Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102 results about "Tungsten target" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

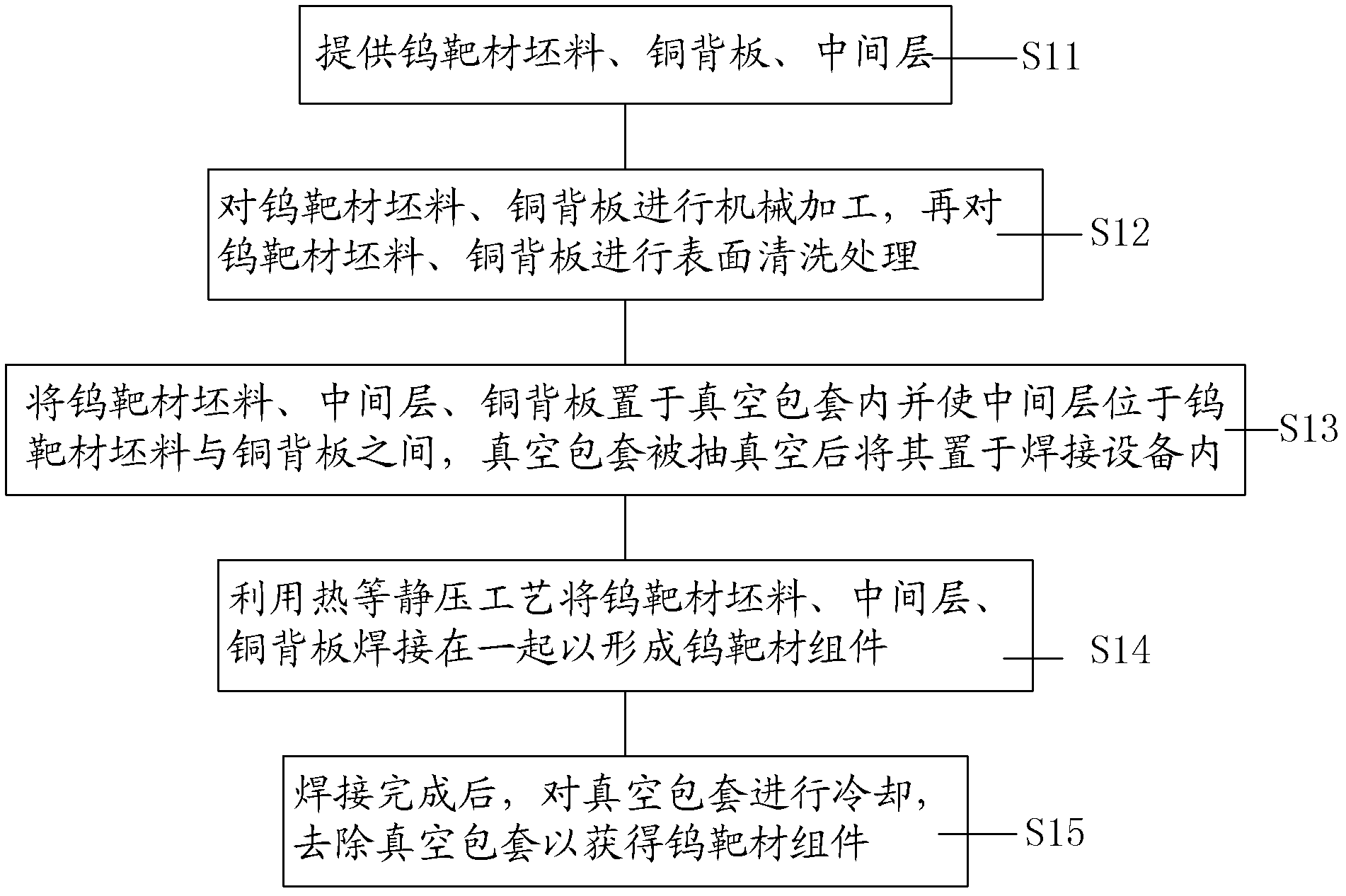

Welding method of tungsten target assembly

InactiveCN102500908APrevent oxidationNo falling offNon-electric welding apparatusCopperBond strength

The invention provides a welding method of a tungsten target assembly, which comprises the following steps of: providing a tungsten target blank and a copper back plate between which an intermediate layer is additionally arranged; placing the tungsten target blank, the intermediate layer and the copper back plate in a vacuum sheath, so that the intermediate layer is positioned between the tungsten target blank and the copper back plate, and the vacuum sheath is placed in welding equipment; welding materials to be welded together by a hot isostatic pressing process to form the tungsten target assembly; and after the ompletion of welding, carrying out cooling, and removing the vacuum sheath to obtain the tungsten target assembly. By additionally arranging the intermediate layer between the tungsten target blank and the copper back plate and welding the tungsten target blank and the copper back plate together by utilizing the hot isostatic pressing process, the large-area welding can be realized, and the surface of the welding material can be prevented from being oxidized because the whole welding process is in a vacuum environment; and in addition, in the formed tungsten target assembly, the bond rate and the bond strength of the tungsten target blank and the copper back plate are higher, and the deformation is small after the tungsten target blank and the copper back plate are welded together.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

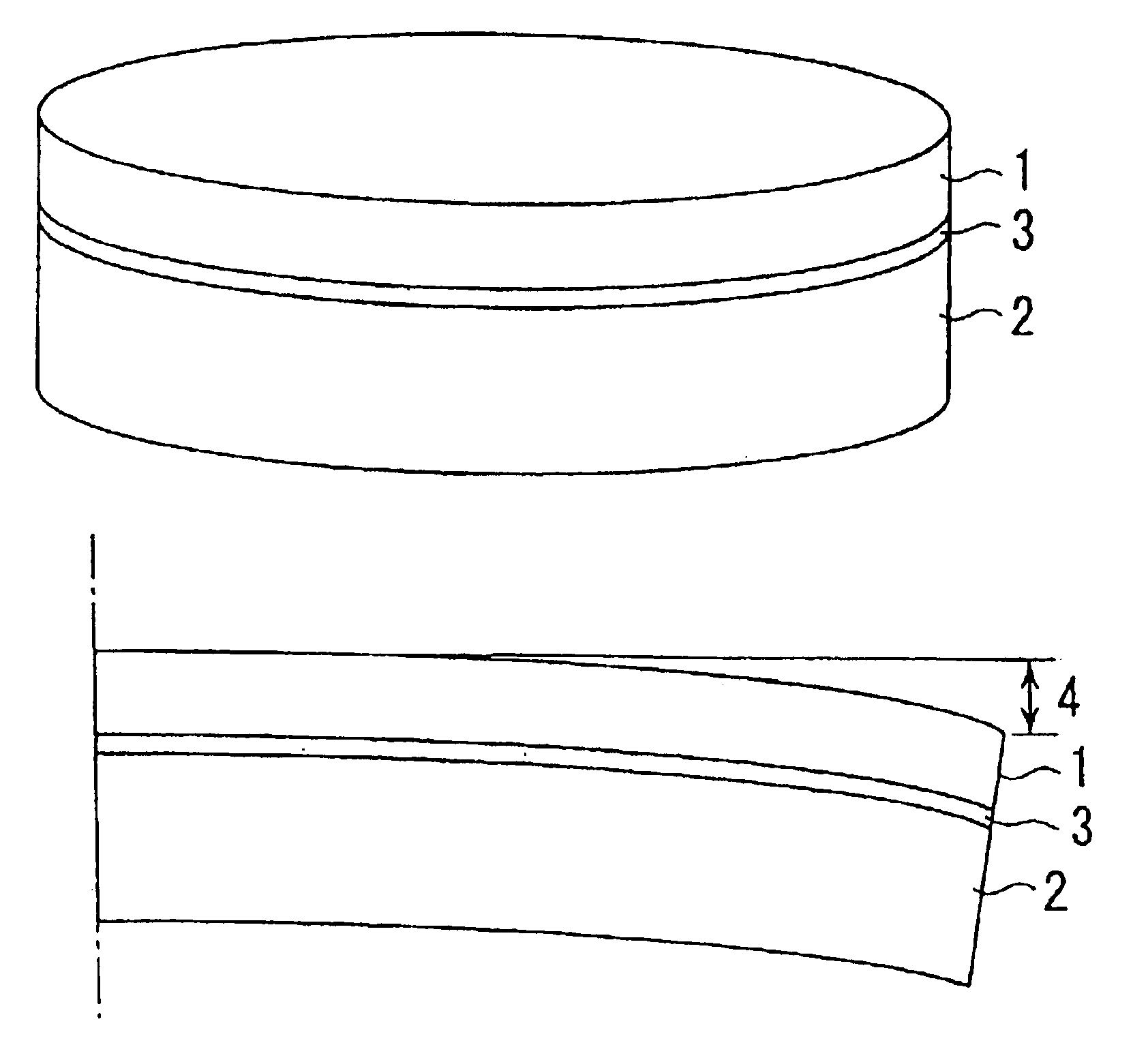

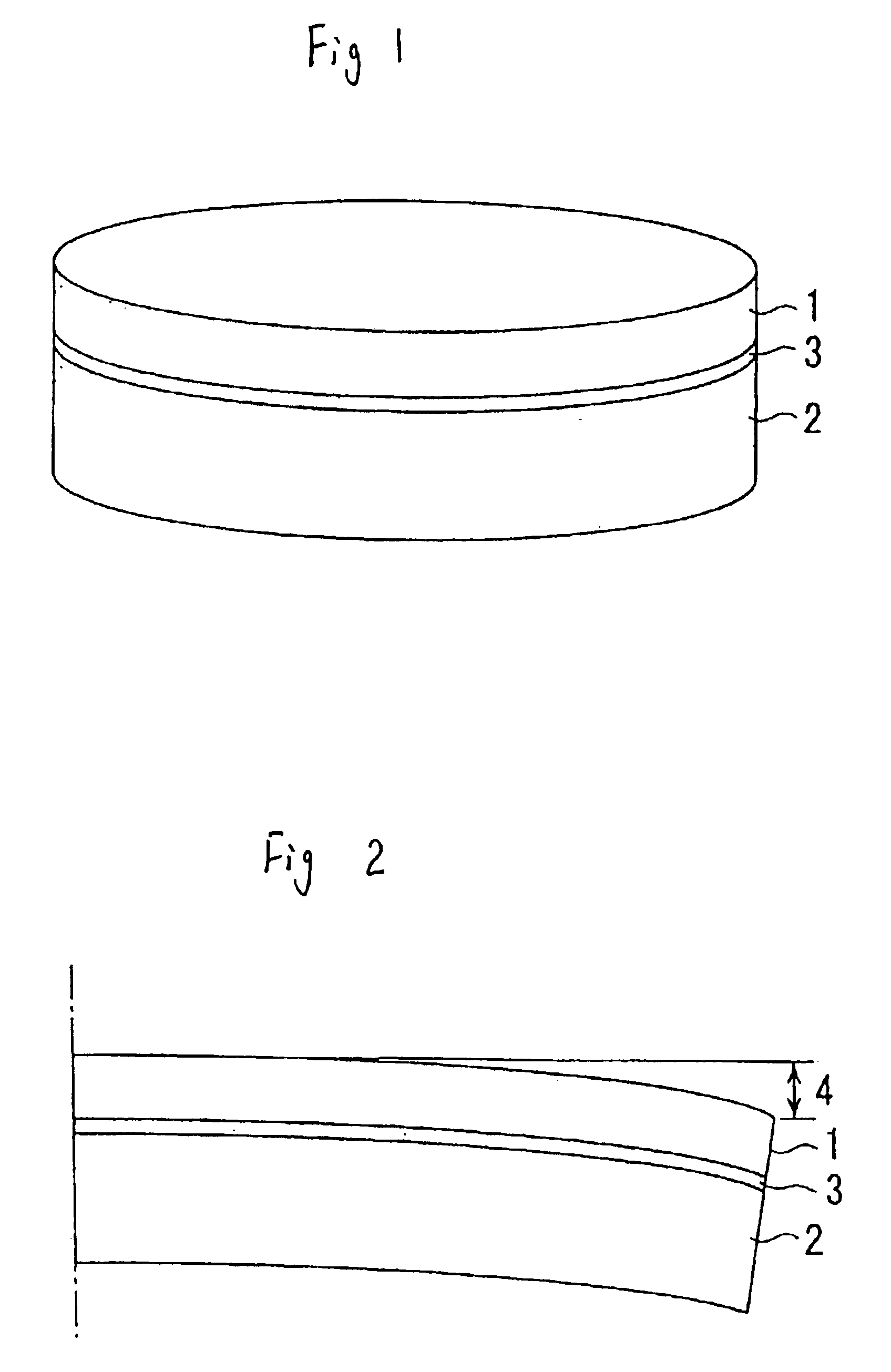

Tantalum or tungsten target-copper alloy backing plate assembly and production method therefor

InactiveUS6759143B2Small overall deformationSurviving high power sputteringVacuum evaporation coatingSputtering coatingSputteringBond interface

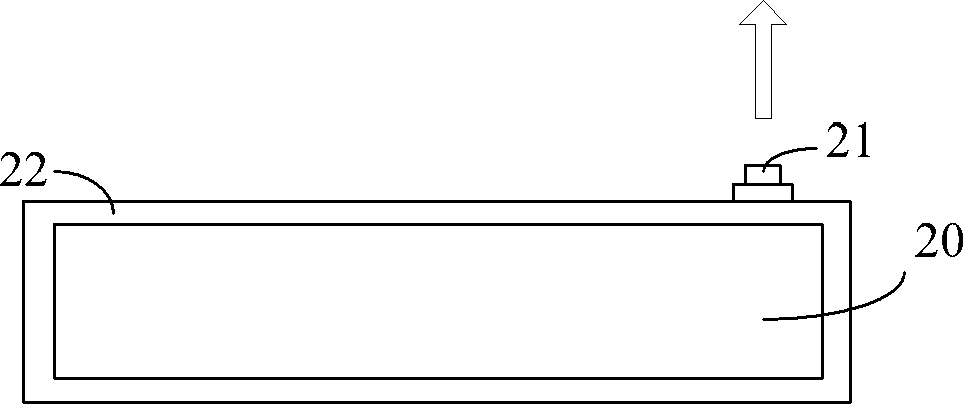

A tantalum or tungsten target-backing plate assembly which comprises a tantalum or tungsten target and a copper alloy backing plate that are subject to diffusion bonding via an aluminum- or aluminum alloy-sheet insert material at least 0.5 mm thick, and which is provided with diffusion bonded interfaces between the respective materials, wherein the assembly suffers only a small deformation after diffusion bonding and is free from separation between the target and the backing plate or from cracking even when the target material and the backing plate differ greatly in thermal expansion, and can survive high power sputtering; and a production method therefor.

