Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Prevent missing soldering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

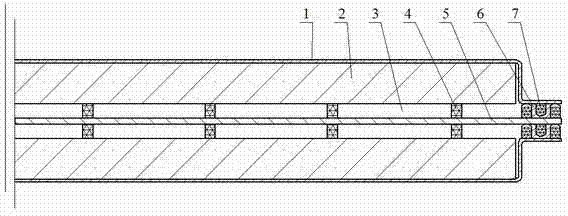

Double-vacuum-layer metal vacuum composite plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746690AImprove air tightnessImprove sound insulationCovering/liningsHeat proofingThermal dilatationComposite plate

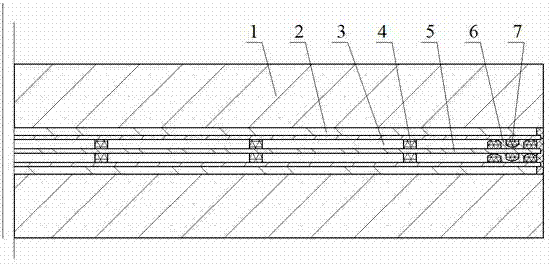

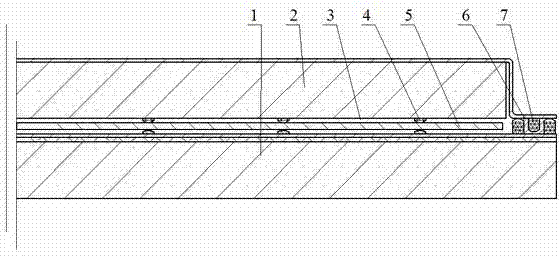

A double-vacuum-layer metal vacuum composite plate with the edge sealed by a seal strip comprises a housing, at least two core plates and a vacuum cavity and is characterized in that the housing is a low-carbon steel plate or a low-carbon steel composite plate, the core plates are located in the vacuum cavity formed through seal welding of the housing, the core plates provide additional strength for the housing and ensure the smoothness of the housing under atmospheric pressure, the vacuum cavity is welded and sealed by utilizing a glass solder in a vacuum furnace under high vacuum and high temperature, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, the coefficient of thermal expansion of the low-carbon steel plate is matched with that of the glass solder, a partition plate is arranged in the vacuum cavity and divides the vacuum cavity into two to form double vacuum layers, and supports are arranged in the vacuum layers and are independently manufactured or are directly formed on the core plate or the partition plate. A manufacturing method of the double-vacuum-layer metal vacuum composite plate is simple in process, and strength, heat-insulation, sound-insulation and fireproof performance and a decorative function can be improved.

