Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "Increase plate thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

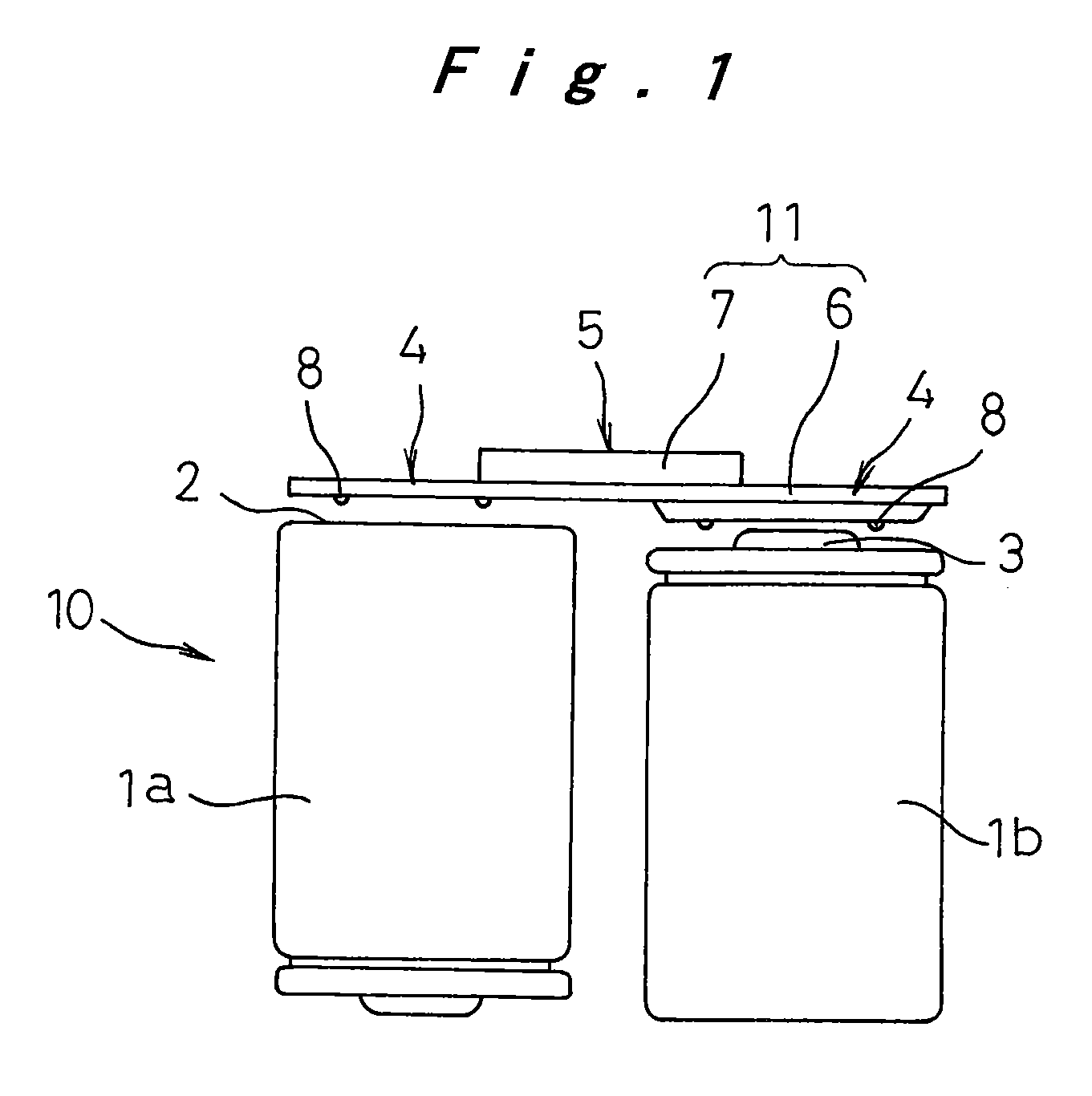

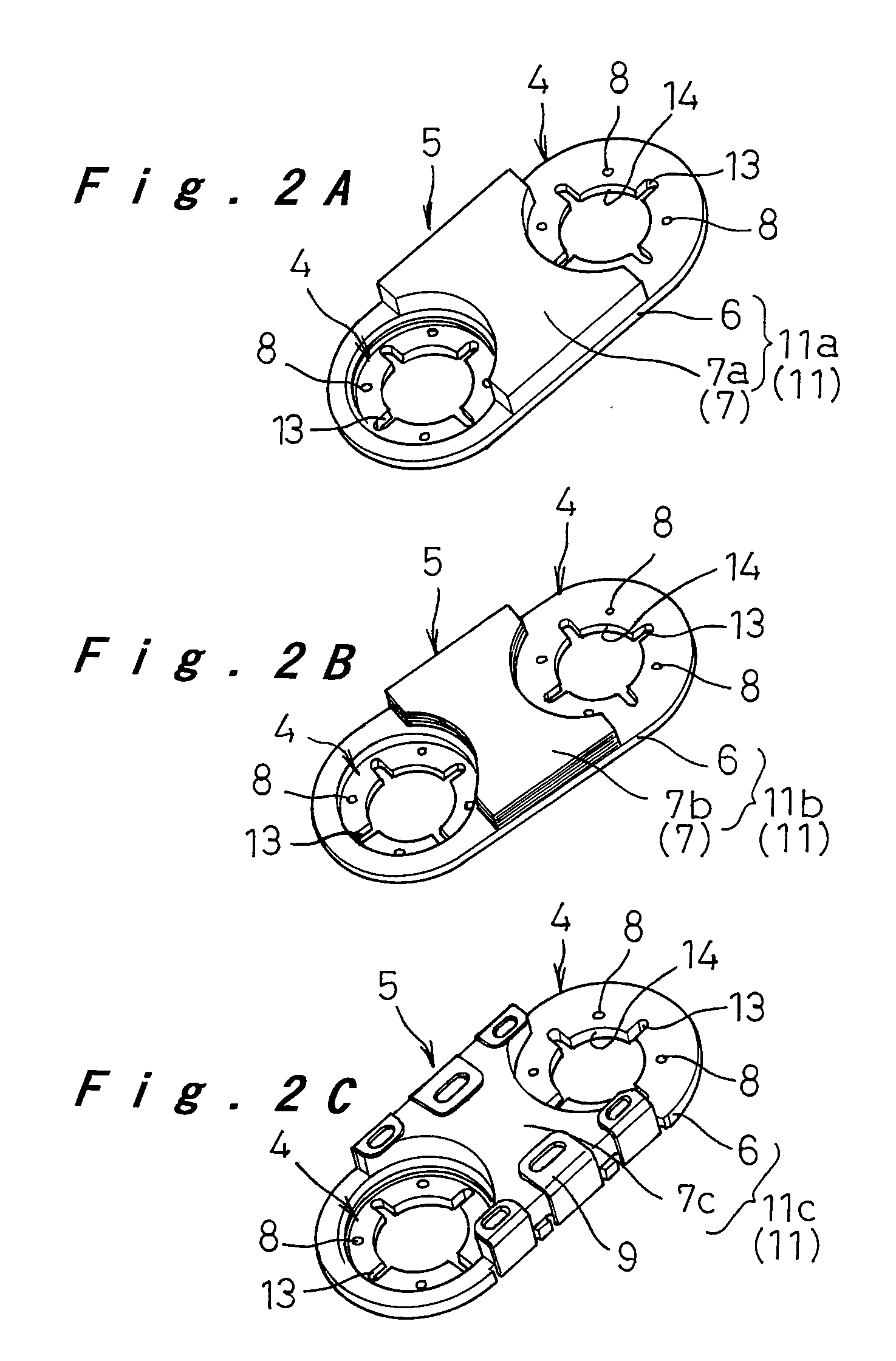

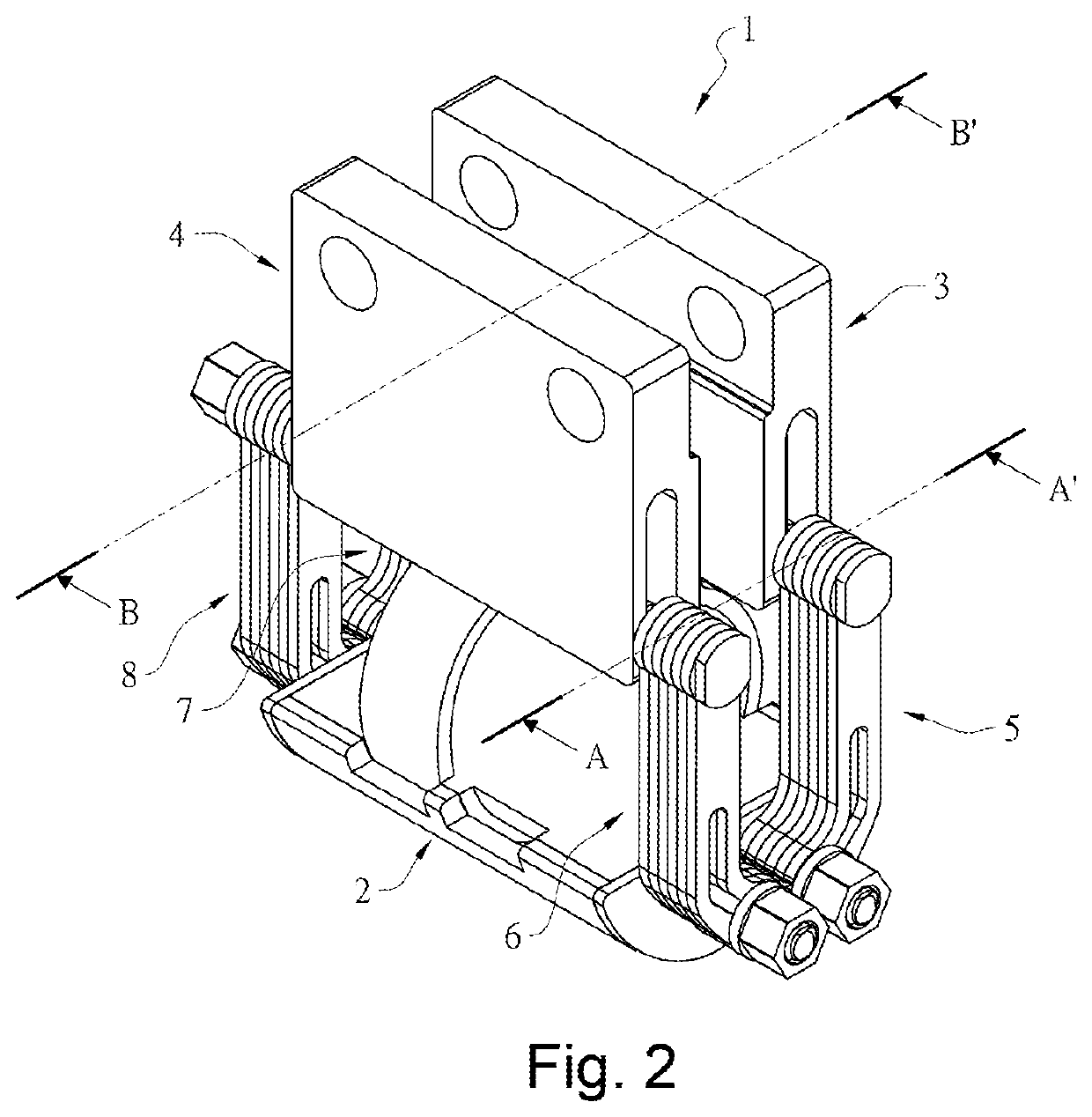

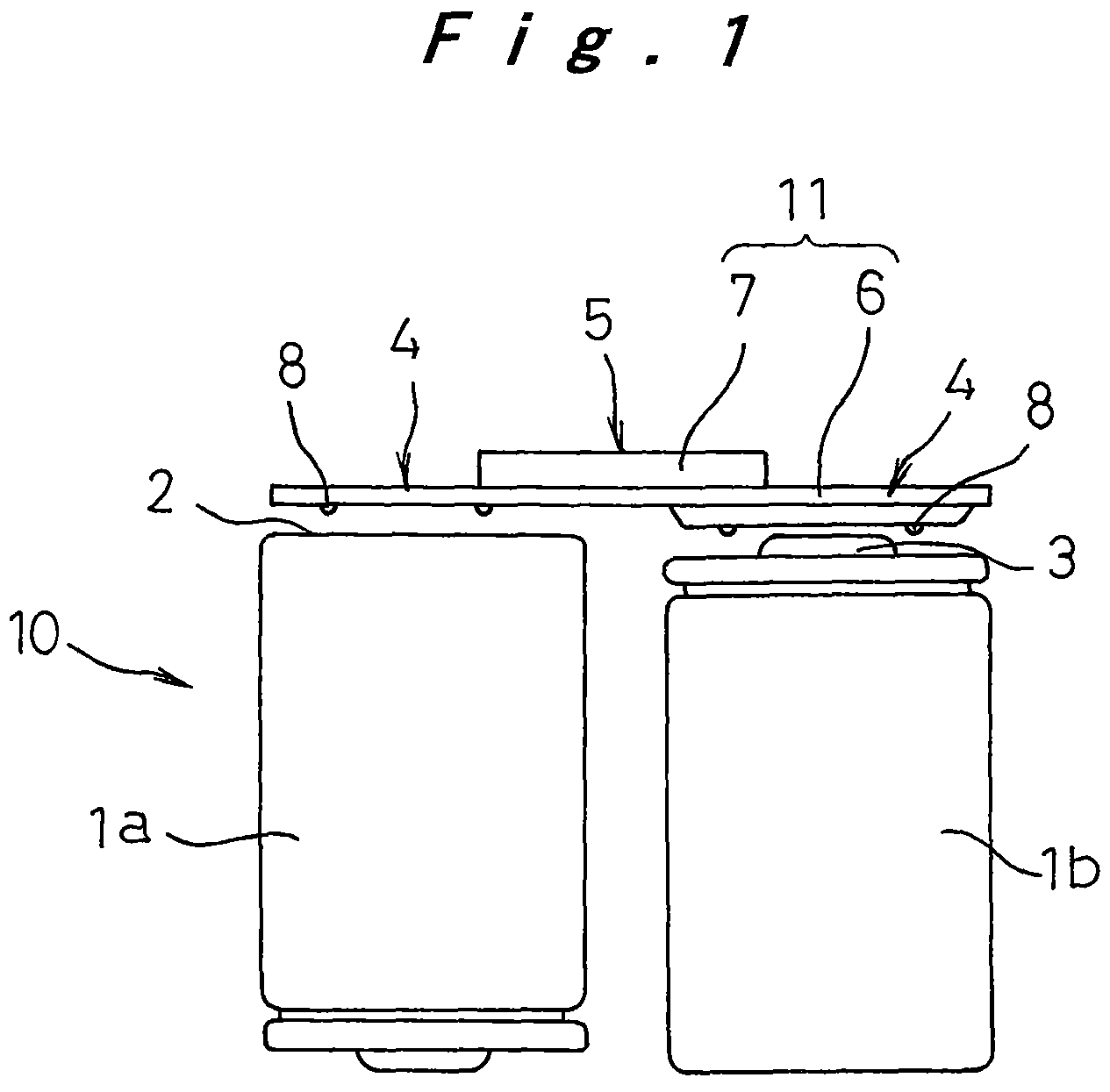

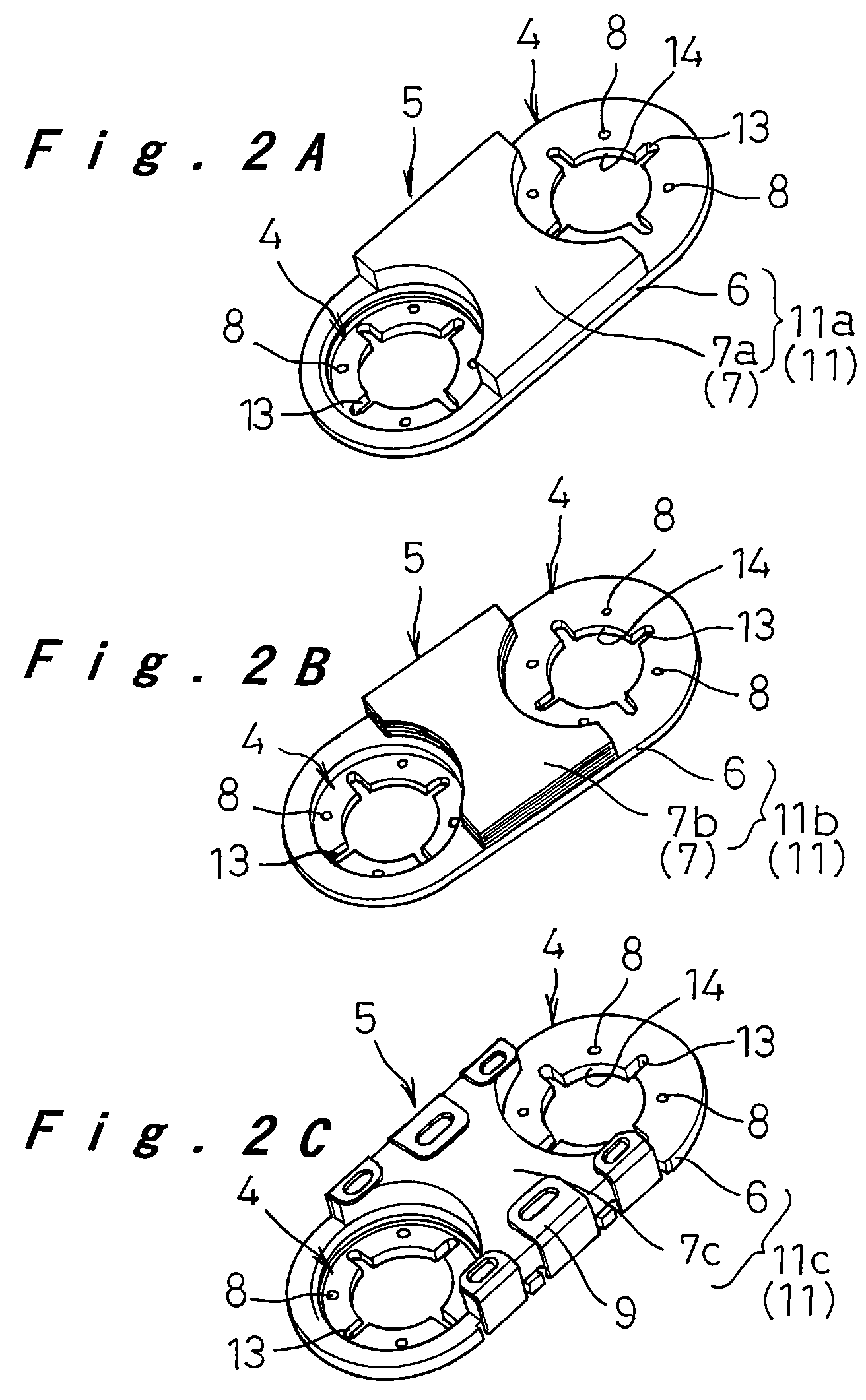

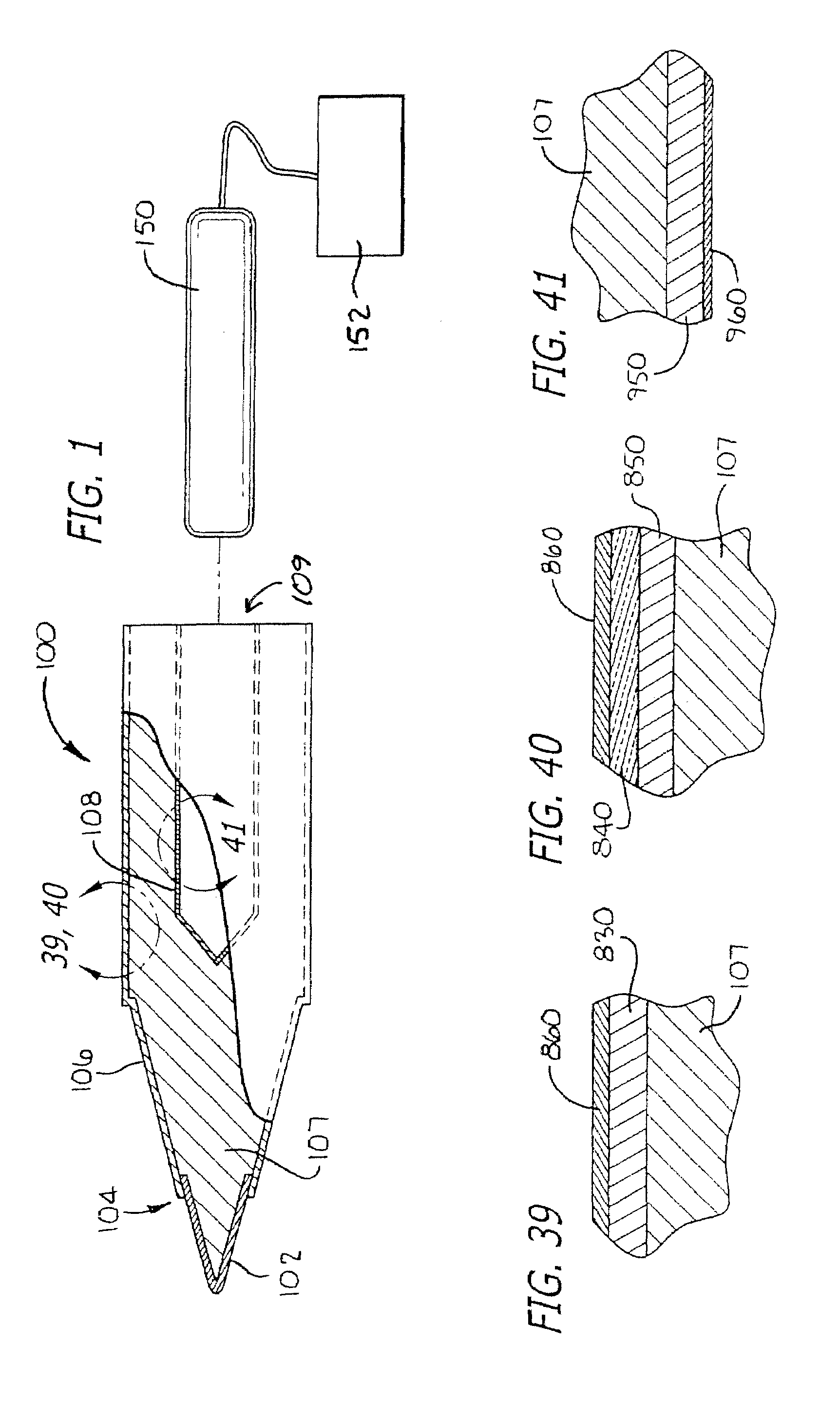

Inter-battery connection device

InactiveUS20090123830A1Avoid problemsReliable weldingPrimary cell to battery groupingNon-aqueous electrolyte accumulatorsElectrical batteryEngineering

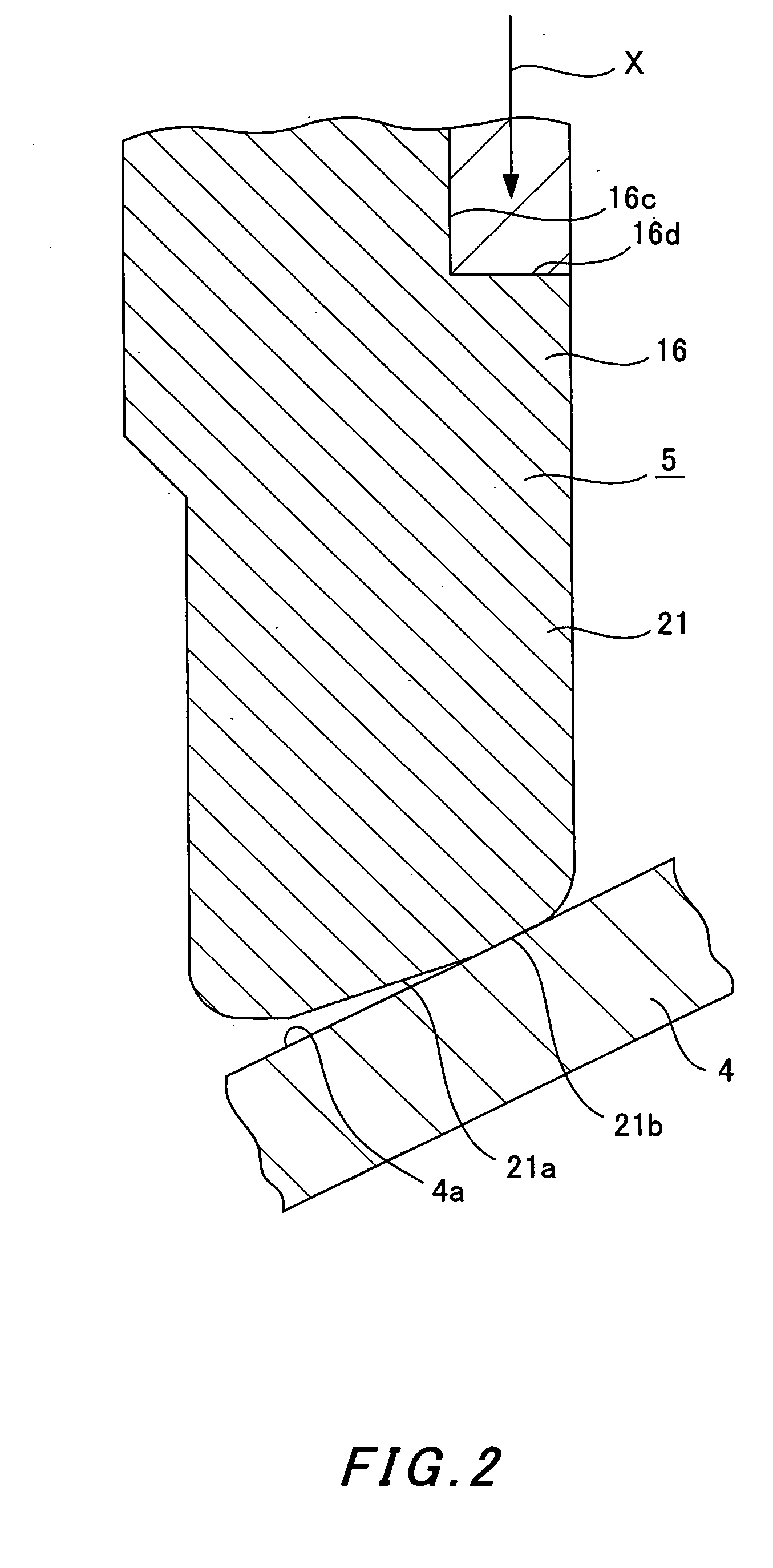

An inter-battery connection device for connecting terminals of two batteries (1a, 1b) arranged with their axes parallel to each other. The inter-battery connection device includes an inter-battery connection plate (11) that connects the battery case bottom (2) and the sealing plate (3) of the two batteries. The inter-battery connection plate (11) includes welding portions (4) at the ends of its base plate (6) for welding to the case bottom (2) and the sealing plate (3), respectively. An intermediate metal plate (7) is joined to the middle part of the base plate (6) between the welding portions (4, 4) to form an intermediate portion (5) having a greater thickness than each welding portion (4). The inter-battery connection device has reduced electric resistance while achieving improved weldability.