Owner:JX NIPPON MINING & METALS CO LTD

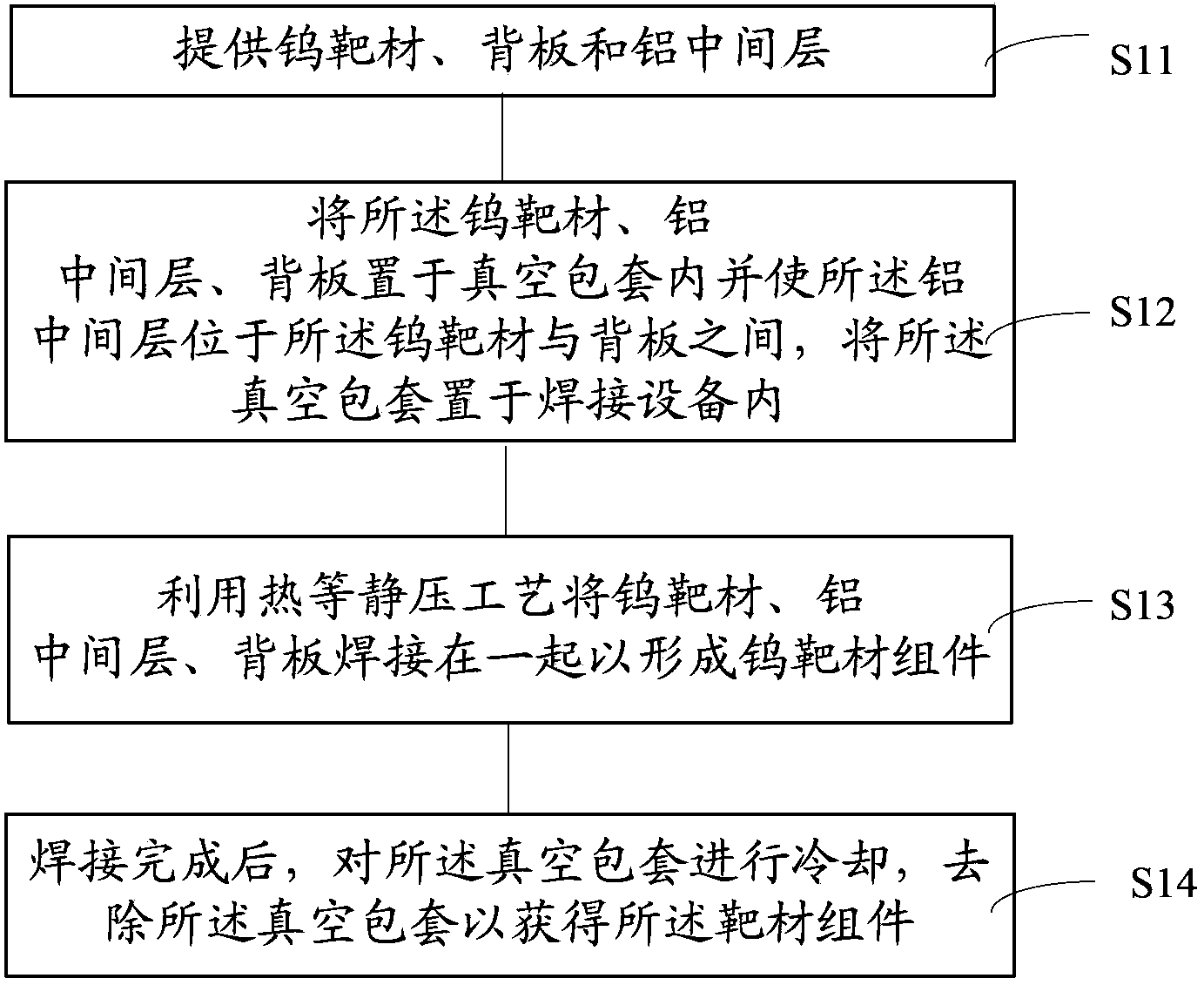

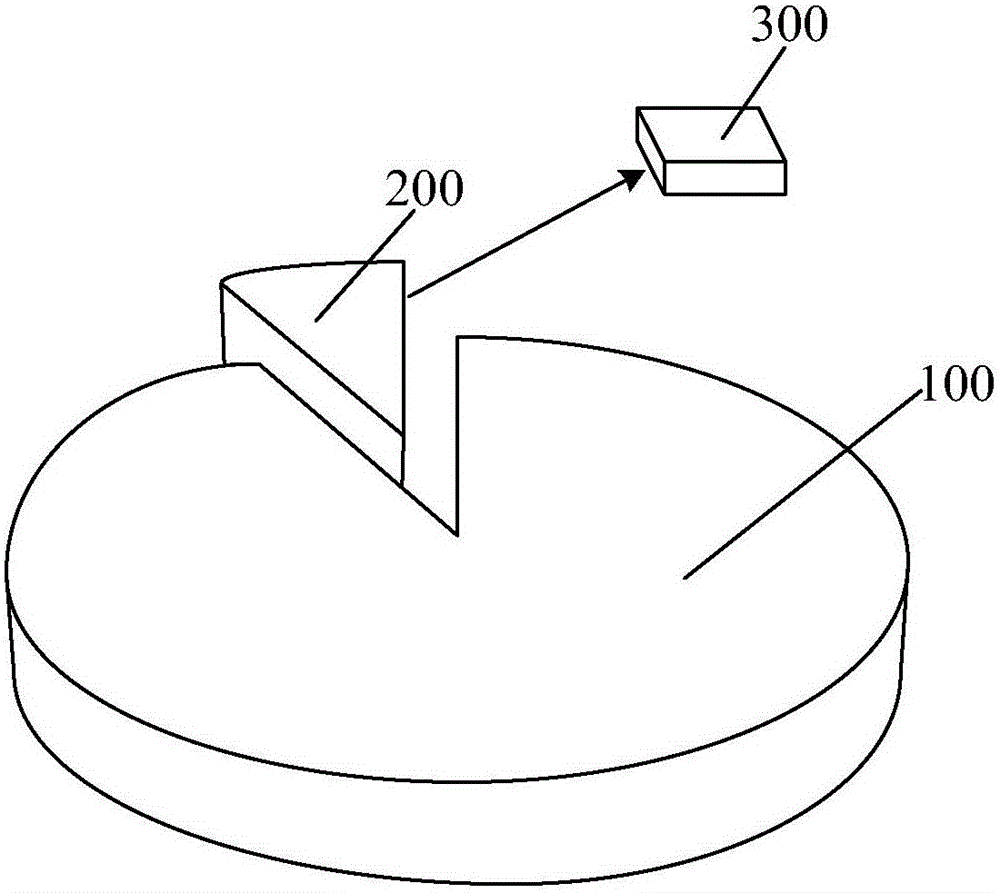

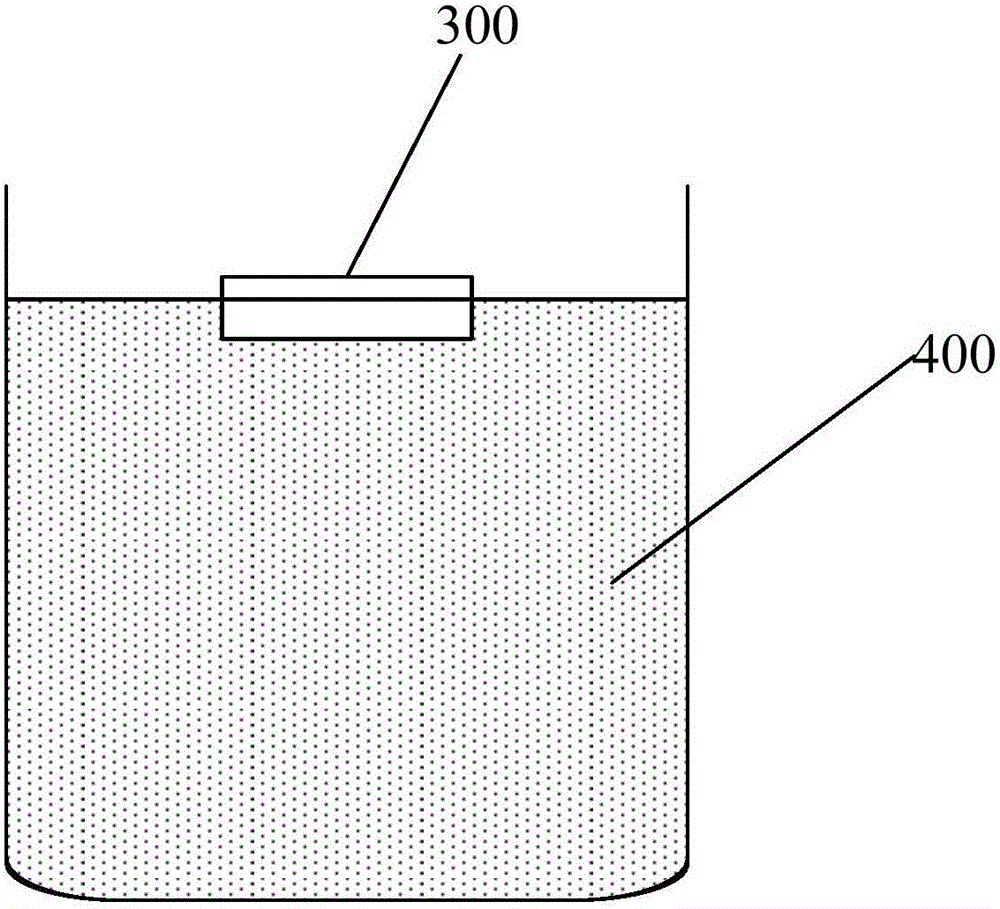

Method for target material component welding

InactiveCN103521916AEasy to spreadAvoid the disadvantage of not being able to realize large-size target weldingNon-electric welding apparatusWeld strengthUltimate tensile strength

The invention provides a method for target material component welding. The method comprises the following steps that a tungsten target material, a back board and an aluminum middle layer are provided; the tungsten target material, the aluminum middle layer and the back board are placed in a vacuum bag, the aluminum middle layer is located between the tungsten target material and the back board, and the vacuum bag is arranged in a welding device; the hot isostatic pressure technology is used for welding the tungsten target material, the aluminum middle layer and the back board together to form a target material component; after welding is completed, the vacuum bag is cooled and removed, so that the target material component is obtained. Due to the fat that the aluminum middle layer is additionally arranged between the tungsten target material and the back board, and the hot isostatic pressure technology is used for welding the tungsten target material and the back board together, welding efficiency is improved, the formed target material component is good in welding binding rate, high in welding strength and small in deformation, large-area welding can be achieved, and therefore the requirements for long-term stable production and using of target materials can be met.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

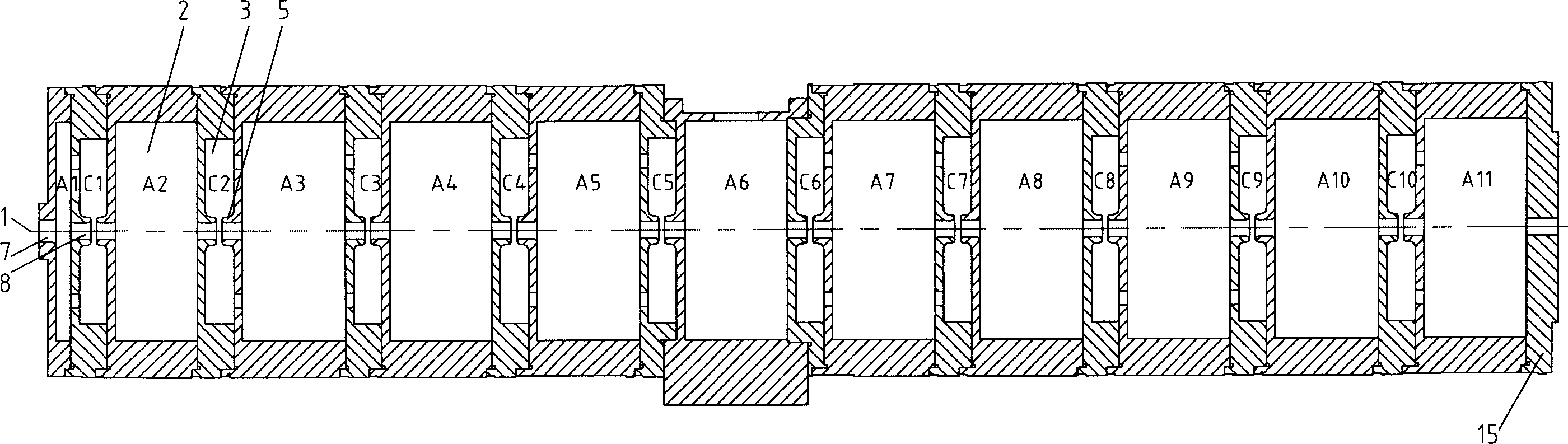

Standing wave electronic straight line accelerator

The invention provides a standing wave electron linear accelerator comprising accelerating chamber, coupling resonator, electron gun, microwave coupler, nose cone, titanium getter pump, thermostatic water jacket and tungsten target, wherein the nose cone is canceled from the accelerating chamber to be arranged in the couple resonator, two nose cones are arranged for each couple resonator on the front and rear end surfaces of the couple resonator. The accelerator by the present invention lowers the radial electric field intensity in the accelerating chamber, and maximize the output dosage. íí