Owner:戴长虹

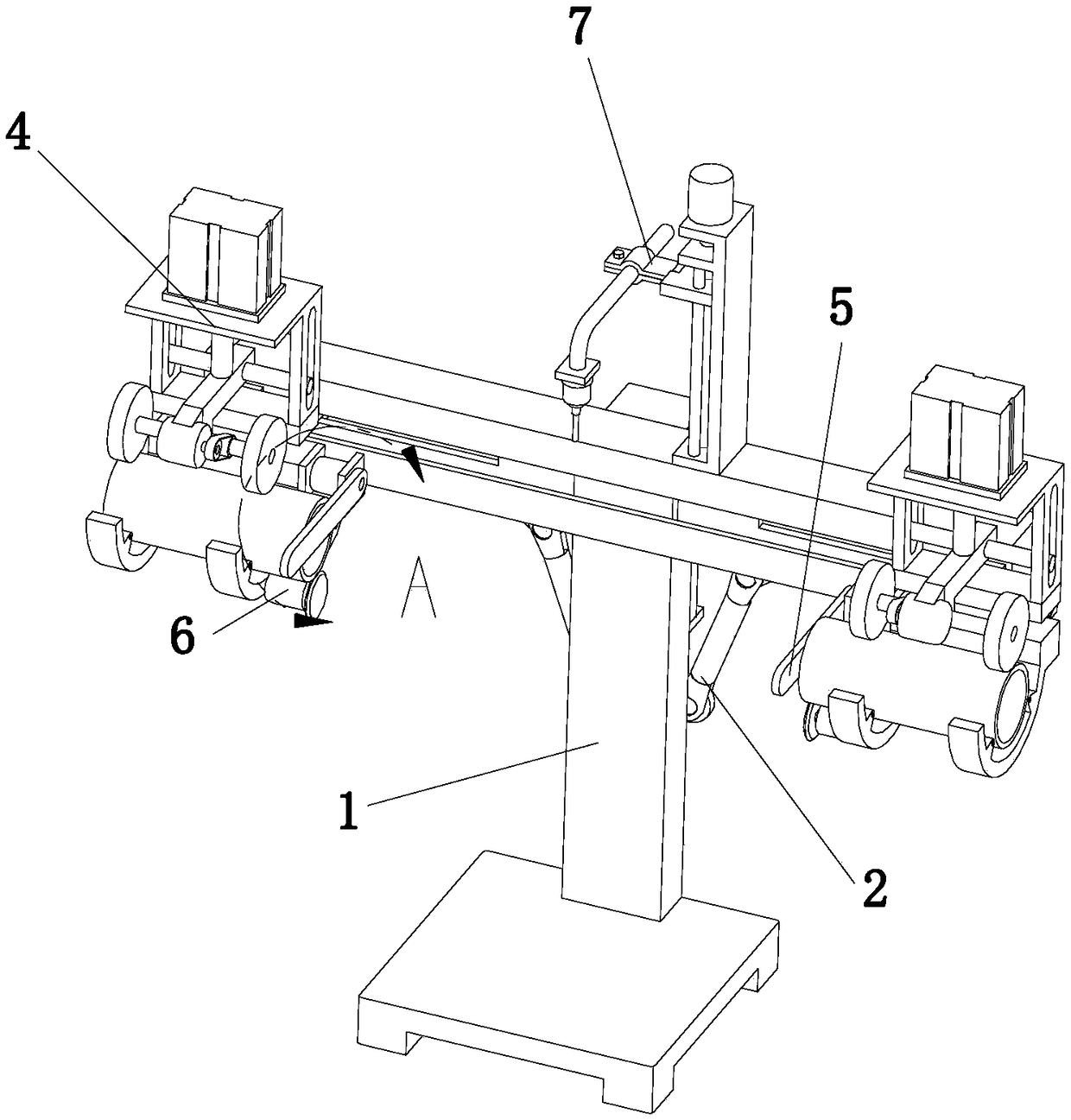

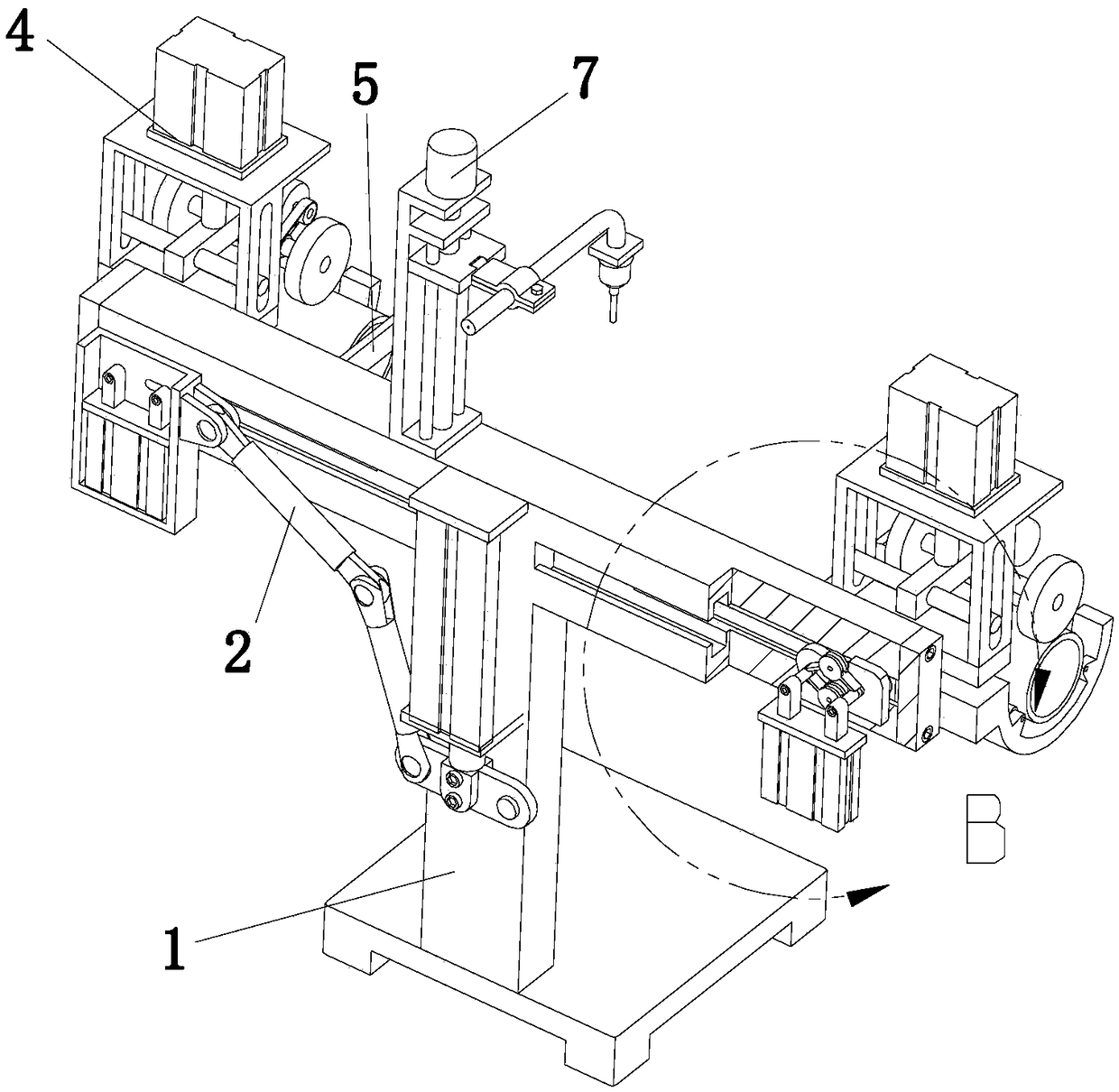

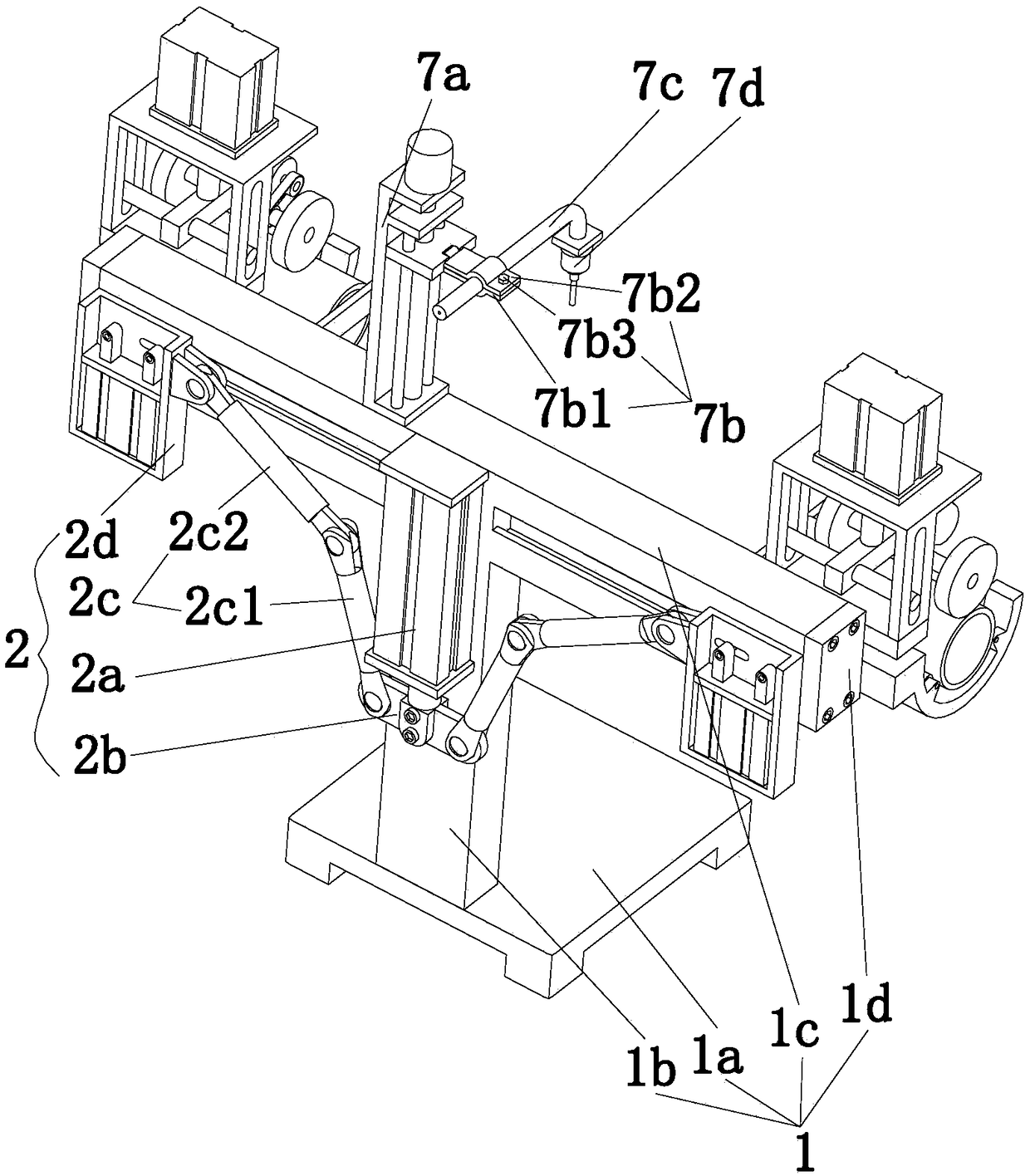

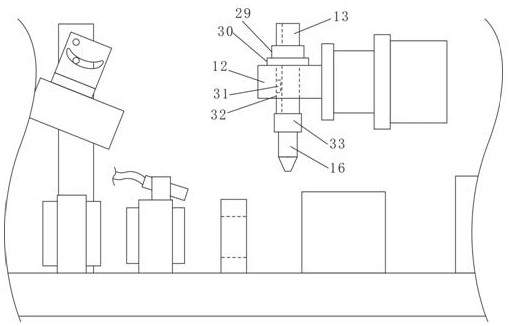

Pipe welding device for building construction

ActiveCN109465594ARealize automatic positioningAvoid partial solderingWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringPipe welding

The invention relates to the field of building construction equipment, in particular to a pipe welding device for building construction, comprising a T-shaped frame, a synchronous moving device, fixing devices, clamping devices, positioning devices, trimming devices and a welding device, wherein the synchronous moving device is arranged on the T-shaped frame, the fixing devices are arranged on both sides of the T-shaped frame and are connected with the synchronous moving device, the clamping devices are arranged on both sides of a beam guide rail, the clamping devices are connected with the fixing devices, and the fixing devices move to drive the clamping devices along the beam guide rail to do synchronized motion, the positioning devices are disposed on the sides of the two clamping devices near columns, the trimming devices are disposed on the sides of the clamping devices near the columns, and the welding device is installed above the middle of the beam guide rail. The invention canrealize the automatic welding of the pipe, realize the automatic alignment of the pipe welding part, can prevent the construction pipe material from being broken at the welded part during the rotation process, effectively reduce the labor intensity of the construction worker, and ensure the construction progress and the construction quality.

Owner:ZHEJIANG AOCHUAN HYDRAULIC

Bellows assembly of SF6 valve and manufacturing method thereof

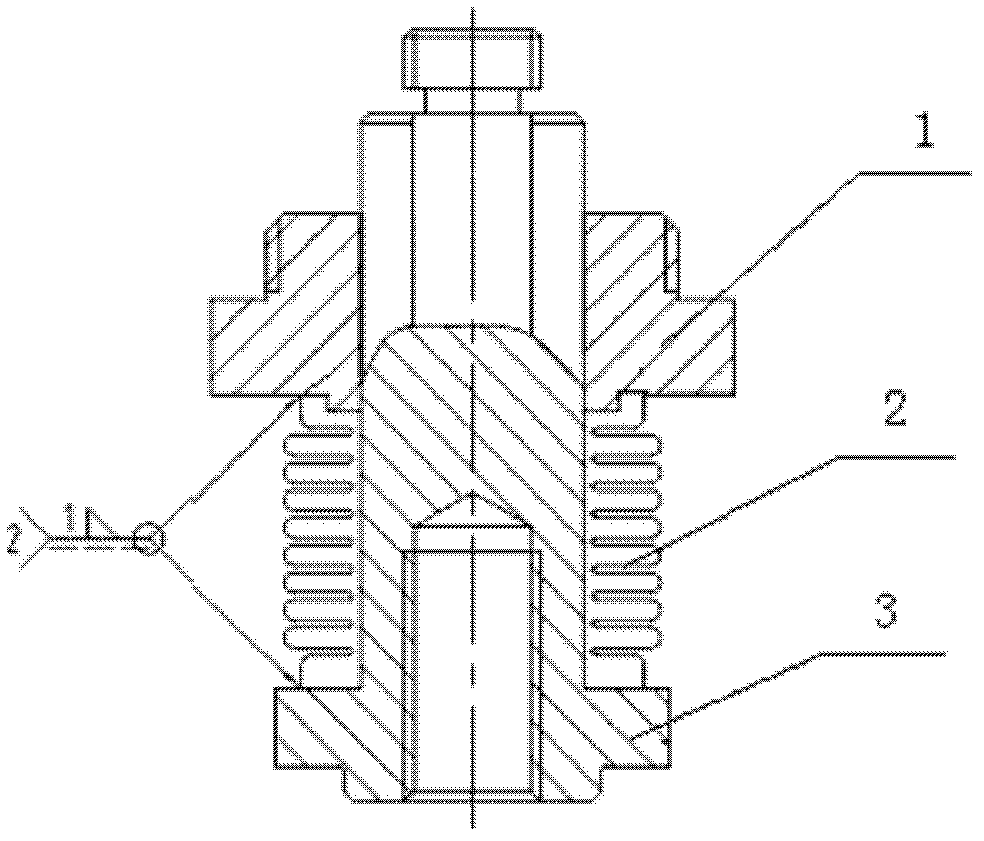

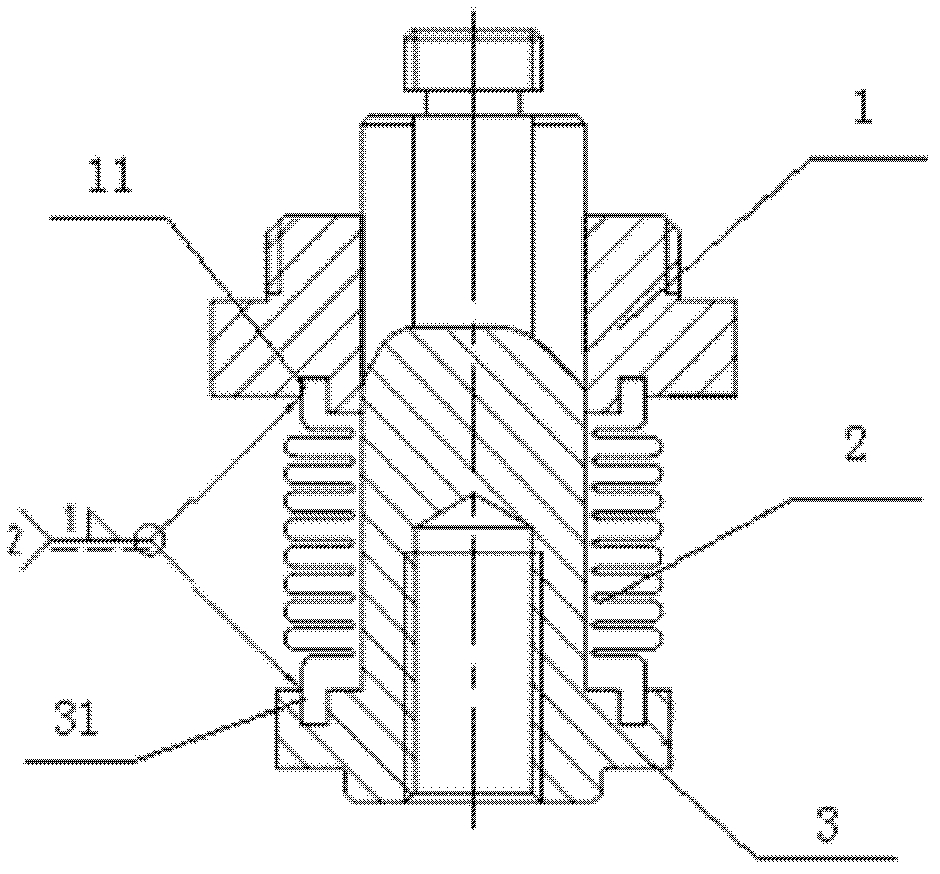

InactiveCN102384310AIncrease the welding areaImprove sealingSpindle sealingsSoldering apparatusEngineeringAir tightness

The invention discloses a bellows assembly of an SF6 valve and a manufacturing method thereof. The bellows assembly comprises a valve rod, a support seat and a bellows, wherein the support seat is fixedly connected with the valve rod, and the valve rod is provided with a circular flange; the bellows is sleeved at the periphery of the valve rod between the circular flange and the support seat; and two ends of the bellows are respectively arranged in annular grooves formed on two oppositely arranged end faces of the circular flange and the support seat, and the bellows and the annular grooves are fixed by means of braze welding. Therefore, by using the bellows assembly of the SF6 valve disclosed by the invention, open welding between the mouth of the bellows and the valve rod as well as the support seat can be effectively avoided, thereby greatly improving the air tightness and service life of the bellows assembly.

