Pipe welding device for building construction

A welding device and building construction technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of missing welding, easy fracture of pipes when turned over, and welding bumps, etc., to save labor costs, simple and effective structure, and device operation. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

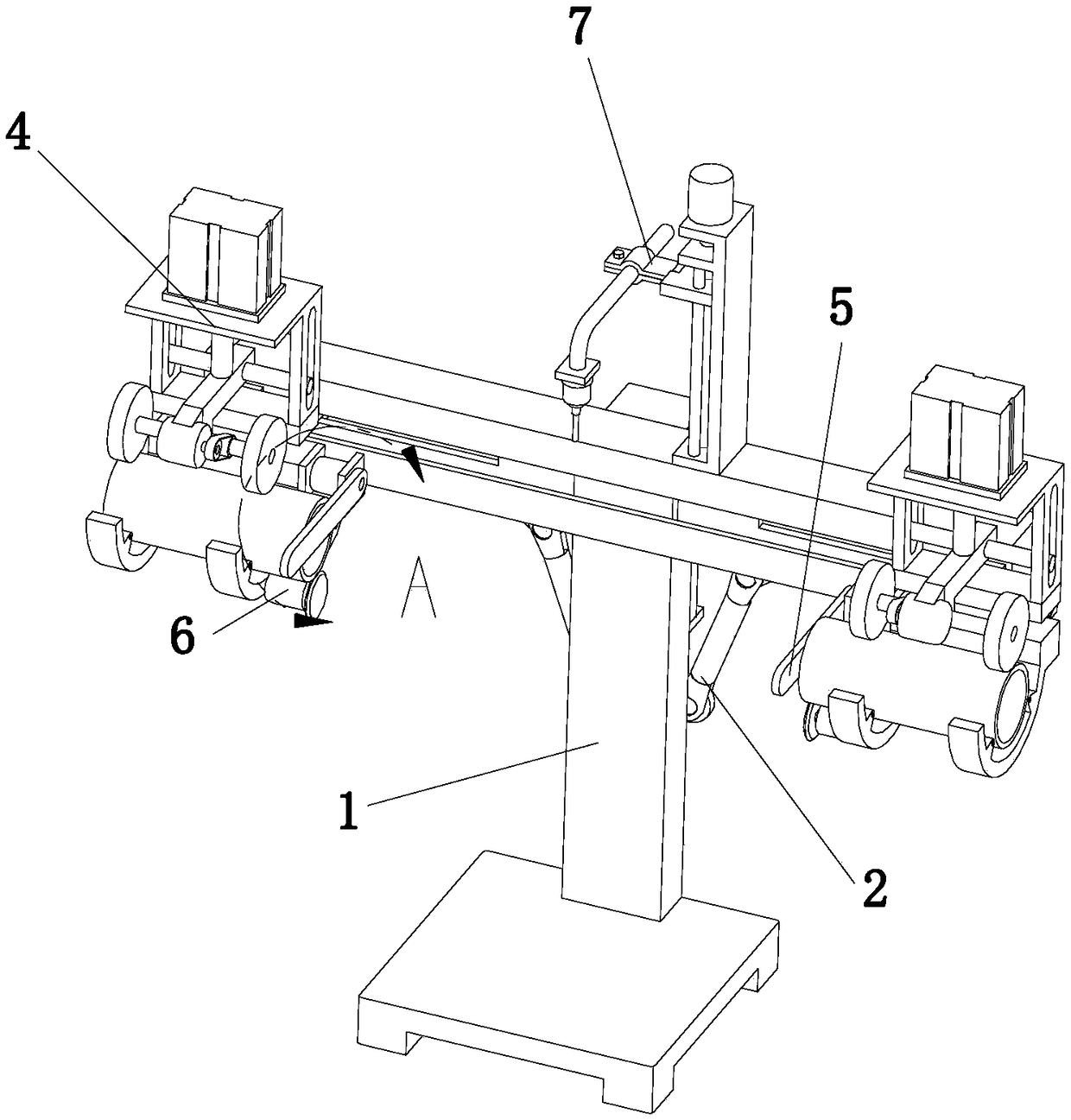

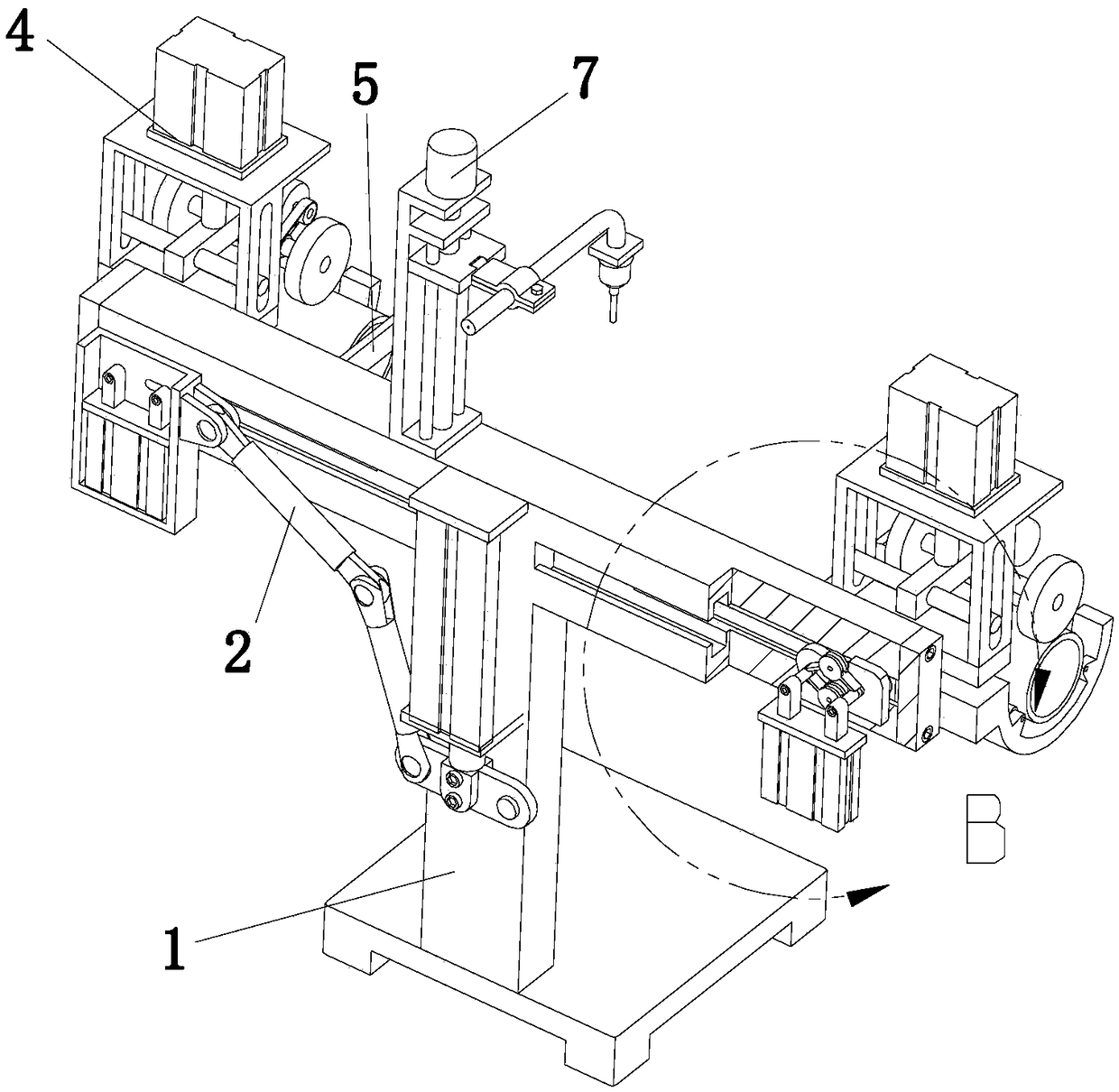

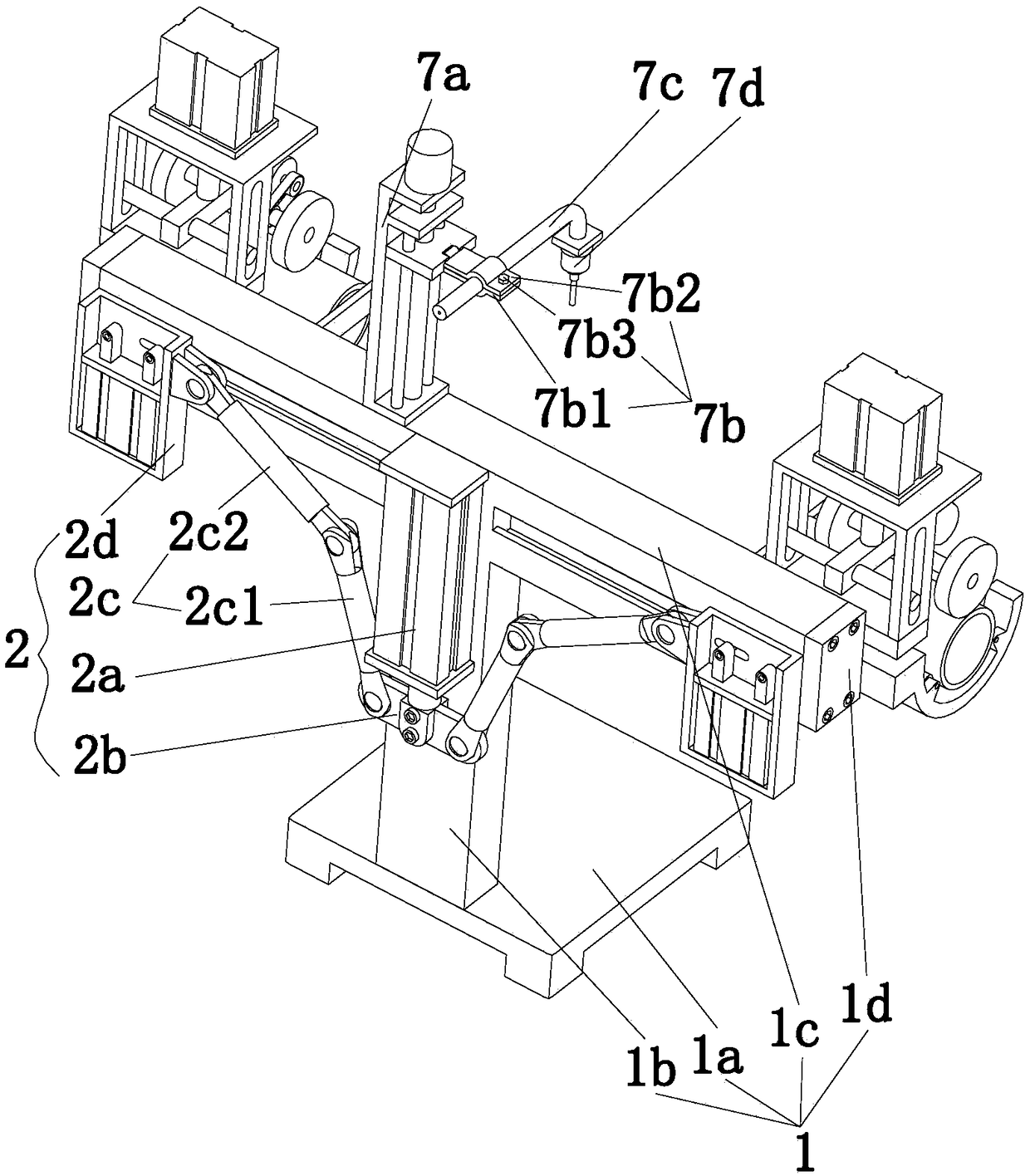

[0037] The invention provides a pipe welding device for building construction, such as Figure 1-Figure 7 As shown, it includes a T-shaped frame 1, a synchronous moving device 2, a fixing device 3, a clamping device 4, a positioning device 5, a trimming device 6, and a welding device 7. The T-shaped frame 1 includes a base 1a, a column 1b, and a beam Track 