Owner:PANASONIC CORP

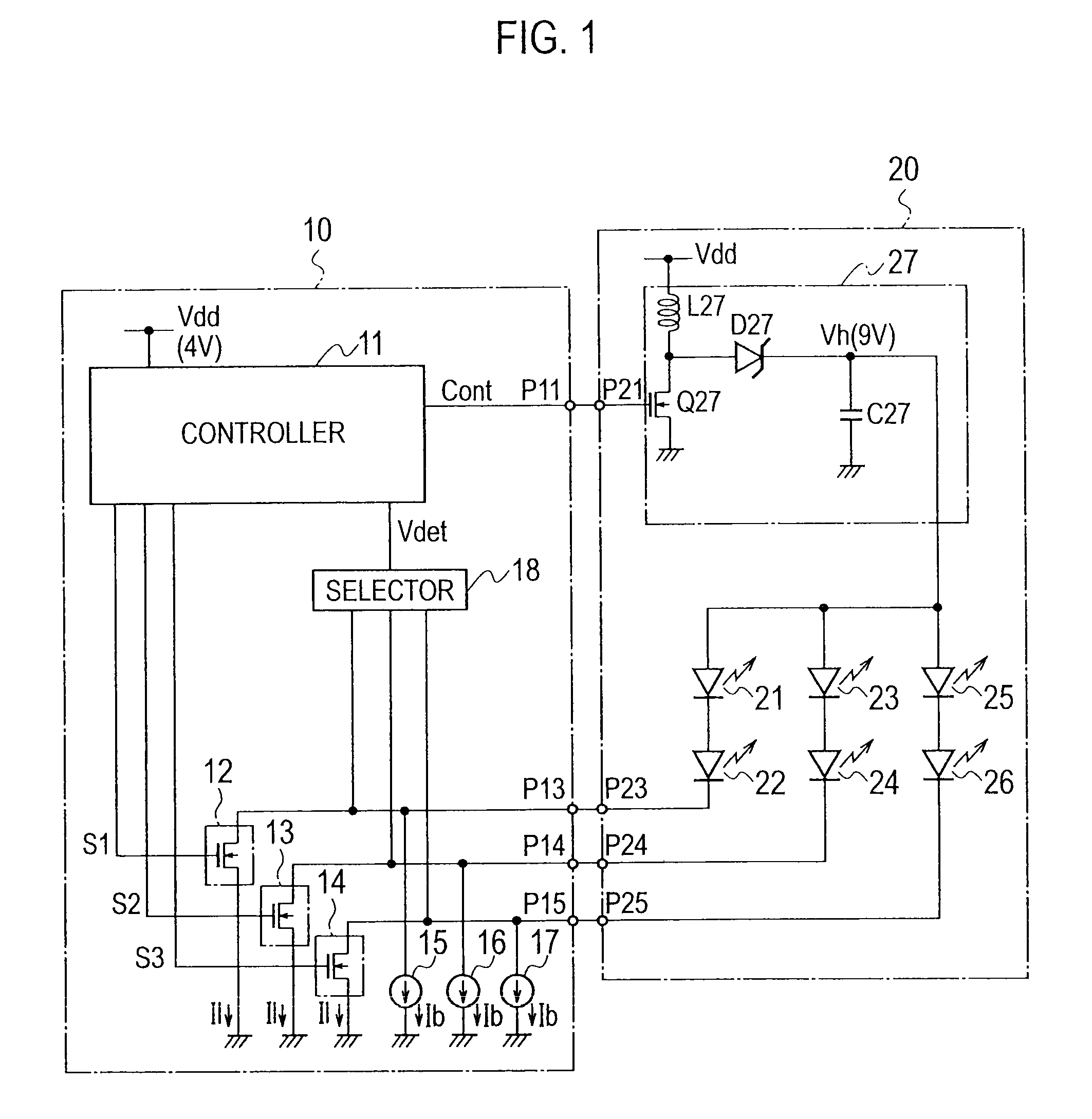

Apparatus for lighting leds

ActiveUS20100052552A1Increase plate thicknessProduces noiseElectrical apparatusElectroluminescent light sourcesTransverterEffect light

An apparatus for lighting LEDs includes an LED group load having the LEDs, a converter to generate a voltage applied to the LED group load, a current controller to control a current of the LED group load, a voltage controller to control an output voltage provided by the converter, a time division circuit to intermittently pass a current through the LED group load, and a selector. The selector, during a period in which the time division circuit passes a current through the LED group load, selects the current controller to control a current of the LED group load and thereby control an output voltage provided by the converter, and during a period in which the time division circuit passes no current through the LED group load, selects the voltage controller to control an output voltage provided by the converter.

