Surface layer template connecting structure of cast-in-place concrete sloping roof

A technology for connecting structures and sloping roofs, applied in the direction of roof covering, connecting parts of formwork/formwork/work frame, roof, etc. Section size and appearance quality, ensure compactness requirements, and solve the effect of structural leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

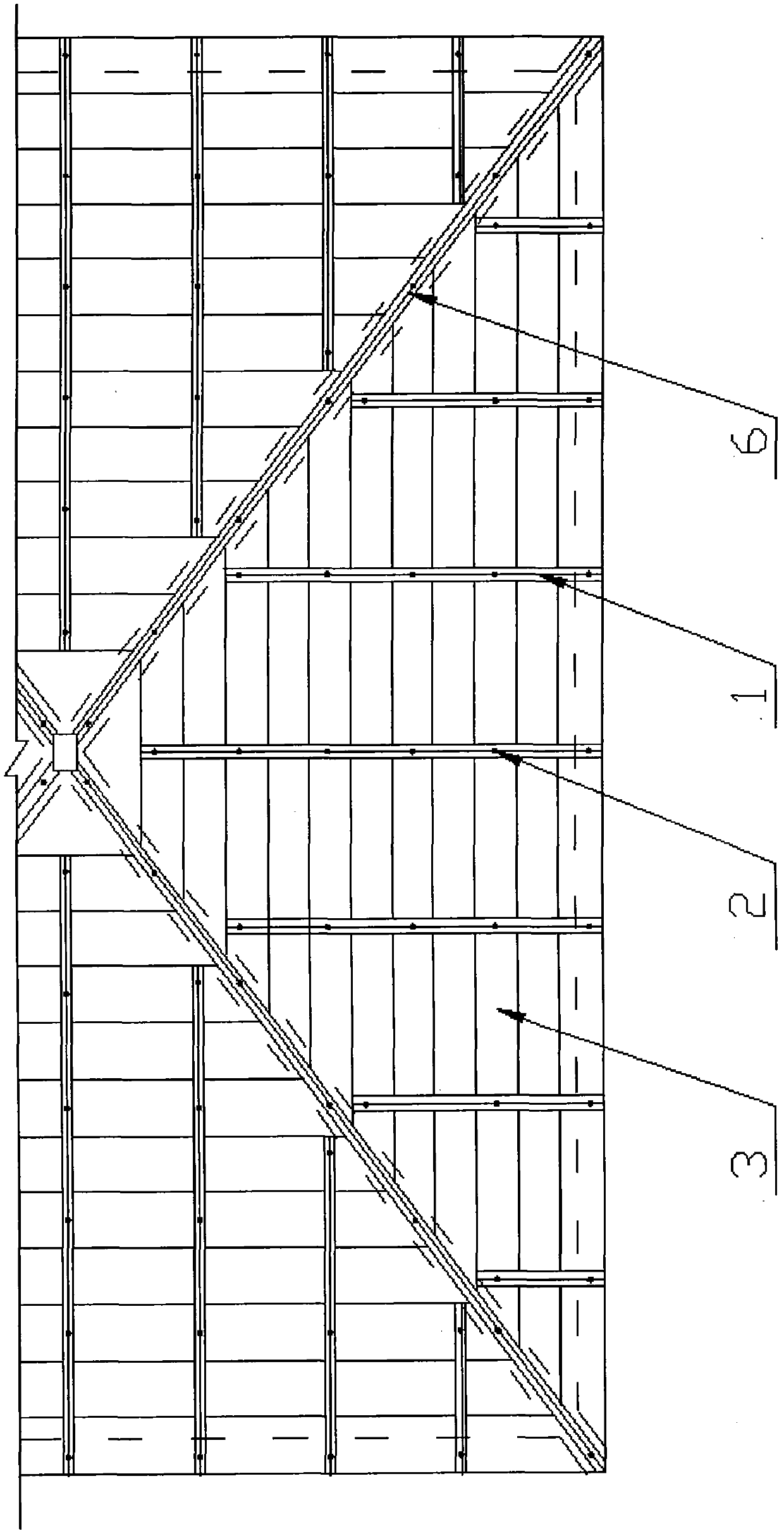

[0014] exist figure 1 Among them, a cast-in-place concrete sloping roof surface formwork connection structure is used to build a compact sloping roof structure with a slope of 45°, including a bottom formwork 5, a surface formwork 3, water-stop bolts 2, and a plurality of vertical keels 1 and a plurality of side keels 4, the bottom formwork 5 is located on the bottom surface, the vertical keels 1 are distributed parallel to each other above the bottom formwork 5, and the length direction of the vertical keels 1 is consistent with the direction from the bottom of the slope to the top of the slope.

