Bellows assembly of SF6 valve and manufacturing method thereof

A bellows assembly and bellows technology, applied in the field of SF6 valves, can solve the problems of difficult to achieve sealing effect, less welding area, missing welding, etc., to improve the sealing performance and service life, and increase the welding area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

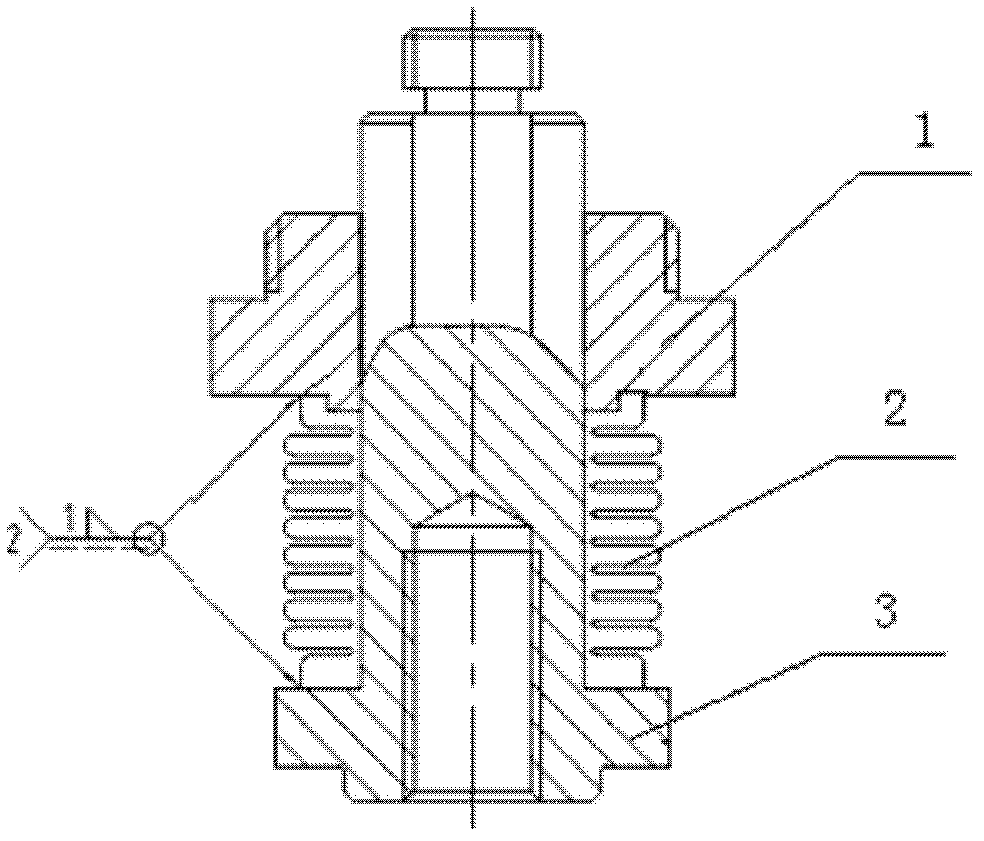

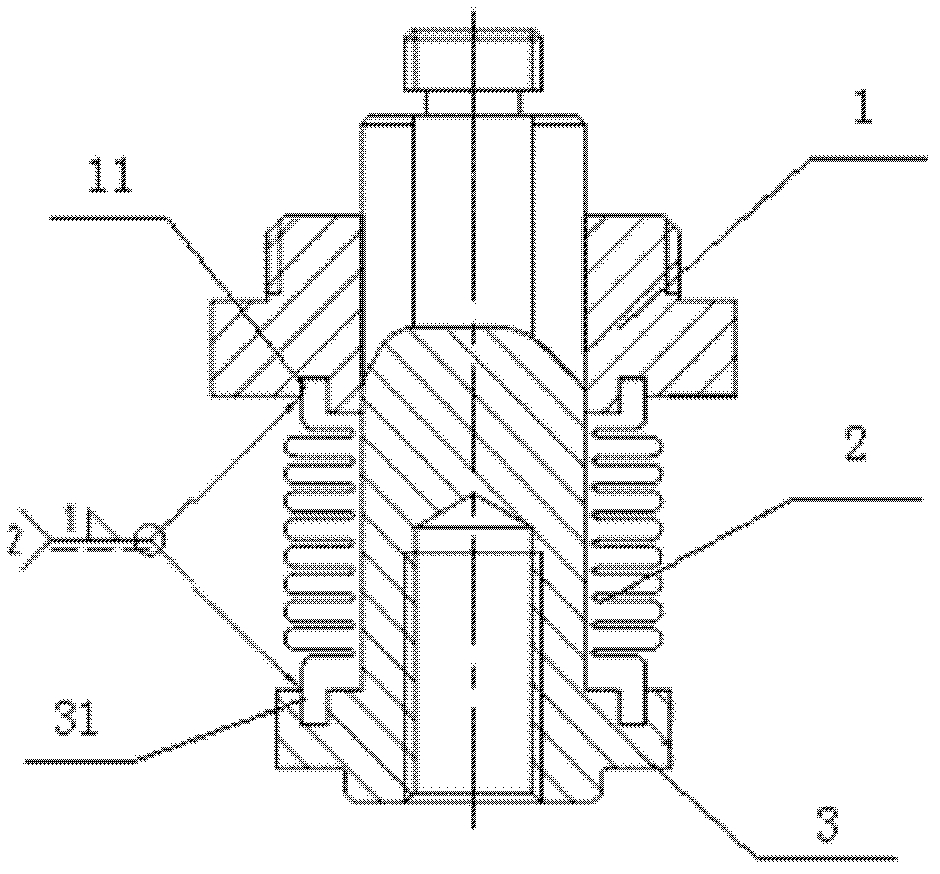

[0014] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] Such as figure 2 As shown, the SF6 valve bellows assembly of the present invention includes a valve stem, a support seat and a bellows; the support seat is fixedly connected to the valve stem, and the valve stem is provided with an annular flange, and the bellows is sleeved on the annular protrusion The periphery of the valve stem between the flange and the support seat, the two ends of the bellows are respectively placed in the annular grooves set on the two ends of the annular flange and the support seat opposite to each other, and the bellows and the annular groove pass through Brazed welding fixed.

[0016] Another technical purpose of the present invention is to provide a prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com