Owner:SICHUAN DNDR DIGITAL RADIOGRAPHY TECH

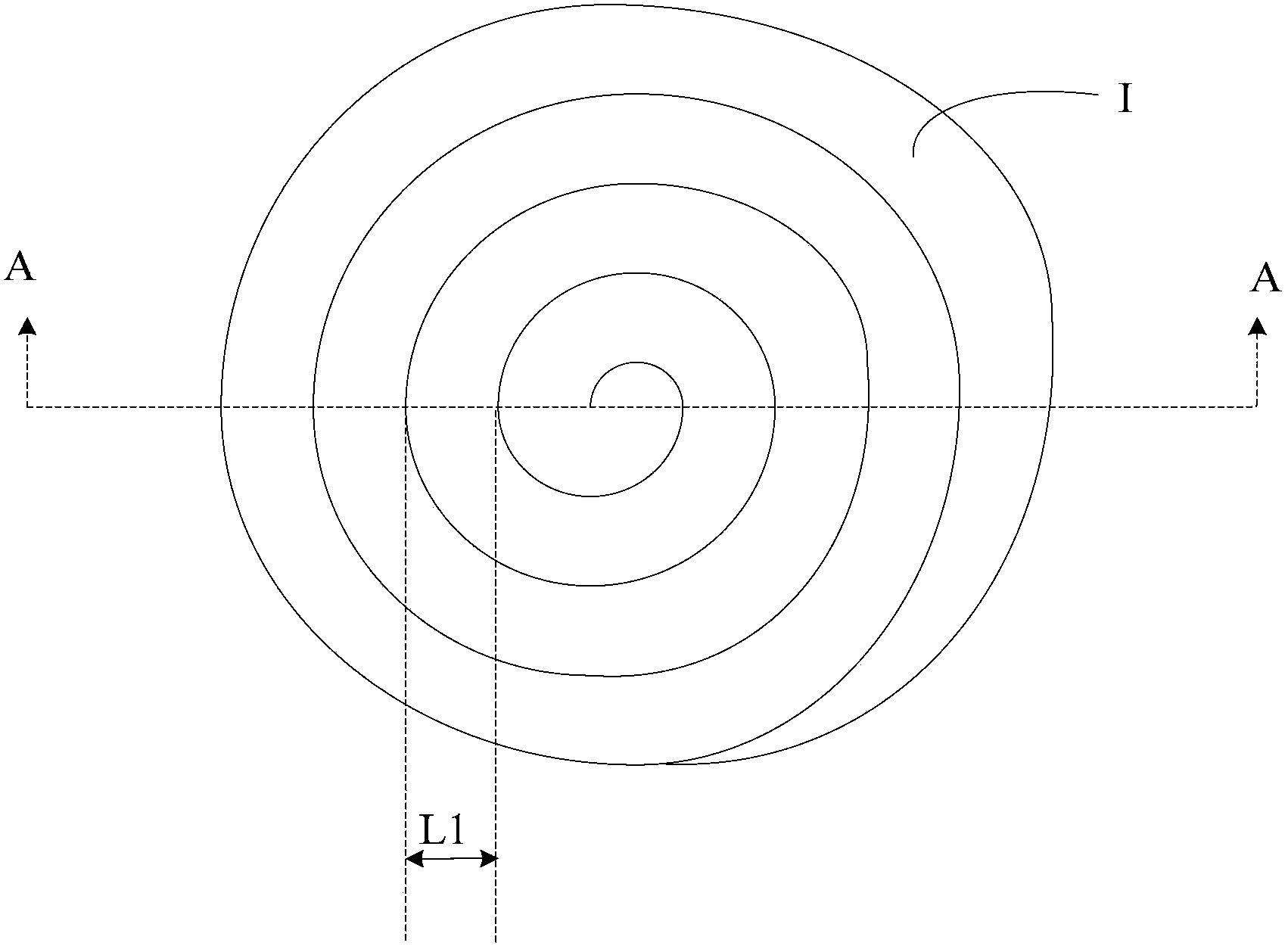

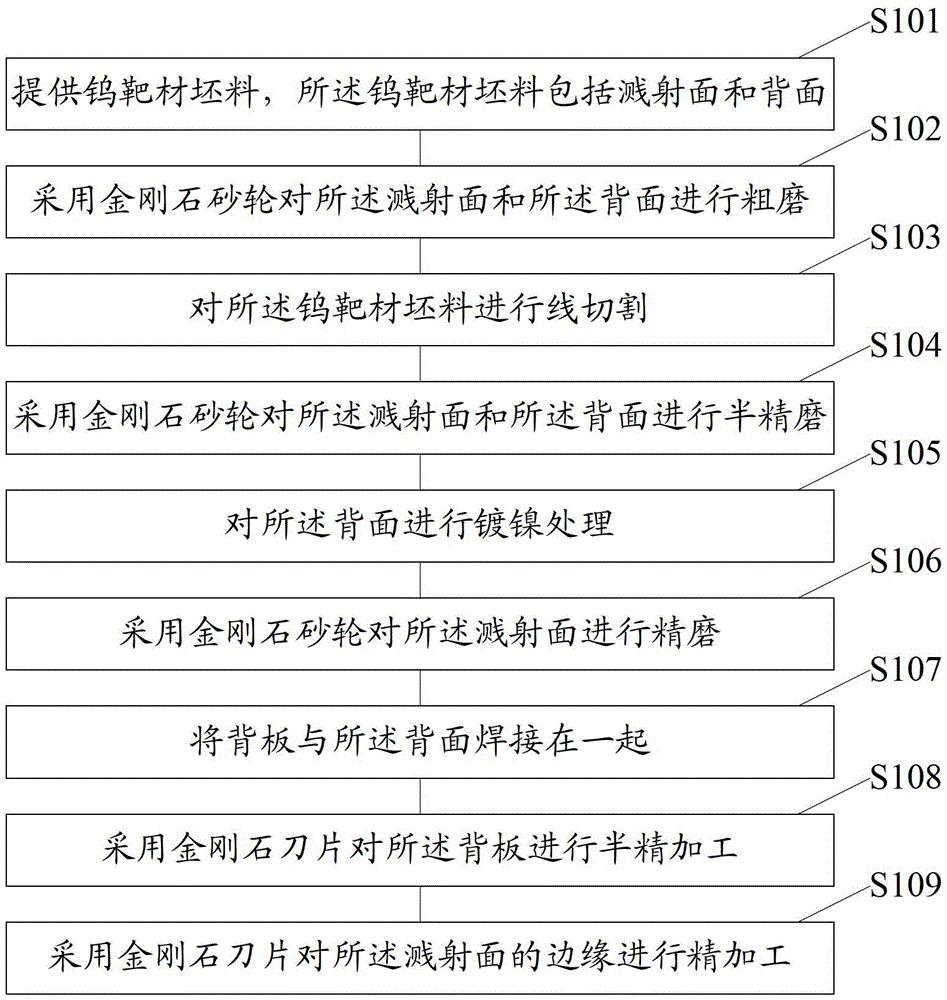

Manufacturing method of tungsten target

ActiveCN104416325AQuick Correction of ThicknessImprove production efficiencyVacuum evaporation coatingSputtering coatingSurface roughnessMachining process

Disclosed is a manufacturing method of a tungsten target. The manufacturing method of the tungsten target comprises providing a tungsten target blank, wherein the tungsten target blank comprises a sputtering surface and a back surface; rough-grinding the sputtering surface and the back surface through a diamond grinding wheel; performing accurate semi-grinding on the sputtering surface and the back surface through the diamond grinding wheel; performing accurate grinding on the sputtering surface through the diamond grinding wheel. The manufacturing method of the tungsten target can reduce or avoid edge failure of the tungsten target blank during the machining process to obtain the tungsten target high in dimensional precision, low in surface roughness and capable of meeting the sputtering performance, and meanwhile, can reduce losses of tools during the machining process of the tungsten target blank and further reduce the machining cost of the tungsten target.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