Owner:JIANGSU CHENDONG MACHINERY MFG

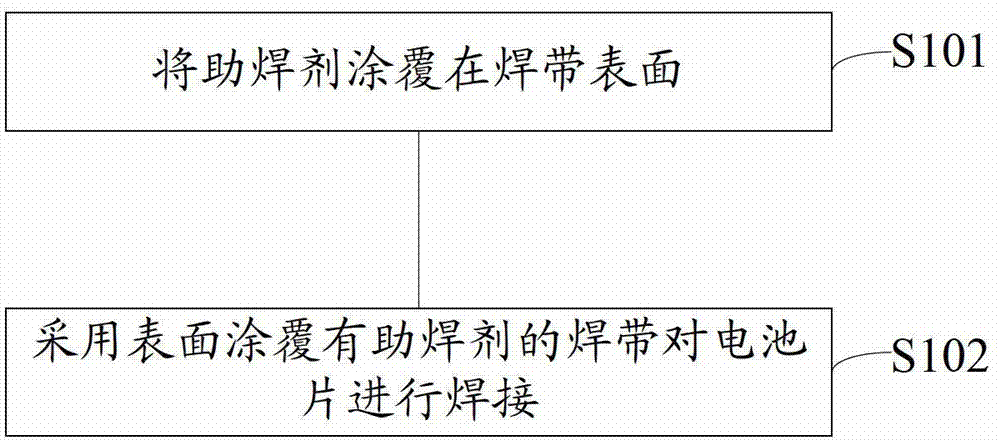

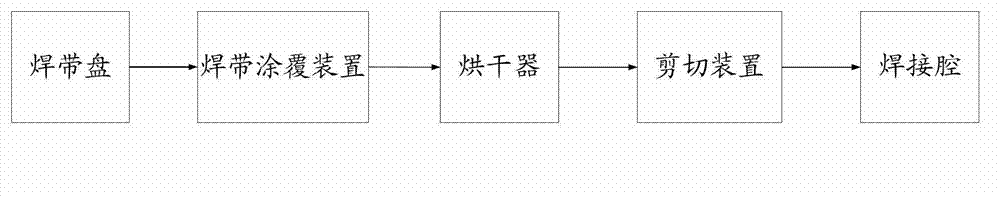

Welding method and welding system

InactiveCN103084685APrevent crystallizationReduced impact on weld qualitySolder feeding devicesMetallurgyImpurity

The invention provides a welding method which comprises coating scaling powder on the surface of a solder strip, and carrying out welding to battery pieces by adopting the solder strip with the scaling powder coated on the surface of the solder strip. The invention further provides a welding system which comprises a solder strip reel with a solder strip installed, a shearing device used for shearing the solder strip and a welding cavity, and further comprises a scaling powder coating device, wherein the first end of the scaling powder coating device is connected with the solder strip reel, the second end of the scaling powder coating device is connected with the shearing device, and the scaling powder is contained inside the scaling powder coating device. On one hand, the welding method and the welding system can reduce the influence of the impurities of the scaling powder to welding quality, avoid a solder skip phenomenon caused by unevenly coated scaling powder, and improve the welding quality between battery pieces. On the other hand, in a scaling powder coating process, the welding method and the welding system remove the turning over operation of the battery pieces, and therefore reduce the fragment risk of the battery pieces.

Owner:LIXIAN YINGLI NEW ENERGY CO LTD

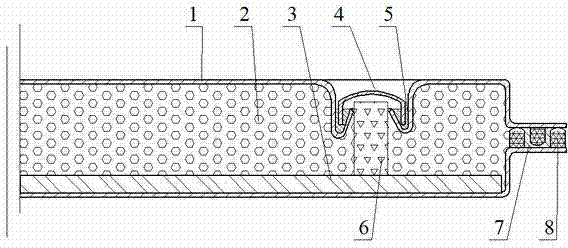

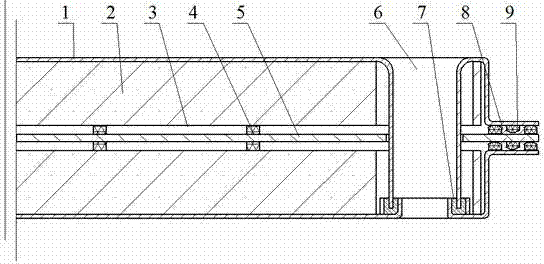

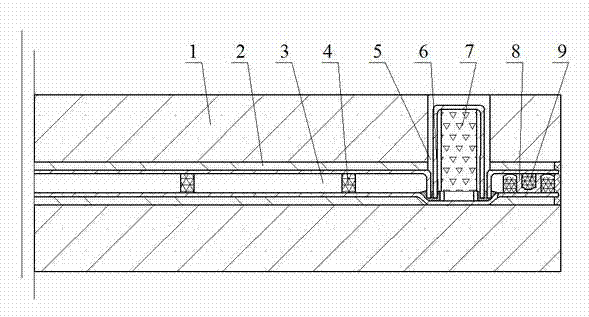

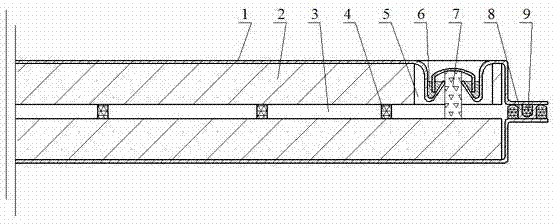

Composite vacuum plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746650AImprove air tightnessImprove sound insulationClimate change adaptationInsulation improvementThermal dilatationAir tightness

A composite vacuum plate with the edge sealed by a seal strip comprises a face plate, a core plate and a vacuum cavity and is characterized in that the face plate is fixed to the upper surface outside the vacuum cavity in a welding or bonding mode, the core plate is arranged at the bottom of the inside of the vacuum cavity, the vacuum cavity is formed by welding a low-carbon steel plate, the face plate and / or the core plate provide / provides additional strength for the vacuum cavity, the vacuum cavity is welded and sealed by utilizing a glass solder in a vacuum furnace under the high vacuum and high temperature, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, the coefficient of thermal expansion of the low-carbon steel plate is matched with that of the glass solder, and a support is arranged in the vacuum cavity and is independently manufactured or is directly formed on the inner wall of the vacuum cavity or the core plate. A manufacturing method of the composite vacuum plate is simple in process, the air impermeability of the vacuum cavity of the composite vacuum plate can be effectively ensured, the service life of the composite vacuum plate can be prolonged, and strength, heat-insulation, sound-insulation and fireproof performance and a decorative function can be improved.

Owner:戴长虹

Glass composite vacuum panel with sealing strips and mounting holes and manufacturing method thereof

InactiveCN104746719AImprove air tightnessImprove sound insulationCovering/liningsHeat proofingAlloyComposite plate

A glass composite vacuum panel with sealing strips and mounting holes comprises a surface plate, a connecting layer and a vacuum chamber and is characterized in that the mounting holes are combined with pumping holes and penetrate through the whole composite plate, the surface plate is a glass plate, the vacuum chamber is a closed chamber formed by a metal plate subjected to glass soldering edge sealing at atmospheric pressure and high temperature and high-temperature opening sealing in vacuum, welding portions of the edge of a low-carbon steel plate are provided with the sealing strips, the opening sealing is the automatic sealing of the pumping holes preformed in the vacuum chamber with low-temperature solder in a vacuum furnace according to the principle of liquid seal, the low-temperature solder comprises low-temperature metal and alloy solder, and supporting members are arranged in the vacuum chamber. A manufacturing method of the glass composite vacuum panel with the sealing strips and the mounting holes is simple in process. The manufactured glass composite vacuum panel with the mounting holes can overcome the deficiencies of existing insulation boards and vacuum insulation panels and the strength and thermal insulation, sound insulation and fireproof performance can be improved.

Owner:戴长虹

Glass composite vacuum plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746737AImprove air tightnessImprove sound insulationCovering/liningsHeat proofingThermal dilatationGlass composites

A glass composite vacuum plate with the edge sealed by a seal strip comprises a face plate, a connecting layer and a vacuum cavity and is characterized in that the face plate is a glass plate, the connecting layer enables the face plate and the vacuum cavity to be connected to form a whole, the vacuum cavity is formed by welding a low-carbon steel plate in a vacuum furnace by utilizing a glass solder under the high vacuum and high temperature, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, the low-carbon steel plate is matched with the coefficient of thermal expansion of the glass solder, and a support is arranged in the vacuum cavity and is independently manufactured or is directly formed on the vacuum cavity. A manufacturing method of the glass composite vacuum plate is simple in process, the manufactured glass composite vacuum plate can overcome the shortcomings of existing heat preservation plates and vacuum heat-insulation plates, the air impermeability of the vacuum cavity of the glass composite vacuum plate can be effectively ensured, the service life of the glass composite vacuum plate can be prolonged, and strength and heat-insulation, sound-insulation and fireproof performance can be improved.

Owner:戴长虹

Double-vacuum-layer glass composite vacuum heat-insulation plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746736AImprove air tightnessImprove sound insulationCovering/liningsHeat proofingGlass compositesAlloy

A double-vacuum-layer glass composite vacuum heat-insulation plate with the edge sealed by a seal strip comprises a face plate, a connecting layer and a vacuum cavity and is characterized in that the face plate is a glass plate, the vacuum cavity is a closed cavity formed by welding a low-carbon steel plate and sealing the edge by utilizing a glass solder under the constant pressure and high temperature and performing high-temperature sealing under the vacuum condition, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, the sealing is automatic sealing performed by utilizing an air exhaust opening pre-formed in the vacuum cavity and a low-temperature solder in a vacuum furnace according to a liquid seal principle, the low-temperature solder includes low-temperature metal and an alloy solder, a partition plate is arranged in the vacuum cavity and divides the vacuum cavity into two to form double vacuum layers, and supports are arranged in the vacuum layers. A manufacturing method of the double-vacuum-layer glass composite vacuum heat-insulation plate is simple in process, the manufactured double-vacuum-layer glass composite vacuum heat-insulation plate can overcome the shortcomings of existing heat preservation plates and vacuum heat-insulation plates, and strength and heat-insulation, sound-insulation and fireproof performance can be improved.

Owner:戴长虹

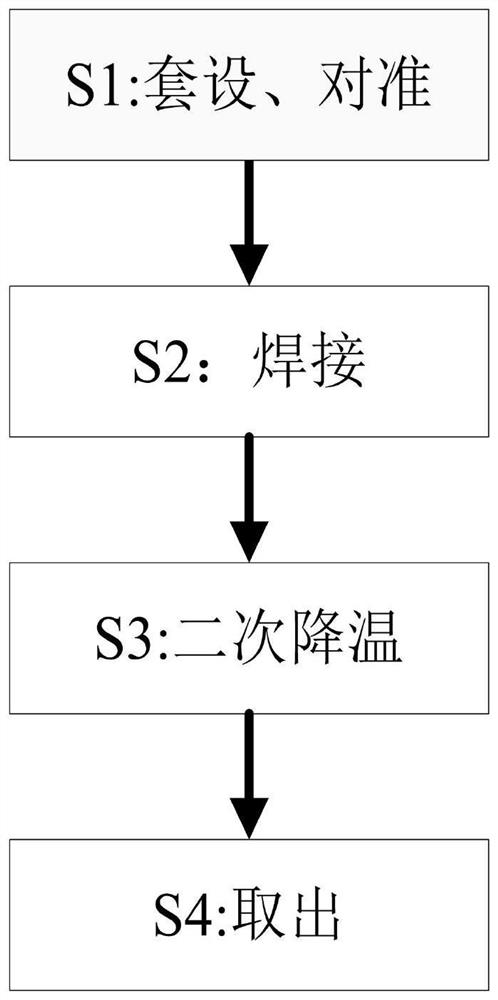

Battery shell manufacturing and processing process

InactiveCN111958140AGuaranteed weldingAvoid indentationCell component detailsWelding apparatusSpot weldingMachining process

The invention provides a battery shell manufacturing and processing process. A bottom plate, a limiting unit, a fixing rod, a lifting air cylinder, a sliding rod, a pushing air cylinder and a spot welding unit cooperate to complete operation. The battery shell manufacturing and processing process can solve the problems that as the thickness of an outer shell is small, a shell is concaved inwards when being clamped by a clamp; lap-joint edge positions are staggered in the clamping process; the condition of leakage welding occurs during electric welding as the lap-joint area of the outer shell is relatively small; the welding position is difficult to rapidly cool down after the battery shell is subjected to spot welding during electric welding; and welding nodules generated after welding aredifficult to timely treat due to the small size, so that the later surface printing process of the battery shell is affected.