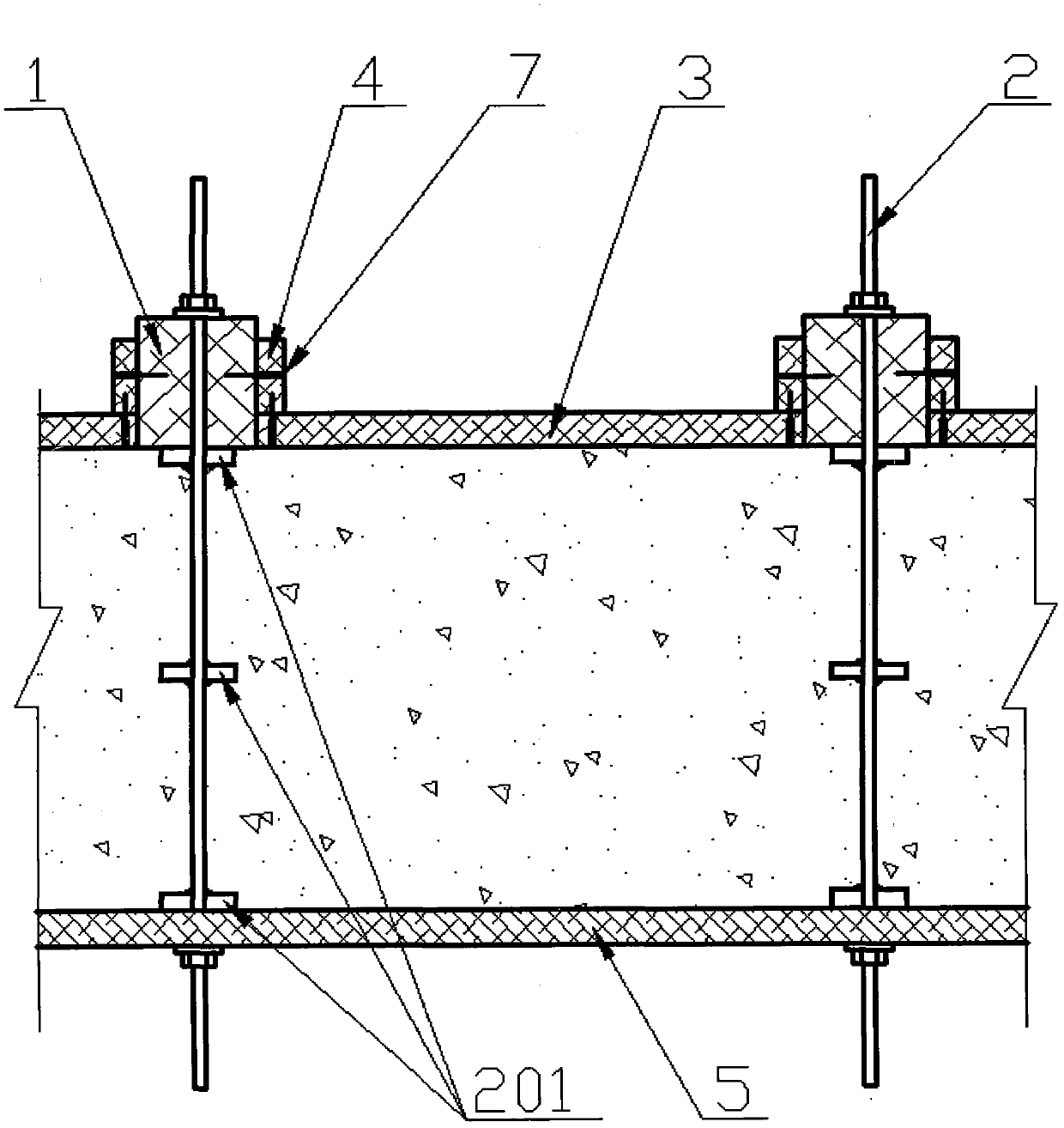

[0015] Such as figure 2 As shown, the water-stop bolt 2 is made by welding three pieces of water-stop sheets 201 in the middle section of the pull bolts, wherein the welding positions of the water-stop sheets at both ends of the bolts just match the pouring thickness of the concrete. The lower end of the water stop bolt 2 passes through the bottom template and is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com