Owner:SANKEN ELECTRIC CO LTD

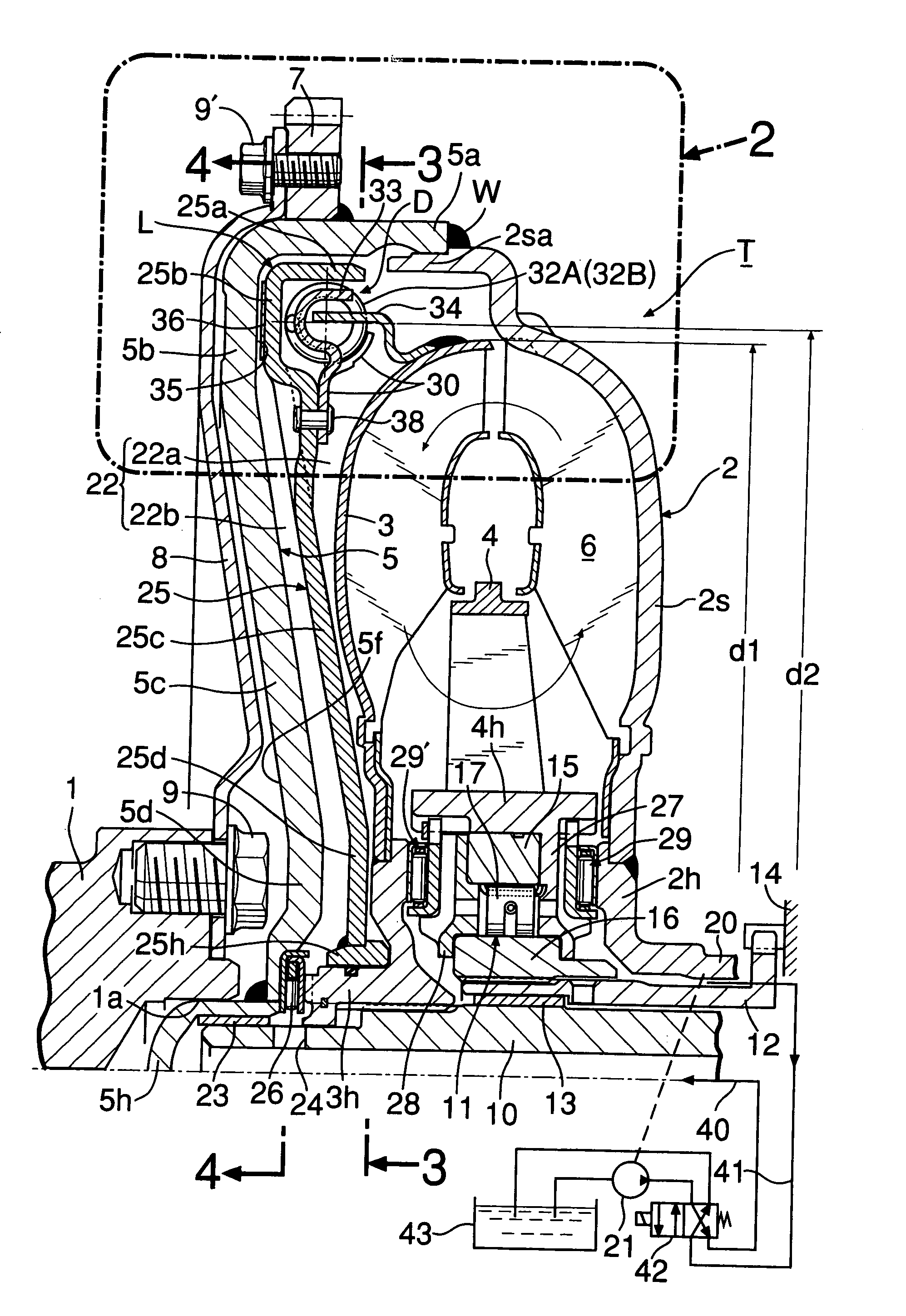

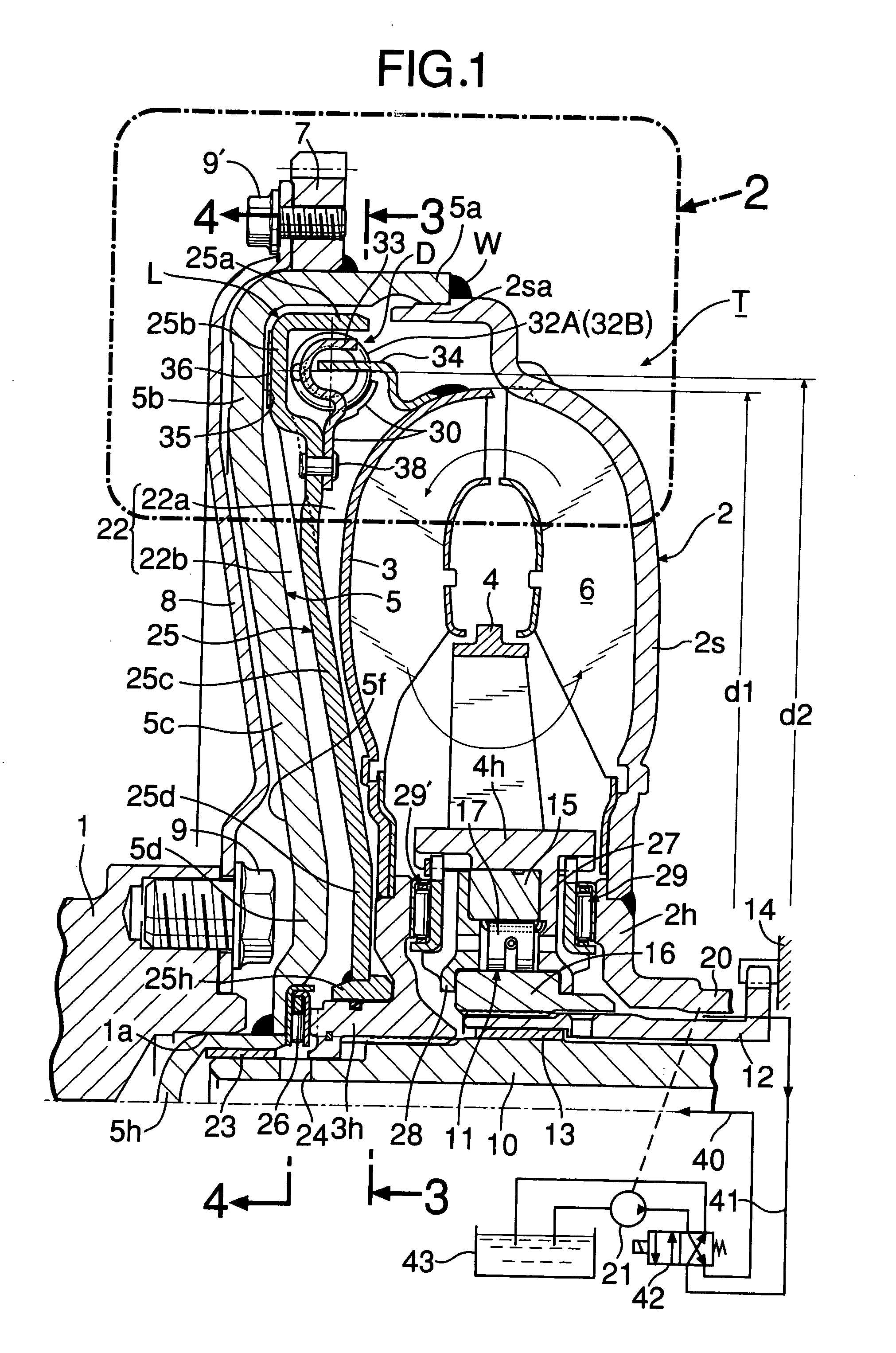

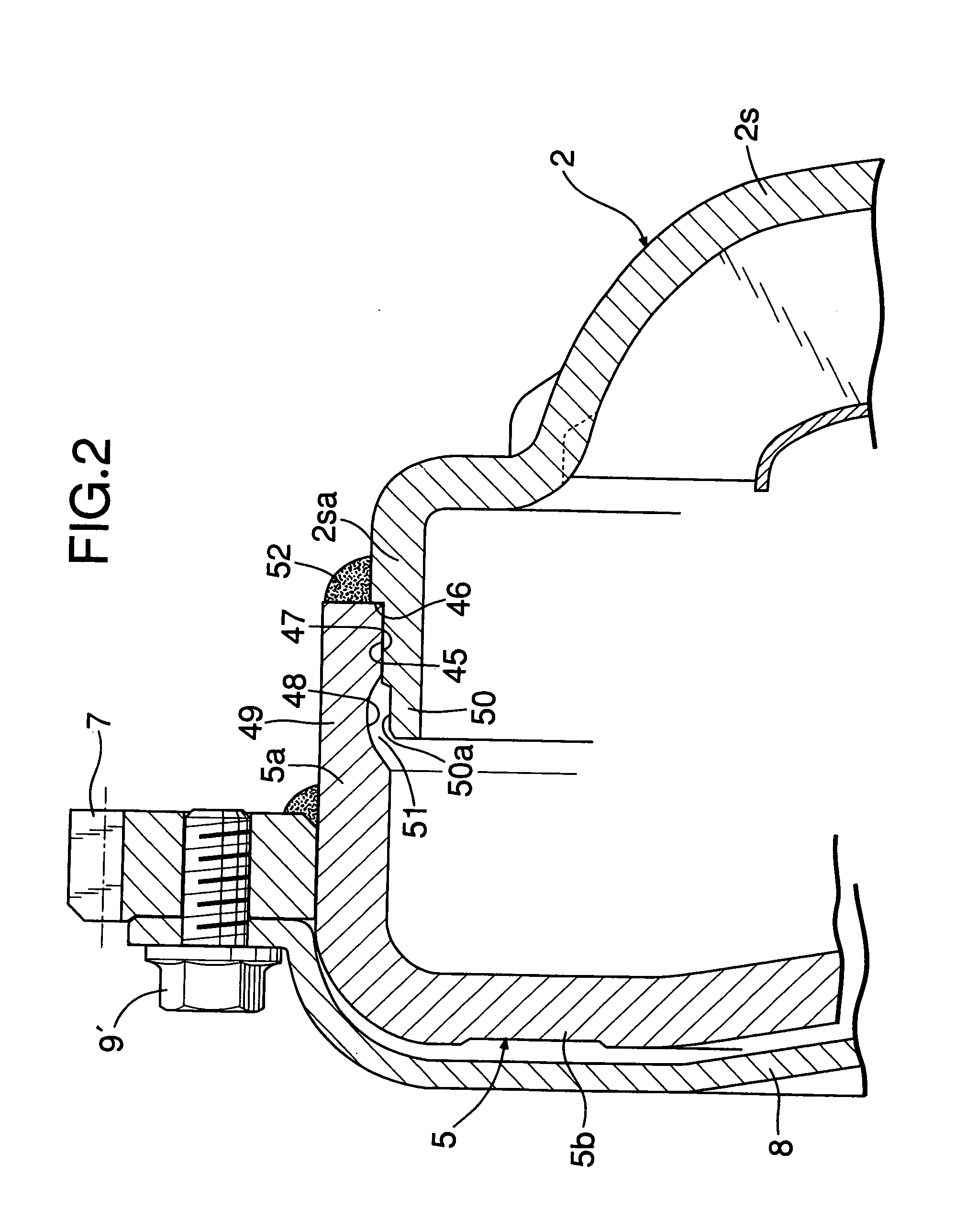

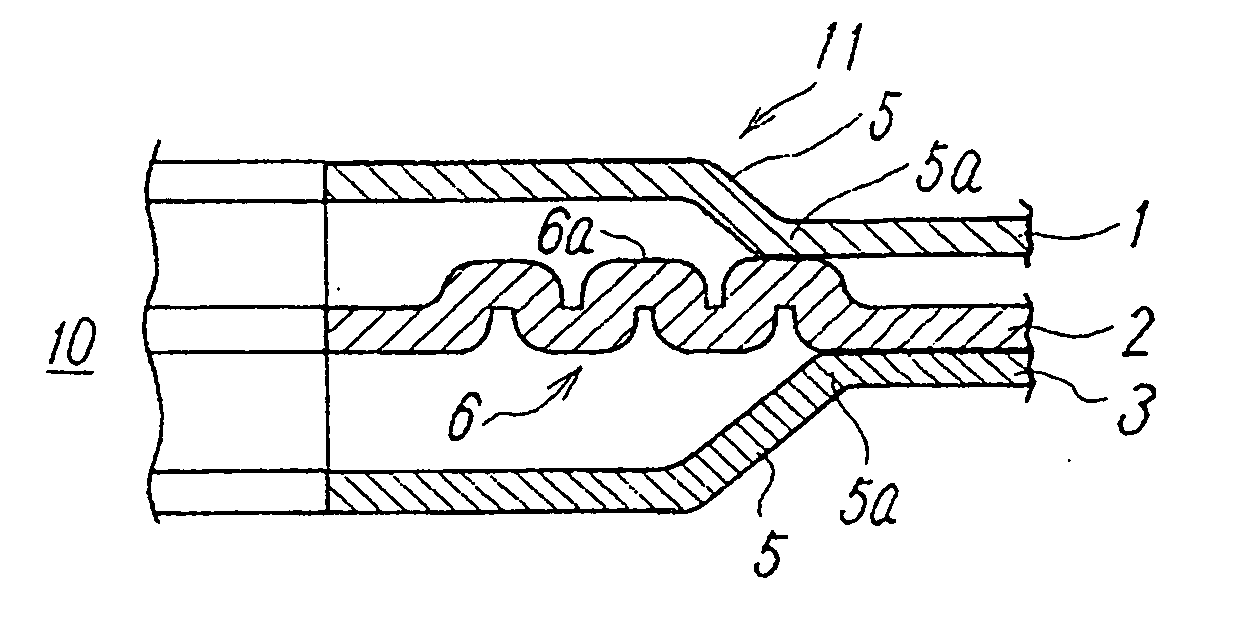

Fluid transmission device

InactiveUS20060000682A1Increased durabilityFacilitate transmissionRotary clutchesFriction clutchesFillet weldStress concentration

In a fluid transmission device, a male fitting surface of a periphery of a diameter-expanded portion of a pump shell is fitted to a female fitting surface of an inner circumference of a peripheral wall portion of a cylindrical transmission cover, and a fillet weld being is formed between an end surface of the peripheral wall portion and a peripheral surface of the diameter-expanded portion along an entire circumference, thereby connecting together the pump shell and the transmission cover. An annular recess is formed in an inner circumferential surface of the peripheral wall portion to adjoin the female fitting surface on the side opposite from the fillet weld. A portion of the transmission cover corresponding to the recess constitutes an annular thin-walled portion which has a thickness smaller than the portions of the transmission cover along the opposite sides of the annular thin wall portion. Therefore, even if the diameters of the pump shell and the transmission cover are increased, the durability of the pump shell and the transmission cover can be improved by alleviating excessive stress concentration on the fillet weld between the pump shell and the transmission cover.

Owner:YUTAKA GIKEN CO LTD

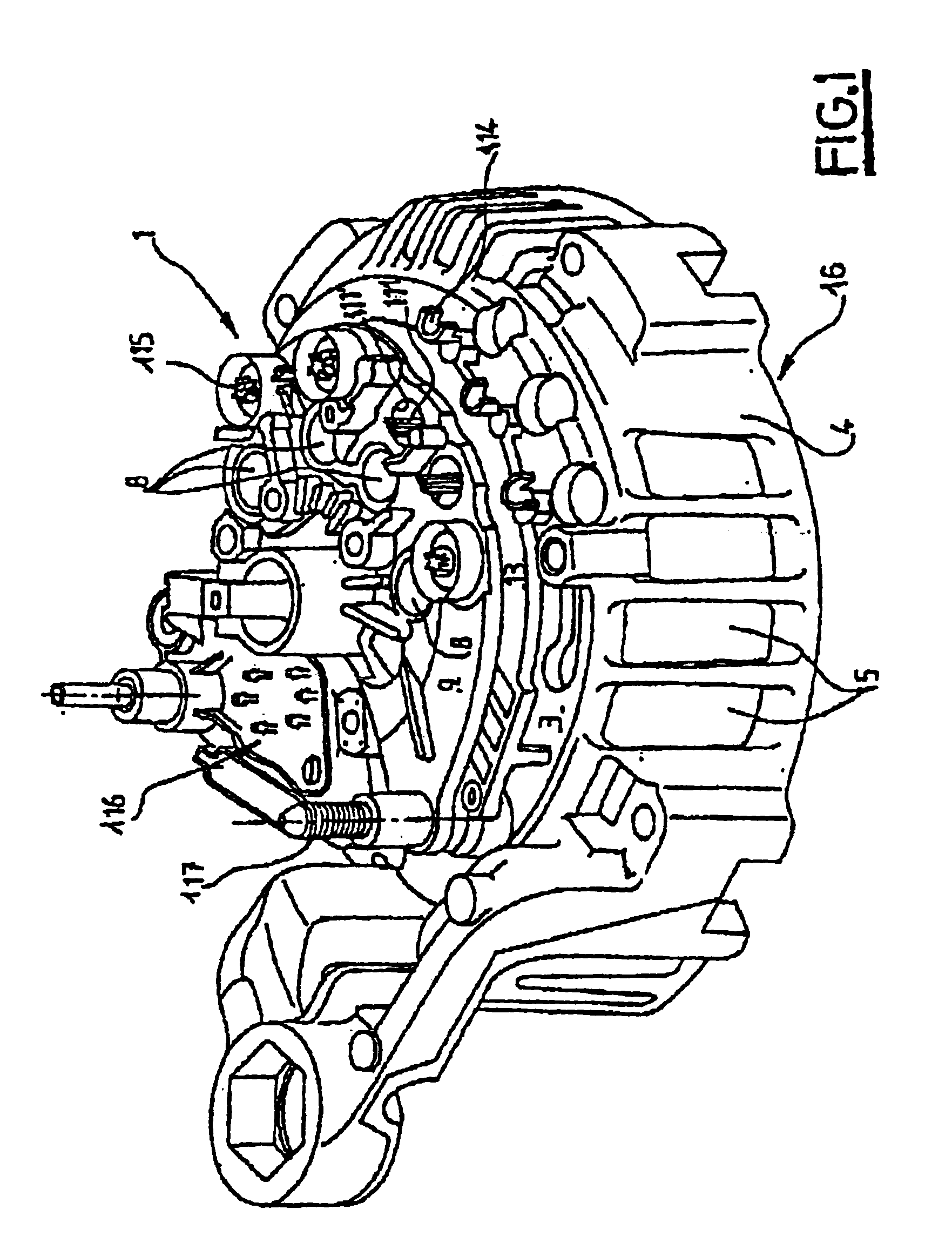

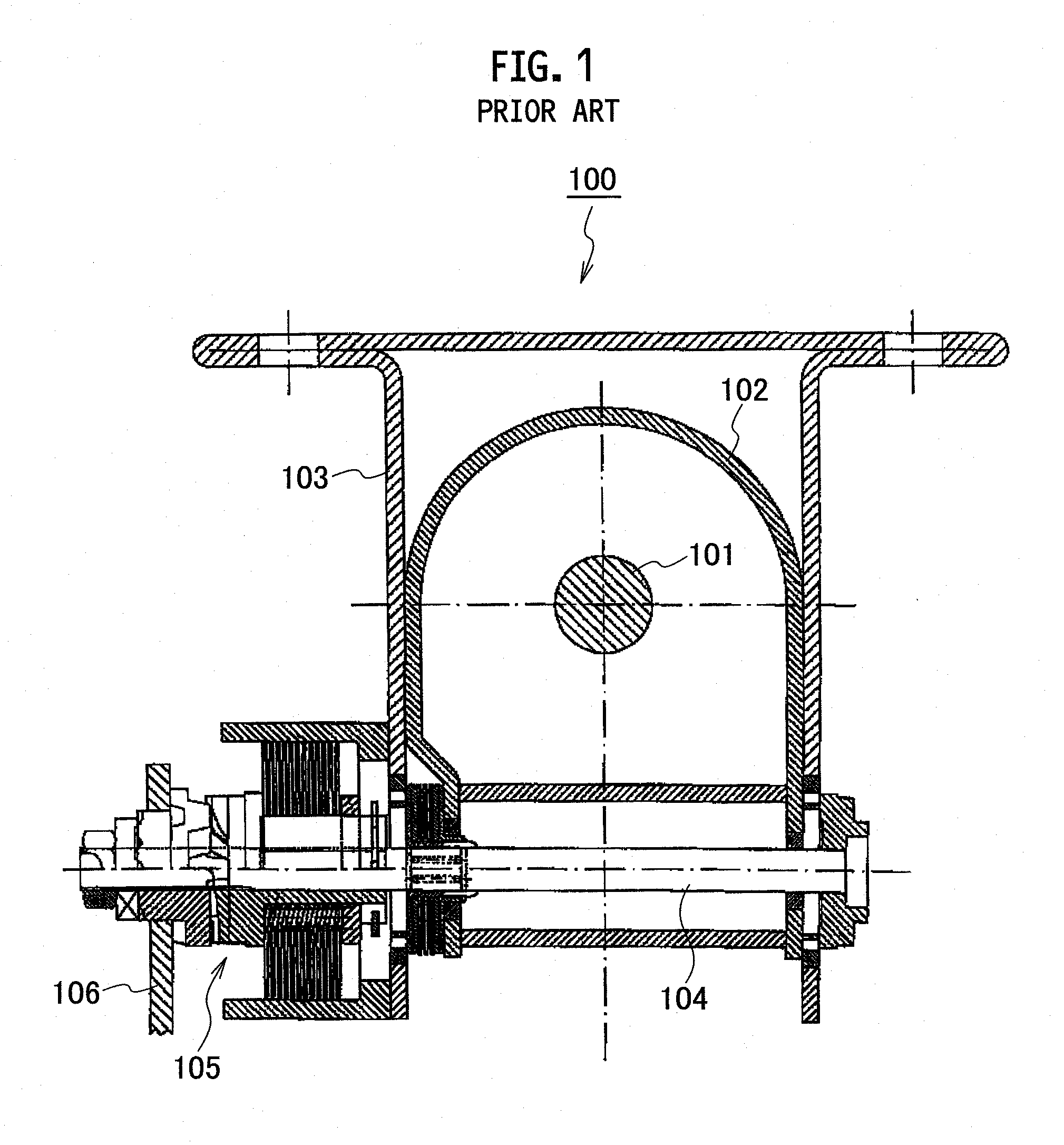

Rotating electrical machine, in particular alternator for motor vehicle

InactiveUS6734587B2Improve cooling effectIncrease plate thicknessSynchronous generatorsMagnetic circuit rotating partsMobile vehicleAlternator

The invention relates to a rotary electric machine comprising a rear bearing (2), an arrangement (1) for rectifying the current produced by the machine, which comprises a number of positive diodes (8) supported by a heat dissipater in the overall form of a plate (9) and a number of negative diodes (10) supported by support means in the form of a plate advantageously forming part of the rear bearing, the plate (9) supporting the positive diodes (8) comprising a great many cooling ribs which have the shape of fins (18, 19) extending practically radially across the plate, while an opening (20) for the passage of cooling air is made between each pair of adjacent fins (18, 19), some fins (18) extending practically as far as the outer periphery of the support plate (9).