Owner:合肥禾松信息科技有限公司

Double-vacuum-layer glass composite vacuum panel with sealing strips and getter and manufacturing method thereof

InactiveCN104746710AIncrease vacuumImprove air tightnessCovering/liningsHeat proofingGlass sheetVacuum chamber

A double-vacuum-layer glass composite vacuum panel with sealing strips and a getter comprises a surface plate, a connecting layer and a vacuum chamber and is characterized in that the surface plate is a glass plate, the vacuum chamber is a closed chamber formed by a low-carbon steel plate subjected to glass soldering edge sealing at atmospheric pressure and high temperature and high-temperature opening sealing in vacuum, welding portions of the edge of the low-carbon steel plate are provided with the sealing strips, the opening sealing is the automatic sealing of pumping holes preformed in the vacuum chamber with low-temperature solder in a vacuum furnace according to the principle of liquid seal, a separation plate separating the vacuum chamber into two to form double vacuum layers is arranged in the vacuum chamber, and supporting members are arranged in the vacuum layers. A manufacturing method of the double-vacuum-layer glass composite vacuum panel with the sealing strips and the getter is simple in process. The manufactured double-vacuum-layer glass composite vacuum panel with the getter can overcome the deficiencies of existing insulation boards and vacuum insulation panels and the strength and thermal insulation, sound insulation and fireproof performance can be improved.

Owner:戴长虹

Metal vacuum composite insulation panel with sealing strips and getter and manufacturing method thereof

InactiveCN104746762ASimple sealing structureReliable sealingCovering/liningsHeat proofingVacuum furnaceClosed cavity

A metal vacuum composite insulation panel with sealing strips and a getter comprises a housing, a core material, a core plate and a vacuum chamber and is characterized in that the housing is a low-carbon steel plate or a low-carbon steel composite plate, the core material is arranged in the vacuum chamber to provide the housing with additional strength to ensure the smoothness of the housing at atmospheric pressure, the vacuum chamber is a closed chamber formed by the housing subjected to glass soldering edge sealing at atmospheric pressure and high temperature and high-temperature opening sealing in vacuum, welding portions of the edge of the low-carbon steel plate are provided with the sealing strips, the coefficient of thermal expansion of the low-carbon steel plate is matched with that of glass solder, the opening sealing is the automatic sealing of pumping holes preformed in the housing with low-temperature solder in a vacuum furnace according to the principle of liquid seal, and the getter is arranged in the vacuum chamber. A manufacturing method of the metal vacuum composite insulation panel with the sealing strips and the getter is simple in process. The manufactured metal vacuum composite insulation panel with the getter can overcome the deficiencies of existing insulation boards and vacuum insulation panels and the strength, thermal insulation, sound insulation and fireproof performance and decorative functions can be improved.

Owner:戴长虹

Ceramic composite vacuum panel with sealing strips and mounting holes and manufacturing method thereof

InactiveCN104746681ANeat and nice edge bandingPrevent missing solderingCovering/liningsHeat proofingVacuum furnaceClosed cavity

A ceramic composite vacuum panel with sealing strips and mounting holes comprises a surface plate, a connecting layer and a vacuum chamber and is characterized in that the mounting holes are combined with pumping holes and penetrate through the whole composite plate, the surface plate is a ceramic plate or tile, the surface plate and / or the connecting layer provide / provides the vacuum chamber with additional strength to ensure the smoothness of the vacuum chamber at atmospheric pressure, the vacuum chamber is a closed chamber formed by a low-carbon steel plate subjected to glass soldering edge sealing at atmospheric pressure and high temperature and high-temperature opening sealing in vacuum, welding portions of the edge of the low-carbon steel plate are provided with the sealing strips, the coefficient of thermal expansion of the low-carbon steel plate is matched with that of glass solder, the opening sealing is the automatic sealing of the pumping holes preformed in the vacuum chamber with low-temperature solder in a vacuum furnace according to the principle of liquid seal, and supporting members are arranged in the vacuum chamber. A manufacturing method of the ceramic composite vacuum panel with the sealing strips and the mounting holes is simple in process. The strength and thermal insulation, sound insulation and fireproof performance of the ceramic composite vacuum panel with the mounting holes can be improved.

Owner:戴长虹

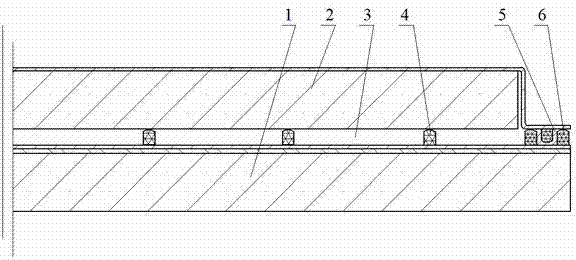

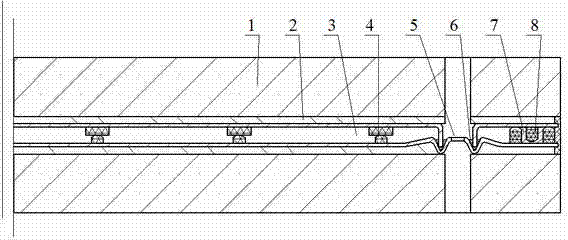

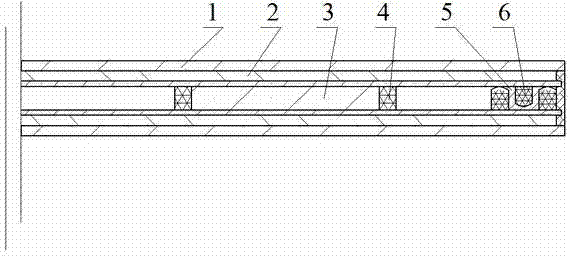

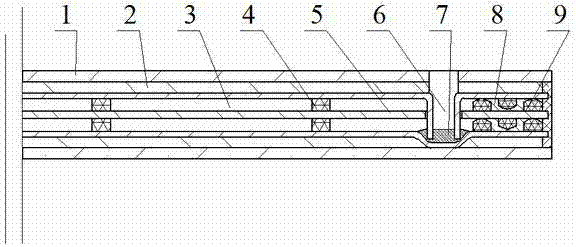

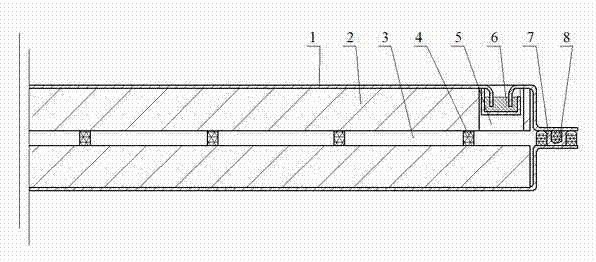

Metal vacuum composite plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746649ANeat and nice edge bandingPrevent missing solderingClimate change adaptationInsulation improvementCarbon steelVacuum furnace

A metal vacuum composite plate with the edge sealed by a seal strip comprises a housing, at least two core plates and a vacuum cavity and is characterized in that the housing is a low-carbon steel plate, the core plates are located in the vacuum cavity formed through seal welding of the housing, the vacuum cavity is welded and sealed by utilizing a glass solder in a vacuum furnace under high vacuum and high temperature, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, the coefficient of thermal expansion of the low-carbon steel plate is matched with that of the glass solder, and a support is arranged between the core plates and is independently manufactured or is directly formed on the core plates. A manufacturing method of the metal vacuum composite plate with the edge sealed by the seal strip is simple in process, the air impermeability of the vacuum cavity of the metal vacuum composite plate can be effectively ensured, the service life of the metal vacuum composite plate can be prolonged, and strength, heat-insulation, sound-insulation and fireproof performance and a decorative function can be improved.

Owner:戴长虹

Double-vacuum-layer ceramic composite vacuum heat-insulation plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746697AImprove air tightnessImprove sound insulationCovering/liningsHeat proofingThermal dilatationCeramic composite

A double-vacuum-layer ceramic composite vacuum heat-insulation plate with the edge sealed by a seal strip comprises a face plate, a connecting layer and a vacuum cavity and is characterized in that the face plate is a ceramic plate or is made of ceramic tiles, the vacuum cavity is a closed cavity formed by welding a low-carbon steel plate and sealing the edge by utilizing a glass solder under the constant pressure and high temperature and performing high-temperature sealing under the vacuum condition, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, and the low-carbon steel plate is matched with the coefficient of thermal expansion of the glass solder. The sealing is automatic sealing performed by utilizing an air exhaust opening pre-formed in the vacuum cavity and a low-temperature solder in a vacuum furnace according to a liquid seal principle, a partition plate is arranged in the vacuum cavity and divides the vacuum cavity into two to form double vacuum layers, and supports are arranged in the vacuum layers. A manufacturing method of the double-vacuum-layer ceramic composite vacuum heat-insulation plate is simple in process, the manufactured double-vacuum-layer ceramic composite vacuum heat-insulation plate can overcome the shortcomings of existing heat preservation plates and vacuum heat-insulation plates, and strength and heat-insulation, sound-insulation and fireproof performance can be improved.

Owner:戴长虹

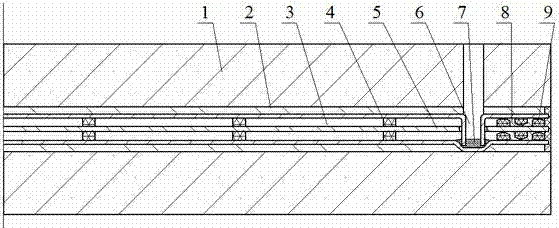

Double-vacuum-layer metal vacuum composite panel with sealing strips and mounting holes and manufacturing method thereof

InactiveCN104746686AImprove air tightnessImprove sound insulationCovering/liningsHeat proofingClosed chamberComposite plate

A double-vacuum-layer metal vacuum composite panel with sealing strips and mounting holes comprises a housing, a core plate and a vacuum chamber and is characterized in that the mounting holes are combined with pumping holes, the housing is a low-carbon steel plate, the core plate is arranged in the vacuum chamber to provide the housing with additional strength to ensure the smoothness of the housing at atmospheric pressure, the vacuum chamber is a closed chamber formed by the housing subjected to glass soldering edge sealing at atmospheric pressure and high temperature and high-temperature opening sealing in vacuum, welding portions of the edge of the low-carbon steel plate are provided with the sealing strips, the opening sealing is the automatic sealing of the pumping holes preformed in the housing with low-temperature solder in a vacuum furnace according to the principle of liquid seal, a separation plate separating the vacuum chamber into two to form double vacuum layers is arranged in the vacuum chamber, and supporting members are arranged in the vacuum layers. A manufacturing method of the double-vacuum-layer metal vacuum composite panel with the sealing strips and the mounting holes is simple in process. The manufactured double-vacuum-layer metal vacuum composite panel can overcome the deficiencies of existing insulation boards and vacuum insulation panels and the strength, thermal insulation, sound insulation and fireproof performance and decorative functions can be improved.

