Novel tool type rectangular column mold reinforcing device

A reinforcement device and tool-type technology, which is applied in the fields of formwork/template/work frame, on-site preparation of building components, construction, etc. The quality of construction and other issues can reduce the amount of capital investment, adjust the section size, and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

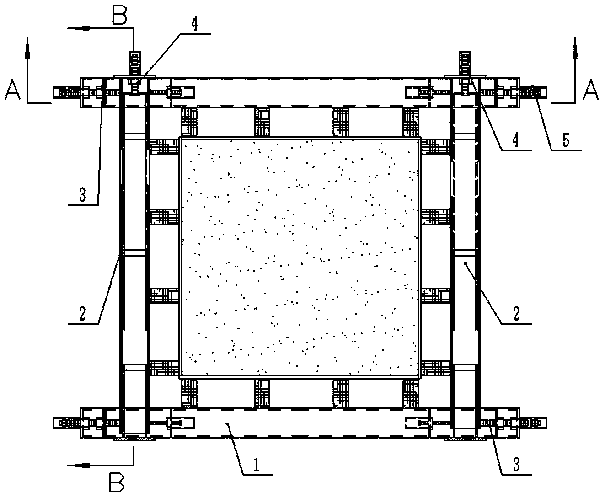

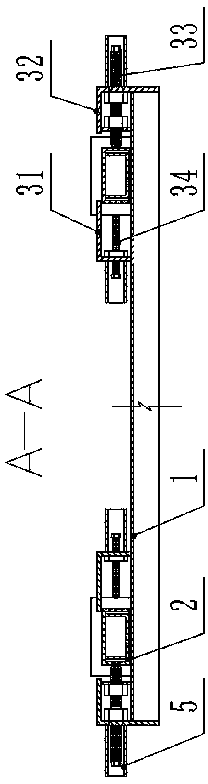

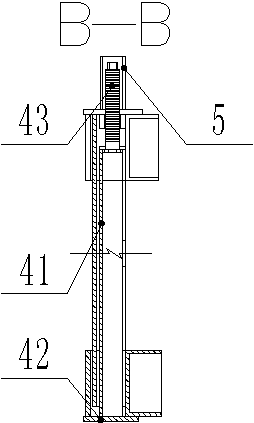

[0025] Such as figure 1 — image 3 As shown, the new tool-type rectangular column form reinforcement device includes two type I rods 1 and two type II rods 2, and the two type I rods 1 and two type II rods 2 are all made of channel steel. The two ends of the type rod 1 are provided with a first limit adjustment device 3, and the type II rod 2 is provided with a second limit adjustment device 4, and two type I rods 1 are arranged in parallel on the rectangular column formwork. On both sides, type II rods 2 are respectively connected to the first limit adjustment device 3 on the same side of two type I rods 1, and the cross-section formed by the two type I rods and the inner side of type II rods 2 is rectangular, and I The two first limit adjustment devices 3 on the type II rod 1 are used to adjust the distance between the two type II rods 2, and the second limit adjustment device 4 on the type II rod 2 is used to adjust the distance between the two type II rods 2 The length a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com