel-containing wastewater with a nickel concentration of 600mg / L is added to sodium sulfide solution, and the nickel-containing wastewater and sodium sulfide solution are reacted in the SBR reactor or reaction tank to generate particulate matter. The molar ratio of nickel and sulfur is used Is 1:1.2, the system flow chart is as follows figure 1 Shown.

[0051] During the system start-up phase, nickel sulfide precipitated particles are added at a dosage rate of 10% of the solution volume. After the system is started, the sediment is used to remix. With this method, the sedimentation of the particles can significantly increase the sedimentation rate of other particles in the solution. Large particles can speed up the settling speed of small particles. After 30 minutes of precipitation, the supernatant obtained has a nickel concentration of 30-40 mg / L. The precipitated particles...

Embodiment 3

[0052] Example 3: A treatment method for sequential batch heavy metal wastewater

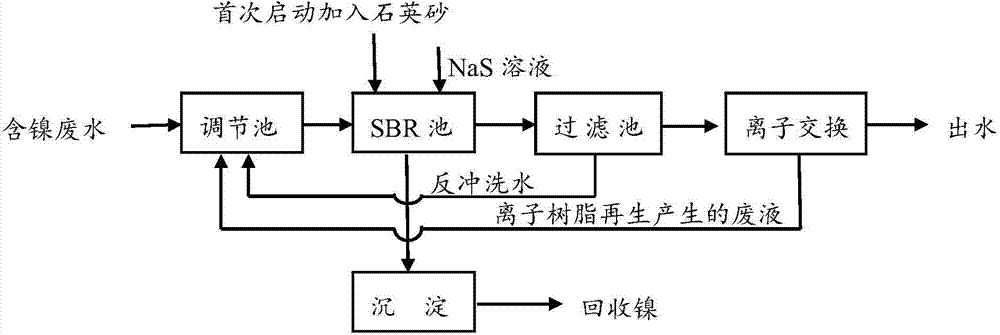

[0053] The influent nickel-containing wastewater with a nickel concentration of 600mg / L is added to sodium sulfide solution, and the nickel-containing wastewater and sodium sulfide solution are reacted in the SBR reactor or reaction tank to generate particulate matter. The molar ratio of nickel and sulfur is used Is 1:1.0, the system flow chart is as follows figure 2 Shown.

[0054] During the system startup phase, add quartz sand at a dosage rate of 30% of the solution volume. After the system is started, use the bottom mud to remix. Using this method, the sedimentation of particles can significantly increase the sedimentation rate of other particles in the solution. Particles can accelerate the sedimentation rate of small particles. After 30 minutes of precipitation, the supernatant obtained has a nickel concentration of 30-40 mg / L. The precipitated particles are beneficial to the recycling of n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com