Owner:戴长虹

Double-vacuum-layer ceramic composite vacuum panel with sealing strips and getter and manufacturing method thereof

InactiveCN104746683AIncrease vacuumImprove air tightnessCovering/liningsHeat proofingCeramic compositeVacuum chamber

A double-vacuum-layer ceramic composite vacuum panel with sealing strips and a getter comprises a surface plate, a connecting layer and a vacuum chamber and is characterized in that the surface plate is a ceramic plate or tile, the surface plate and / or the connecting layer provide / provides the vacuum chamber with additional strength to ensure the smoothness of the vacuum chamber at atmospheric pressure, the vacuum chamber is a closed chamber formed by a low-carbon steel plate subjected to glass soldering edge sealing at atmospheric pressure and high temperature and high-temperature opening sealing in vacuum, welding portions of the edge of the low-carbon steel plate are provided with the sealing strips, the opening sealing is the automatic sealing of pumping holes preformed in the vacuum chamber with low-temperature solder in a vacuum furnace according to the principle of liquid seal, a separation plate separating the vacuum chamber into two to form double vacuum layers is arranged in the vacuum chamber, and supporting members are arranged in the vacuum layers. A manufacturing method of the double-vacuum-layer ceramic composite vacuum panel with the sealing strips and the getter is simple in process. The manufactured double-vacuum-layer ceramic composite vacuum panel with the getter can overcome the deficiencies of existing insulation boards and vacuum insulation panels and the strength and thermal insulation, sound insulation and fireproof performance can be improved.

Owner:戴长虹

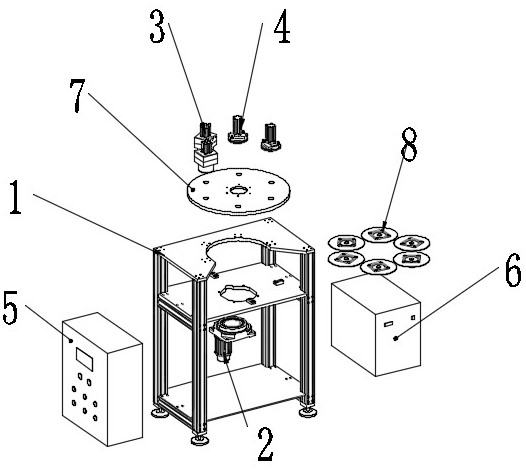

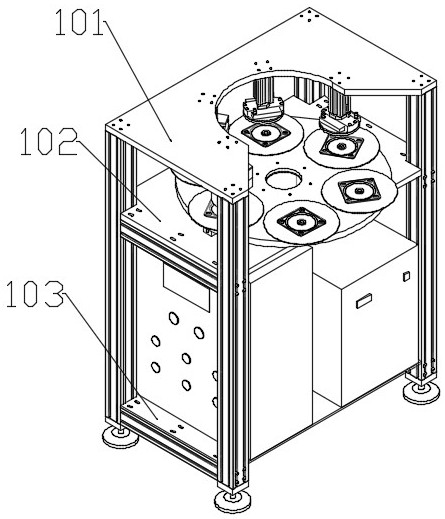

Macromolecule prefabricated part numerical control heat conduction welding table

PendingCN112406113AUniform heat conductionAvoid missing welding and missing weldingEngineeringDigital control

The invention discloses a macromolecule prefabricated part numerical control heat conduction welding table. The welding table is characterized in that an upper plate of a rack is arranged to be in a semi-notch shape, an electric heating constant-temperature welding system and a cooling system are installed on the upper plate, and an air cylinder controls an electric heating metal welding disc anda copper cooling disc to ascend and descend; and a hollow part for placing a central control servo deceleration system is arranged on a workbench of the rack, a turntable is placed on the workbench, the turntable is divided into a welding station, a cooling station and a preparation station, welding workpieces are sequentially placed at the upper end of the turntable, and the central control servodeceleration system is arranged at the lower end of the turntable to drive the turntable to rotate. A numerical control system and a constant-temperature cooling-water machine are arranged on a lowerplate of the rack. The welding table achieves the technical effects of integrating mechanical, electrical, pneumatic and digital control, and embodying high precision, high quality and high efficiency; and the welding process is safer, more environmentally friendly and more comfortable, the structure is integrated, intelligent and flexible, and the production requirements of workpieces of different specifications can be met.

Owner:优尔屋面科技(苏州)有限公司

Glass composite vacuum panel with sealing strips and getter and manufacturing method thereof

InactiveCN104746705AIncrease vacuumImprove air tightnessCovering/liningsHeat proofingThermal insulationAir tightness

A glass composite vacuum panel with sealing strips and a getter comprises a surface plate, a connecting layer and a vacuum chamber and is characterized in that the surface plate is a glass plate, the connecting layer connects the surface plate and the vacuum chamber as a whole, the vacuum chamber is a closed chamber formed by a low-carbon steel plate subjected to glass soldering edge sealing at atmospheric pressure and high temperature and high-temperature opening sealing in vacuum, welding portions of the edge of the low-carbon steel plate are provided with the sealing strips, the opening sealing is the automatic sealing of pumping holes preformed in the vacuum chamber with low-temperature solder in a vacuum furnace according to the principle of liquid seal, and supporting members and the getter are arranged in the vacuum chamber. A manufacturing method of the glass composite vacuum panel with the sealing strips and the getter is simple in process. The glass composite vacuum panel with the getter can effectively ensure the gas tightness of the vacuum chamber, the service life can be prolonged, and the strength and thermal insulation, sound insulation and fireproof performance can be improved.

Owner:戴长虹

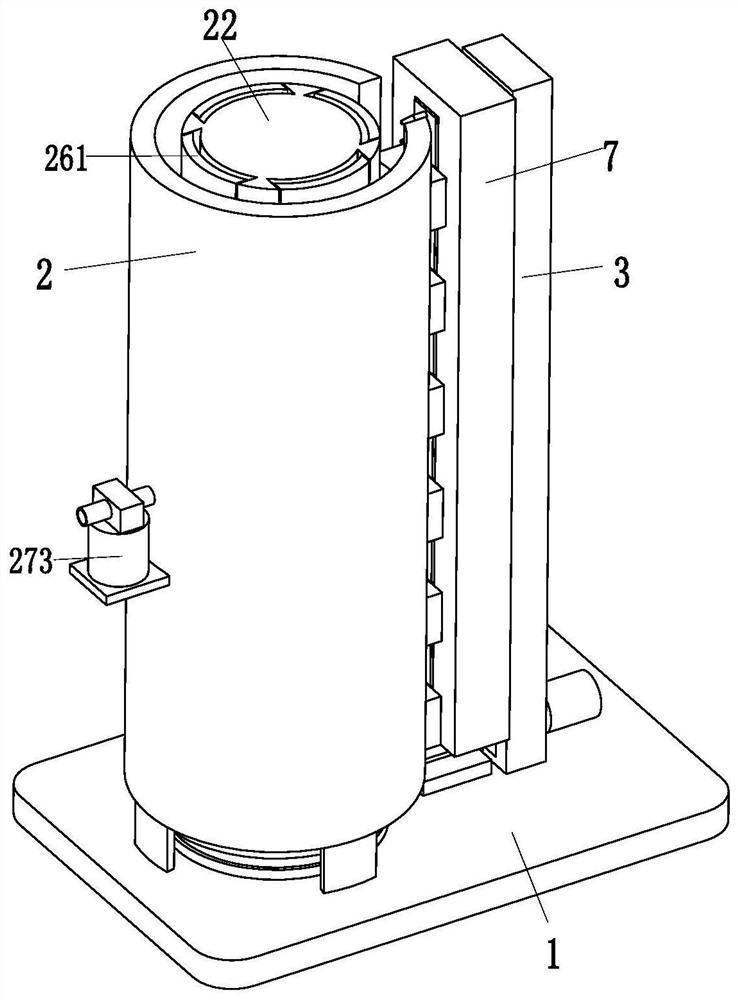

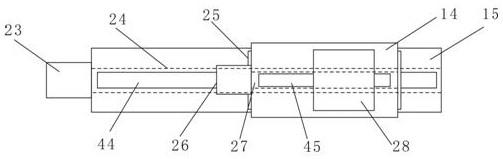

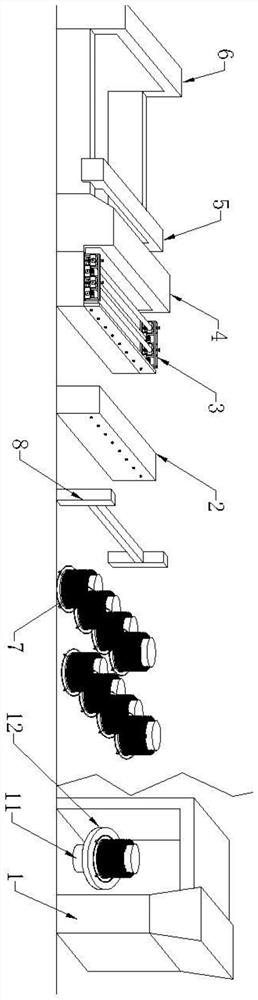

High-precision welding system for metal sheath for fireproof cable

InactiveCN113245740AAvoid missing solderQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesPhysicsWeld seam

The invention relates to a high-precision welding system for a metal sheath for a fireproof cable, which comprises a workbench, and an edge trimming device, a wire wrapping device, a welding joint device and a cooling device which are sequentially arranged on the upper surface of the workbench. The welding joint device comprises a detection mechanism and a welding mechanism. The welding mechanism comprises an adjuster fixedly connected to the workbench, a fine adjustment component connected with the adjuster and a welding head connected with the fine adjustment component. The detection mechanism comprises a visual tracking system, the visual tracking system can drive the fine adjustment component to drive the welding head to reciprocate in the horizontal direction, and a welding edge line cleaning device is arranged on the front side of the welding joint device. Before welding, the side edge of a metal band is treated and deburred through the welding edge line cleaning device, the situation that since powder accumulation occurs at the butt welding joint position, the welding quality is affected is avoided, the butt joint position of the metal band is tracked through the visual tracking system in the welding process and fed back to the fine adjustment component for real-time adjustment, and the phenomenon of weld skip is avoided.