Owner:VALEO EQUIP ELECTRIC MOTEUR

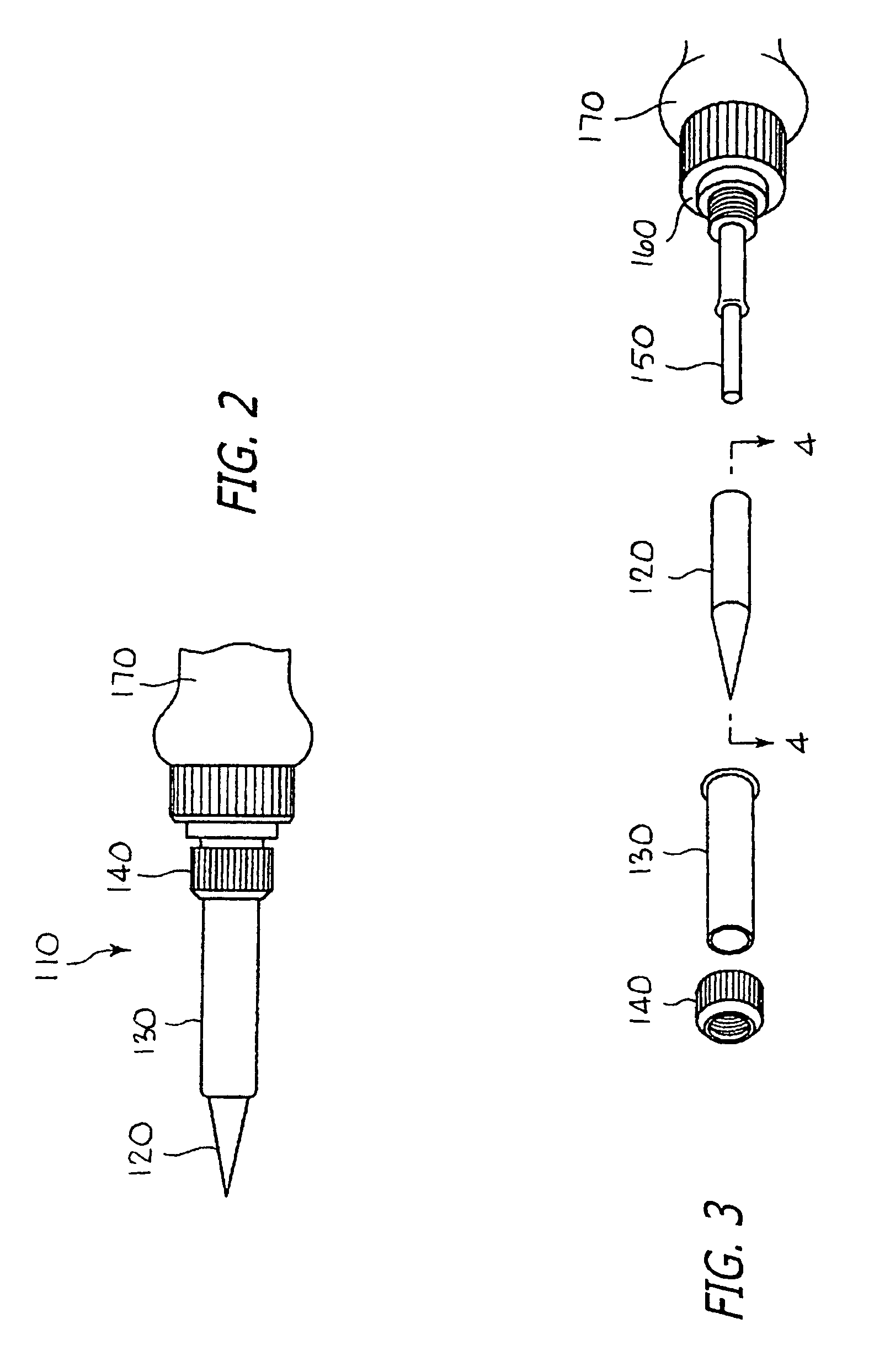

Soldering iron tip with metal particle sintered member connected to heat conducting core

ActiveUS7030339B2Increase plate thicknessExtended processing timeHeating element shapesSoldering bitsCeramic coatingHeat conducting

A soldering iron tip having a copper or copper alloy core and a metal particle sintered member connected to the core to transfer heat therefrom to form a working soldering tip. The sintered member can be manufactured by powder metallurgy from a base material (iron, nickel and / or cobalt particles) and an additive (silicon, copper, silver, tin, boron and / or carbon particles) where needed. The sintered member can be formed as a cap which is fitted onto the working tip with a silver paste sandwiched therebetween, a brazing filler metal ring is positioned between an abutment shoulder and the cap, flux applied to the joint and the cap brazed into place. A metal, cermet or ceramic coating sprayed on the outer surface of the core, except for the (masked) working tip end, is not wettable by solder. An Ag—Al—Cu alloy coating layer in the rearwardly-disposed cavity improves heat conduction from the heater therein.

Owner:HAKKO CO LTD

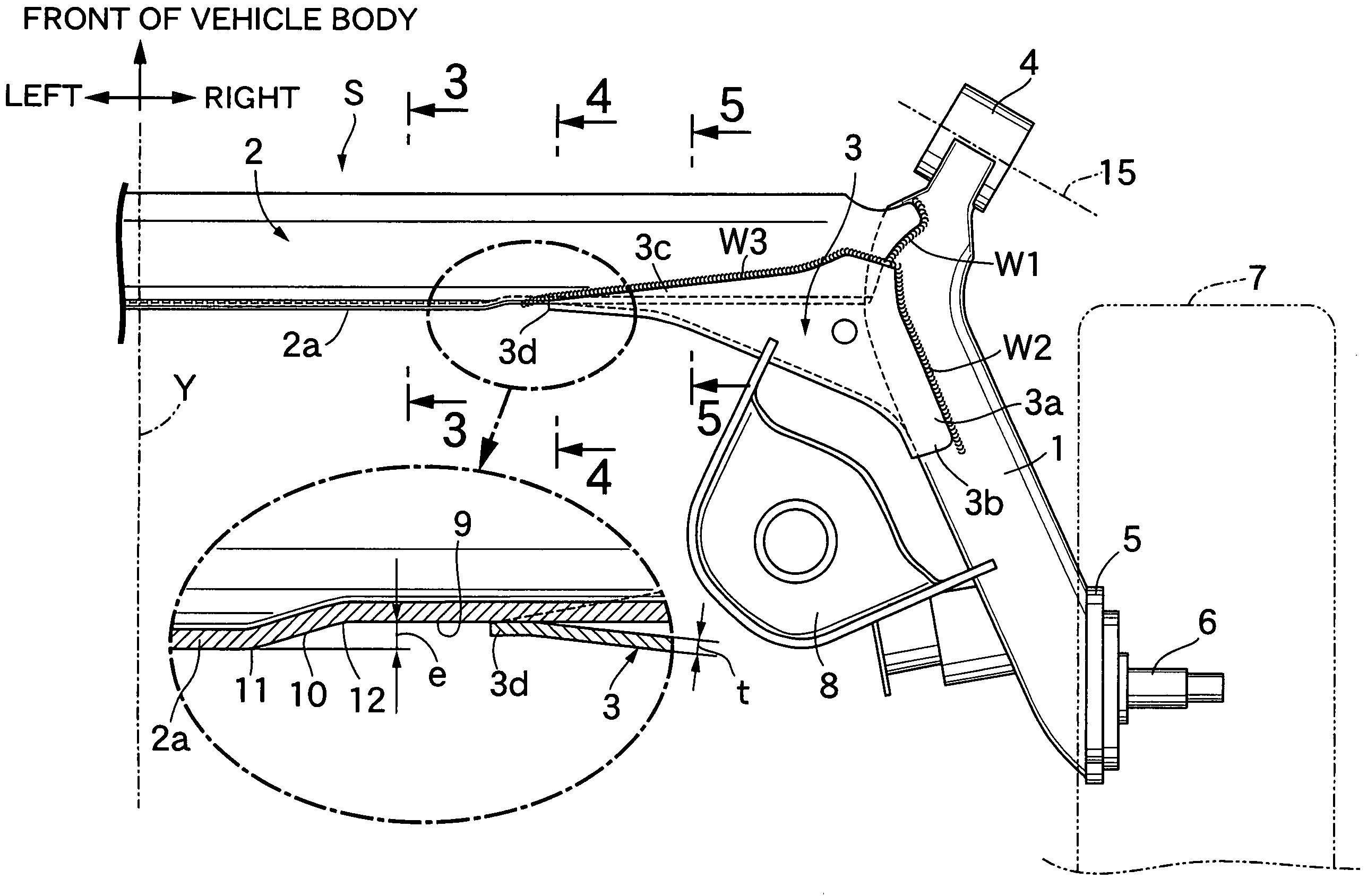

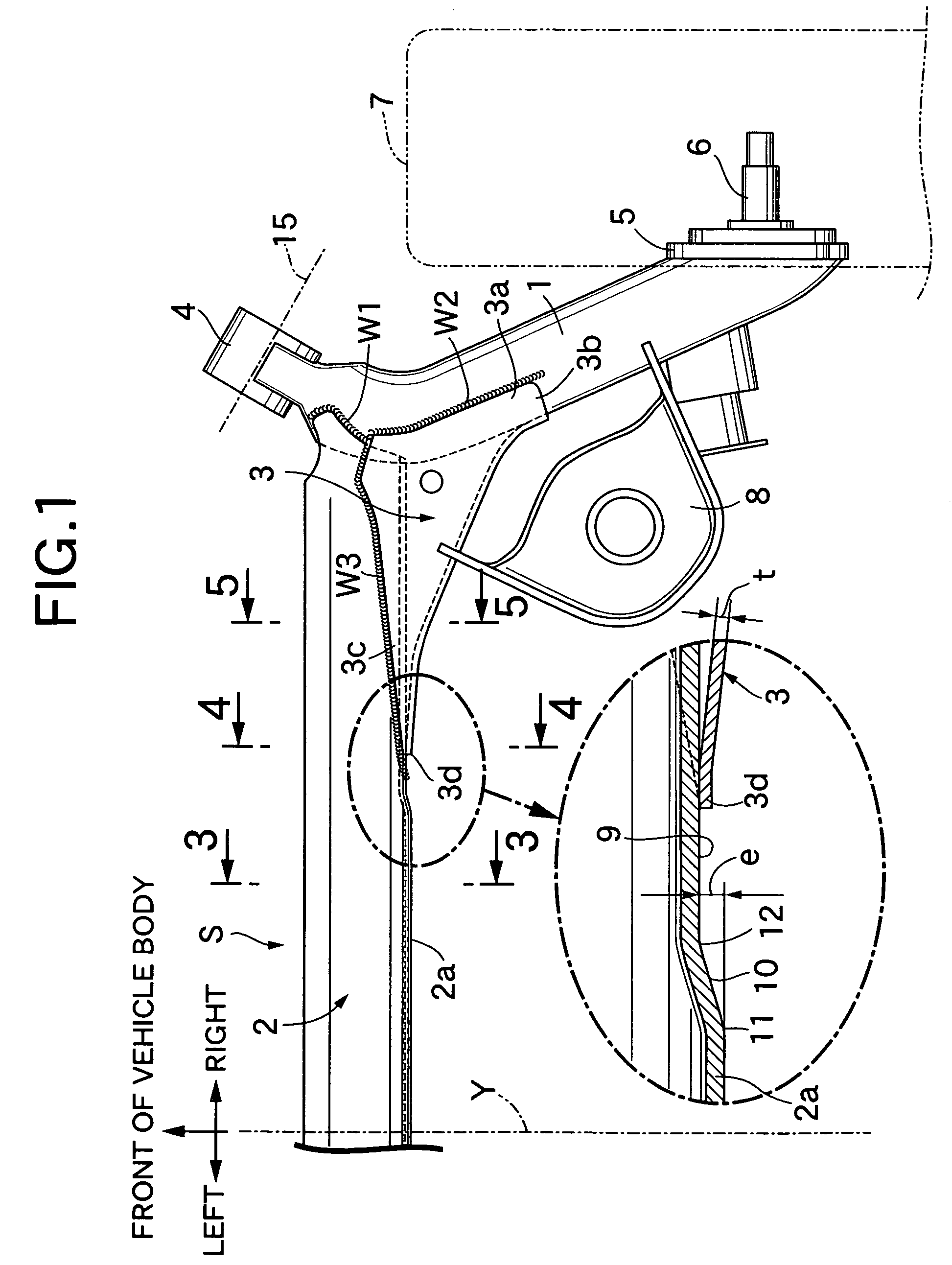

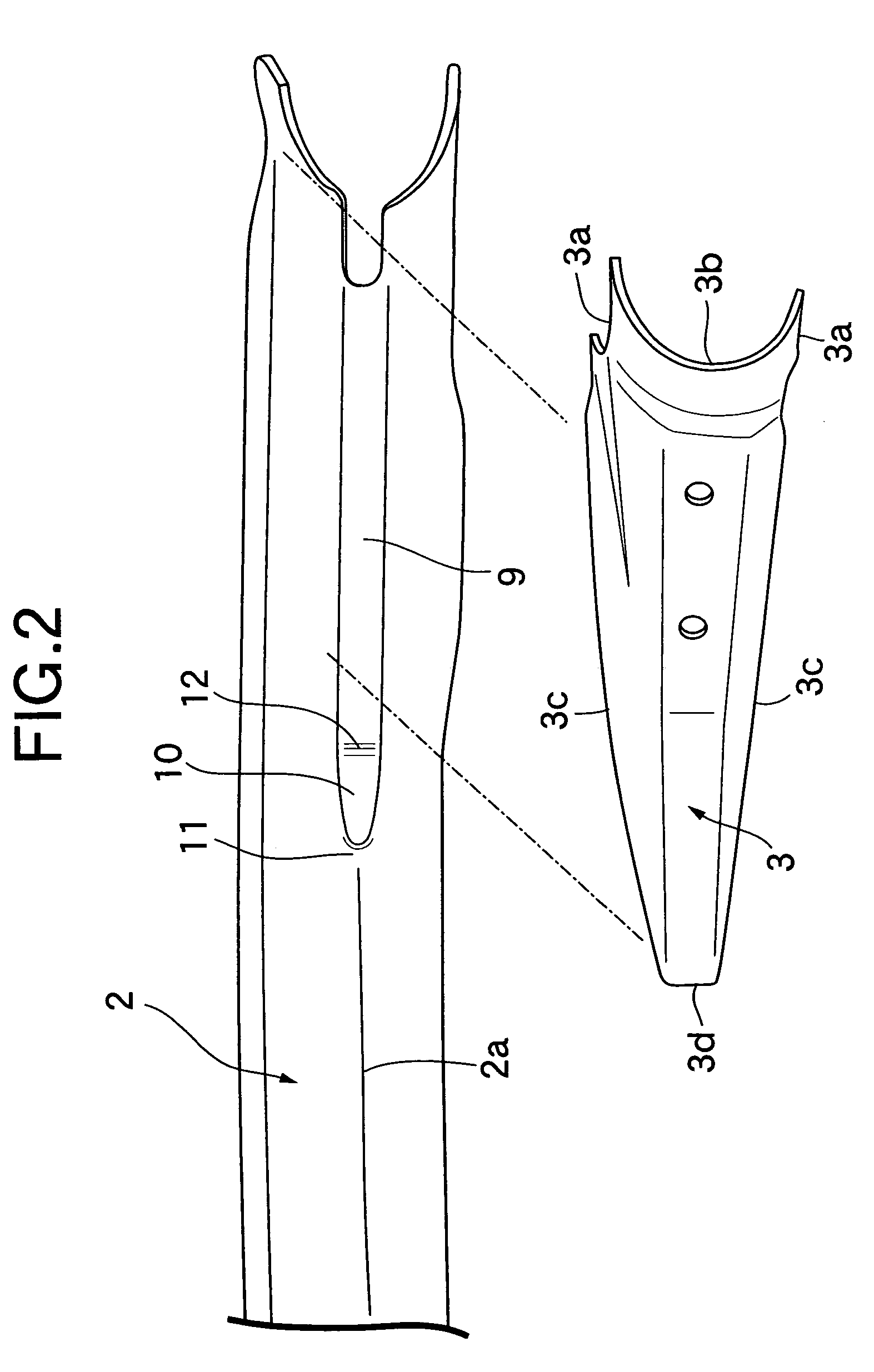

Torsion beam suspension

InactiveUS7284765B1Increased durabilityReduction in weight and costInterconnection systemsResilient suspensionsIn planeStress concentration

In a torsion beam suspension including: a pair of left and right trailing arms 1; a torsion beam 2 providing connection between the trailing arms 1; and gussets 3 which are U-shaped in section and substantially triangular in plane view and which are welded to inner side surfaces of connecting portions between the trailing arms 1 and the torsion beam 2, seat surfaces 9 are formed by crushing at left and right opposite end portions of a rear wall 2a of the torsion beam 2, the seat surfaces 9 being offset forward from a general outer surface of the rear wall 2a by an amount e larger than a plate thickness t of the gussets 3, and each gusset 3 includes an inner end edge portion 3d superposed on an intermediate portion in a lateral direction of the seat surface 9, and upper and lower front edge portions 3c, 3c connected by a weld W3 to upper and lower portions of an outer surface of the torsion beam 2. Thus, in the torsion beam, an abrupt increase in torsional rigidity is suppressed in the gusset inner end portion without reducing strength of the torsion beam to alleviate stress concentration, thereby providing a torsion beam suspension having a high durability.