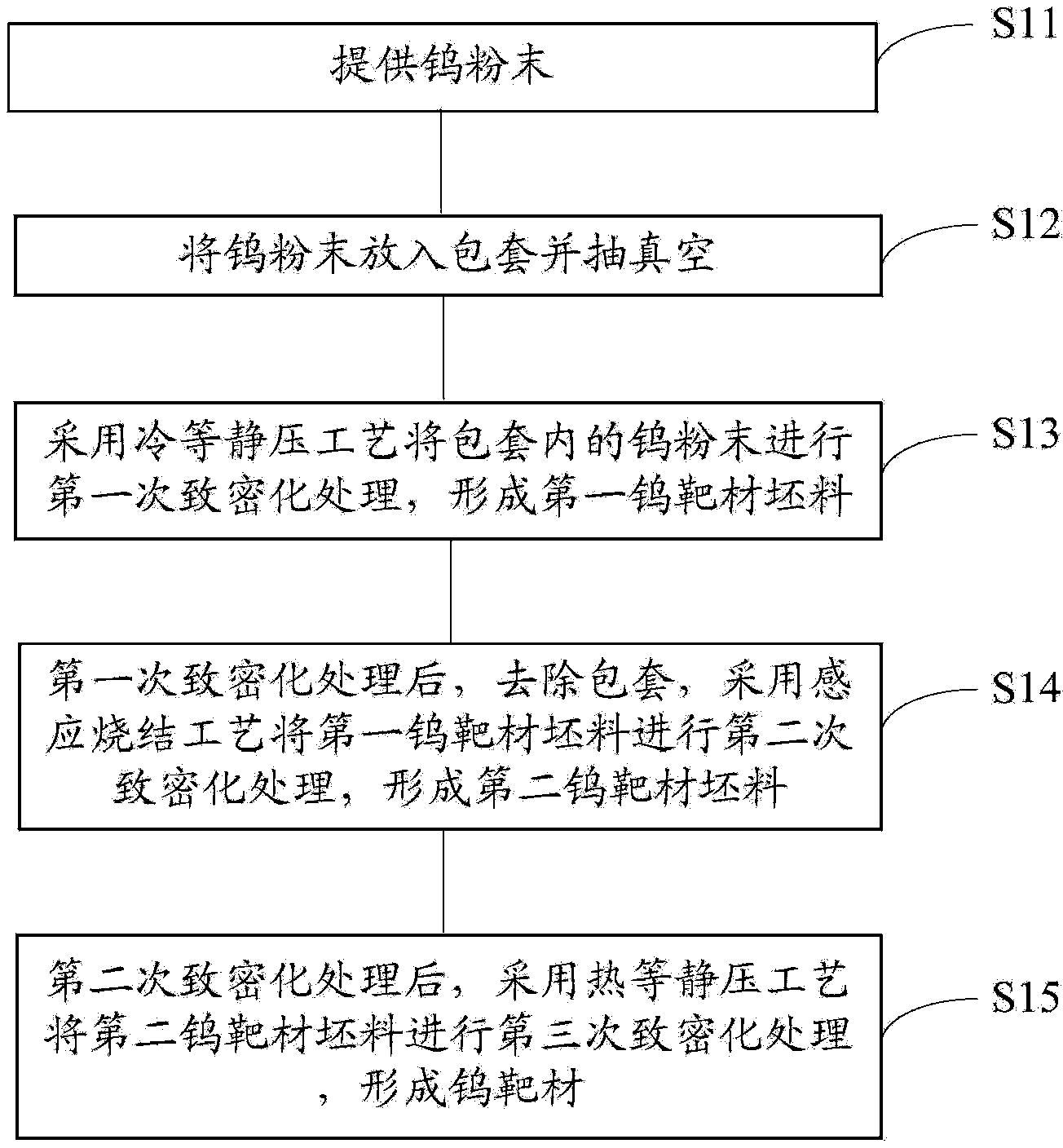

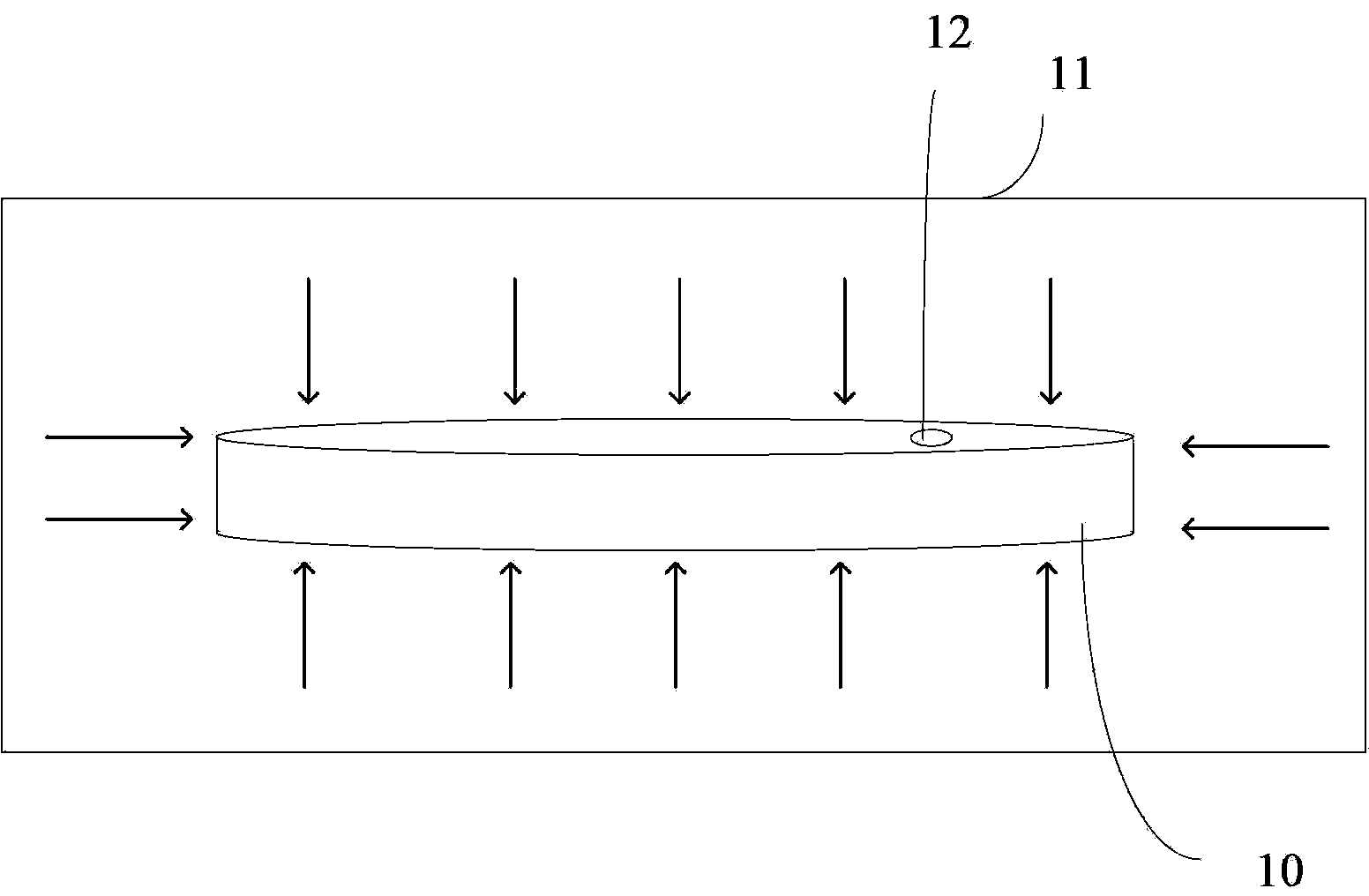

Tungsten target manufacturing method

ActiveCN103567444APrevent oxidationAvoid mutual contaminationVacuum evaporation coatingSputtering coatingVacuum pumpingVolumetric Mass Density

A tungsten target manufacturing method comprises the steps of providing tungsten powder; placing the tungsten powder in a package sleeve and performing vacuum pumping; adopting a cold isostatic pressing to enable the tungsten powder in the package sleeve to undergo primary densifying processing, and forming primary tungsten target blank; after the primary densifying processing, removing the package sleeve, adopting an induction sintering process to enable the primary tungsten target blank to undergo secondary densifying processing, and forming secondary tungsten target blank; after the secondary densifying processing, adopting a hot isostatic pressing process to enable the secondary tungsten target blank to undergo third-time densifying processing, and forming a tungsten target. The tungsten target with the full density of over 99.4% can be manufactured through the tungsten target manufacturing method; and the uniformity of the internal organizational structure and the grain size of the tungsten target meet a sputtering process with the requirement higher and higher.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

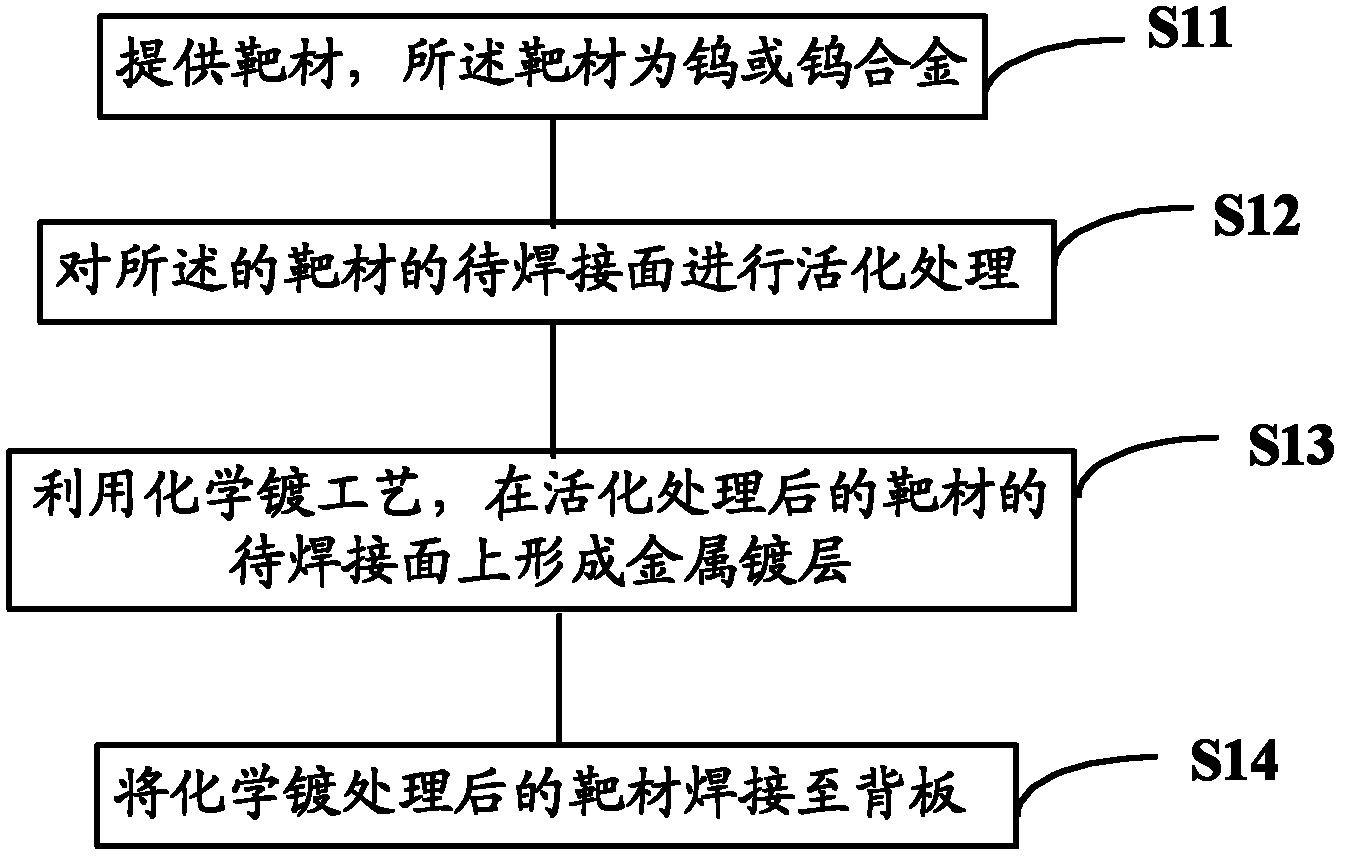

Manufacture method of target structure

InactiveCN102586743AHigh bonding strengthRealize industrial productionVacuum evaporation coatingSputtering coatingMetal coatingChemical plating

The invention relates to a manufacture method of a target structure, which includes providing a target such as tungsten or a tungsten alloy; conducting activating treatment on a face to be welded of the target; forming a metal coating on the face to be welded of the target after activating treatment; and welding the target after chemical plating treatment to a back panel. The metal coating is formed on a face to be welded of a tungsten target or a tungsten alloy target through chemical plating, the metal coating is used as an intermediation, firm combination of the target and the back panel is achieved after the target and the back panel are welded, and high combination strength is achieved. The manufacture method explores a stable technological process of plating the metal coating through the chemical plating method on the face to be welded of the tungsten target or the tungsten alloy target and achieves industrialized production.

Owner:余姚康富特电子材料有限公司

Tungsten Sintered Sputtering Target

InactiveUS20110094879A1Avoid abnormal grain growthImprove production yieldCellsElectric discharge tubesAbnormal grain growthImpurity

Provided is a tungsten sintered sputtering target, wherein the phosphorus content is 1 wtppm or less and the remainder is other unavoidable impurities and tungsten. The inclusion of phosphorus heavily affects the abnormal grain growth of tungsten and the deterioration in the target strength. In particular, if phosphorus is contained in an amount exceeding 1 ppm, crystal grains subject to abnormal grain growth will exist in the tungsten target. Thus, the object is to prevent the abnormal grain growth of tungsten and improve the product yield of the target by strongly recognizing the phosphorus contained in the tungsten as a harmful impurity and controlling the inclusion thereof to be as low as possible.

Owner:JX NIPPON MINING & METALS CO LTD

Method for manufacturing composite film gas sensor

InactiveCN101824603AImprove physical propertiesGood chemical propertiesVacuum evaporation coatingMaterial analysis by electric/magnetic meansPlatinumComposite film

The invention relates to the technical field of manufacturing gas sensors, in particular to a method for manufacturing a composite film gas sensor. The method is characterized by comprising the following steps of: 1, performing acid treatment on MWCNT, then adding and dispersing the MWCNT into an organic solvent, treating the mixture to obtain a fully-mixed suspension, and spin-coating the suspension to a tin target and a tungsten target of a radio frequency reaction magnetron sputtering device respectively; 2, manufacturing a heater and an interdigital electrode of the sensor on a silicon chip or a ceramic tube; 3, using a radio frequency reaction magnetron sputtering technique to sputter a layer of SnO2-MWCNT film on the area of the interdigital electrode, and sputter a layer of WO3-MWCNT film on the SnO2-MWCNT film to form a composite film; 4, sintering the silicon chip or the ceramic tube attached with the film in a high-temperature furnace; and 5, welding a platinum wire between the heater of the silicon chip or the ceramic tube and an outer leading wire post of the sensor and welding a platinum wire between the electrode of the silicon chip or the ceramic tube and the outer leading wire post of the sensor respectively. The SnO2-WO3-MWCNT composite film gas sensor manufactured by the method has a high gas-sensing property and a good using effect.

Owner:FUZHOU UNIV

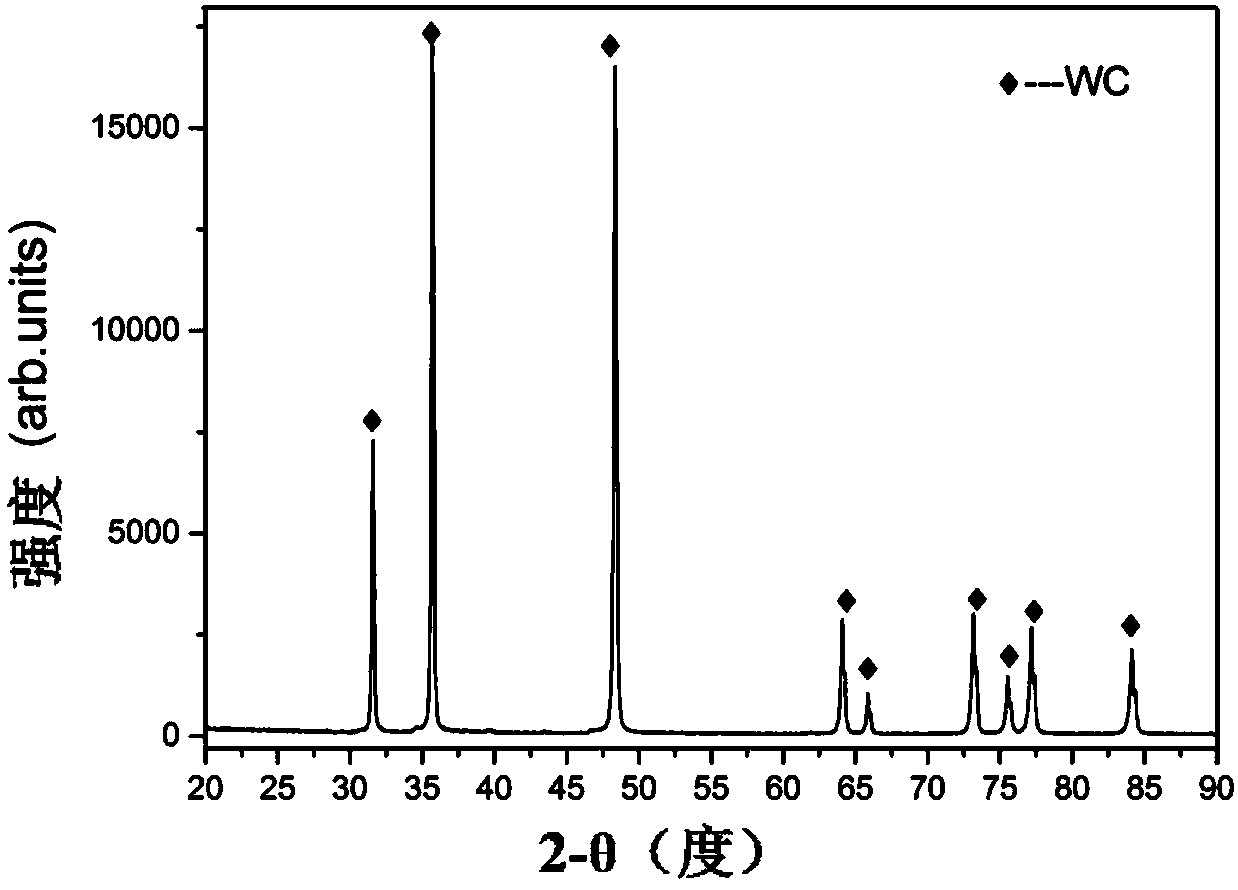

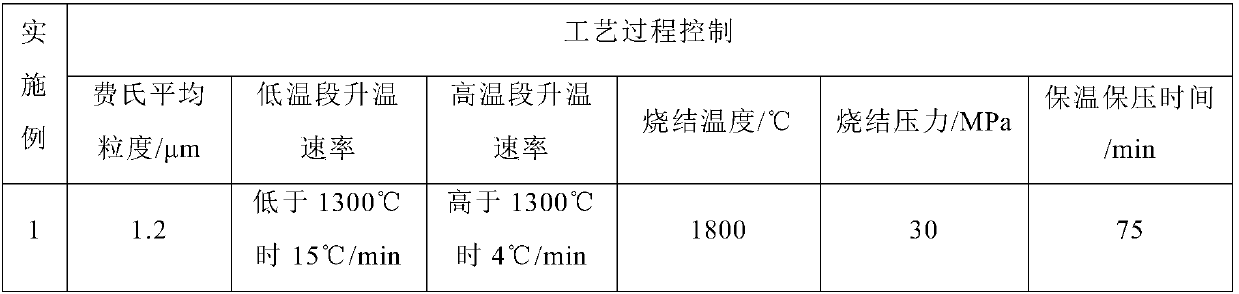

Preparation method for non-bonding-phase pure-carbonation tungsten target material