Owner:NANYANG CABLE TIANJIN

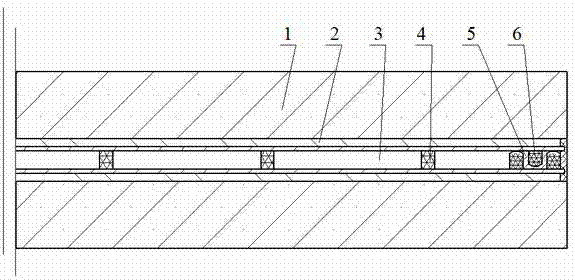

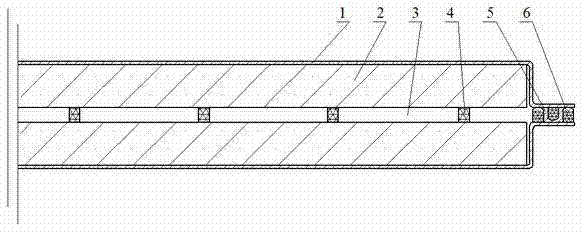

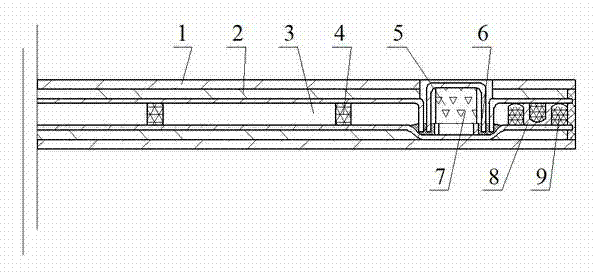

Metal composite vacuum plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746657ANeat and nice edge bandingPrevent missing solderingClimate change adaptationInsulation improvementCarbon steelVacuum furnace

A metal composite vacuum plate with the edge sealed by a seal strip comprises a face plate, a connecting layer and a vacuum cavity and is characterized in that the face plate is a metal plate, the connecting layer enables the face plate and the vacuum cavity to be connected to form a whole, the face plate and / or the connecting layer provide / provides additional strength for the vacuum cavity and ensure / ensures the smoothness of the vacuum cavity under atmospheric pressure, the vacuum cavity is formed by welding a low-carbon steel plate in a vacuum furnace by utilizing a glass solder under the high vacuum and high temperature, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, the low-carbon steel plate is matched with the coefficient of thermal expansion of the glass solder, and a support is arranged in the vacuum cavity and is independently manufactured or is directly formed on the vacuum cavity. A manufacturing method of the metal composite vacuum plate is simple in process, the air impermeability of the vacuum cavity of the metal composite vacuum plate can be effectively ensured, the service life of the metal composite vacuum plate can be prolonged, and strength and heat-insulation, sound-insulation and fireproof performance can be improved.

Owner:戴长虹

Metal vacuum composite panel with sealing strips and getter and manufacturing method thereof

InactiveCN104746682ASimple sealing structureReliable sealingCovering/liningsHeat proofingVacuum furnaceClosed cavity

A metal vacuum composite panel with sealing strips and a getter comprises a housing, at least two core plates and a vacuum chamber and is characterized in that the housing is a low-carbon steel plate, the core plate is arranged in the vacuum chamber to provide the housing with additional strength to ensure the smoothness of the housing at atmospheric pressure, the vacuum chamber is a closed chamber formed by the housing subjected to glass soldering edge sealing at atmospheric pressure and high temperature and high-temperature opening sealing in vacuum, welding portions of the edge of the low-carbon steel plate are provided with the sealing strips, the coefficient of thermal expansion of the low-carbon steel plate is matched with that of glass solder, the opening sealing is the automatic sealing of pumping holes preformed in the housing with low-temperature solder in a vacuum furnace according to the principle of liquid seal, the getter is arranged in the vacuum chamber, and supporting members are arranged between the core plates. A manufacturing method of the metal vacuum composite panel with the sealing strips and the getter is simple in process. The manufactured metal vacuum composite panel with the getter can overcome the deficiencies of existing insulation boards and vacuum insulation panels and the strength, thermal insulation, sound insulation and fireproof performance and decorative functions can be improved.

Owner:戴长虹

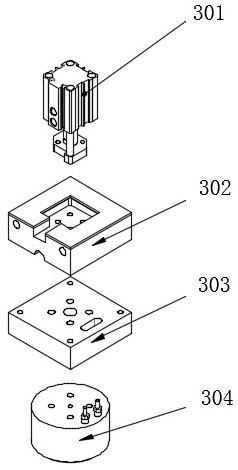

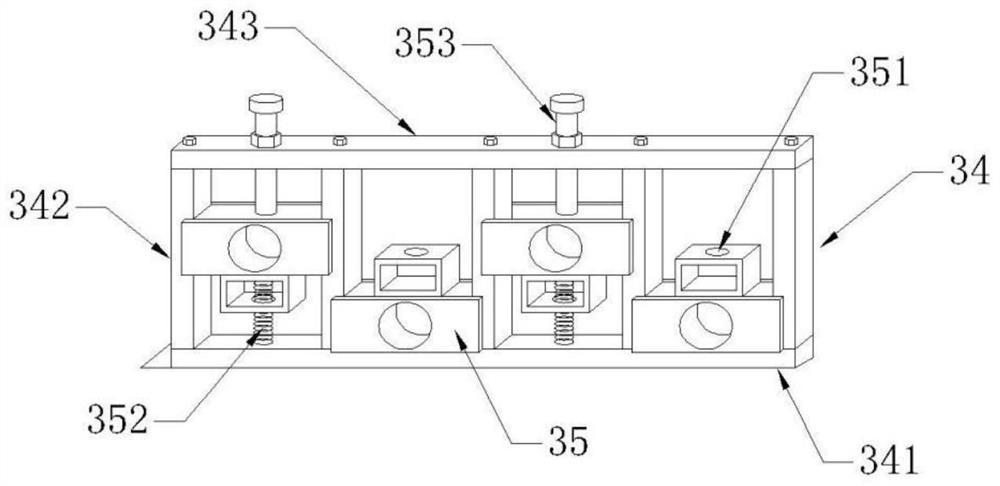

Integrated circuit processing method and processing equipment

PendingCN113690165AAvoid welding inaccurate positionsPrevent lack of weldingSolid-state devicesSemiconductor/solid-state device manufacturingSolderingMechanical engineering

The invention discloses an integrated circuit processing method and equipment, and the equipment comprises a pedestal, the top of the pedestal is fixedly provided with a positioning plate through a support, one side of the top of the positioning plate is fixedly provided with a console, and the top of the positioning plate is fixedly provided with two solder wire fixing plates through a support. Two tin soldering plates are fixedly arranged on the inner walls of the two tin wire fixing plates, a downward-inclined tin soldering plate is fixedly arranged on the outer wall of one side of each tin soldering plate, a fixing groove is formed in the outer wall of the top of each tin soldering plate, and a fixing sleeve is fixedly arranged on the inner wall of each fixing groove. The top of the integrated circuit board is welded through cooperation of the multiple lead sleeves and the laser tin melting spotlight, after the integrated circuit board moves on the tin soldering plate and the bottom of the tin soldering plate, top tin soldering of the integrated circuit board is completed, the tin soldering efficiency of the top of the integrated circuit board is greatly improved, the using effect is good, and large-scale batch processing of integrated circuit boards in existing factories is met.