Owner:F TECH INC

Process for preparing through-hole foam aluminium plate

The invention relates to a method for preparing porous foam aluminum sheet. Wherein, it selects aluminum alloy to be heated via smelting furnace at constant temperature; selects food particle salt as foam porous stuff to be baked at high temperature and constant temperature; adds heated particle salt into mould, to be pressurized by compressor into block; adds melt aluminum to be pressurized by compressor, to make the melt aluminum into the space between particle salts, to form compact foam aluminum skeleton; then solidifies it to be extracted out from the mould to be cooled. The produced porous foam aluminum plate has uniform factor of porosity, with high porous rate, stable structure, adjustable thickness, improved quality, reduced producing cost and the application for batch production.

Owner:上海众汇泡沫铝材有限公司

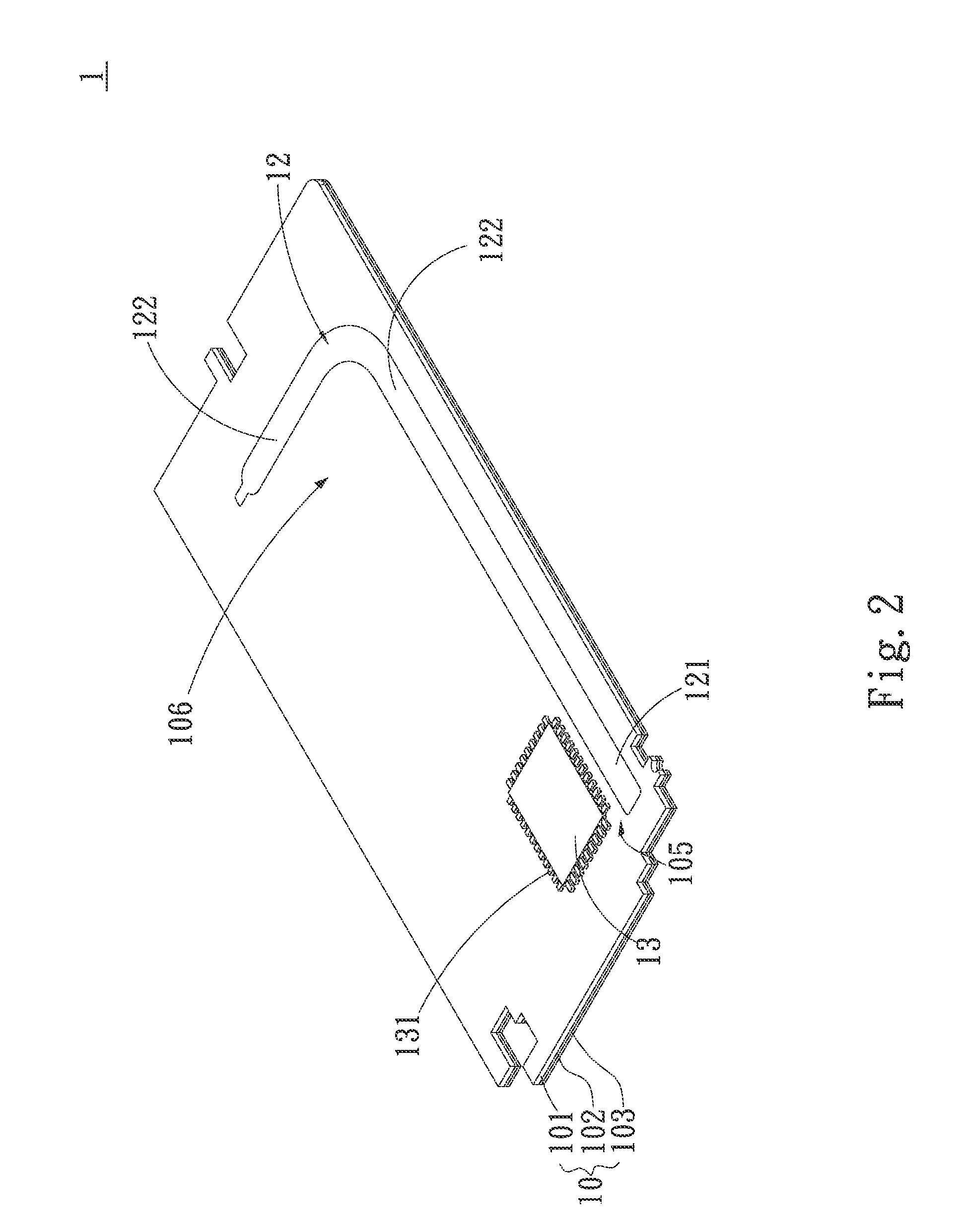

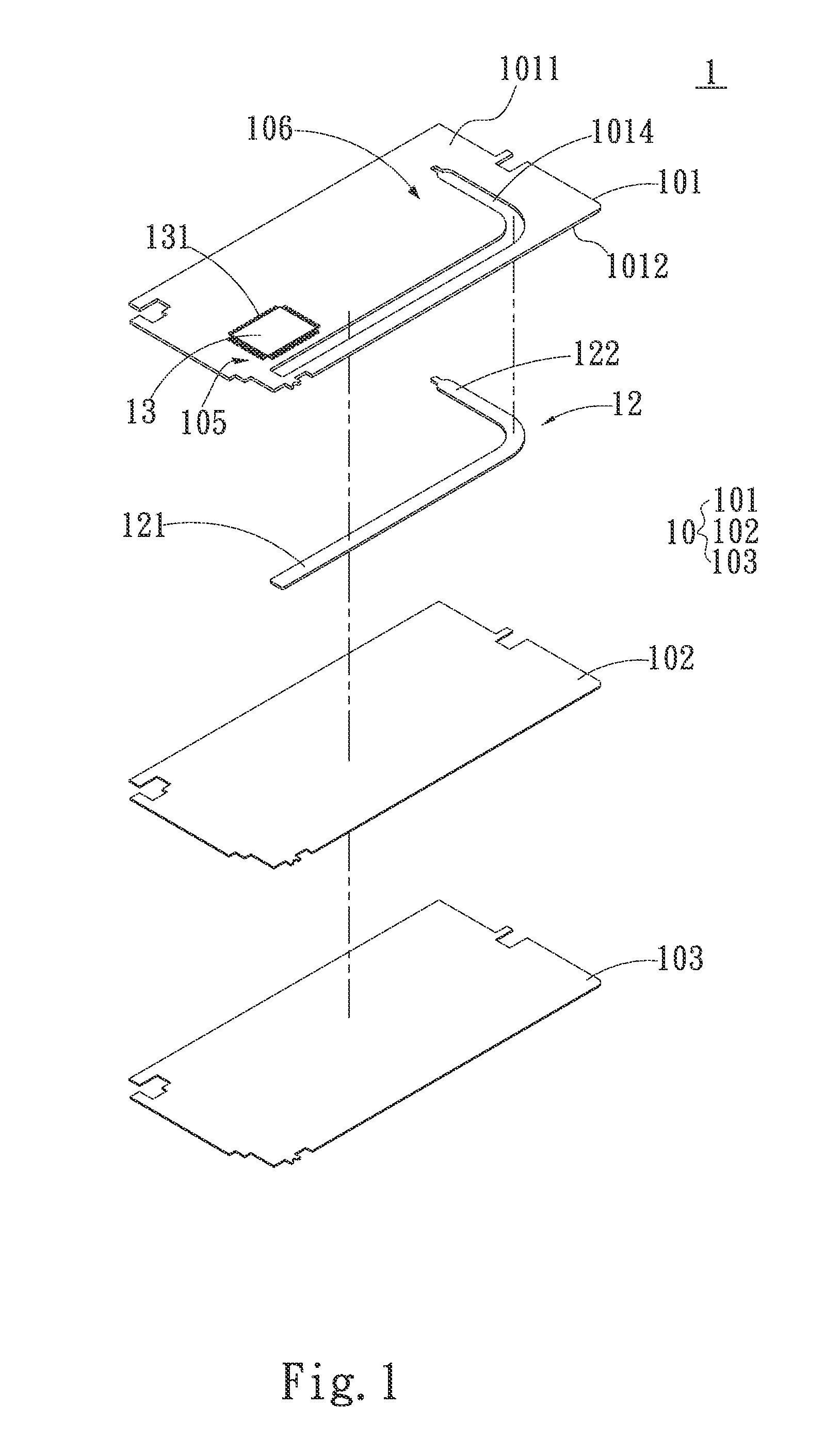

Electronic substrate with heat dissipation structure

ActiveUS20160007504A1Improve efficiencyExtended service lifeDigital data processing detailsCircuit fluid transportInsulation layerCooling effect

An electronic substrate with heat dissipation structure includes a substrate plate and at least one heat pipe. The substrate plate includes a wiring layer, a grounding layer and an insulation layer from top to bottom. The wiring layer has at least one heat-producing element mounted thereon, and is formed with a receiving hole for the heat pipe to tightly fit therein. Heat produced by the heat-producing element and distributed over a high-temperature zone of the substrate plate surrounding the heat-producing element is absorbed by the heat pipe and then transferred to a low-temperature zone of the substrate plate distant from the heat-producing element, from where the heat is dissipated into ambient air to achieve cooling effect at upgraded heat dissipation efficiency.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

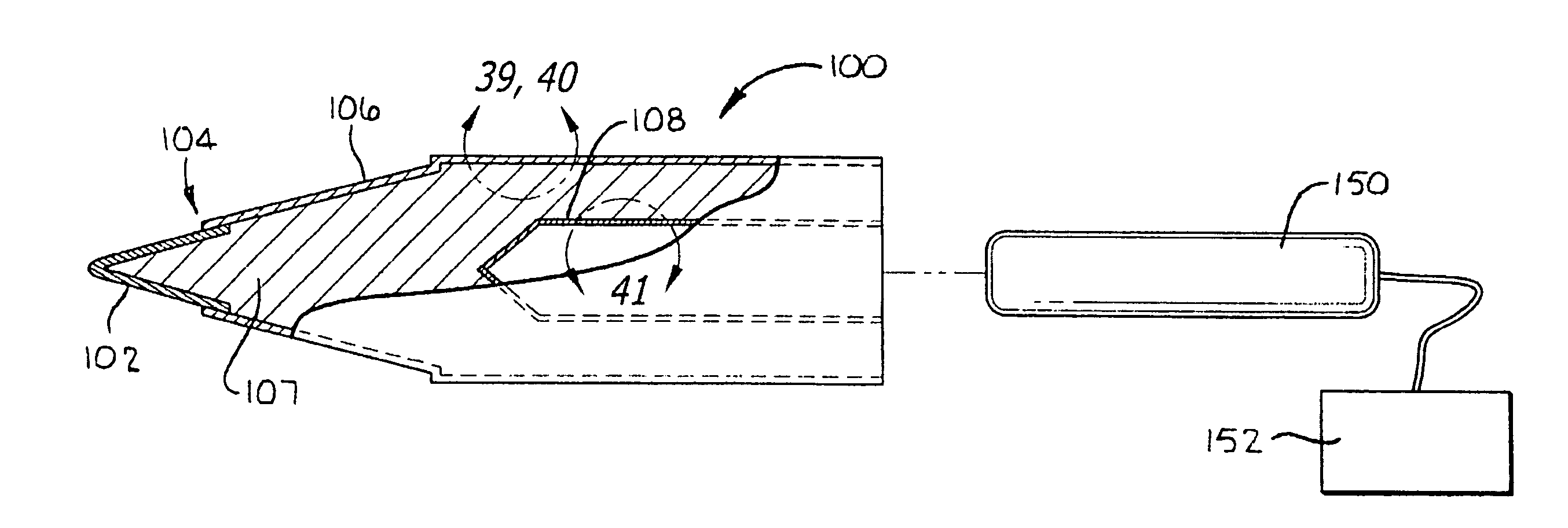

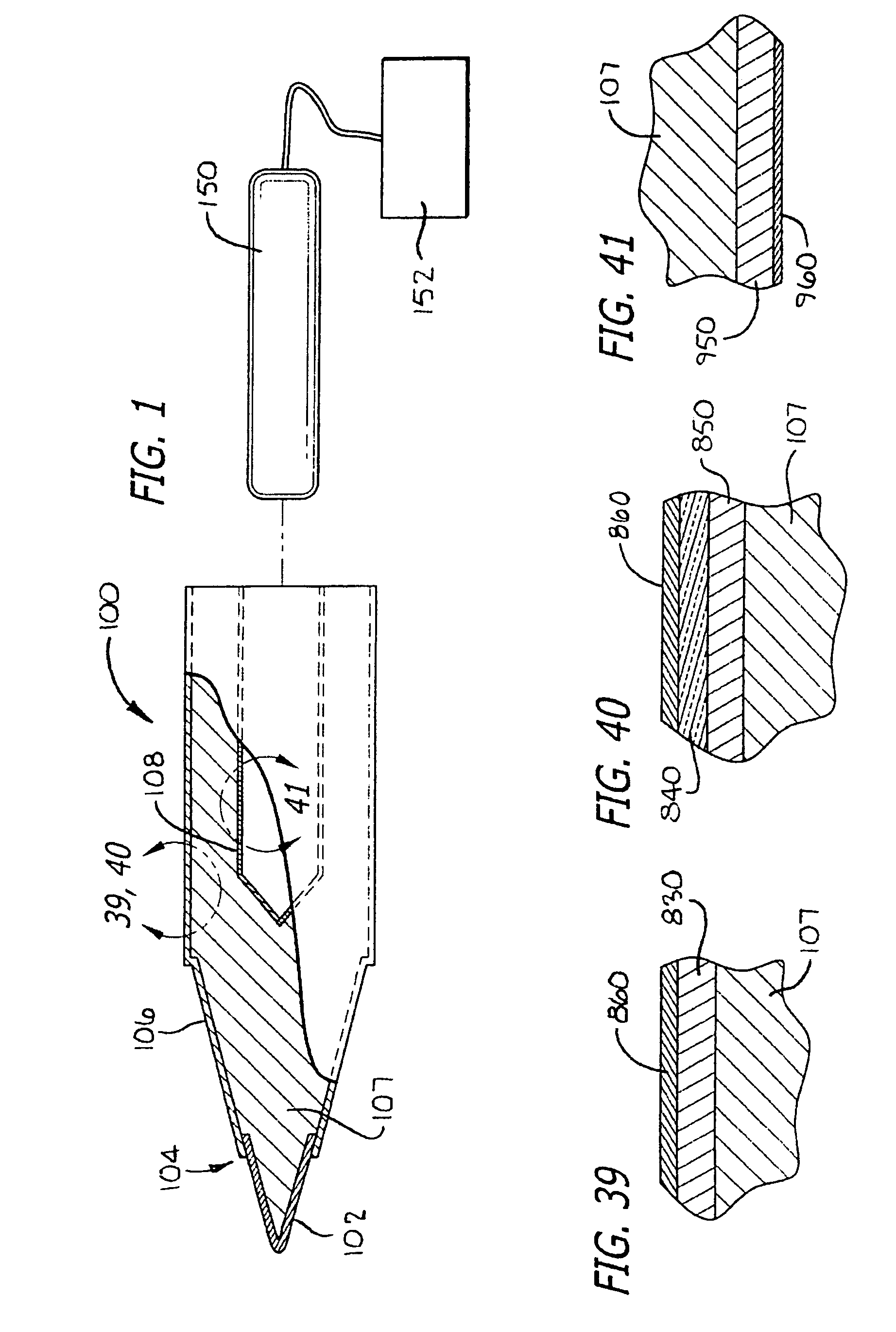

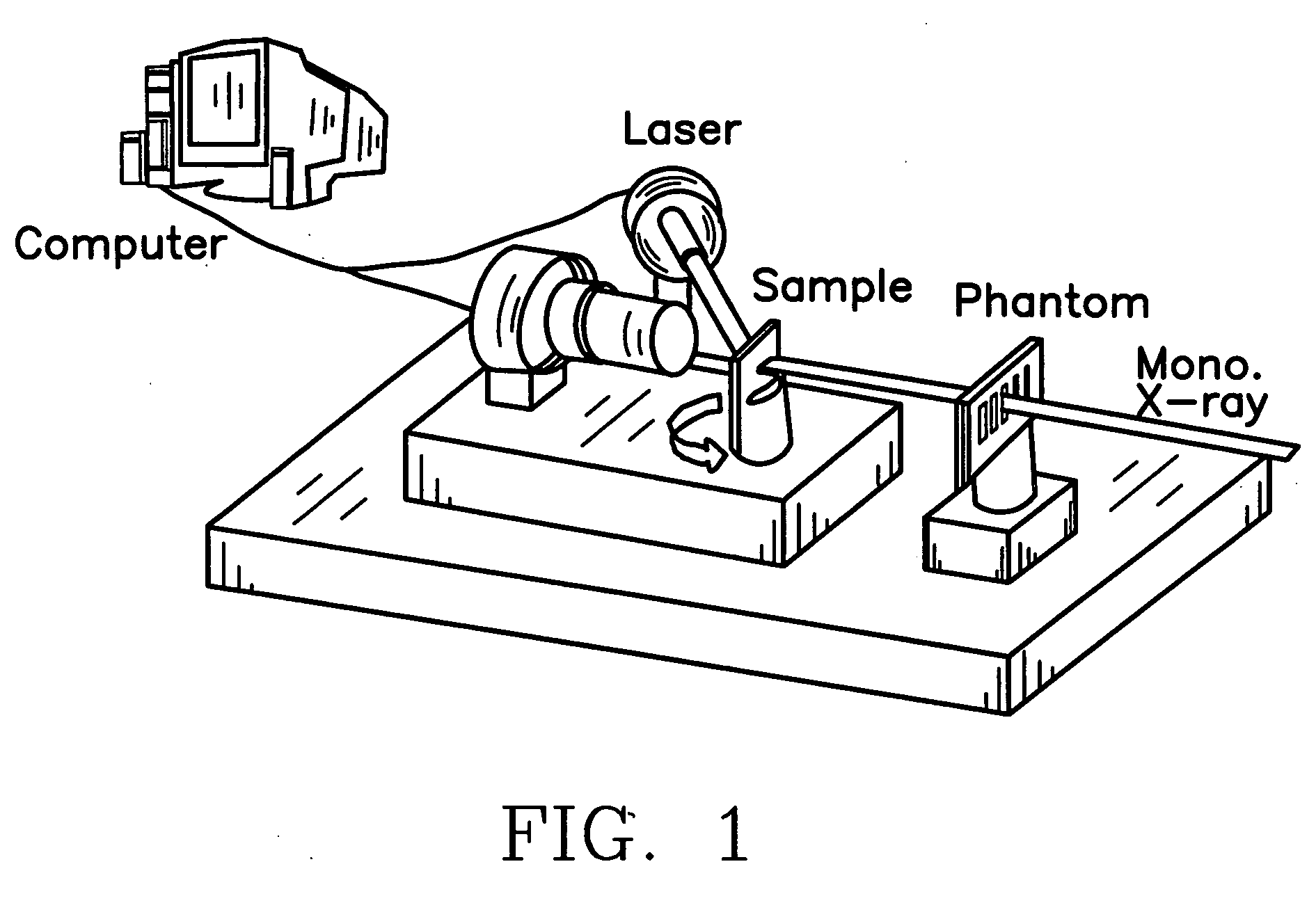

Computed radiography system for mammography

InactiveUS20090078874A1Maximize x-ray absorptionIncrease plate thicknessMaterial analysis by optical meansPatient positioning for diagnosticsLight reflexProximate