1c and sealing end 1d, the column 1b is installed on the base 1a, the beam track 1c is horizontally installed on the column 1b, the sealing end 1d is installed at both ends of the beam track 1c, and the synchronous moving device 2 is arranged on On the column 1b, the two fixing devices 3 are arranged on both sides of the column 1b and are connected in transmission with the synchronous moving device 2, and the synchronous moving device 2 can drive the two fixing devices 3 to face each other along the beam track 1c Or relatively synchronous movement, the clamping device 4 is arranged on both sides of the beam track 1c, two cla...

Embodiment 2

[0050] Another scheme after the improvement of the pipe welding device used for building construction of the present invention is as follows, it is a kind of scheme that can be easily moved, as Figure 8 , which includes a guide rail 8a used in conjunction with the base 1a. The guide rail 8a is fixedly installed on the workshop floor. A through groove 8e is provided on the extension part 8c; a plurality of universal balls 8d are set on the top surface of the convex strip 8b, the base 1a can slide on the convex strip 8b, and the universal ball 8d can reduce the frictional force during sliding; the base There are two lockable bolt assemblies 8f on 1a, and the bolt assemblies 8f can slide in the through groove 8e at the same time. When the base 1a moves to a suitable position, the bolt assemblies 8f are locked, and the base 1a and the guide rail 8a are integrated , so that the pipe welding device is in a reasonable position. The advantage of this scheme is that the whole pipe we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com