Stackable semiconductor encapsulation construct for multi-cylinder body

A semiconductor and structural technology, which is applied in the framework of high-density package stacking modules and the field of stackable semiconductor package structure, can solve the problems of reducing crack growth and complicating the shape of welding interface, so as to reduce crack growth and increase the reliability of solder joints , The effect of high welding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

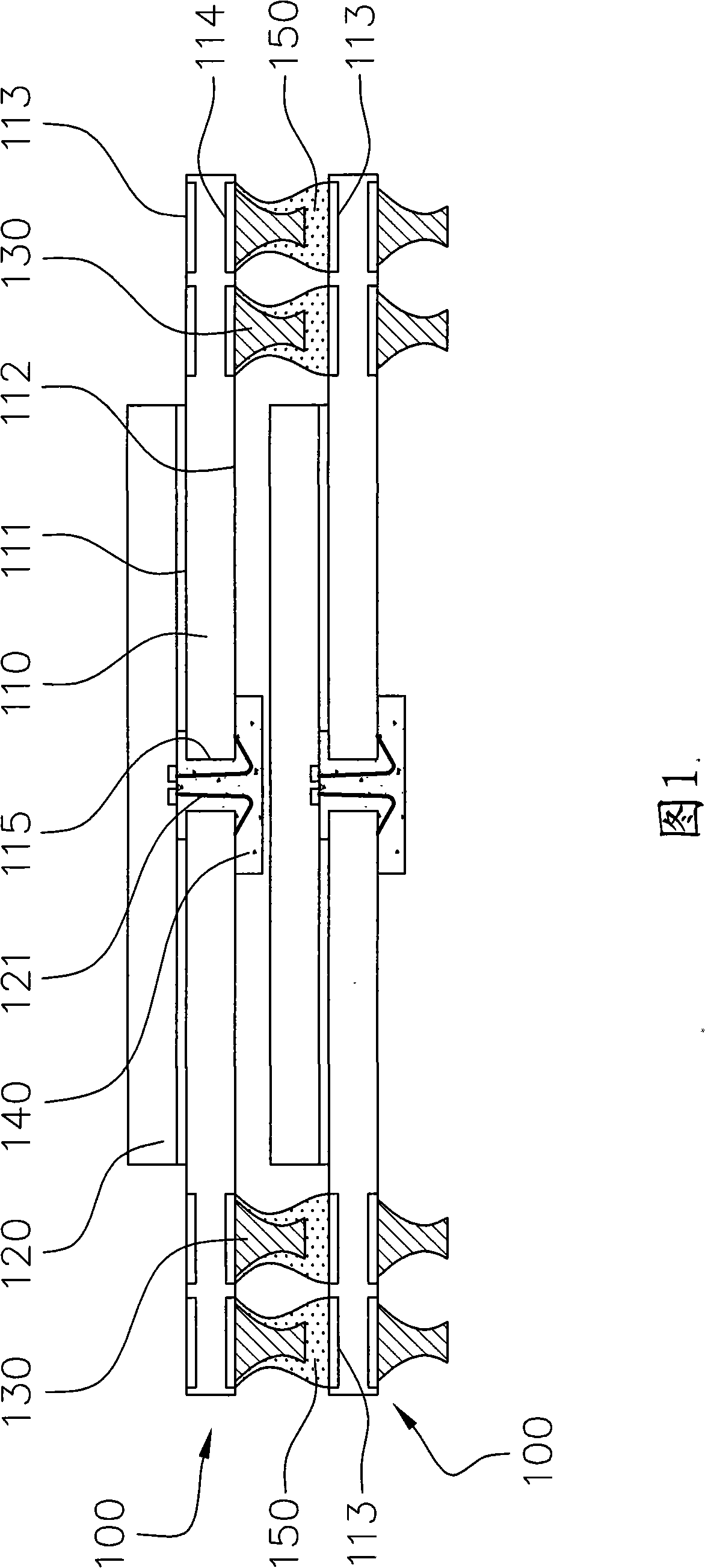