A computed radiography system including a stimulating light source such as a laser, a photostimulable glass imaging plate (PGIP) substantially transparent to the stimulating light positioned such that the stimulating light impinges the PGIP perpendicularly thereto producing photostimulated luminescence light (PLL), a light collector having a light reflecting inner surface proximate the PGIP for collecting PLL emitted from the PGIP and having a hole or slot therein for admitting stimulating light into the light collector and onto the PGIP. An optical filter in communication with the light collector for blocking stimulating light waves and passing PLL therethrough. A light detector receives PLL from the optical filter and the light collector, mechanism providing relative movement between the PGIP and the stimulating light source, and mechanism including an analog to digital converter for converting the collected and detected PLL to a diagnostic readout. The system is particularly useful in mammography.

Owner:UCHICAGO ARGONNE LLC

Hidden Type Split Hinge

ActiveUS20200392983A1Increase plate thicknessIncrease spacingBearing assemblyDigital data processing detailsStructural engineeringMechanical engineering

Owner:JARLLYTEC CO LTD

Continuous fiber laminated plate and preparation method thereof

InactiveCN102049895AIncreased plate thicknessImprove rigidityLamination ancillary operationsSynthetic resin layered productsFiberComposite laminates

The invention discloses a continuous fiber laminated plate and a preparation method thereof and particularly discloses a continuous fiber laminated plate, which has an increasable thickness and can lower cost. The method comprises the following steps of: impregnating continuously reinforced fiber or fiber cloth with thermoplastic resin so as to form a continuously reinforced fiber laminated body; symmetrically clamping and stacking one or more than two fiber laminated bodies with one or more than two thermoplastic resin sheets at intervals; and heating, laminating and fusing so as to obtain a composite continuous fiber laminated plate. Through the design, the composite continuous fiber laminated plate can be put into a mold by a continuous processing method for heating shaping, and a shaped shell is trimmed so as to form a shell of a continuously reinforced fiber composite laminated body. The amount of resin in the longitudinal direction of the cross section of the fiber laminated plate fulfills the aims of increasing the thickness and enhancing the rigidity of the continuously reinforced fiber composite laminated body; simultaneously, material cost can be lowered.

Owner:马水源

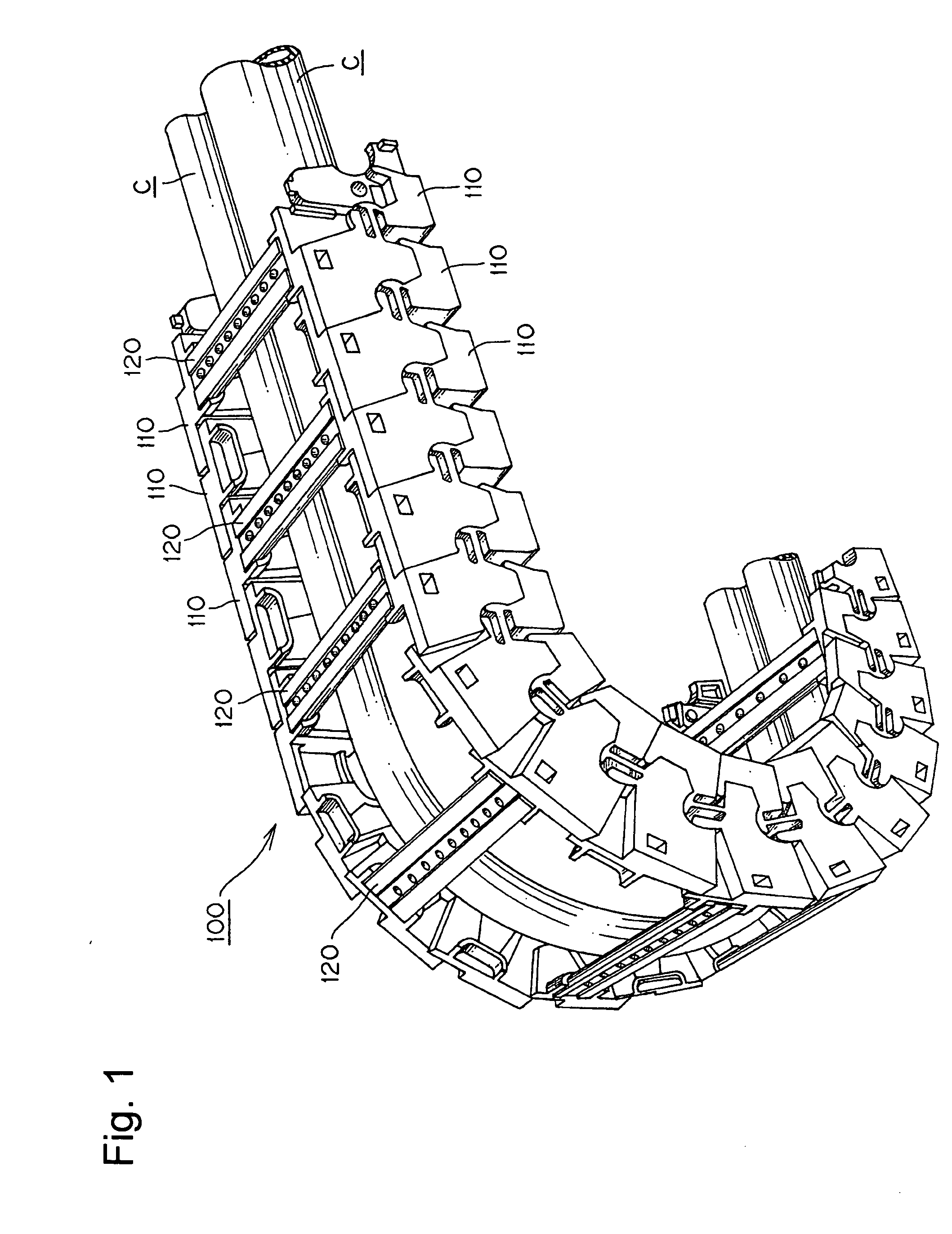

Cable or the like protection and guide device

ActiveUS7317160B2Reduce the number of partsReduce stepsHauling chainsHoisting chainsStress concentrationCoupling

Owner:TSUBAKIMOTO CHAIN CO

Joint structure for steel-pipe pile, and steel-pipe pile

This joint structure is a steel-pipe-pile joint structure for joining a first steel-pipe pile and a second steel-pipe pile to one another in series, and equipped with an outer-engaging-end part which is the opening end of the first steel-pipe pile, and a columnar inner-engaging-end part for forming a part to be inserted into the outer-engaging-end part and located at one end of the second steel-pipe pile, wherein: the outer-engaging-end part has a plurality of outer-engaging projections for projecting from the inner-circumferential surface thereof toward the inside in the radial direction, an outer-engaging groove part formed between the outer-engaging projections, and an outer-engaging coupling groove formed at a location toward the inside in the axial direction in relation to the outer-engaging projections and the outer-engaging groove; and the inner-engaging-end part has a plurality of inner-engaging projections projecting from the outer-circumferential surface thereof toward the outside in the radial direction.

