Al-Si based alloy and alloy member made therefrom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0032] In the following, the present invention will be explained in more detail by Examples.

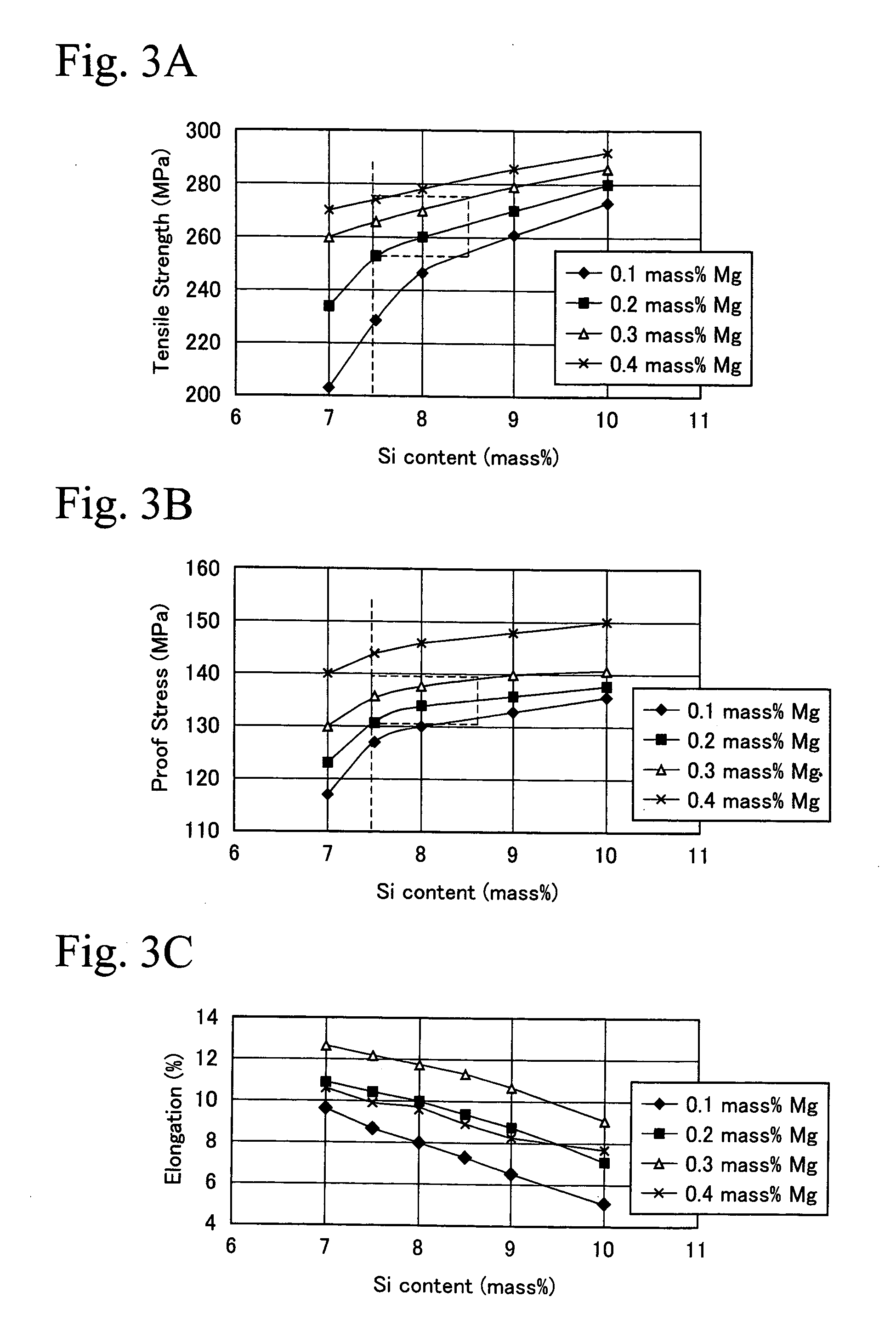

[0033] Alloys having the compositions shown in Table 1 were dissolved at 720° C., respectively and then were deoxidized and degassed by molten metal treatment using Ar gas and flux. Next, under a vacuum condition at an internal pressure of a metal mold of 5 kPa and at molten metal temperature 700° C., the alloys were cast using a metal mold for plate-shaped diecasting having width of 100 mm, depth of 300 mm, and height of 5 mm, and plate-shaped diecasting products having each composition shown in Table 1 (Examples 1 to 5 and Comparative Examples 6 to 12 of the present invention) were thereby obtained. Here, temperature of the metal mold was 150° C. Subsequently, the above diecasting products were subjected to each heat treatment which was respectively suitable under the condition described in Table 1.

TABLE 1units: mass %Heating ConditionSiFeCuMnMgZnTiSr(only Aging)Example 17.50.130.140.460...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com