Welding method of tungsten target assembly

A welding method and target material technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of large difference in melting point, low bonding strength, poor welding tightness of target components, etc., to prevent oxidation, High binding rate, small deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

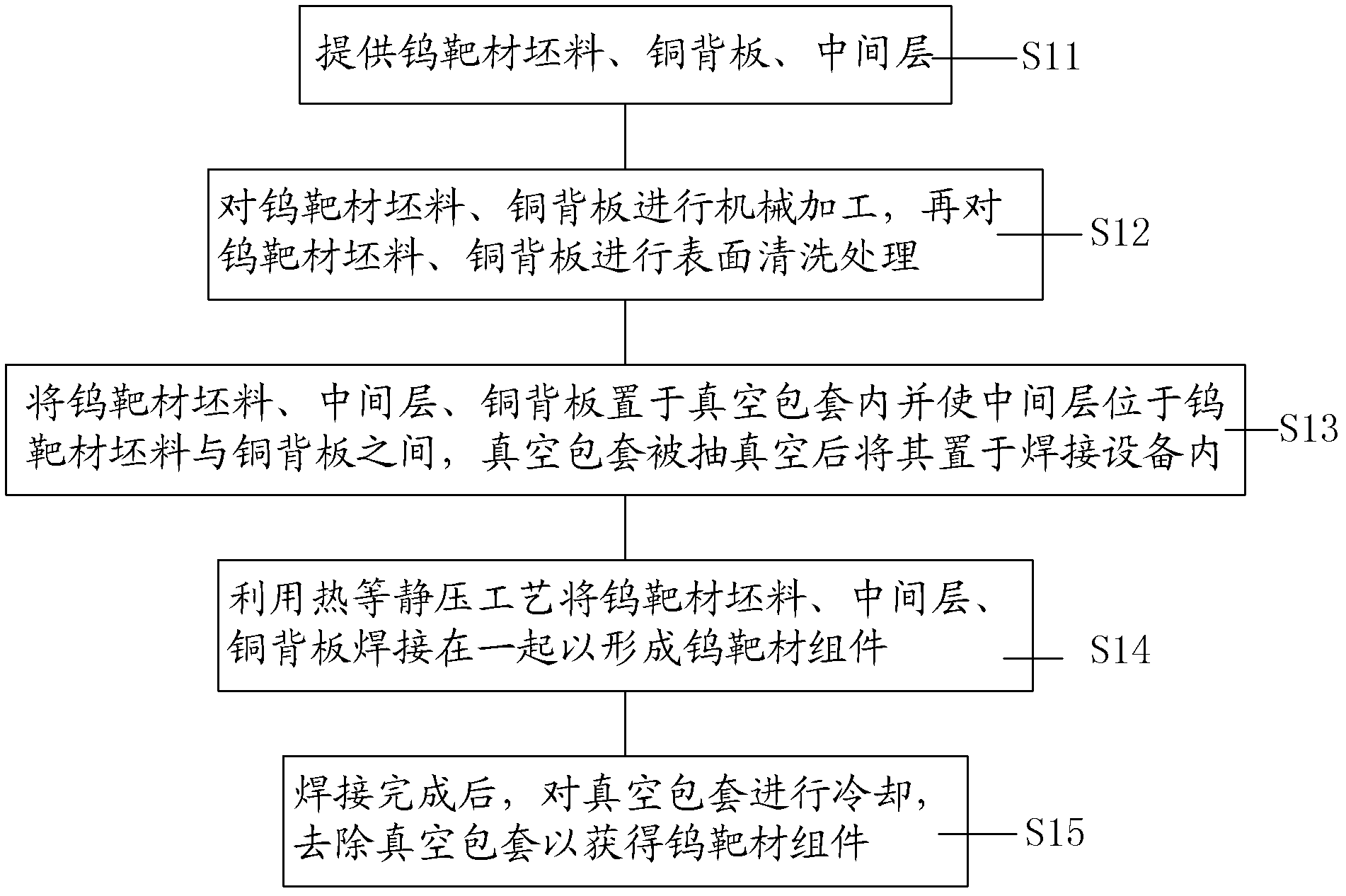

[0061] figure 1 It is the flow chart of the welding method of the tungsten target assembly in the first embodiment of the welding method of the tungsten target assembly of the present invention, which shows that the target assembly is formed when the intermediate layer between the tungsten target and the copper back plate is manufactured separately The welding process, the following will figure 1 and figure 2 , image 3 , Figure 4 Embodiment 1 will be described in detail in combination.

[0062] Step S11 is first performed: providing a tungsten target blank, a copper back plate, and an intermediate layer.

[0063] A tungsten target blank 11 is provided. In this embodiment, a tungsten target blank with a purity of 99.995% is taken as an example. According to the actual requirements of the application environment and sputtering equipment, the shape of the tungsten target blank 11 can be any of circular, rectangular, annular, conical or other similar shapes (including regu...

Embodiment 2

[0077] Figure 5 It is the flow chart of the welding method of the tungsten target assembly in the second embodiment of the welding method of the tungsten target assembly of the present invention, which shows that when the intermediate layer between the tungsten target and the copper back plate is formed on the pre-combined tungsten target blank The welding process of the target assembly on the surface, the following will Figure 5 and Figure 6 , Figure 7 Embodiment 2 will be described in detail in combination.

[0078] First, step S21 is performed: providing a tungsten target blank and a copper back plate.

[0079] A tungsten target blank is provided. In this embodiment, a tungsten target blank with a purity of 99.995% is taken as an example. According to the actual requirements of the application environment and sputtering equipment, the shape of the tungsten target blank 21 can be any of circular, rectangular, annular, conical or other similar shapes (including regular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com