ActiveCN107620049AReduce surface defectsSimple preparation processVacuum evaporation coatingSputtering coatingDiamond-like carbonSuperficial mass

The invention provides a preparation method for a non-bonding-phase pure-carbonation tungsten target material. The method comprises the steps that pure-carbonation tungsten raw material powder is screened firstly to obtain pure-carbonation tungsten powder with the even particle size; then a mould is evenly filled with the pure-carbonation tungsten powder, hot-pressing sintering treatment is conducted under the vacuum condition, cooling is conducted, and then mould release is conducted to obtain a sintered blank; and finally, the sintered blank is machined to obtain the non-bonding-phase pure-carbonation tungsten target material meeting the size and surface-quality requirements. According to the preparation method for the non-bonding-phase pure-carbonation tungsten target material, the technique is simple, the forming effect is good, and industrialized large-scale production is facilitated; the target material does not contain any bonding phase component, grains are even, the average grain size is 5 [mu]m or below, the compactness can reach 99% or more, and the purity is 99.9% or more; and according to the target material, the arc starting discharging phenomenon in the sputtering process is reduced, the surface defects of a prepared film layer are few, a coating is more compact, the target material can be used for preparing an adulteration phase of diamond-like carbon (DLC) coating and a transitional layer, and coating mechanical performance and tribological performance are improved.

Owner:北京安泰六九新材料科技有限公司 +1

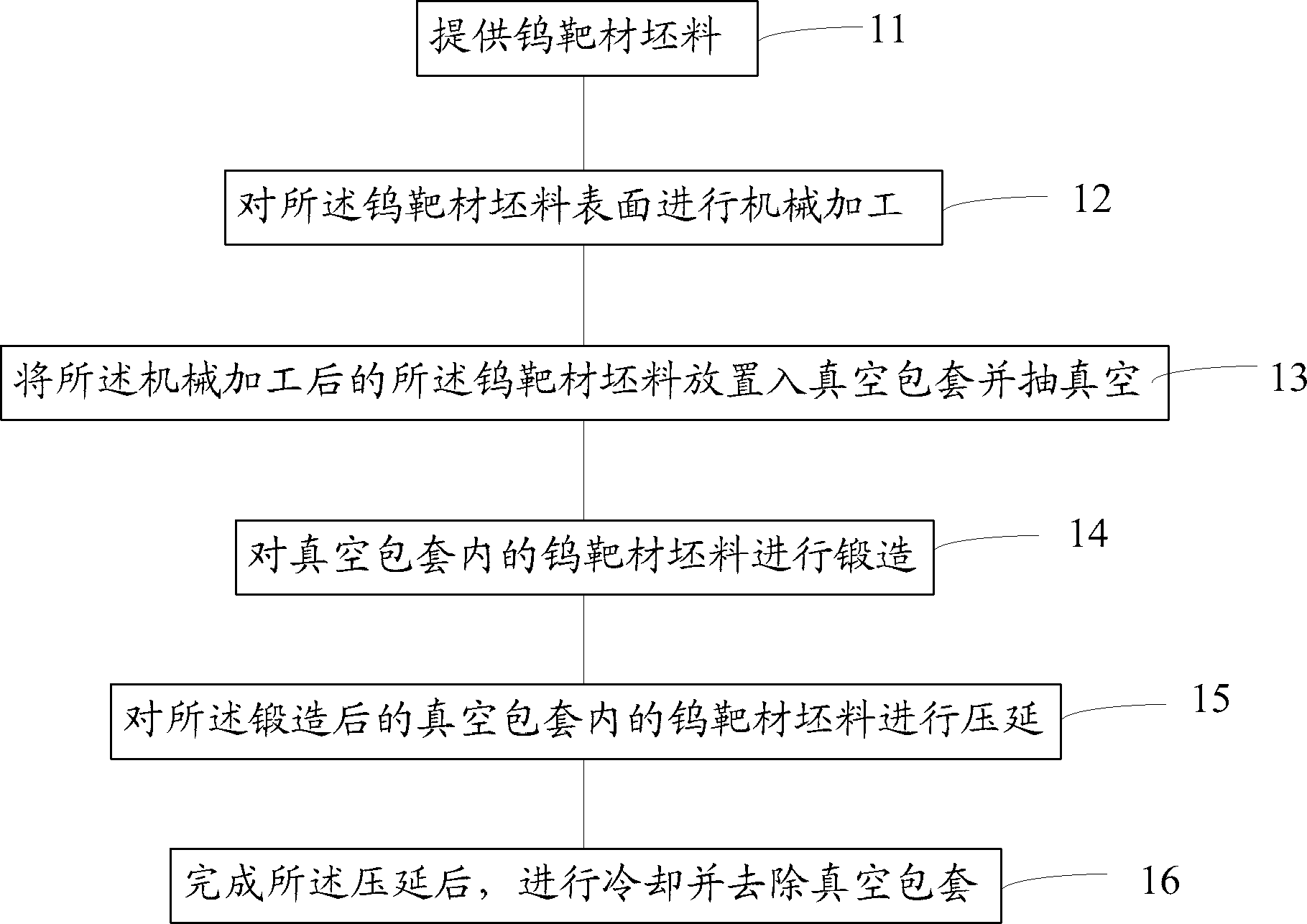

Manufacturing method of tungsten target material

ActiveCN102513789AAvoid crackingUniform structureVacuum evaporation coatingSputtering coatingMachiningTungsten target

A manufacturing method of a tungsten target material includes the steps of providing tungsten target blank, machining the surface of the tungsten target blank, placing the machined tungsten target blank in a vacuum sheath and vacuumizing, forging the tungsten target blank in the vacuum sheath, rolling the forged tungsten target blank in the vacuum sheath, cooling and removing the vacuum sheath after rolling. The manufacturing method of the tungsten target material does not require a mould, resolves the problems that cracks exist in rolling and extending the tungsten target blank and the surface of the tungsten target blank is prone to oxidation, is capable of manufacturing the tungsten target material which has uniform internal organization structure and meets the requirement of a sputtering target material for grain size. In addition, the manufacturing method of the tungsten target material has the advantages of being easy to machine and low in rejection ratio. The manufacturing method is more suitable for manufacturing the large-sized tungsten target material.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

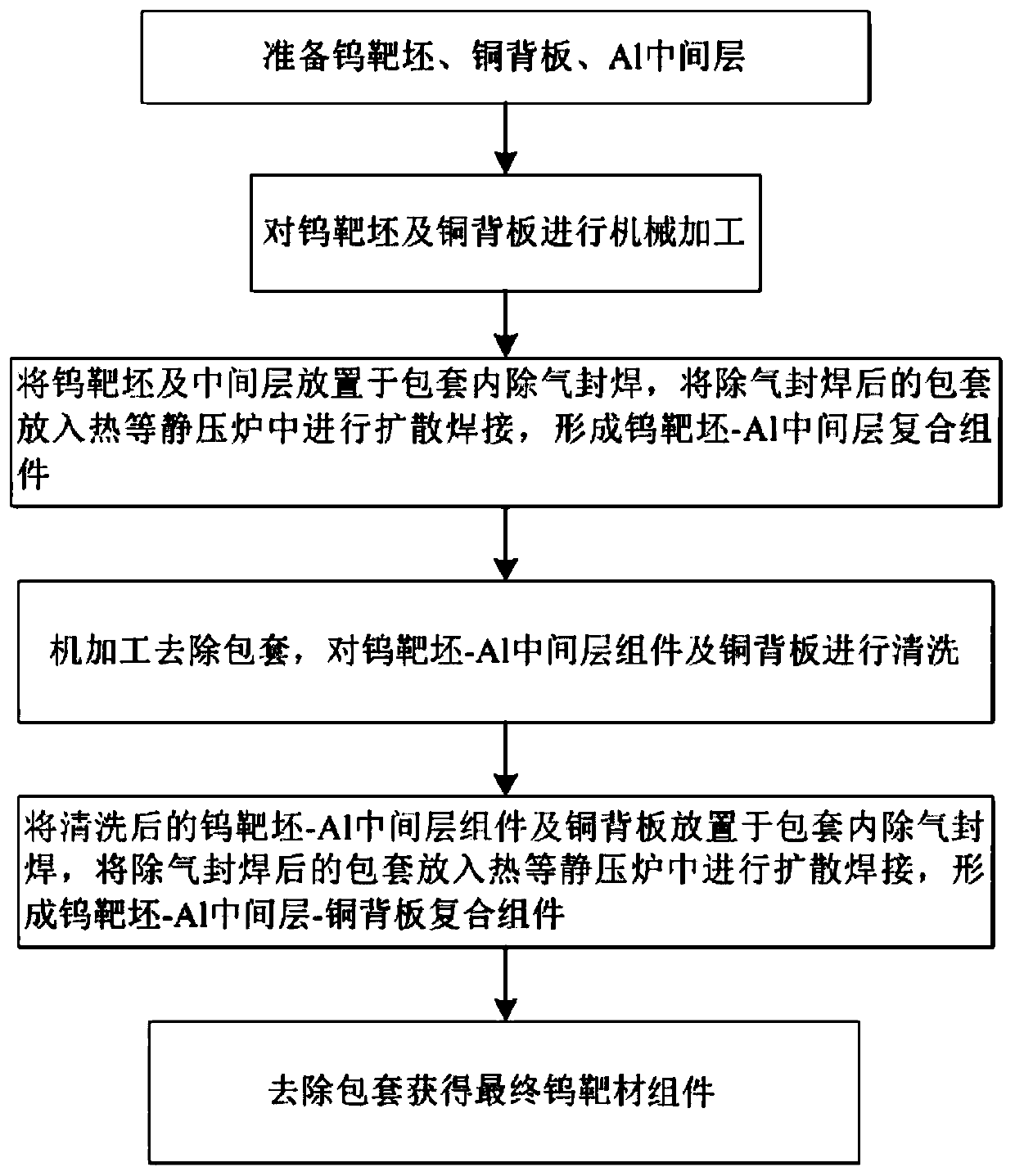

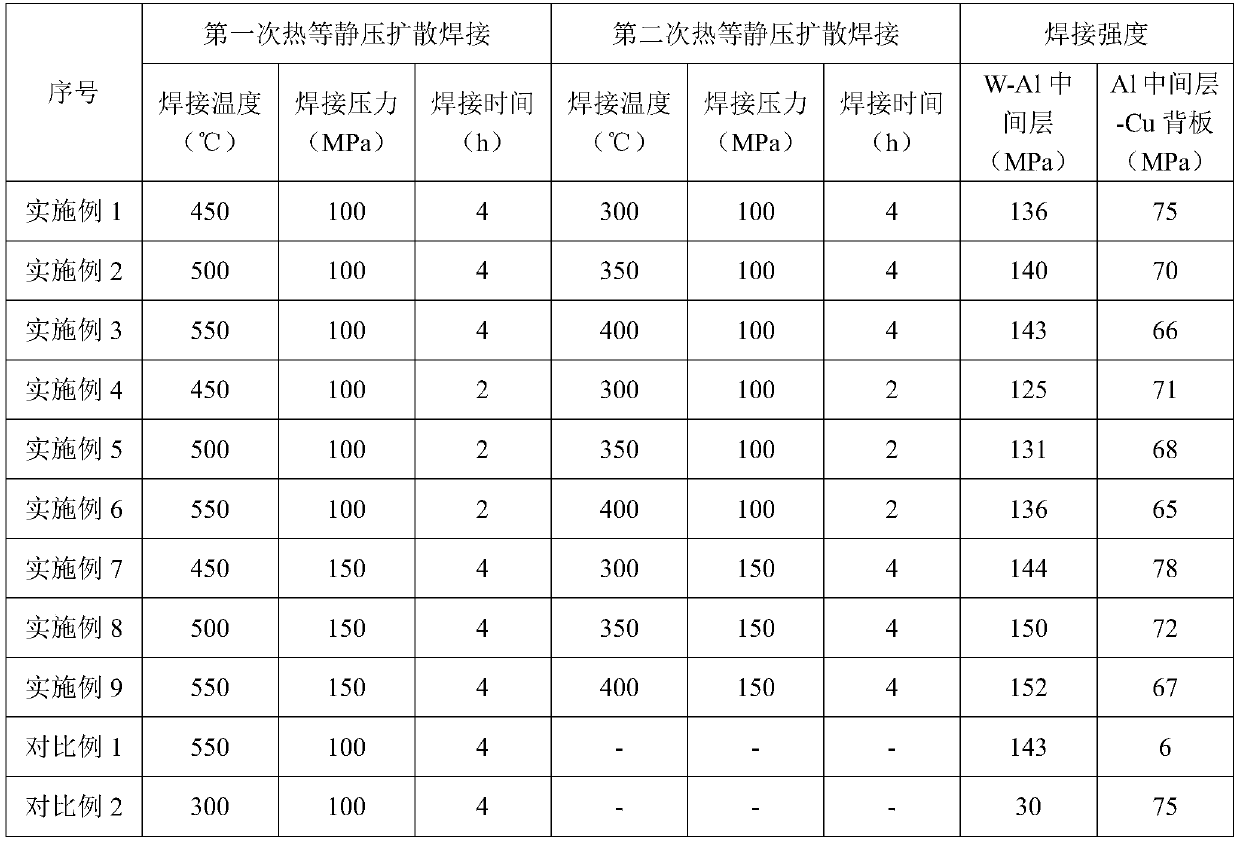

Two-step hot isostatic pressing diffusion welding method for tungsten target assembly

