Internal-gear-type oil pump for vehicle

An internal meshing, gear-type technology, applied in the direction of rotary piston pump, pump, rotary piston type/oscillating piston type pump components, etc. Insufficient pressure balance and other problems to achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

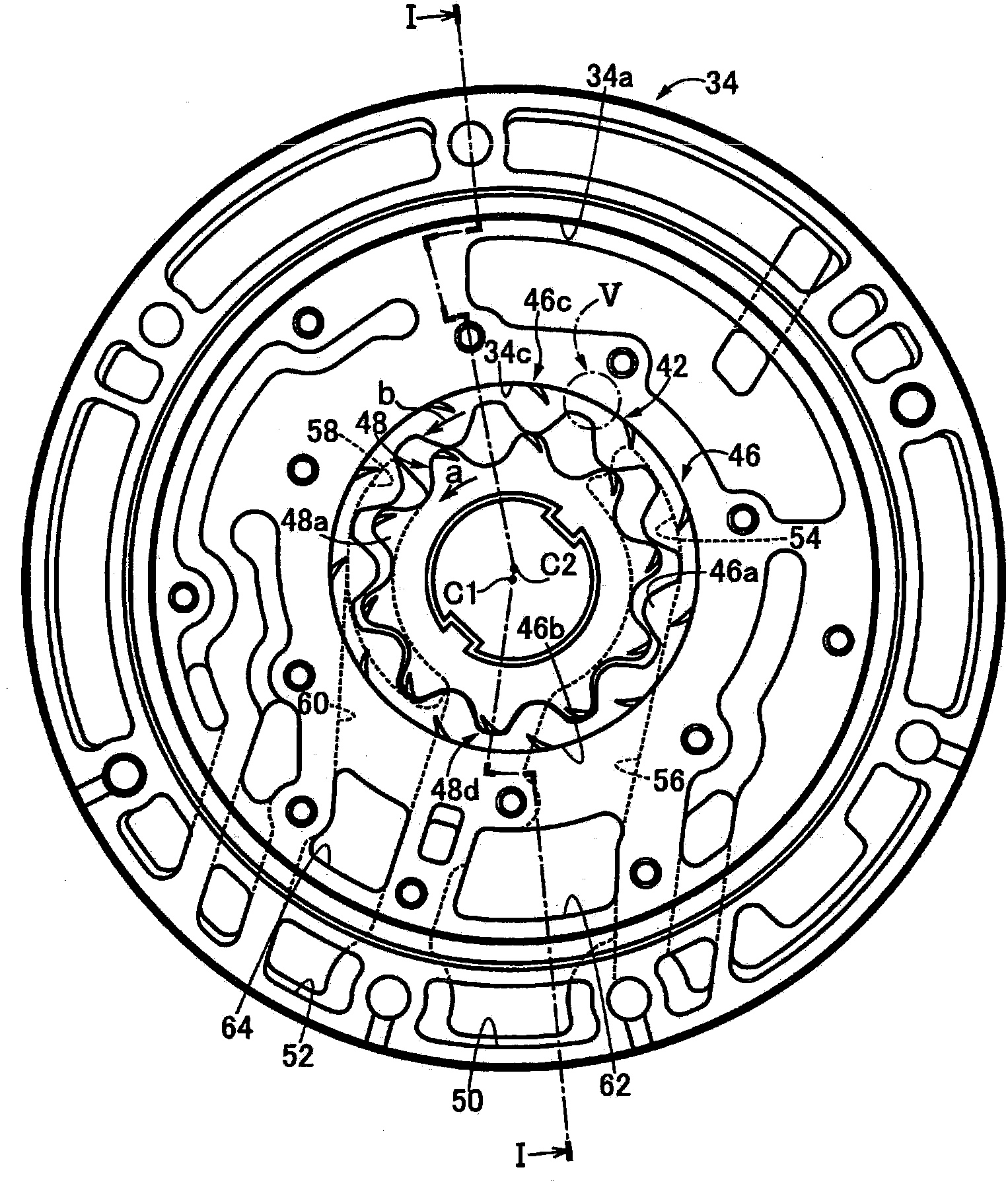

[0048] figure 1 It is a partial sectional view showing a part of a vehicle power transmission device 12 including a vehicle internal gear oil pump (hereinafter, referred to as an oil pump) 10 according to an embodiment of the present invention. The vehicle power transmission device 12 includes a torque converter 16 provided at a rear stage of a crankshaft 14 of an engine serving as a drive source of the vehicle, and a stepped automatic transmission 18 .

[0049] exist figure 1 Among them, the torque converter 16 includes: a pump impeller 20 connected to the crankshaft 14 capable of transmitting power; The input shaft 22 and the stator impeller 28 are disposed between the pump impeller 20 and the turbine impeller 24 and are rotatably supported via the one-way clutch 26 . In the torque converter 16 configured in this way, the rotation of the pump impeller 20 integrally rotating with the crankshaft 14 is transmitted to the turbine impeller 24 via the working fluid. Here, the p...

Embodiment 2

[0104] Next, other embodiments of the present invention will be described. In addition, in the following description, the same code|symbol is attached|subjected to the common part between embodiment, and description is abbreviate|omitted.

[0105] Compared with the oil pump 10 of the first embodiment, the oil pump of this embodiment differs only in that the shape of the first dynamic pressure generating groove 46i is different from that of the first dynamic pressure generating groove 46c of the first embodiment, and the other configurations are substantially the same. .

[0106] like Figure 18 As shown, the depth D1 in the radial direction of the driven gear 46 of the first dynamic pressure generating groove 46i is set so as to extend from the deepest part of the first dynamic pressure generating groove 46i to the inside of the pump body 34, as in the first embodiment. The gap ratio m1 (=h1 / h2), which is the ratio of the distance h1 of the gap H1 on the peripheral surface 3...

Embodiment 3

[0109] Compared with the oil pump 10 of the first embodiment, the oil pump of this embodiment differs only in that the shape of the first dynamic pressure generating groove 46k is different from that of the first dynamic pressure generating groove 46c of the first embodiment, and the other configurations are substantially the same. .

[0110] like Figure 19 As shown, the depth D1 in the radial direction of the driven gear 46 of the first dynamic pressure generating groove 46k is set so as to extend from the deepest part of the first dynamic pressure generating groove 46k to the inside of the pump body 34, as in the first embodiment. The gap ratio m1 (=h1 / h2), which is the ratio of the distance h1 of the gap H1 on the peripheral surface 34c to the distance h2 of the gap H2 from the outer peripheral surface 46b of the driven gear 46 to the inner peripheral surface 34c of the pump body 34, is predetermined. In the range.

[0111] like Figure 19 As shown, the outer peripheral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com