Owner:NIPPON STEEL CORP

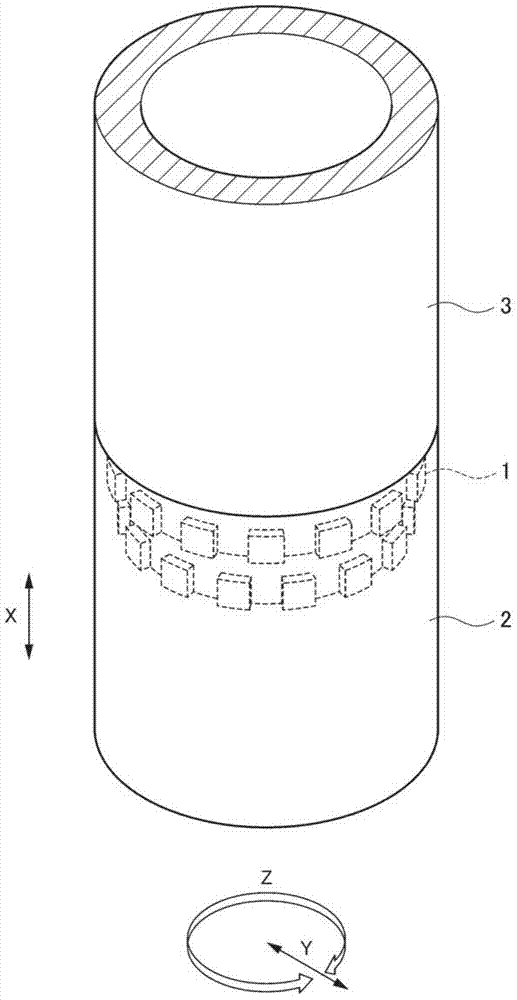

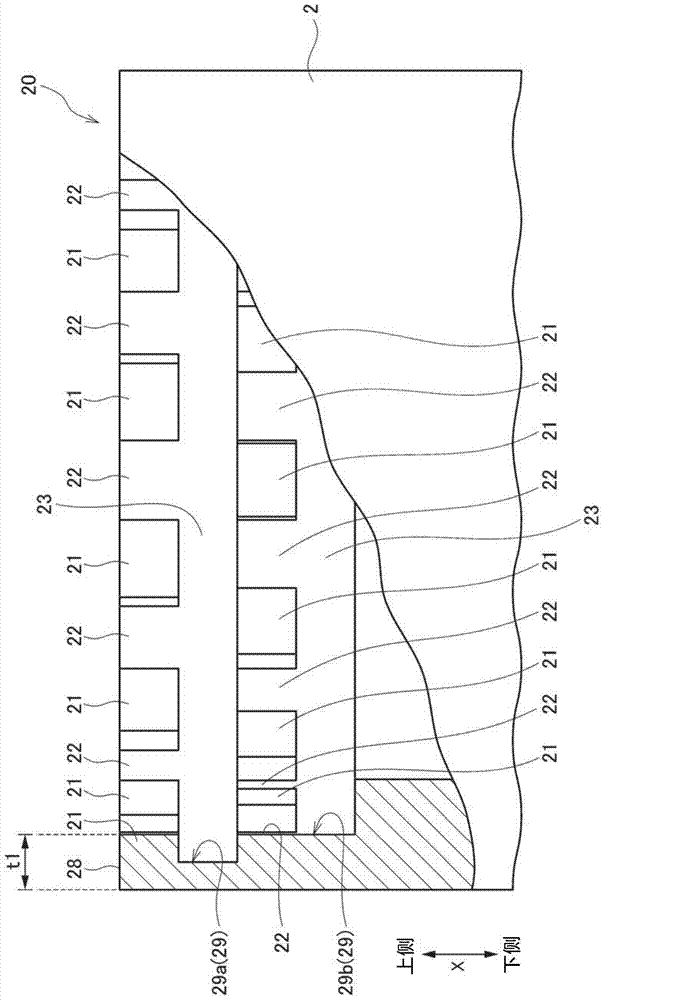

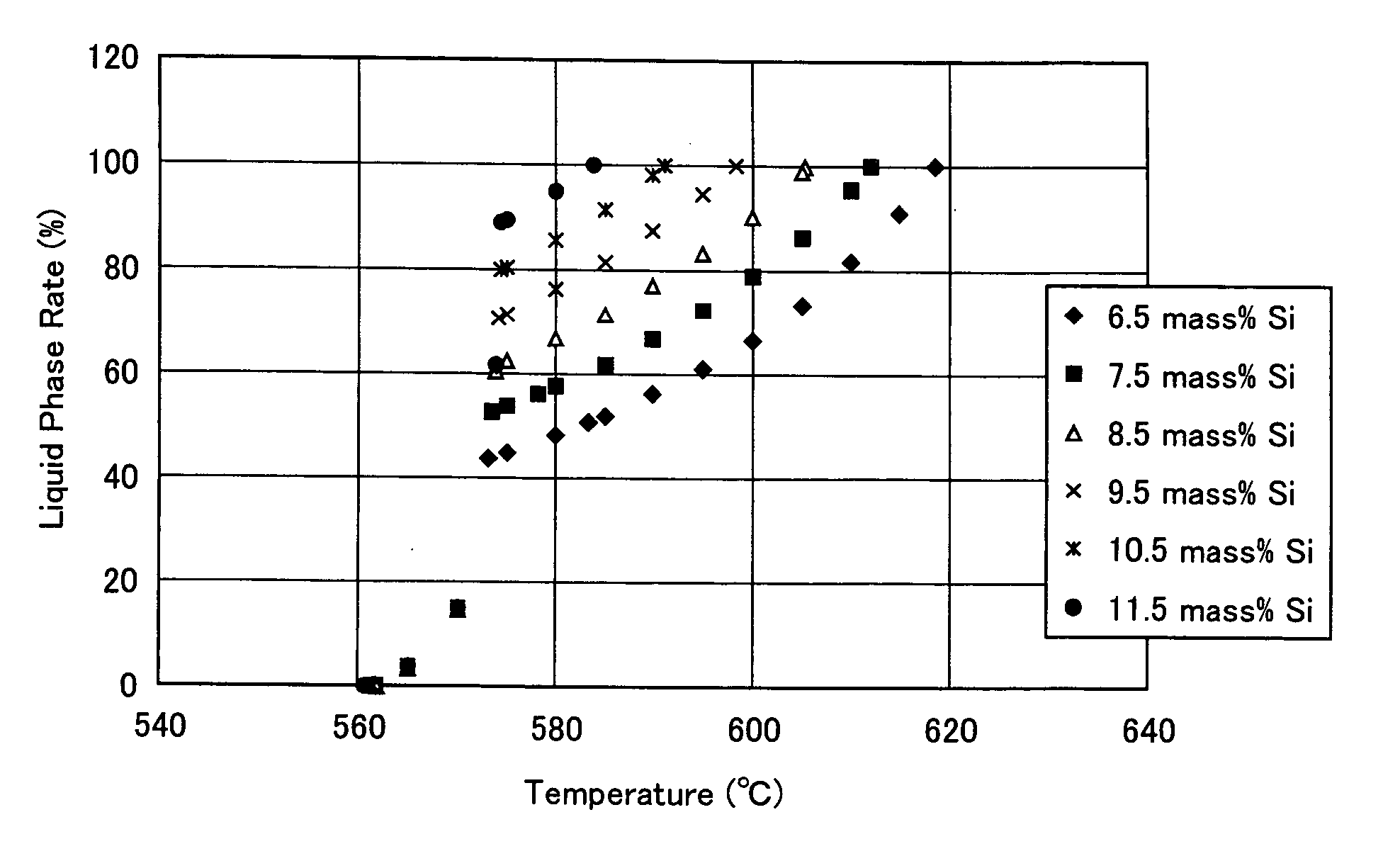

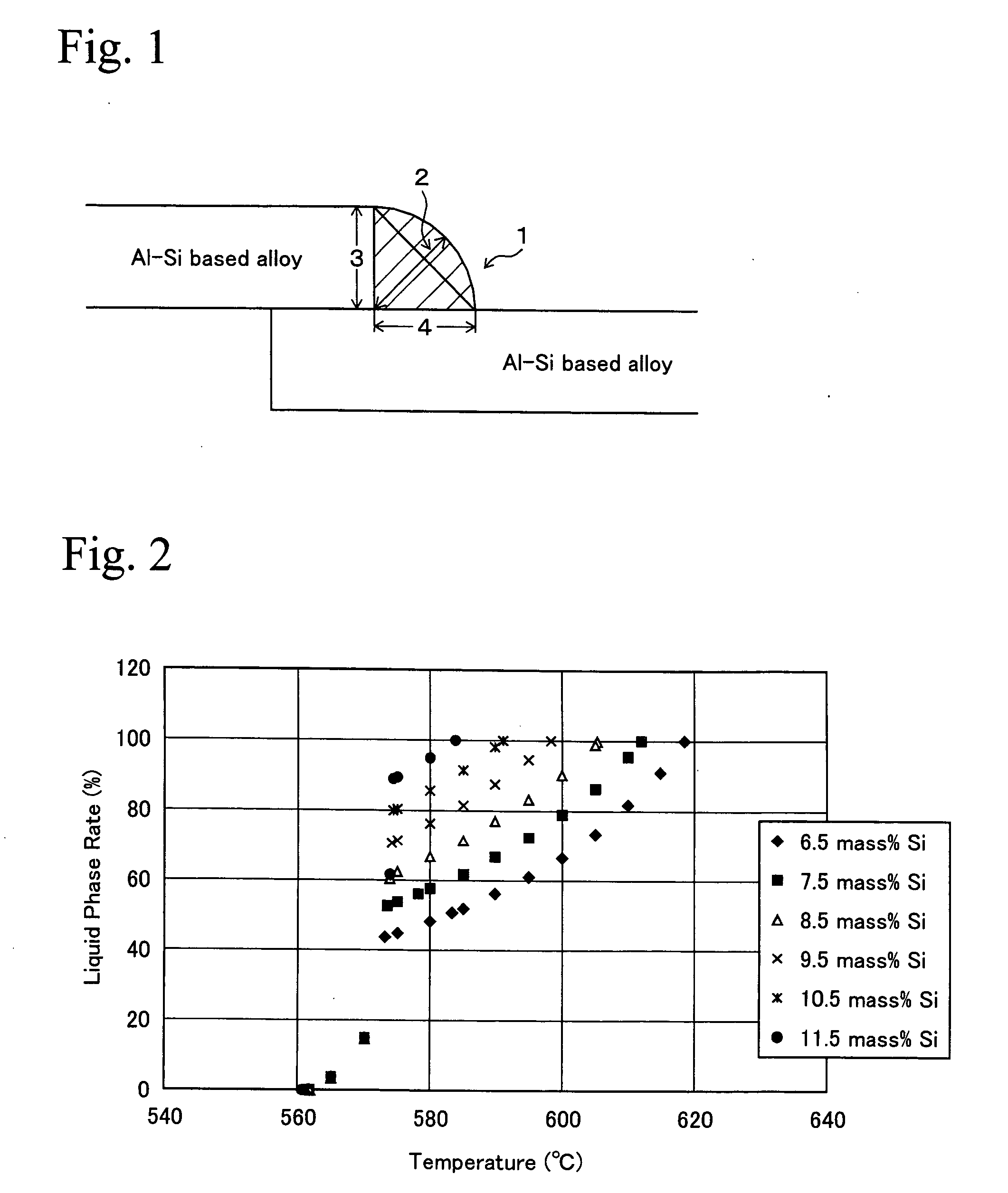

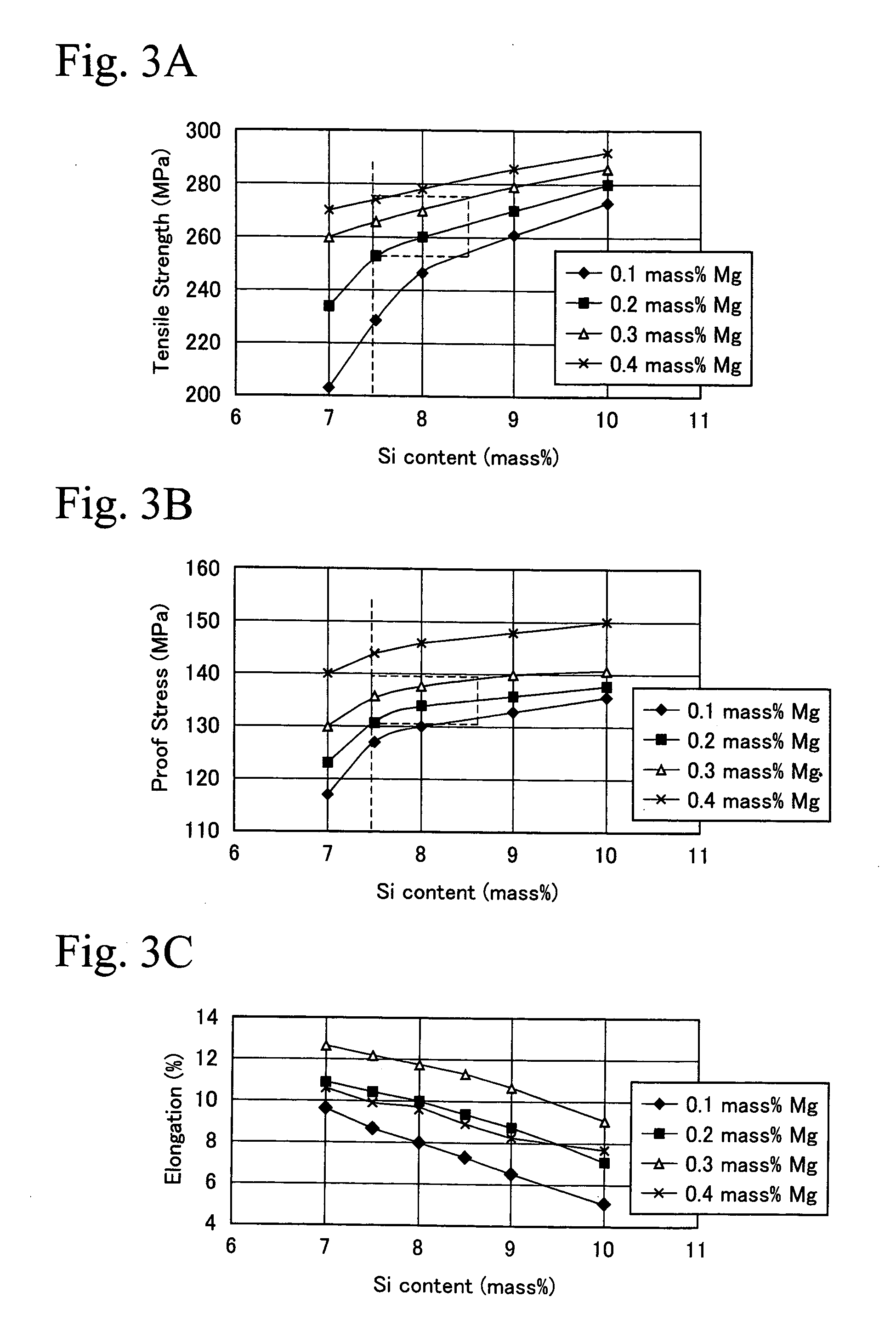

Al-Si based alloy and alloy member made therefrom

An Al—Si based alloy and an alloy member made of the alloy, in which when alloys produced by diecasting under high vacuum conditions are welded, weldability can be improved without increasing plate thickness of welded portions and reducing gas content in diecasting.

Owner:HONDA MOTOR CO LTD

Inter-battery connection device

InactiveUS7776467B2Increase resistanceIncrease plate thicknessPrimary cell to battery groupingNon-aqueous electrolyte accumulatorsMechanical engineeringMetal

Owner:PANASONIC CORP

Heat dissipation substrate for mounting electric component

InactiveCN107004647AConsolidate the gapReduce wire resistanceAssociation with control/drive circuitsElectrical measurement instrument detailsElectrical conductorHemt circuits

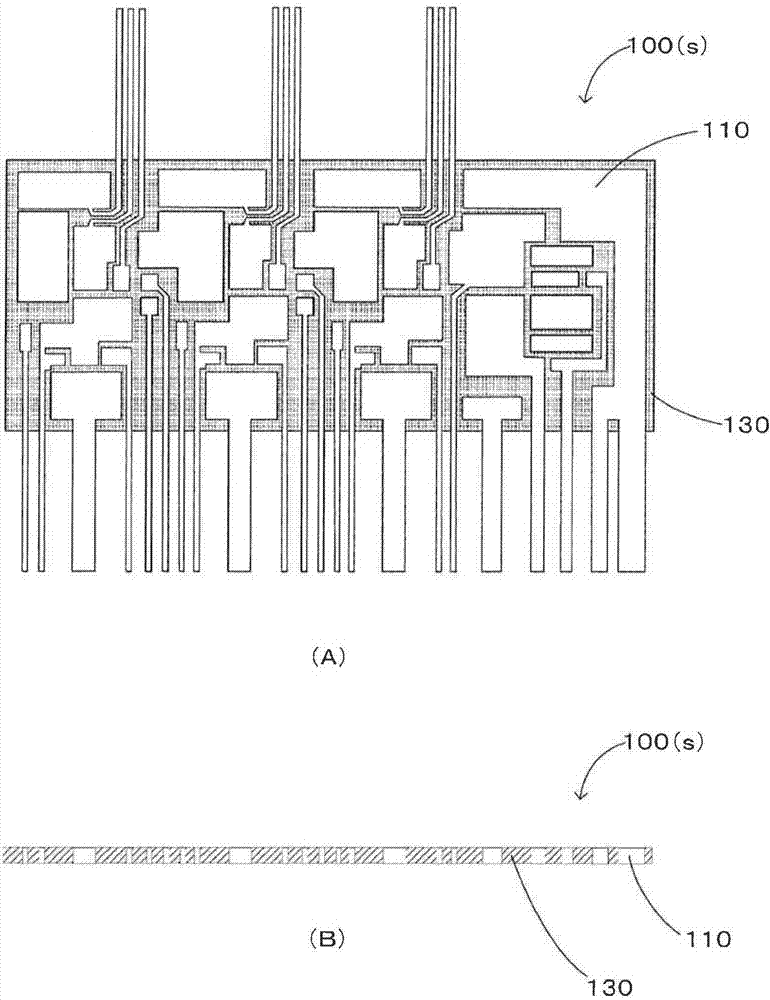

To provide a heat dissipation substrate for mounting an electric component, said substrate making it possible, even in the case of a circuit using a power semiconductor, etc. in which a large current flows, to achieve an improvement in heat dissipation and a reduction in wiring resistance due to high power operation. This heat dissipation substrate 100(d) for mounting an electric component is formed such that: the substrate is composed of lead frames that are formed into a wiring pattern shape from a conductor plate, and an insulating material 130 that is provided between the lead frames 110; the lead frames have at least two types of thicknesses that are different from each other, wherein a thick lead frame 110H is used for a large current signal and a thin lead frame 110L is used for a small current signal; a component disposition surface plate surface of the lead frames 110 and a component disposition surface-side plate surface of the insulating material 130 form one continuous surface; and the plate surface of the lead frames on the rear surface of the component disposition surface and the plate surface of the insulating material on the rear surface side of the component disposition surface side are formed on the same plane so as to match the plate surface on the rear surface of the component disposition surface of the thickest lead frame from among the lead frames.

Owner:NSK LTD

Sound-absorbing material, production method of the same, and sound-absorbing-panel

InactiveCN101042865AImprove sound-absorbing propertiesNo harm to aestheticsSound producing devicesComposite material

In order to provide a sound-absorbing material and a sound-absorbing panel which can be produce at a low-cost and have excellent beauty or appearance and excellent sound-absorbing characteristics, the sound-absorbing material is applied which is made from a metallic plate member (2), and multiple pierced apertures of 200 [mu] m or smaller diameter are arranged along a board thickness on the plate-shaped member (2).

Owner:YAMAHA CORP +1

Cable or the like protection and guide device

ActiveUS20070068694A1Reduce the number of partsReduce stepsHauling chainsHoisting chainsStress concentrationCoupling

A cable or the like protection and guide device is disclosed in which inadvertent disconnection in a coupling portion of a side plate due to the repetition of flexional movements is avoided. Stress concentration is reduced in a flexion portion during restriction of flexional movements whereby excellent endurance on repeated flexion fatigue can be exhibited and in which the number of parts and the assembly operation can be reduced. Plates disposed in a right and left pair are integrally formed by a front side plate portion 111, a rear side plate portion 112, and a flexible coupling portion 113 interposed between the front side plate portion 111 and the rear side plate portion 112. The coupling portion 113 includes a thin plate-shaped central flexion allowable region 113a and base end continuous regions 113b, 113b with gradually increased plate thickness from the central flexion allowable region 113a side toward the front side plate portion 111 and rear side portion 112, respectively.

Owner:TSUBAKIMOTO CHAIN CO

Metal plate for dual plate check valve

ActiveUS20120042968A1Increasing the thicknessUniformly distortedMelt-holding vesselsCheck valvesExtremity PartCheck valve

A metal plate (100) for a dual plate check valve comprises a substantially circular segment shaped plate member (1) of a predetermined substantially uniform thickness, a means (2) for pivotally mounting said plate member to enable rotation about an axis substantially parallel and adjacent to chord (3) of said circular segment of the plate member, said plate member (1) having a central portion and two extreme end portions (4) distal to said central portion, whereby said end portions are provided with reinforcements (5, 5′), thereby increasing the thickness of the plate member in the end portions, the reinforcements being so located that when the plate member of the check valve is in closed position, the end portions with reinforcements are in radially outward direction from the valve seat of the check valve, when back pressure acts on said plate member, said reinforcements enable said plate member to distort substantially uniformly to maintain sealing contact with the valve seat.

Owner:ADVANCE VALVES PVT

Hidden type split hinge

ActiveUS11009061B2Increase plate thicknessIncrease spacingBearing assemblyDigital data processing detailsStructural engineeringMechanical engineering

Owner:JARLLYTEC CO LTD

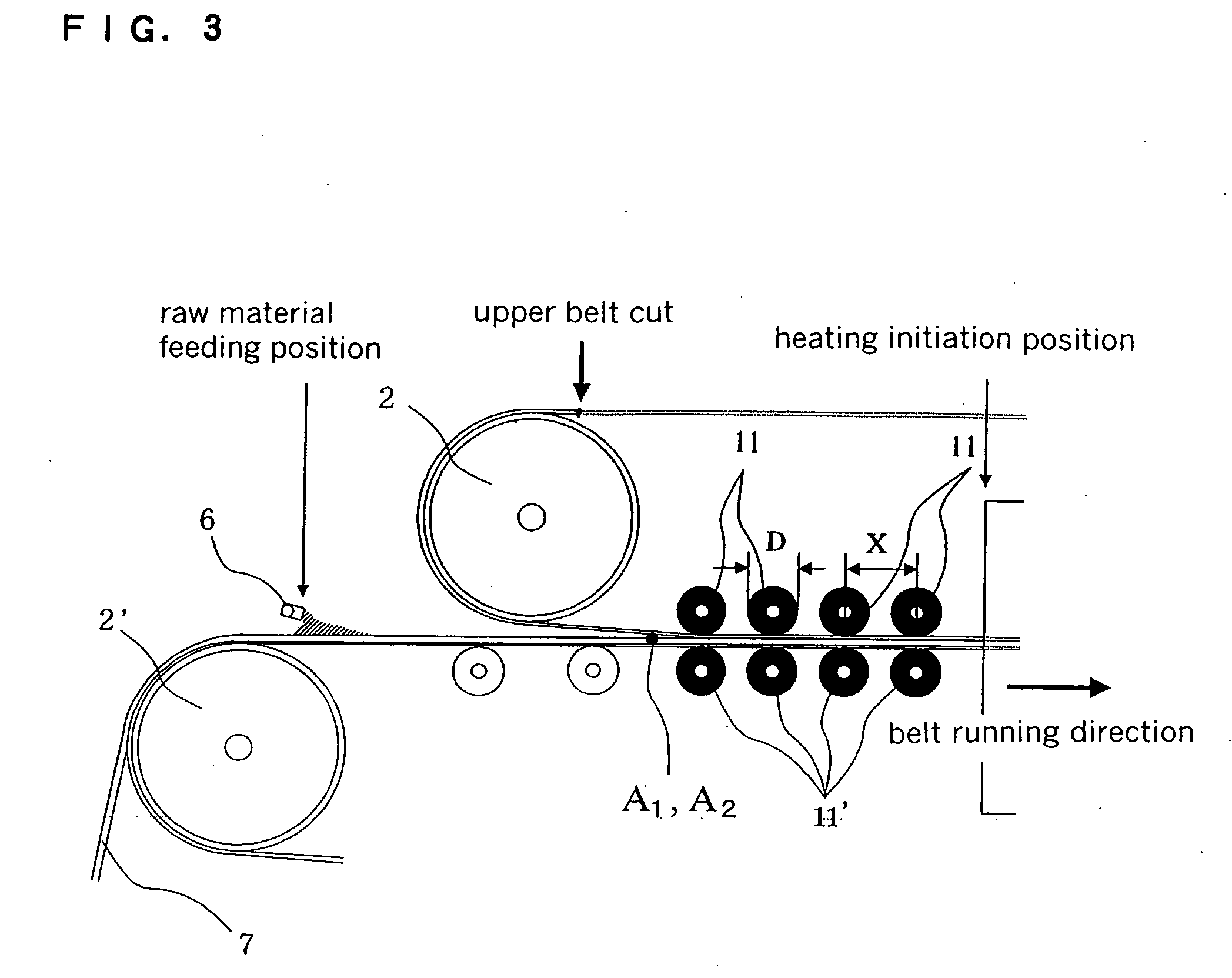

Belt type continuous plate manufacturing device and method of manufacturing sheet polymer

InactiveUS20060071363A1High thickness accuracyIncrease plate thicknessDough-sheeters/rolling-machines/rolling-pinsConfectioneryManufactured apparatusEngineering

A belt type continuous plate manufacturing apparatus comprising two facing endless belts 1, 1′ and gaskets 7 sandwiched by belt surfaces at their both side edge portions, wherein a polymerizable raw material is fed into a space surrounded by the facing belt surfaces and the gaskets 7 from its one end, the polymerizable raw material is solidified together with running of the belts in a heating zone, and the plate polymer is taken out from the other end, characterized in that three or more upper and lower roll pairs satisfying the following formulae (1) and (2) are placed so that respective axes thereof orthogonally cross the belt running direction, between a raw material feeding position and a heating initiation position; and a method of producing a plate polymer by using it: D / Z≧0.04 (1), 0.30≦D / X≦0.99 (2) [D=outermost diameter of roll body portion (mm), Z=width of roll body portion (mm), X=distance between axis centers of adjacent upper and lower roll pairs (mm)].