ActiveCN111014930AGuaranteed welding strengthImprove welding strengthNon-electric welding apparatusWeld strengthUltimate tensile strength

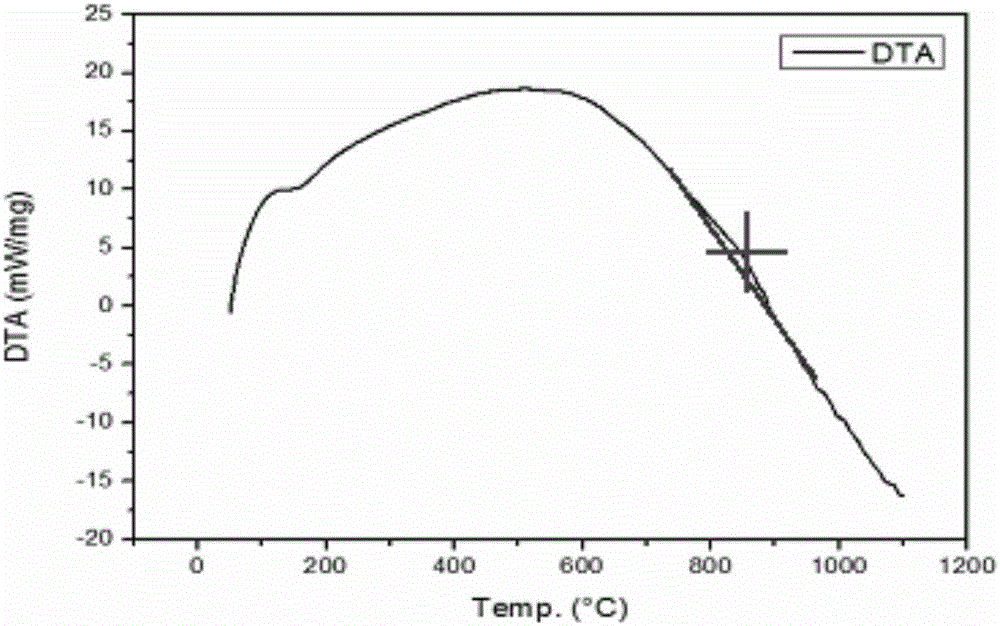

The invention discloses a two-step hot isostatic pressing diffusion welding method for a tungsten target assembly, and belongs to the technical field of magnetron sputtering target manufacturing. According to the welding method, hot isostatic pressing diffusion welding is carried out on a tungsten target blank and an Al intermediate layer, then secondary hot isostatic pressing diffusion welding iscarried out on the tungsten target blank and a copper back plate, finally, the tungsten target material assembly is obtained, and the welding strength of the tungsten target blank-Al intermediate layer welding face of the tungsten target material assembly is larger than or equal to 125 MPa, the welding strength of the Al intermediate layer-copper back plate welding face is larger than or equal to65 MPa, the welding-on rate of the two welding faces is larger than 99.5%, the overall deformation degree of the target material after welding is small, the target material is suitable for a high-power sputtering machine table, and it is guaranteed that desoldering and target falling are avoided in the sputtering process.

Owner:有研亿金新材料(山东)有限公司 +1

Tungsten Sintered Compact Sputtering Target and Tungsten Film Formed Using Same Target

Provided is a tungsten sintered compact sputtering target, wherein the purity of the tungsten is 5N (99.999%) or more, and the content of impurity carbon in the tungsten is 5 wtppm or less. An object of the present invention is to decrease the specific resistance of a tungsten film sputter-deposited by using a tungsten sintered compact sputtering target by reducing a carbon content in the tungsten target.

Owner:JX NIPPON MINING& METALS CORP

Tungsten target material welding method and tungsten target material assembly

InactiveCN108544045AReduce welding deformationAvoid causing welding failureSoldering apparatusWelding/soldering/cutting articlesCopperSemiconductor

The invention provides a tungsten target material welding method and a tungsten target material assembly, and relates to the technical field of semiconductor manufacturing. The method comprises the steps that a tungsten target material and a copper backboard are processed and cleaned before being welded; a flux guide part is positioned between the tungsten target material and the copper backboard;then the tungsten target material and the copper backboard are subjected to braze welding by a braze welding technology to obtain the tungsten target material assembly; and the tungsten target material assembly is cooled. According to the method, the flux guide part is positioned between the tungsten target material and the copper backboard before welding, so that fluxes can be uniformly distributed between the tungsten target material and the copper backboard, and as a result, the weld seam uniformity, the welding success rate and the welding stability can be improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Diffusion welding method for tungsten target and copper-zinc alloy back plate

InactiveCN112122764AUniform stress distributionEfficient weldingNon-electric welding apparatusZinc alloysTitanium

The invention relates to a diffusion welding method for a tungsten target and a copper-zinc alloy back plate. The diffusion welding method comprises the following steps that (1) titanium film platingtreatment is conducted on the welding face, with the roughness Ra smaller than or equal to 3 micrometers, of the tungsten target, and then the tungsten target obtained after film plating is sequentially cleaned and dried; and (2) the tungsten target dried in the step (1) and the copper-zinc alloy back plate are assembled and then placed in a sheath, then the sheath is sequentially welded, vacuumized and degassed, hot isostatic pressing welding is conducted on the degassed sheath, and after hot isostatic pressing welding is completed, the sheath is dismounted to obtain a tungsten target assembly. An aluminum alloy middle layer is arranged between the tungsten target and the copper-zinc alloy back plate in the sheath. After titanium plating treatment is conducted on the welding face of the target under the specific roughness, effective welding of the target and the back plate is achieved, stress distribution of the welding face is uniform after welding, the welding bonding rate is largerthan or equal to 98%, the heat transfer performance between the target and the back plate is enhanced, and the service life is prolonged.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Preparing method of porous tungsten oxide film

InactiveCN101660124AObvious advancementObvious originalityVacuum evaporation coatingSputtering coatingSelective leachingCorrosion

The invention provides a preparing method of a porous tungsten oxide film, which is characterized in that the preparing method comprises the following steps: adopting a tungsten-target and aluminum-target magnetic control co-sputtering technology to deposit tungsten and aluminum on a substrate to form an aluminum alloy film; dipping the obtained tungsten-aluminum alloy film into alkaline solutionfor selective corrosion and oxidation; and finally, obtaining the porous tungsten oxide film on the substrate. The porous tungsten oxide film prepared with the method has even aperture distribution, and the average aperture size is about 100nm. The invention has the following obvious advancement and originality of simple preparation, easy control of technological parameters, controllable porosityand aperture size and even aperture distribution. The product structure and the property thereof are very suitable for manufacturing electrochromic devices and air-sensitive devices.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Method for preparing Ag-Cu/W nanometer multilayer film solder for brazing stainless steel

ActiveCN106271214AImprove practicalityThe biggest advantage lies in the practicality and low brazing temperatureVacuum evaporation coatingSputtering coatingTotal thicknessSilver copper

The invention relates to a method for preparing Ag-Cu / W nanometer multilayer film solder for brazing stainless steel. The multilayer film solder contains 16.7 percent to 37.5 percent of silver, 12.5 percent to 33.3 percent of copper and 50 percent of tungsten. A silver-copper layer and a tungsten layer are alternately sputtered by utilization of a magnetron sputtering method. The silver-copper layer is sputtered by simultaneously sputtering a silver target and a copper target, and a tungsten target is used for independently sputtering. The thickness of each silver-copper layer is 8 nm to 14 nm, and the thickness of each W layer is smaller than 10 nm. The atom proportion of Ag to Cu in each silver-copper layer is (0.5 to 1) to (3 to 1). Alternating deposition is performed for 200 to 400 periods, so that the total thickness of a final film is 4 microns to 8 microns. The method provided by the invention has the advantages that the solder uniformity can be guaranteed; moreover, the solder thickness can be easily controlled through a sputtering period; the melting point of a nanometer particle is dramatically decreased by utilization of a melting point decreasing effect of the nanometer particle; during a brazing process, a reactive layer and a matrix can be formed into an eutectic structure with a low melting point or a hypo-eutectic structure with a low melting point, so that the brazing temperature is effectively lowered.

Owner:BEIJING UNIV OF TECH

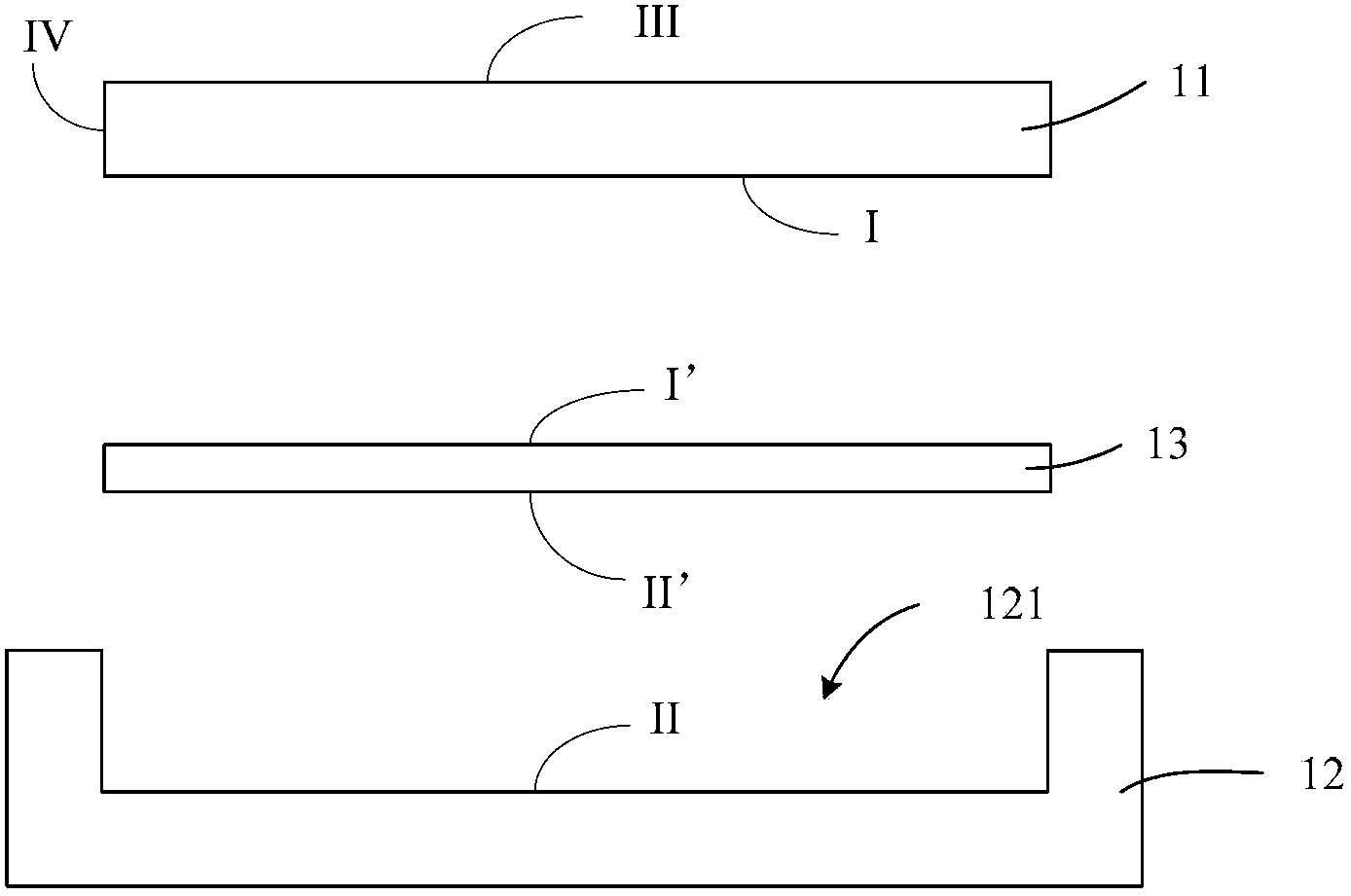

Tungsten target diffusion welding structure and tungsten target diffusion welding method

ActiveCN108247190AReduce crackingRealization of HIP welding processVacuum evaporation coatingSputtering coatingSputteringSemiconductor

The invention provides a tungsten target diffusion welding structure and a tungsten target diffusion welding method, and relates to the technical field of semiconductor sputtering target manufacturing. The tungsten target diffusion welding structure comprises a tungsten target main body, a copper alloy back plate, a vacuum layer, a first middle layer and a second middle layer; the copper alloy back plate is provided with a containing groove, and the tungsten target main body, the vacuum layer, the first middle layer and the second middle layer are sequentially arranged in the containing groove; and the tungsten target diffusion welding structure is characterized in that the stress of the tungsten target main body and the copper alloy back plate is released through the first middle layer, diffusion welding of the copper alloy back plate and the first middle layer is guaranteed through the second middle layer, and finally cracking of the tungsten target main body during diffusion weldingis prevented through the vacuum layer, so that the technical problems that in the prior art, cracks are prone to occurrence in the welding process of the tungsten target main body, and diffusion between the tungsten target and the middle layers, and between the middle layers and the copper alloy is not prone to achieve are solved, the semiconductor sputtering target welding surface treatment is achieved, the HIP welding process of the tungsten target main body is realized, and the structure and the method are more practical.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Tungsten sintered material sputtering target

ActiveCN102046822AReduce intensityImprove uniformityElectric discharge tubesSolid-state devicesAbnormal growthsParticle growth

Provided is a tungsten sintered material sputtering target having a phosphorus content of 1 ppm by weight or less, with the remainder being tungsten and unavoidable impurities. A decrease in the strength of the target and abnormal tungsten particle growth are strongly influenced by the phosphorus content, and particularly when the phosphorus content exceeds 1 ppm, crystal particles that have undergone abnormal growth will be present in the tungsten target. Consequently, the issue is to prevent abnormal tungsten particle growth and increase target product yield by vigorously identifying phosphorus contained in the tungsten as a harmful impurity and keeping the content to a minimum.

