Industrial circulating water dirt purifying device and dirt removal method thereof

A purification device and water fouling technology, applied in the field of descaling and anti-scaling, can solve the problems of reduced production efficiency, narrow application range, low descaling efficiency, etc., and achieve the effects of improving efficiency, reducing energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

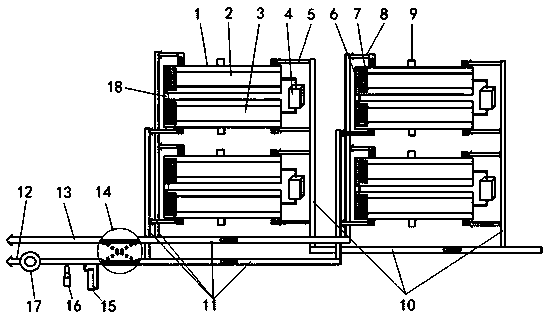

[0032] The industrial circulating water dirt purification device is a unit module for treating circulating water. The specific quantity is limited according to actual application conditions.

[0033] Such as figure 1As shown, the present invention is provided with 4 unit modules of the industrial circulating water dirt purification device, and the industrial circulating water dirt purification equipment mainly includes: a housing 1, a first electrode 2, a second electrode 3, a control power supply 4, a first Conductor 6, second conductor 7, water inlet branch pipe 5, drainage branch pipe 8, main water inlet pipe 10, main drain pipe 11, alkaline drain pipe 12, acid drain pipe 13, seed grinder 15, seed crystal coalescence device 16, filter 17, the first electrode 2 and the second electrode 3 are independently arranged in the two housings 1, one end of the first electrode 2 is connected to one pole of the control power supply 4, and the second electrode 3, one end is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com