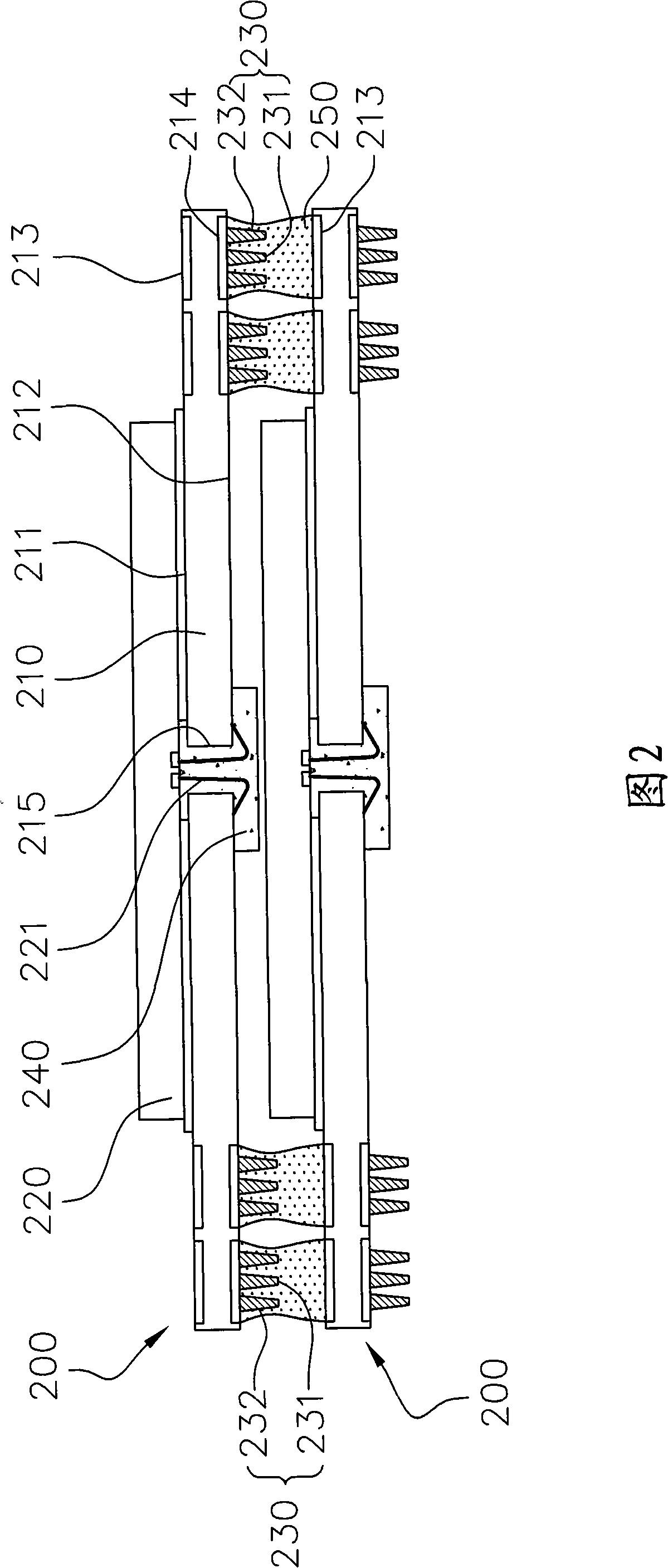

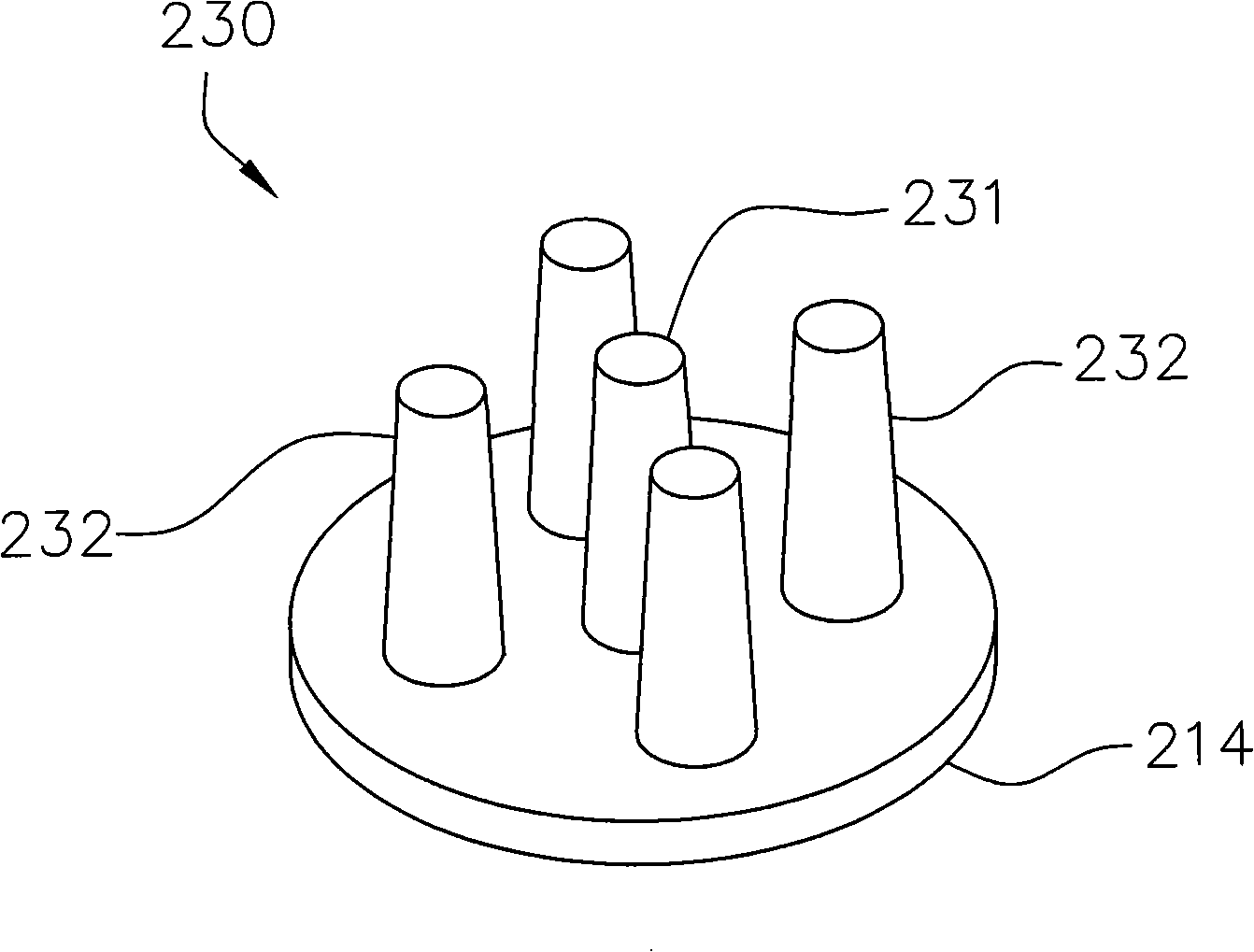

[0080] According to the first specific embodiment of the present invention, a multi-pillar stackable semiconductor package structure is disclosed. Please refer to FIG. 2, which is a schematic cross-sectional view of a stackable semiconductor package structure with multiple pillars stacked on each other according to the first embodiment of the present invention, which is a stack combination of two stackable semiconductor package structures 200, but Without limitation, more stackable semiconductor packaging structures 200 may be stacked on top, for example, three, four or more. Each stackable semiconductor package structure 200 mainly includes a chip carrier 210, a chip 220, and a plurality of lower bump groups 230.

[0081] The chip carrier 210 may be a multilayer printed circuit board with a structure with electrical conduction on both sides. The chip carrier 210 has an upper surface 211 and a lower surface 212, wherein the upper surface 211 is provided with a plurality of transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com