Owner:MITSUBISHI RAYON CO LTD

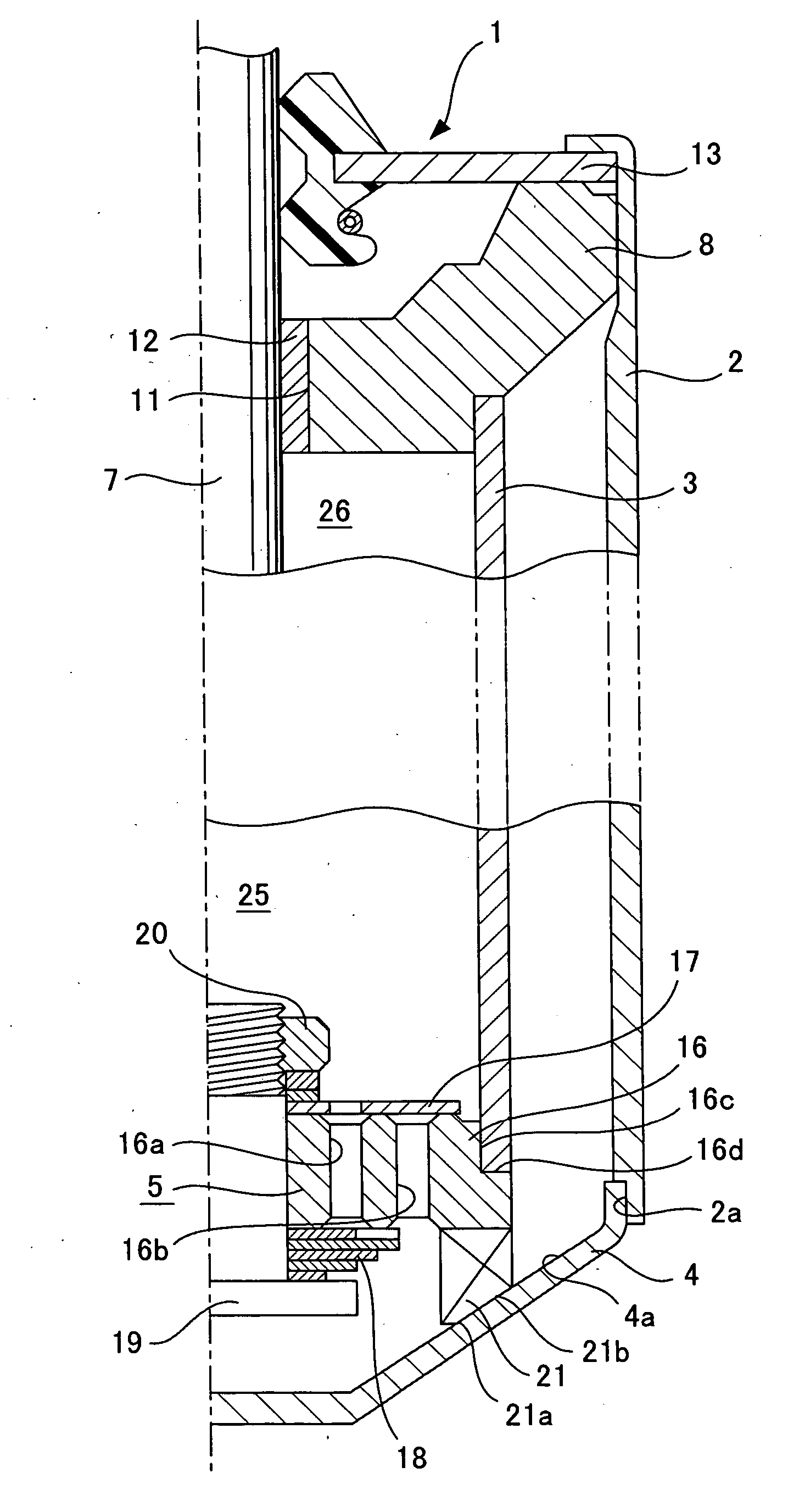

Double tube hydraulic shock absorber

ActiveUS20060213734A1Reduce plate thicknessWithout needSpringsShock absorbersDouble tubeLine of action

A double tube hydraulic shock absorber comprises: an outer tube; an inner tube; a base valve which is fitted and fixed to a base end of the inner tube; a lower cap provided so as to contact a leg portion of the base valve and seal a base end of the outer tube in an oil tight fashion; a piston rod inserted into the inner tube so as to be capable of an axial reciprocation; and a guide member attached to a top side of the outer tube and the inner tube so as to support the piston rod and apply an axial force on the inner tube. In this double tube hydraulic shock absorber, the leg portion of the base valve and the lower cap contact each other on a line of action of the axial force that is applied toward the base end of the inner tube.

Owner:KYB CORP

Steering column device

InactiveUS20110210538A1Increase the sectionStiffness can be ensuredHand wheelsSteering columnsSteering columnEngineering

A steering column device includes a mount bracket including a suspended portion hanging from a fixation portion. The suspended portion includes: a first wall extending along and adjacent to the jacket guide, a second wall located on an outside of the first wall in a vehicle width direction; and a front side wall and a rear side wall connecting front ends and rear ends of the first wall and the second wall to each other. Operation of an operating lever protruding from the suspended portion tightens a clamp bolt to connect and fix the jacket to the mount bracket.

Owner:FUJI KIKO CO LTD

Terminal fitting and connector

ActiveUS10305214B2Increase plate thicknessRestrict movementVehicle connectorsCoupling contact membersEngineeringMechanical engineering

A terminal fitting includes a case (20) provided with an opening (31) into which a mating contact (91) is inserted, and an electrical contact member (60) disposed in the case (20) to face the opening (31) and configured to retreat while rotating to compress a resilient member (40) by being biased toward the opening (31) and pressed against the mating contact (91) by the resilient member (40).

Owner:AUTONETWORKS TECH LTD +2

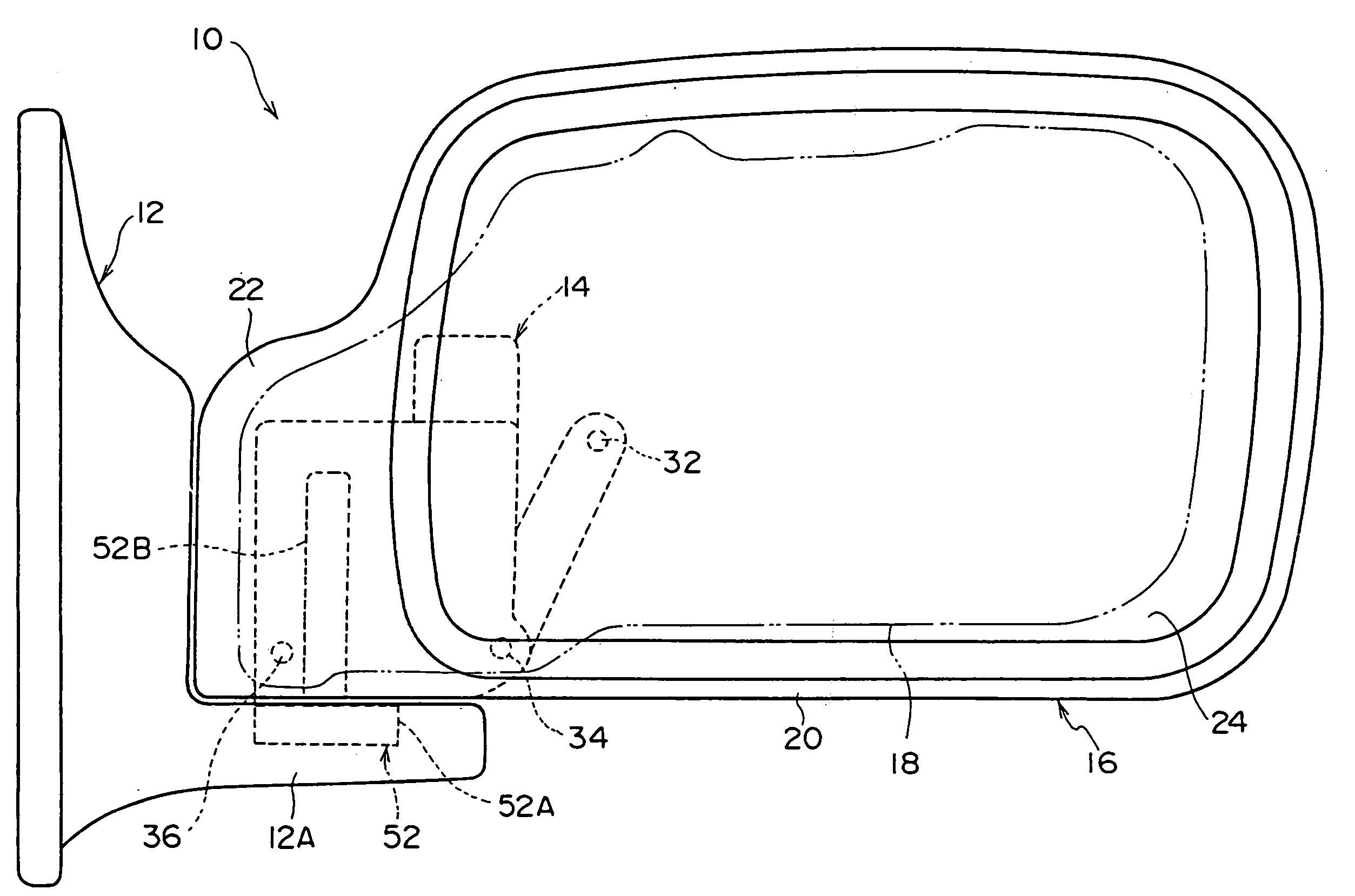

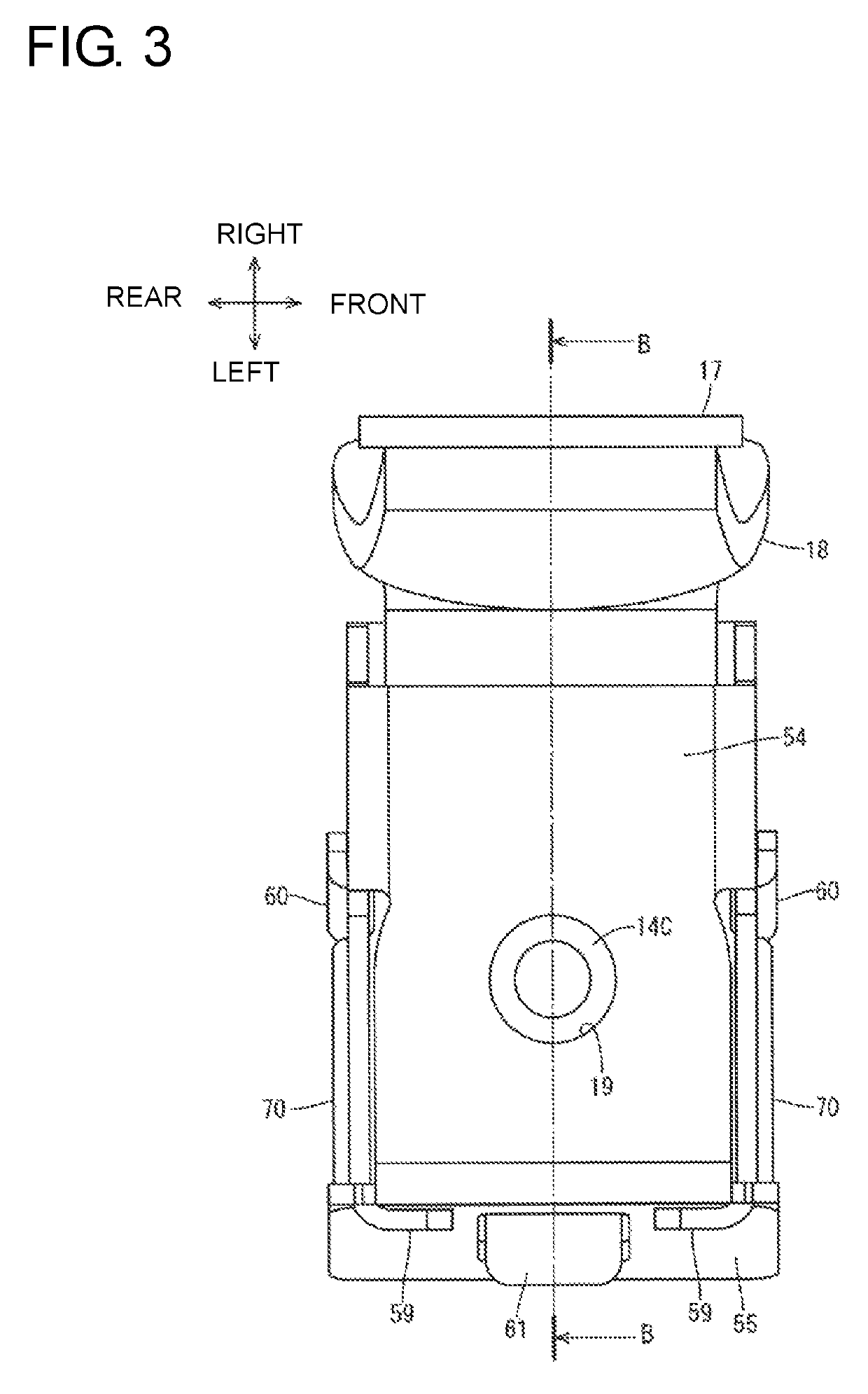

Mirror device for vehicle

A foldable mirror device for a vehicle, in which a case is mounted on a support shaft erected from a base. The case includes a ring-shaped support portion for supporting the shaft, a motor connected to a transmission for swinging the mirror, and a clutch portion for disengageably engaging with the base. The support portion can be strengthened by ribs between the support portion and other portions of the case. A worm gear of the transmission can be mounted on a motor output shaft to be freely movable therealong, and supported and constrained by supporting a bottom end of the worm gear on the case and accommodating an upper end of the worm gear in a cylindrical projection from a motor base which supports the motor. End portions of convexities and concavities at the engagement portion can be formed in a concave or convex screw shape.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

Electronic substrate with heat dissipation structure

ActiveUS9535470B2Efficient upgradeReduce the thickness of the structureDigital data processing detailsCircuit fluid transportInsulation layerCooling effect

An electronic substrate with heat dissipation structure includes a substrate plate and at least one heat pipe. The substrate plate includes a wiring layer, a grounding layer and an insulation layer from top to bottom. The wiring layer has at least one heat-producing element mounted thereon, and is formed with a receiving hole for the heat pipe to tightly fit therein. Heat produced by the heat-producing element and distributed over a high-temperature zone of the substrate plate surrounding the heat-producing element is absorbed by the heat pipe and then transferred to a low-temperature zone of the substrate plate distant from the heat-producing element, from where the heat is dissipated into ambient air to achieve cooling effect at upgraded heat dissipation efficiency.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

Wheel and method of manufacturing the same

ActiveUS20050241740A1Deterioration of design characteristicCorrosion of partRimsTyre beadsEngineeringMechanical engineering

The present invention provides a wheel and manufacturing method of the same which make it possible to prevent the formation of indentations along the hump parts in the inner circumferential surface of the rim. In a wheel which comprises a cylindrical rim consisting of a rolled metal plate, and in which hump parts that are used to lock the inner circumferential edge part of the tire are disposed circumferentially so that these hump parts protrude to the outside in the vicinity of the end part of the outer circumferential surface of the rim on at least the design surface side, the outer hump part is formed to have an increased thickness by damming so that this outer hump part protrudes outward while the inner circumferential surface of the rim that corresponds to the outer hump part is formed into a flat circumferential surface.

Owner:WORK

Method of soldering iron tip with metal particle sintered member connected to heat conducting core

ActiveUS7490751B2Increase plate thicknessWork has been limitedHeating element shapesSoldering bitsCeramic coatingHeat conducting

A soldering iron tip having a copper or copper alloy core and a metal particle sintered member connected to the core to transfer heat therefrom to form a working soldering tip. The sintered member can be manufactured by powder metallurgy from a base material (iron, nickel and / or cobalt particles) and an additive (silicon, copper, silver, tin, boron and / or carbon particles) where needed. The sintered member can be formed as a cap which is fitted onto the working tip with a silver paste sandwiched therebetween, a brazing filler metal ring is positioned between an abutment shoulder and the cap, flux applied to the joint and the cap brazed into place. A metal, cermet or ceramic coating sprayed on the outer surface of the core, except for the (masked) working tip end, is not wettable by solder. An Ag—Al—Cu alloy coating layer in the rearwardly-disposed cavity improves heat conduction from the heater therein.

Owner:HAKKO CO LTD

Terminal module

ActiveUS10418740B2Increase plate thicknessSmooth bootElectrically conductive connectionsCoupling contact membersCoil springEngineering

A terminal fitting (50) includes a metal case (52) having an opening (52A) through which a mating contact point (31) is inserted, a coil spring (16) accommodated in the metal case (52), and an electrical contact (53) biased toward the opening (52A) by the coil spring (16) and configured to move while compressing the coil spring (16) by being pressed by the mating contact point (31). The metal case (52) includes a first guide (parts at both front and rear sides of an opening (57) in a front wall (55) of the metal case (52)) configured to guide the electrical contact (53) to a position shifted from a position before a movement in a direction orthogonal to an inserting direction of the mating contact point (31) by sliding in contact with the electrical contact (53) when the electrical contact (53) moves by being pressed by the mating contact point (31).

Owner:AUTONETWORKS TECH LTD +2

Metal laminate gasket

ActiveUS20100225068A1Improve sealingIncrease plate thicknessEngine sealsSealing arrangements for enginesSurface pressureMetal

A metal laminate gasket includes a plurality of metal plates including a first metal plate having a first hole to be sealed and a bead around the first hole, and a second metal plate laminated under the first metal plate and having a second hole corresponding to the first hole. Concavities and convexities are formed at the second metal plate concentrically around the second hole for increasing an apparent plate thickness of the second metal plate. The concavities and convexities are provided continuously at a position corresponding to the foot portion or the top portion of the bead of the first metal plate. The concavities and convexities have a height and width smaller than those of the bead, and have a deformation characteristic due to a surface pressure when compressed, smaller than that of the bead.

Owner:ISHIKAWA GASKET CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com