Owner:谢利洪

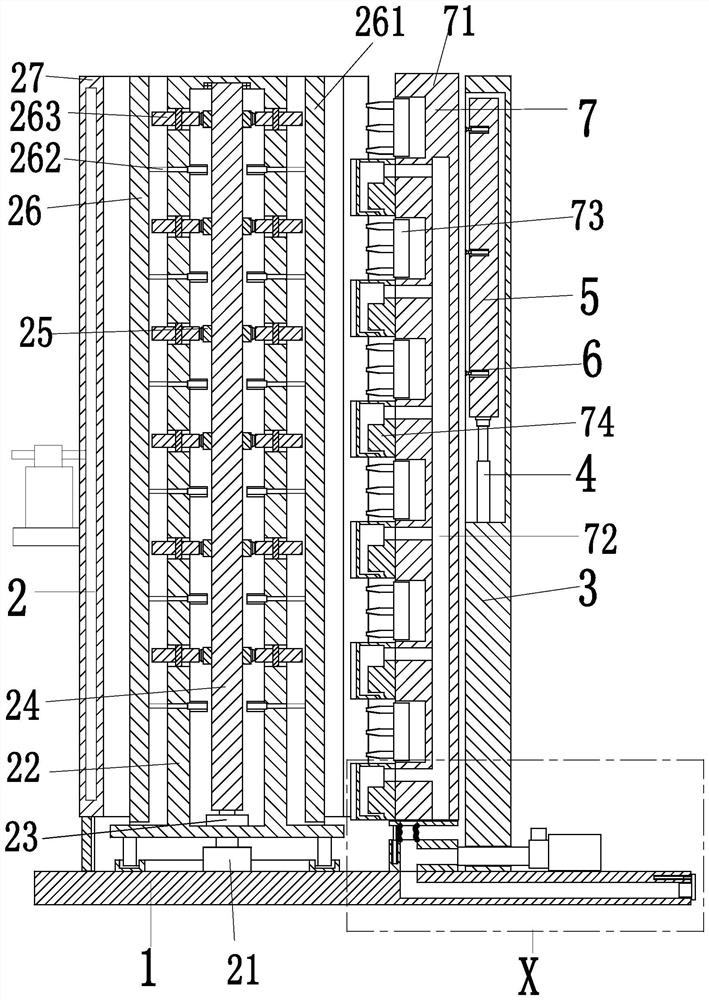

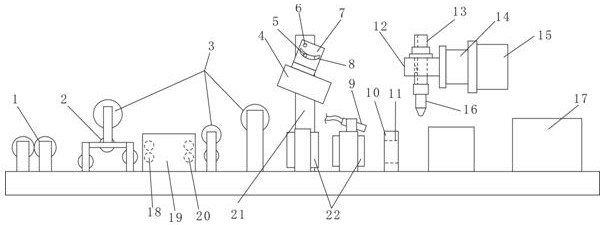

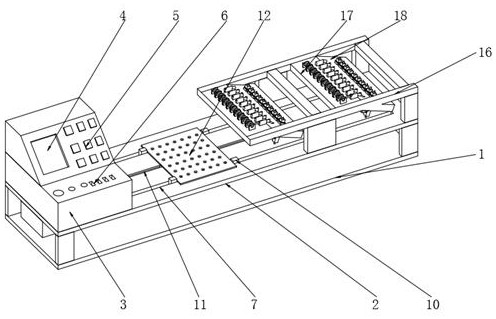

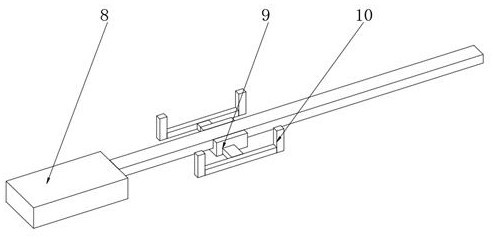

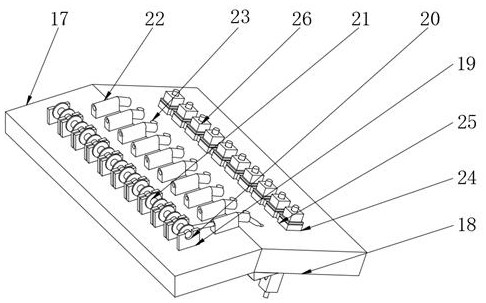

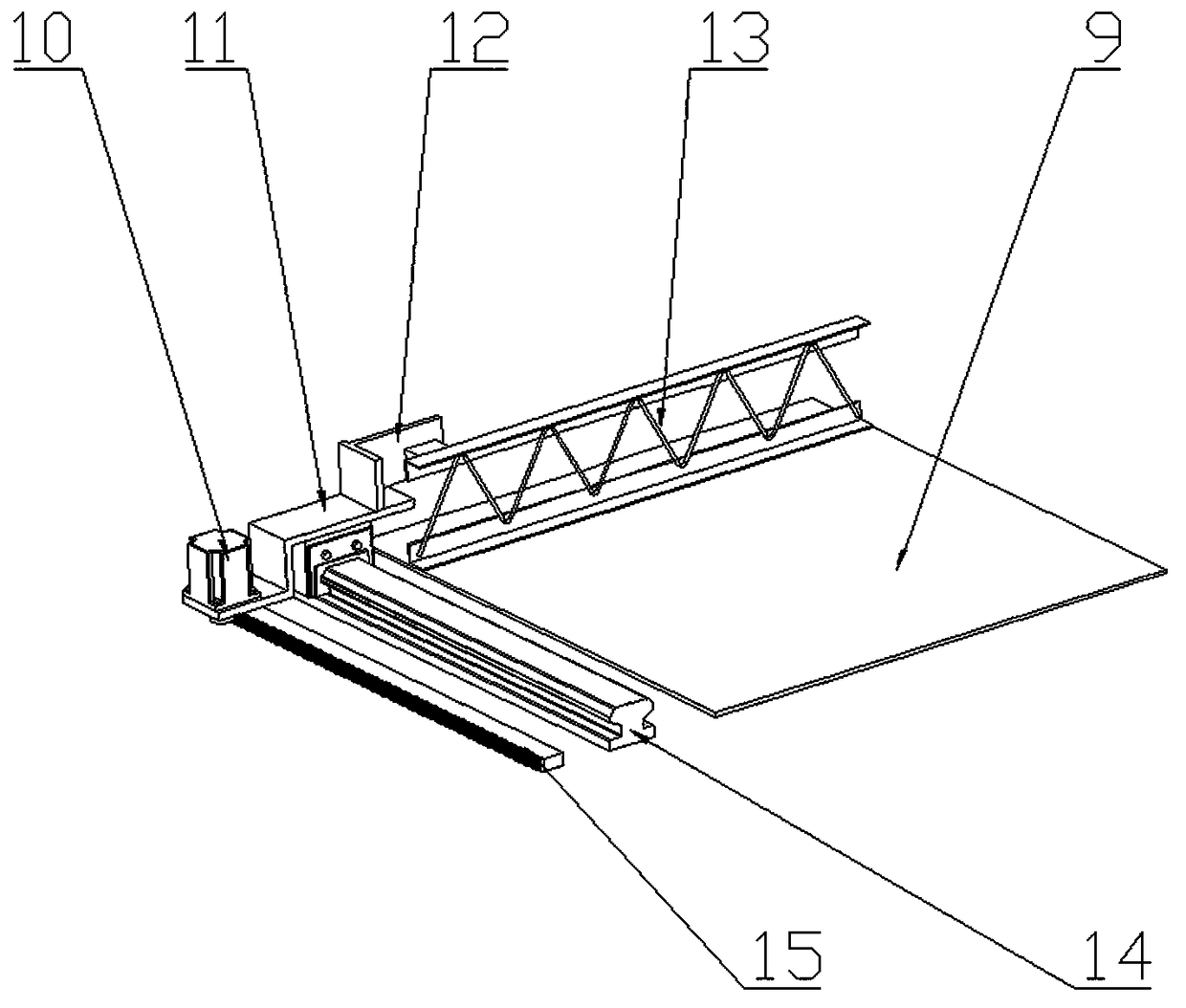

Automatic welding device and process for reinforcing mesh

ActiveCN114054992APrevent missing solderingAvoid offsetWelding/soldering/cutting articlesMetal working apparatusRebarManufacturing engineering

The invention discloses an automatic welding device and process for a reinforcing mesh, and the automatic welding device is sequentially provided with a wire drawing mechanism, a pay-off rack, a straightening mechanism, a feeding mechanism, a welding mechanism, a moving mechanism and a mesh cutting mechanism in the moving direction of longitudinal bars. The production process comprises the steps of wire drawing, straightening (cutting), feeding, welding and automatic cutting to form the reinforcing mesh. The production efficiency and the production quality are greatly improved, the feeding mechanism is arranged at the front end of the welding mechanism, reinforcing steel bars are clamped through the upper feeding roller and the lower feeding roller, and the reinforcing steel bars stably enter the welding mechanism at a preset interval, so that deviation caused by jumping of the reinforcing steel bars is avoided, and the phenomenon of missing welding of the reinforcing steel bars is avoided.

Owner:GUIZHOU PANJIANG REFINED COAL

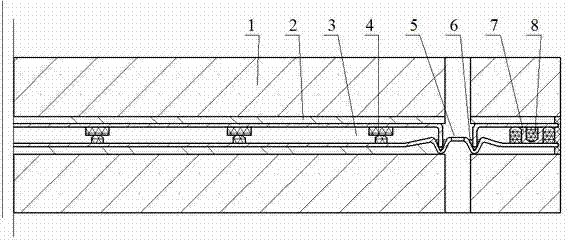

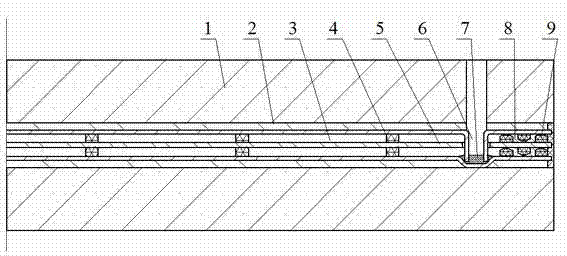

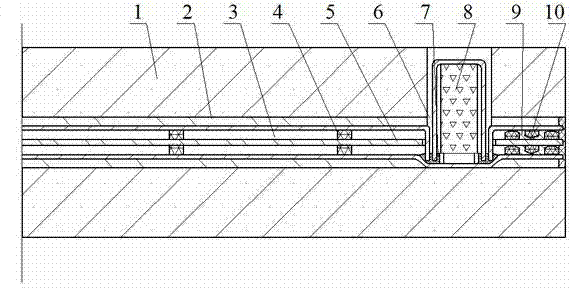

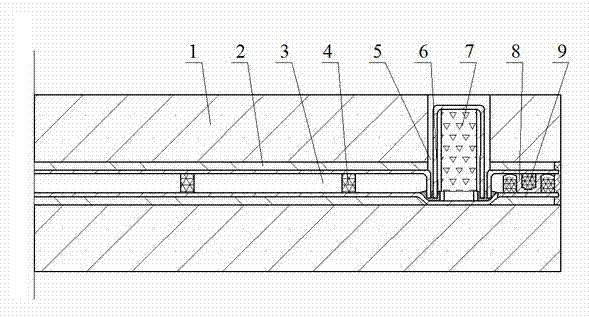

Double-vacuum-layer ceramic composite vacuum plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746691ANeat and nice edge bandingPrevent missing solderingCovering/liningsHeat proofingVacuum furnaceCarbon steel

A double-vacuum-layer ceramic composite vacuum plate with the edge sealed by a seal strip comprises a face plate, a connecting layer and a vacuum cavity and is characterized in that the face plate is a ceramic plate or is made of ceramic tiles, the connection layer enables the face plate and the vacuum cavity to be connected to form a whole, the vacuum cavity is formed by welding a thin low carbon metal plate and is welded and sealed by utilizing a glass solder in a vacuum furnace under the high vacuum and high temperature, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, the coefficient of thermal expansion of the low-carbon steel plate is matched with that of the glass solder, a partition plate is arranged in the vacuum cavity and divides the vacuum cavity into two to form double vacuum layers, and supports are arranged in the vacuum layers and are independently manufactured or are directly formed on the vacuum cavity or the partition plate. A manufacturing method of the double-vacuum-layer ceramic composite vacuum plate is simple in process, and strength and heat-insulation, sound-insulation and fireproof performance can be improved.

Owner:戴长虹

Double-vacuum-layer composite vacuum plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746751AImprove air tightnessImprove sound insulationCovering/liningsHeat proofingThermal expansionEngineering

A double-vacuum-layer composite vacuum plate sealed by a seal strip comprises a face plate, a core plate and a vacuum cavity and is characterized in that the face plate is fixed to the upper surface outside the vacuum cavity in a welding or bonding mode, the core plate is arranged at the bottom of the inside of the vacuum cavity, the vacuum cavity is formed by welding a thin low-carbon steel plate, the face plate and / or the core plate provide / provides additional strength for the vacuum cavity, the vacuum cavity is welded and sealed by utilizing a glass solder in a vacuum furnace under the high vacuum and high temperature, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, the low-carbon steel plate is matched with the coefficient of thermal expansion of the glass solder, a partition plate is arranged in the vacuum cavity and divides the vacuum cavity into two to form double vacuum layers, and supports are arranged in the vacuum layers. A manufacturing method of the double-vacuum-layer composite vacuum plate is simple in process, and strength, heat-insulation, sound-insulation and fireproof performance and a decorative function can be improved.