Owner:JX NIPPON MINING & METALS CORP

Surface clad layer treatment method of copper tungsten electrical contact material for arc extinguish chamber

ActiveCN106978586AExtended service lifeImprove abnormal breakdown discharge phenomenonVacuum evaporation coatingSputtering coatingDistributed structureArgon atmosphere

The invention discloses a surface clad layer treatment method of a copper tungsten electrical contact material for an arc extinguish chamber. The method includes the steps that the copper tungsten alloy contact material is prepared to serve as a substrate material; mechanical buffing, washing and drying are carried out; the substrate material is placed into a vacuum chamber to deposit a chromium layer, a nickel layer or a titanium layer on a base body through a chromium target, a nickel target or a titanium target under the argon atmosphere; a copper target and a tungsten target are used for codeposition of a copper-tungsten clad layer on the substrate deposited with the chromium target, the nickel target or the titanium target continuously, and a copper tungsten-tungsten clad layer with a certain film thickness is obtained; and annealing is carried out under protection of a mixed atmosphere of inert gas and hydrogen, furnace cooling is carried out, a sample is taken out, and a copper tungsten electrical contact material surface clad layer is obtained. By means of the two-phase nanoscale uniform distributed structure, the ablation uniformity can be greatly improved, the ablation pit depth is reduced, and the service life is prolonged; meanwhile, a provided nanocrystalline tungsten framework can improve the arc ablation resistant capacity. By means of the method, equipment is simple and convenient to operate, the effect is obvious, and the good industrial application prospect is achieved.

Owner:XI AN JIAOTONG UNIV

Multi-pixel x-ray source with tungsten-diamond transmission target

A multi-pixel x-ray source is provided. The x-ray source includes a plurality of transmission target assemblies. The transmission target assembly includes a tungsten target and a diamond substrate. The substrate includes a first transmission surface and a second transmission surface opposite first transmission surface. The substrate further includes a first side surface and a second side surface disposed between the first and second transmission surfaces. The target covers the first transmission surface of the substrate. The transmission target assembly further includes a base. The base surrounds the first and second side surfaces of substrate, exposing a collimator surface of the second transmission surface and the target. The transmission target assembly is configured to transmit x-ray generated by the target through the target and the substrate.

Owner:WASHINGTON UNIV IN SAINT LOUIS

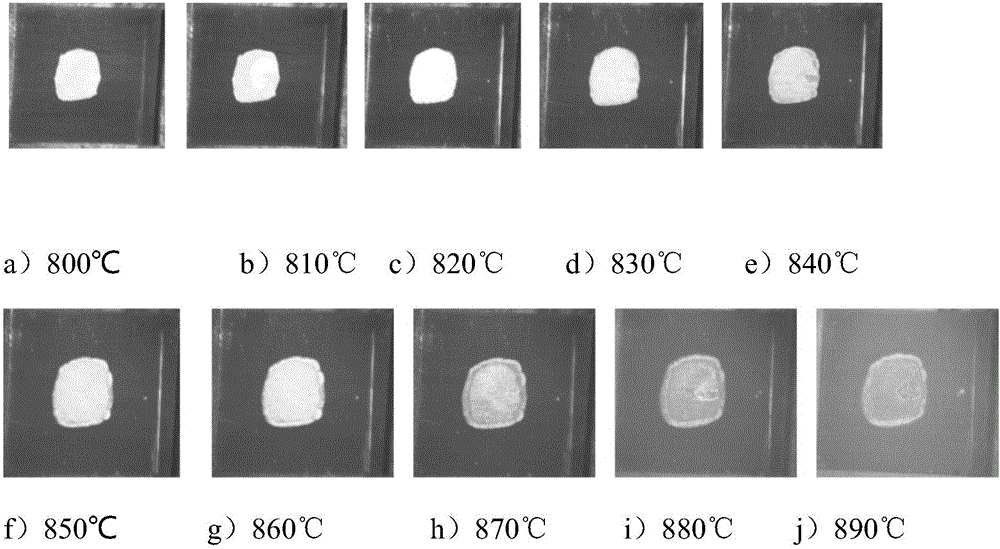

Large-sized high purity tungsten target and production method thereof

ActiveCN103805952APrevent surface oxidationVacuum evaporation coatingSputtering coatingMiddle frequencyMachining

The invention discloses a large-sized high purity tungsten target with the diameter of over 400mm for a semiconductor, wherein the purify can be over 99.999%, the compactness is over 99.5% and the grain size is less than or equal to 100 mu m. The preparation method comprises the following steps: uniformly mixing tungsten powder with the purify over 99.999% and the grain size of 2.2-2.6 mu m; compression moulding by isostatic cool pressing at 180-250MPa for 5-10 minutes; carrying out middle frequency induction sintering for 8-12 hours at 2300-2400 DEG C; after annealing for 90-180 minutes at 1450-1550 DEG C, carrying out multi-pass hot rolling to 5-15mm thick, wherein the total deformation of hot rolling is greater than 60%; and then, after annealing for 90-150 minutes at 1300-1400 DEG C and machining, wherein the machining amounts of the upper and lower surfaces are greater than or equal to 1.5mm. Finally, the obtained tungsten target is not only excellent in performance, but also relatively simple in process and low in equipment requirement.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

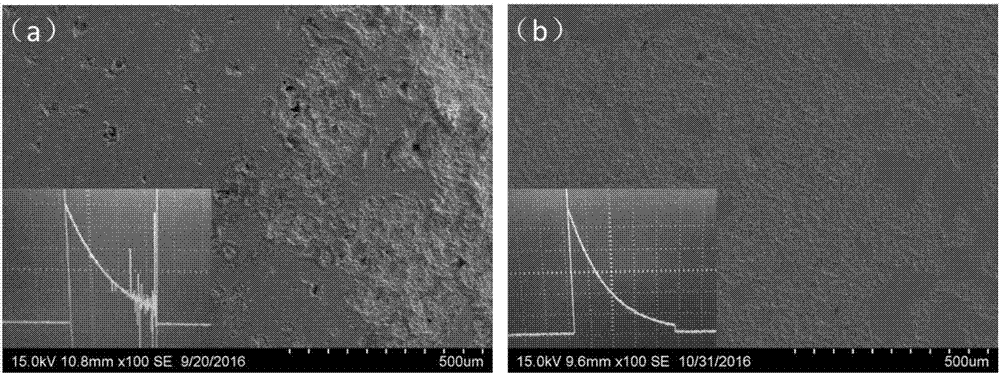

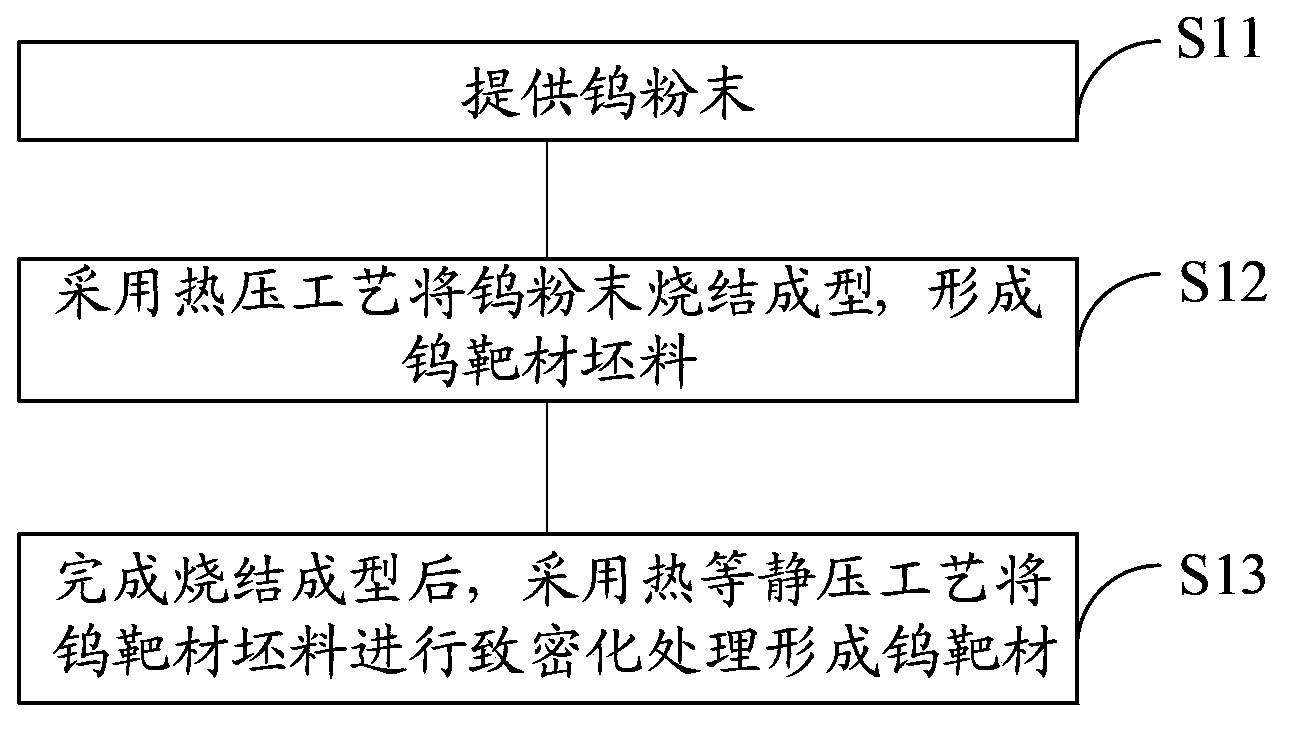

Tungsten target manufacturing method

A tungsten target manufacturing method comprises the steps of providing tungsten powder; adopting a hot pressing process to perform sintering forming of the tungsten powder, and forming tungsten target blank; and after sintering forming, adopting a hot isostatic pressing process to enable the tungsten target blank to be subjected to densifying processing to form a tungsten target. The tungsten target with the full density of over 99.4% can be manufactured through the tungsten target manufacturing method; and the uniformity of the internal organizational structure and the grain size of the tungsten target meet a sputtering process with the requirement higher and higher.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

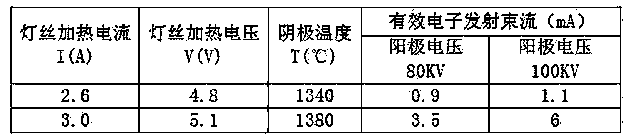

X light pipe with liquid cooling compelling double window positive pole

The invention discloses an X light pipe with a liquid cooling compelling double window positive pole, which comprises a pipe housing, a positive component and a negative component, wherein the positive component comprises a target material and a positive outer wall surrounding the target material; an electron entrance port and an X ray escape port are formed in the positive outer wall; an X light penetrating isolation window is arranged on the X ray escape port. Through the adoption of the X light pipe with the liquid cooling compelling double window positive pole, the electrons emitted from the negative pole can reach a tungsten target smoothly through the isolation window; X rays produced after the high-energy electrons hit the tungsten target can be enabled to penetrate through the isolation window smoothly to be outputted; meanwhile through the liquid cooling compelling, the phenomenon that material evaporated by the tungsten target reach the inner wall of the pipe housing and other insulators to cause the reduction of the X light effective output or high-pressure fire striking can be effectively prevented; the purpose of prolonging the service life of the device is achieved.