Owner:戴长虹

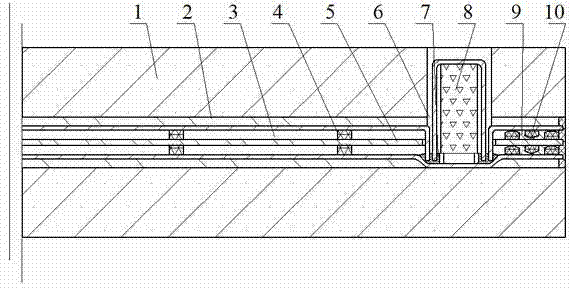

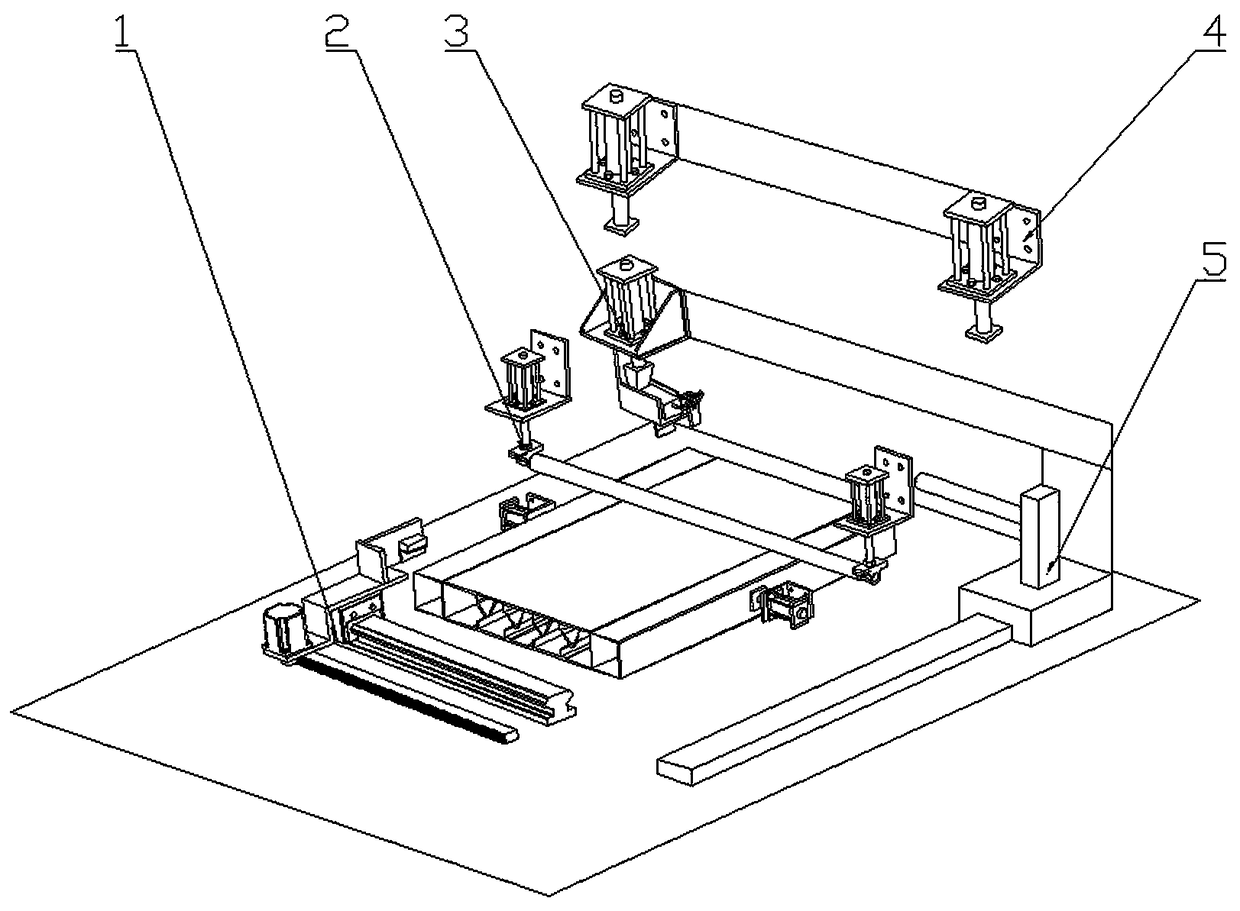

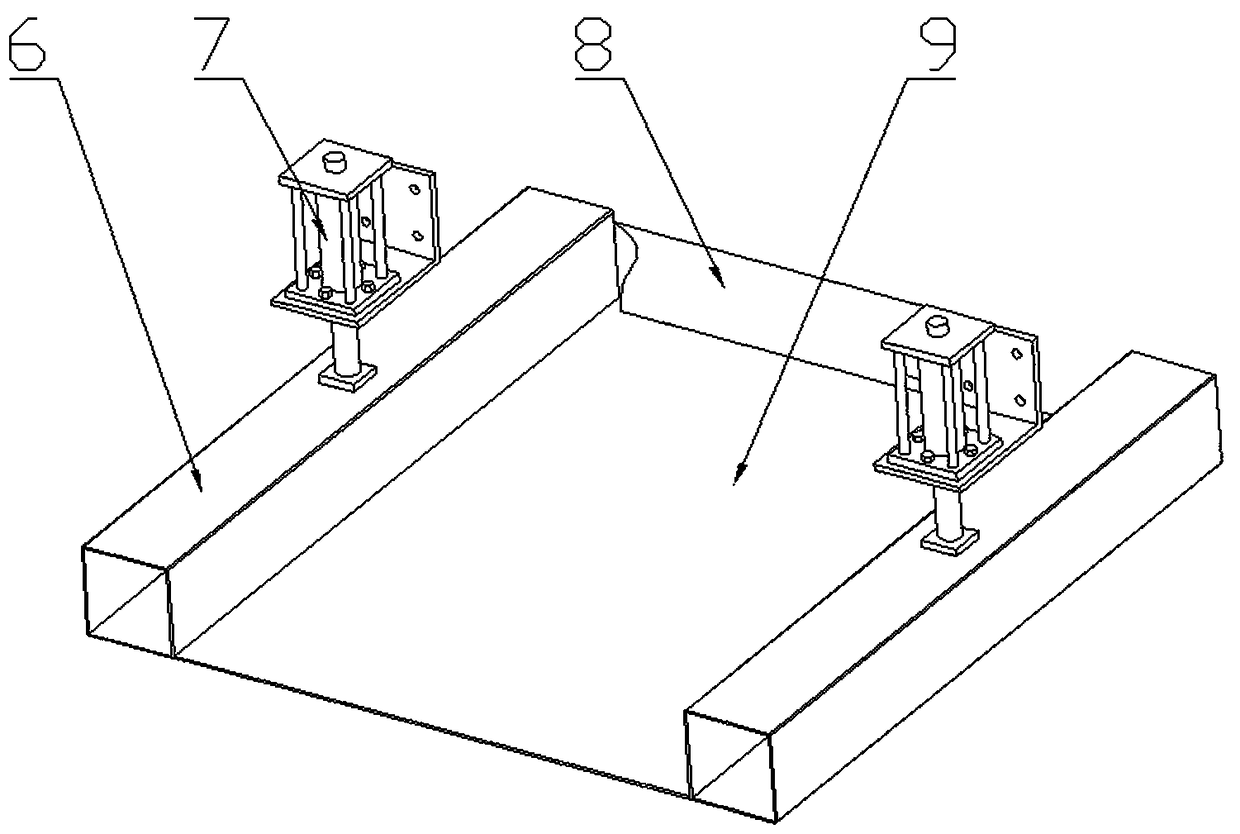

Control method of multi-cavity steel component assembling and positioning mechanism

ActiveCN109048166AIncrease productionImprove qualityWelding/cutting auxillary devicesAuxillary welding devicesDrive motorEngineering

The invention relates to a control method of a multi-cavity steel component assembling and positioning mechanism, and belongs to the technical field of multi-cavity steel component assembling equipment. The mechanism comprises a square tube positioning and pressing frame. Two ends of the square tube positioning and pressing frame are provided with square tube positioning and pressing pieces connected with the square tube positioning and pressing frame in a displacement mode. An electromagnet is arranged at a front end of an end primary positioning piece. A lower end of the end primary positioning piece is provided with an end primary positioning piece guide rail which is in sliding connection with the end primary positioning piece. A driving motor is arranged at the rear end of the end primary positioning piece. A rack guide rail parallel to the end primary positioning piece guide rail is arranged below the driving motor. The rack guide rail is movably engaged with the drive motor. Thelower end of a displacement cylinder is provided with a lock pressing piece which is movably contacted. Two ends of a pressing roller are provided with bearing seats which are movably sleeved with the pressing roller. Pressing cylinders are arranged on the bearing seats. According to the control method of the multi-cavity steel component assembling and positioning mechanism, the method has the advantages of being compact in structure, accurate in positioning and integrated in assembling and welding; and the machining precision of the multi-cavity steel components is improved, and the machining period is shortened.

Owner:浙江东南网架股份有限公司

Double-vacuum-layer metal composite vacuum heat-insulation plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746712AImprove air tightnessImprove sound insulationCovering/liningsHeat proofingComposite plateCarbon steel

A double-vacuum-layer metal composite vacuum heat-insulation plate with the edge sealed by a seal strip comprises a face plate, a connecting layer and a vacuum cavity and is characterized in that the face plate is a metal plate or a metal composite plate, the vacuum cavity is a closed cavity formed by welding a low-carbon steel plate and sealing the edge by utilizing a glass solder under the constant pressure and high temperature and performing high-temperature sealing under the vacuum condition, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, the sealing is automatic sealing performed by utilizing an air exhaust opening pre-formed in the vacuum cavity and a low-temperature solder in a vacuum furnace according to a liquid seal principle, a partition plate is arranged in the vacuum cavity and divides the vacuum cavity into two to form double vacuum layers, and supports are arranged in the vacuum layers. A manufacturing method of the double-vacuum-layer metal composite vacuum heat-insulation plate is simple in process, the manufactured double-vacuum-layer metal composite vacuum heat-insulation plate can overcome the shortcomings of existing heat preservation plates and vacuum heat-insulation plates, and strength and heat-insulation, sound-insulation and fireproof performance can be improved.

Owner:戴长虹

Metal composite vacuum panel with sealing strips and getter and manufacturing method thereof

InactiveCN104746724AGuaranteed suction capacityIncrease vacuumCovering/liningsHeat proofingComposite plateAir tightness

A metal composite vacuum panel with sealing strips and a getter comprises a surface plate, a connecting layer and a vacuum chamber and is characterized in that the surface plate is a metal plate or a metal composite plate, the vacuum chamber is a closed chamber formed by a low-carbon steel plate subjected to glass soldering edge sealing at atmospheric pressure and high temperature and high-temperature opening sealing in vacuum, welding portions of the edge of a low-carbon steel plate are provided with the sealing strips, the opening sealing is the automatic sealing of pumping holes preformed in the vacuum chamber with low-temperature solder in a vacuum furnace according to the principle of liquid seal, and supporting members and the getter are arranged in the vacuum chamber. A manufacturing method of the metal composite vacuum panel with the sealing strips and the getter is simple in process. The manufactured metal composite vacuum panel with the getter can overcome the deficiencies of existing insulation boards, can effectively ensure the gas tightness of the vacuum chamber, the service life can be prolonged, and the strength and thermal insulation, sound insulation and fireproof performance can be improved.

Owner:戴长虹

Stone composite vacuum panel with sealing strips and getter and manufacturing method thereof

InactiveCN104746693AGuaranteed suction capacitySimple sealing structureCovering/liningsHeat proofingAir tightnessNatural stone

A stone composite vacuum panel with sealing strips and a getter comprises a surface plate, a connecting layer and a vacuum chamber and is characterized in that the surface plate is made of natural stone or artificial stone, the vacuum chamber is a closed chamber formed by a low-carbon steel plate subjected to glass soldering edge sealing at atmospheric pressure and high temperature and high-temperature opening sealing in vacuum, welding portions of the edge of the low-carbon steel plate are provided with the sealing strips, the opening sealing is the automatic sealing of pumping holes preformed in the vacuum chamber with low-temperature solder in a vacuum furnace according to the principle of liquid seal, and supporting members and the getter are arranged in the vacuum chamber. A manufacturing method of the stone composite vacuum panel with the sealing strips and the getter is simple in process. The manufactured stone composite vacuum panel with the getter can overcome the deficiencies of existing insulation boards and vacuum insulation panels, can effectively ensure the gas tightness of the vacuum chamber, can prolong the service life and the strength and thermal insulation, sound insulation and fireproof performance can be improved.

Owner:戴长虹

Metal vacuum composite heat-insulation plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746696ANeat and nice edge bandingPrevent missing solderingCovering/liningsHeat proofingVacuum furnaceCarbon steel

A metal vacuum composite heat-insulation plate with edge sealed by a seal strip comprises a housing, at least two core plates and a vacuum cavity and is characterized in that the housing is a low-carbon steel plate, the core plates are located in the vacuum cavity and provides additional strength for the housing, the vacuum cavity is a closed cavity formed by welding the housing and sealing the edge by utilizing a glass solder under the constant pressure and high temperature and performing high-temperature sealing under the vacuum condition, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, and the low-carbon steel plate is matched with the coefficient of thermal expansion of the glass solder. The sealing is automatic sealing performed by utilizing an air exhaust opening pre-formed in the housing and a low-temperature solder in a vacuum furnace according to a liquid seal principle, the low-temperature solder includes low-temperature metal and an alloy solder, and a support is arranged between the core plates. A manufacturing method of the metal vacuum composite heat-insulation plate is simple in process, the manufactured metal vacuum composite heat-insulation plate can overcome the shortcomings of existing heat preservation plates and vacuum heat-insulation plates, and strength, heat-insulation, sound-insulation and fireproof performance and a decorative function can be improved.

Owner:戴长虹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com