Owner:CHENGDU CHUANGYUAN ELECTRONICS

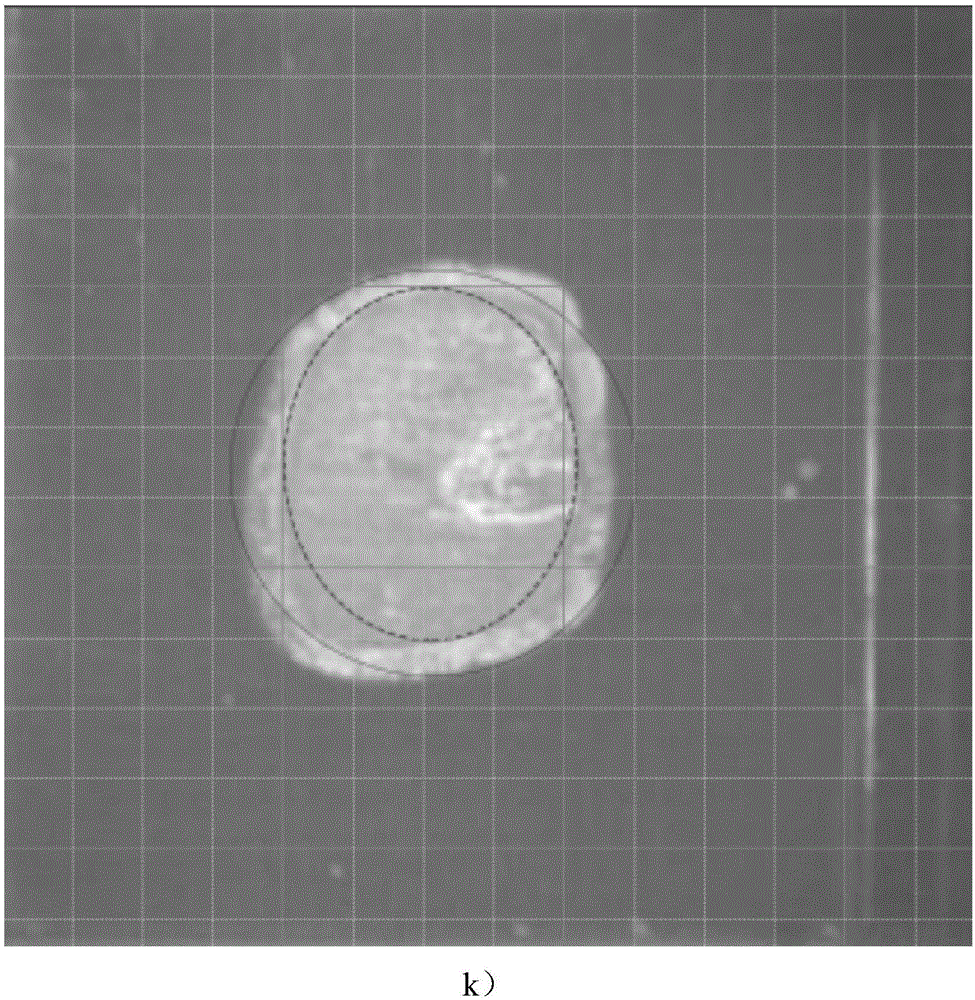

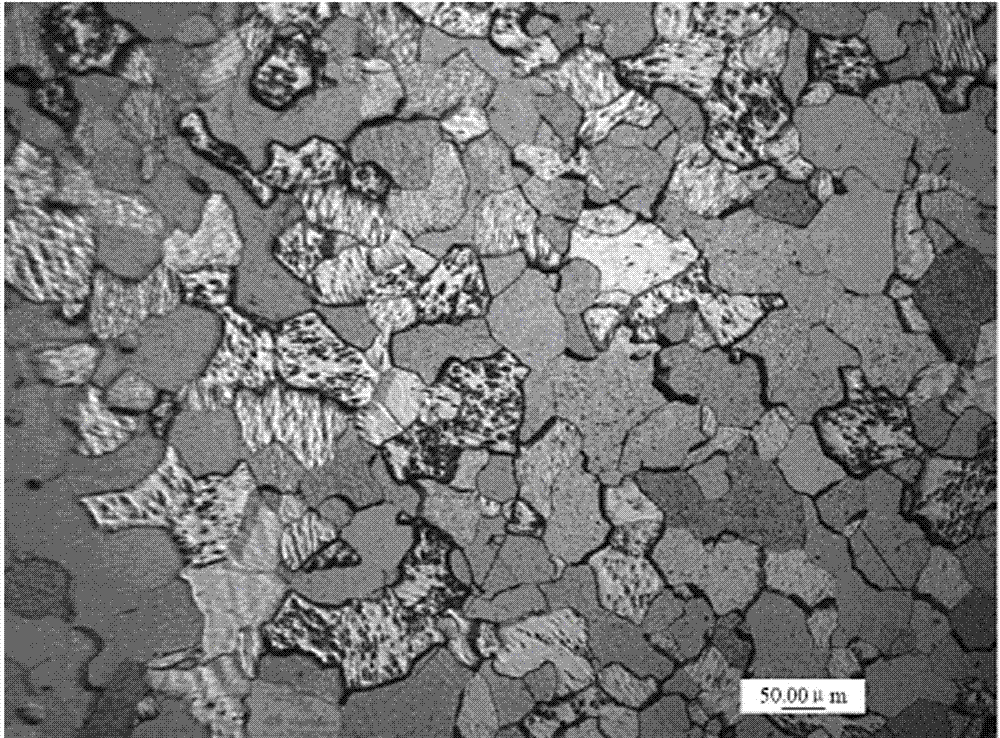

Display method of target material metallographic structure

InactiveCN106289924ASmooth responseAccelerated corrosionPreparing sample for investigationTest sampleAmmonia

The invention provides a display method of a target material metallographic structure. The display method comprises the following steps: providing a tungsten target material; cutting a part of the tungsten target material as a test sample; performing surface treatment on the test sample, and forming at least one polished surface; corroding the polished surface of the test sample by adopting etching agent formed by hydrogen peroxide and ammonia water; and performing metallographic observation on the test sample by adopting a metallographic microscope. The etching agent formed by the hydrogen peroxide and the ammonia water is stable in reaction and good in corrosion effect, and the crystal boundary morphology of the corroded test sample is clear, so that the metallographic structure of the test sample is good in display effect, and the observation on the metallographic structure by adopting the metallographic microscope is facilitated.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

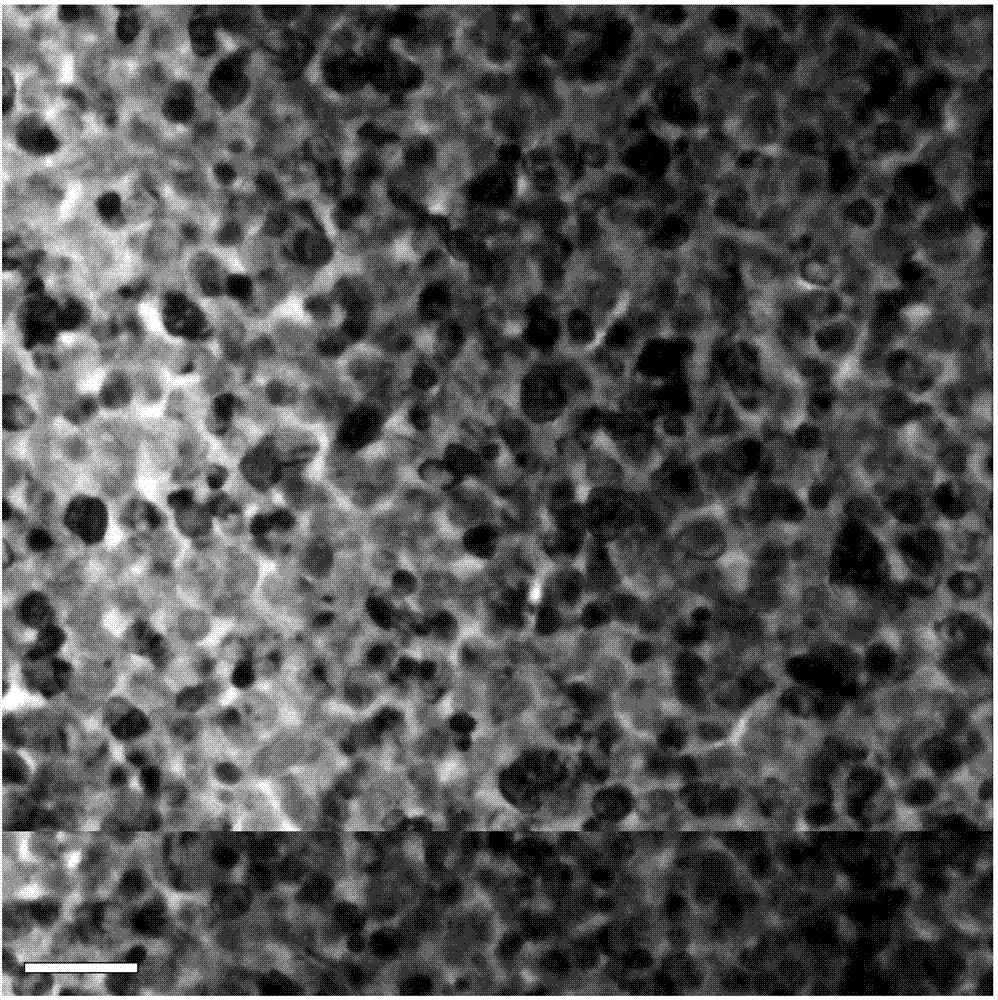

Preparation method of high-density fine-grain easy-to-form W target material

ActiveCN110983264AReduce the probability of crackingImprove yieldVacuum evaporation coatingSputtering coatingHigh densityFine grain

The invention discloses a preparation method of a high-density fine-grain easy-to-form W target material, which belongs to the technical field of magnetron sputtering target material manufacturing. The W target material is preformed in a cold pressing mode to obtain a preformed W target blank, and the relative density of the preformed W target blank is 60%-70%; then the preformed W target blank issubjected to hot isostatic presssure sintering densification to obtain a densified W target blank, and the relative density of the densified W target blank ranges from 93% to 96%; and finally, the Wtarget material is subjected to sheath-free secondary hot isostatic pressure sintering densification, the density of the prepared W target material is greater than 99%, the average grain size is lessthan 20 microns, and the yield is greater than 95%. The W target material is low in forming cracking probability, high in yield, simple in process and easy to operate, secondary hot isostatic pressuresintering densification is achieved, the sintering temperature in the hot isostatic pressure process can be reduced, and the tungsten target material with fine grains is obtained.

Owner:有研亿金新材料(山东)有限公司 +1

Method for preparing column-shaped nano-tungsten

InactiveCN103361613AGuaranteed normal growthUniform and ordered depositionVacuum evaporation coatingSputtering coatingSputteringParticle flow

The invention discloses a method for preparing column-shaped nano-tungsten. The method enables tungsten to grow on a graphite substrate in a tilted column shape, and can be used for studying the radiation performance of a first wall material. The method mainly comprises the following steps of: (1) manufacturing a sample rack, namely manufacturing a cylinder, and clamping four substrates at different angles inside the cylinder for simultaneously sputtering; (2) preparing the graphite substrate, namely preparing the graphite substrate with the size of 1cm*1cm, and washing the substrate to a certain extent; and (3) preparing the column-shaped nano-tungsten by a direct-current magnetron sputtering glancing angle deposition method, namely sputtering a pure tungsten target material on the graphite conductive substrate by changing the included angle alpha between the normal direction of the substrate and an incident particle flow so as to prepare a column-shaped nano-tungsten membrane.

Owner:BEIHANG UNIV

Tungsten sintered compact sputtering target and method for producing same

ActiveUS20150357170A1Avoid abnormal grain growthInhibit deterioration in target strengthCellsElectric discharge tubesAbnormal grain growthImpurity

Owner:JX NIPPON MINING& METALS CORP

Diffusion welding method for tungsten target material and copper back plate

PendingCN113305412AImprove bindingSolve the problem of insufficient binding abilityOther manufacturing equipments/toolsNon-electric welding apparatusMaterials scienceDiffusion welding

The invention provides a diffusion welding method for a tungsten target material and a copper back plate. The diffusion welding method comprises the following steps that accurate grinding and PVD film plating are sequentially carried out on the welding face of the tungsten target material, and polishing treatment is carried out on the non-welding face of the tungsten target material; PVD film plating is carried out on the welding surface of the copper back plate; and the tungsten target material, the welding surface and the middle layer are assembled, and sequentially subjected to sheath welding and hot isostatic pressing welding. According to the diffusion welding method for the tungsten target material and the copper back plate, the bonding performance of the tungsten target and the copper back plate can be improved, and the problem that the bonding capacity of the tungsten target and the copper back plate is insufficient is solved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Method of manufacturing chemical vapor deposition high-purity tungsten sputtering target material

InactiveCN109609926AReduce discharge voltageNot easy to polluteVacuum evaporation coatingSputtering coatingSputteringGas phase

The invention discloses a method of manufacturing a chemical vapor deposition high-purity tungsten sputtering target material. The method comprises the following steps that (1) raw materials are prepared, tungsten hexafluoride which is in gaseous state at normal temperature and normal pressure is taken as a raw material; (2) the high-purity metal tungsten is prepared, the tungsten hexafluoride isreduced into the high-purity metal tungst by using a reducing gas through chemical vapor deposition equipment, the tungsten hexafluoride is reduced into high-purity metal tungsten by using the reducing gas; and (3) and the high-purity metal tungsten obtained in the step (2) is deposited on a matrix material, a one-step method is used for producing the high-purity tungsten target material or the tungsten target material blank material. According to the method, the problems that an existing tungsten target material is low in purity and not easy to process, the surface is easy to pollute, the quality consistency is poor are solved, the vapor deposition reaction is a continuous gaseous reaction, the reaction process is uniform, and the product consistency is good; the one-step method is adopted to prepare the tungsten target material, secondary machining pollution is avoided, it is beneficial to guaranteeing the quality of the tungsten target product, and the production cost is low.

Owner:苏州鑫沣电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com